A movable splitter frame for tooth-shaped paper feeding

A feeding and toothed technology, applied in papermaking, paper/cardboard containers, packaging, etc., can solve problems such as abnormal turnover and inability to ensure smooth feeding of toothed paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

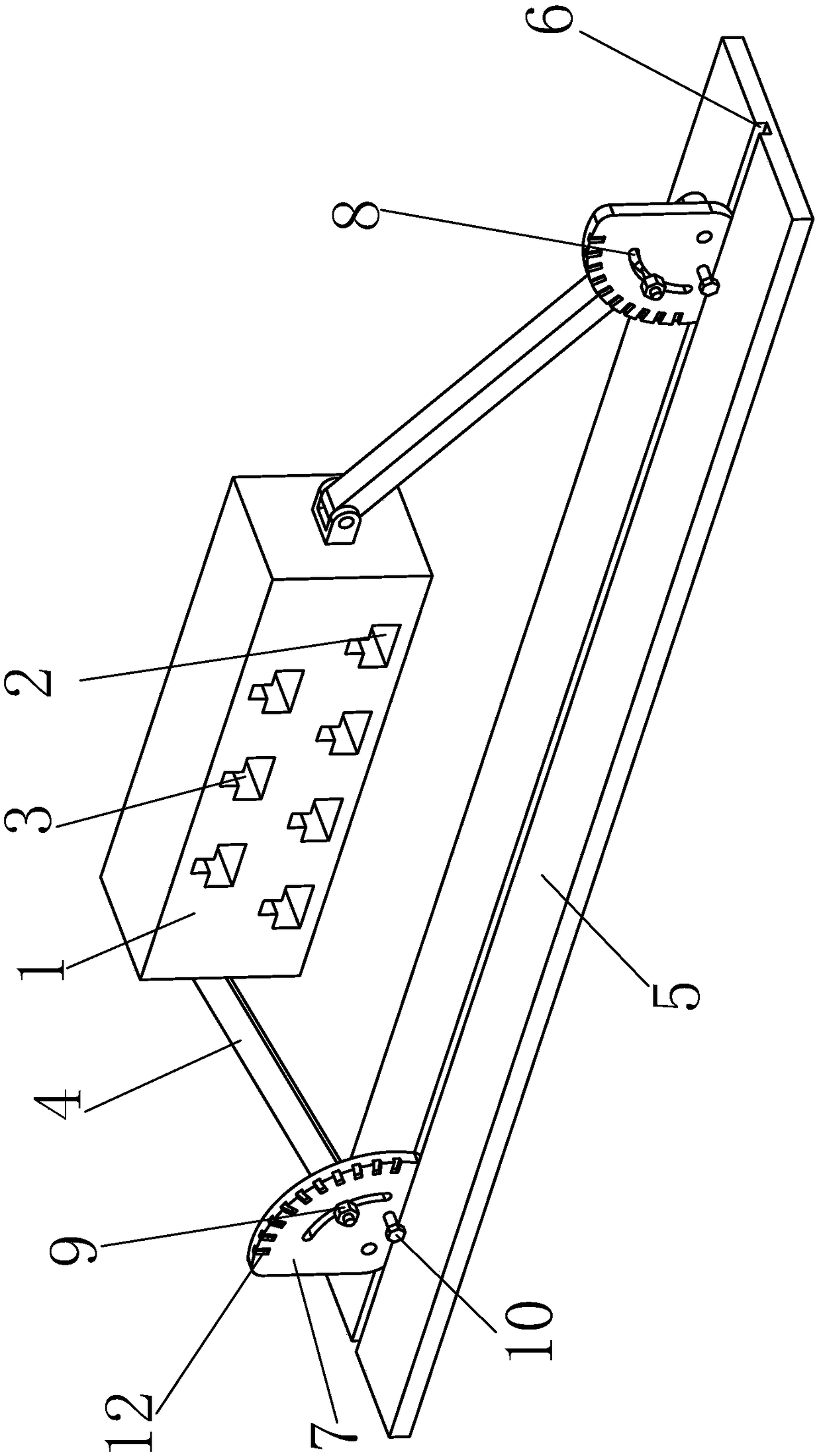

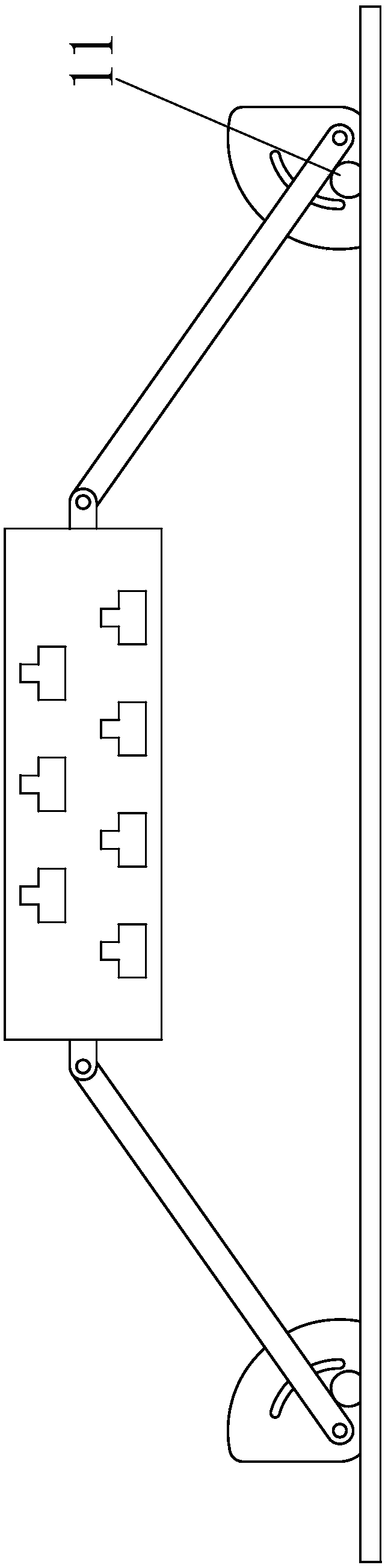

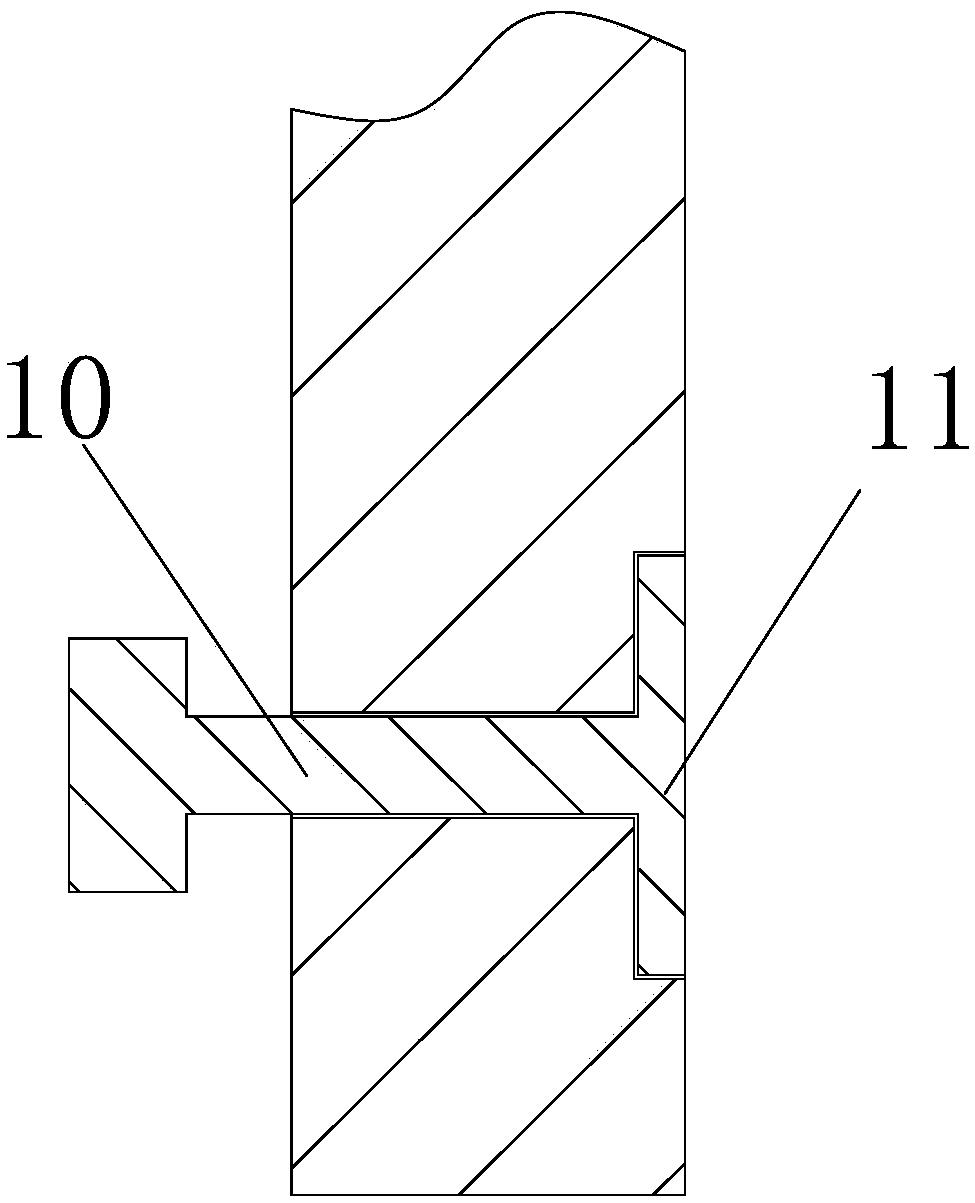

[0017] Such as Figure 1 to Figure 3 As shown, a toothed paper feeding movable splitter frame includes a main body block 1, the lower part of the main body block 1 is provided with a number of No. 1 through holes 2, and the upper part of the main body block 1 is provided with a number of No. 2 through holes 3. The No. 1 through hole 2 and the No. 2 through hole 3 are arranged along the longitudinal direction, and the No. 1 through hole 2 and the No. 2 through hole 3 are distributed in a staggered manner; the No. 1 through hole 2 and the No. 2 through hole 3 are both inverted T-shaped holes.

[0018] The left and right ends of the main body block 1 are respectively connected with a connecting rod 4 in a hinged manner, the bottom of the main body block 1 is provided with a bottom plate 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com