Gear drilling clamp

A drilling fixture and gear technology, applied in the field of workpiece clamping devices, can solve problems such as pressure dispersion and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

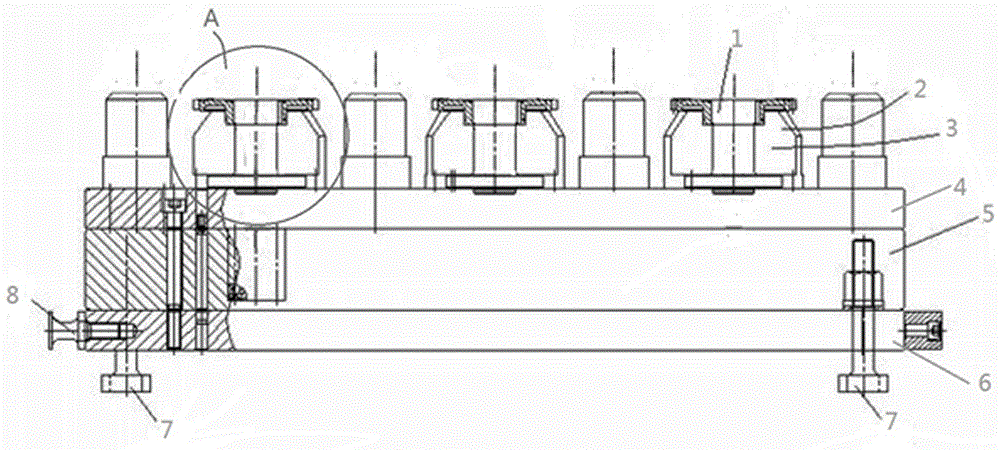

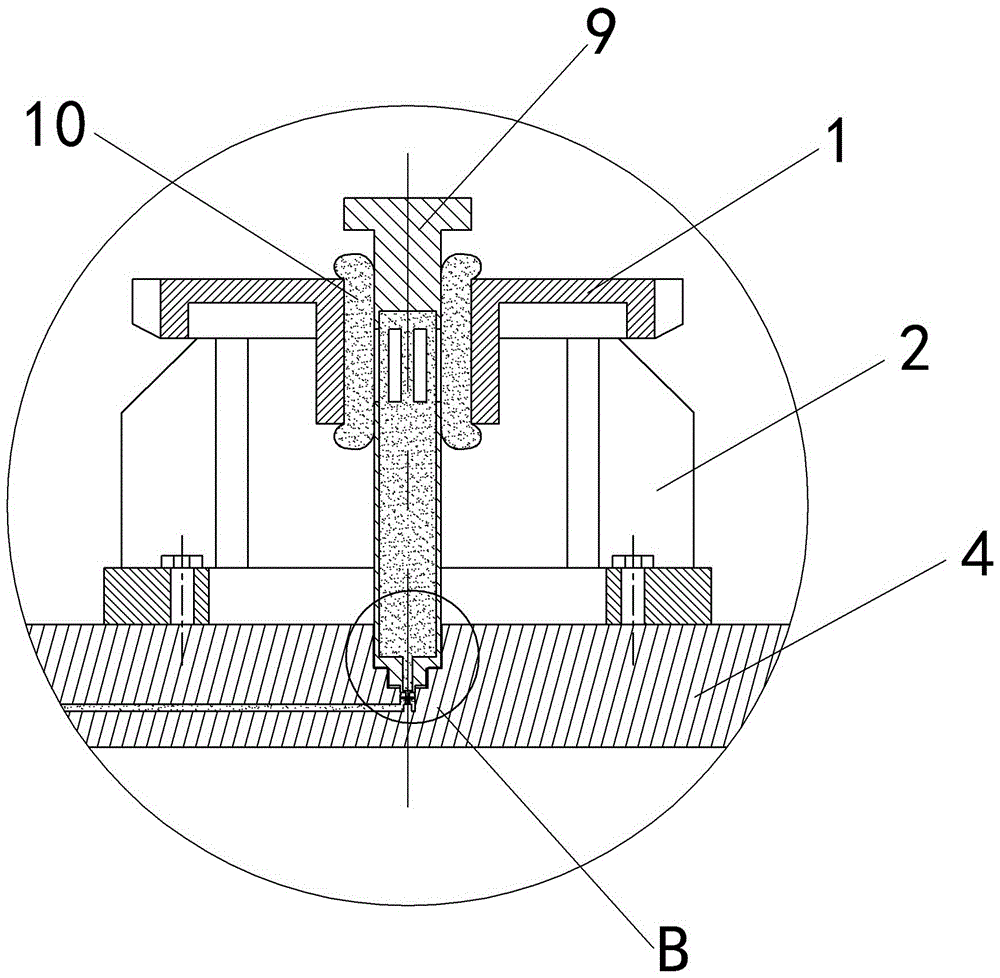

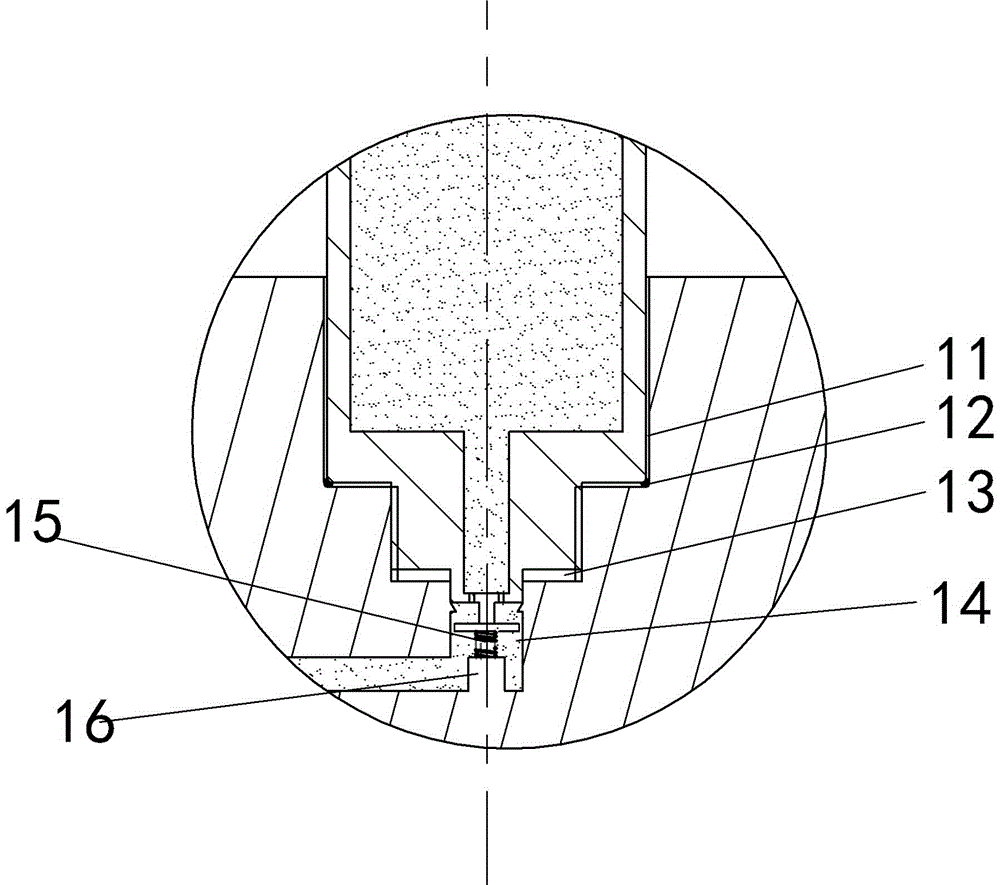

[0021] Example: such as figure 1 As shown, the gear drilling fixture in this technical solution includes a base. There are six stations arranged in a 2x3 matrix on the base. Each station is equipped with a fixture combination. The base consists of an upper base plate 4, a lower base plate 6, and A backing plate 5 between the upper and lower bottom plates 6 is formed. The upper bottom plate 4 and the lower bottom plate 6 are connected together by screws, and the outer periphery of the bottom plate is provided with a lifting bolt 8. The drilling fixture is installed on the machine tool, and a T-slot quick-release bolt is arranged under the base for connection with the machine tool. The clamp assembly includes a supporting base 3 and a fixing element group. The supporting base 3 is screwed on the base. The supporting base 3 is in the shape of a disc. The outer periphery of the disc is extended with pillars 2 arranged at intervals. The supporting base 3 is screwed on the base, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com