Hoisting tool for drum and screw of horizontal spiral decanter centrifuge

A decanter centrifuge, horizontal screw technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of screw scratching the inner wall of the drum, long maintenance time, high risk, etc., to avoid mutual scratches, The effect of ensuring quality and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with preferred embodiment, the specific implementation mode provided according to the present invention is described in detail as follows: embodiment

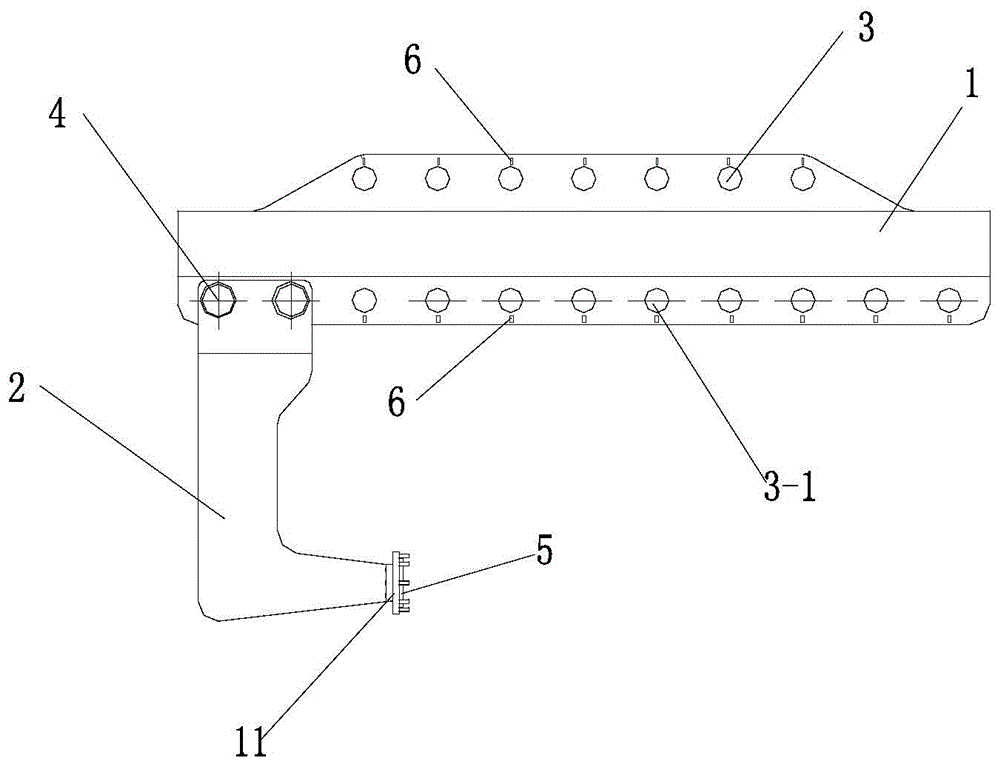

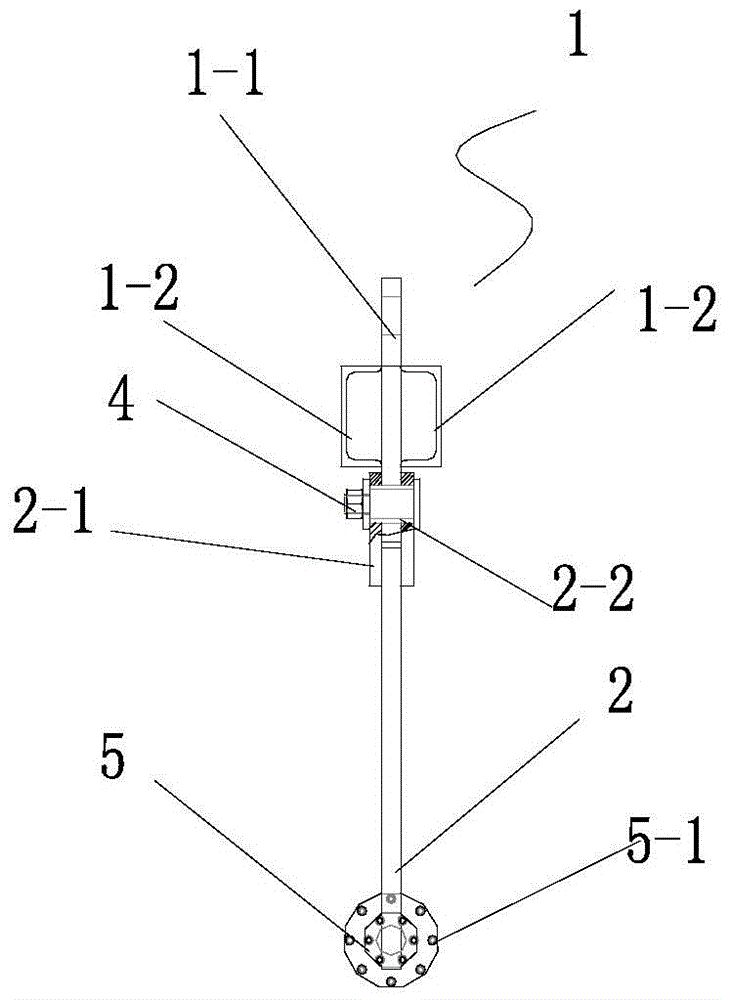

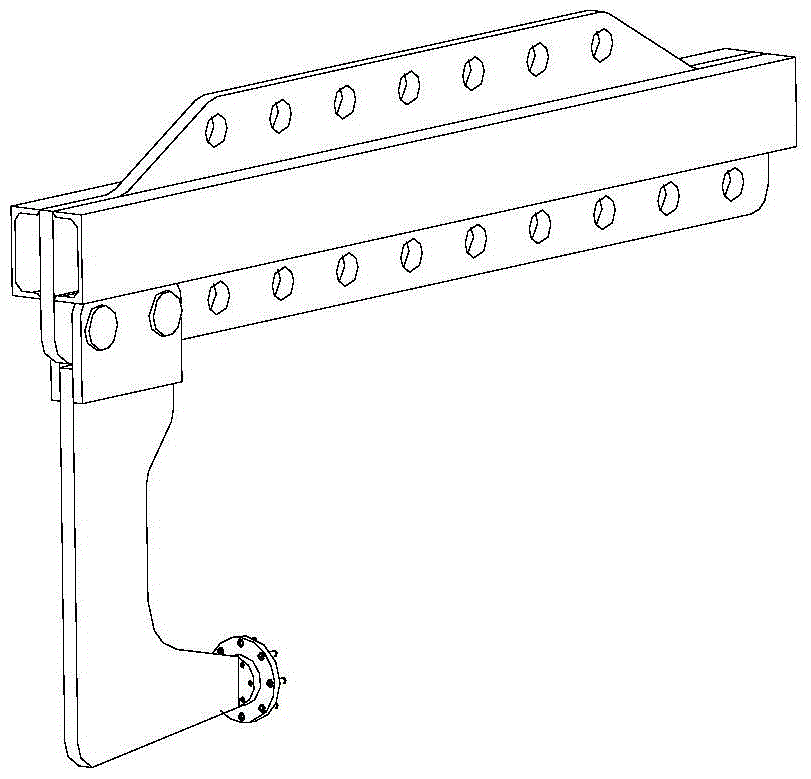

[0018] see attached Figure 1-3 , compared with the prior art, the present invention provides a hoisting tool for a drum and a screw of a horizontal spiral decanter centrifuge, including a sling body, and the sling body includes a drum sling body 1 and a screw sling body 2. The main body of the drum spreader is in the shape of a strip plate. Two rows of upper and lower wire rope hoisting holes 3 and 3-1 are arranged on the drum hanger body, and the upper and lower wire rope hoisting holes are equidistant from each other. Setting, the apertures of the upper and lower wire rope hoisting holes are respectively φ40-60mm. The present embodiment is φ60mm, and the center hole distance is 180mm. The drum spreader body is 420mm wide and 2000mm long; there are six hoisting holes for the upper wire rope and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com