Lead frame transmission device

A transmission device and lead frame technology, which is used in the field of conveying material for the electronic industry, can solve the problems of reducing the scrap rate of products, the material being stuck in the material box, and affecting the production efficiency, so as to avoid mutual scratches and increase the transmission capacity. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

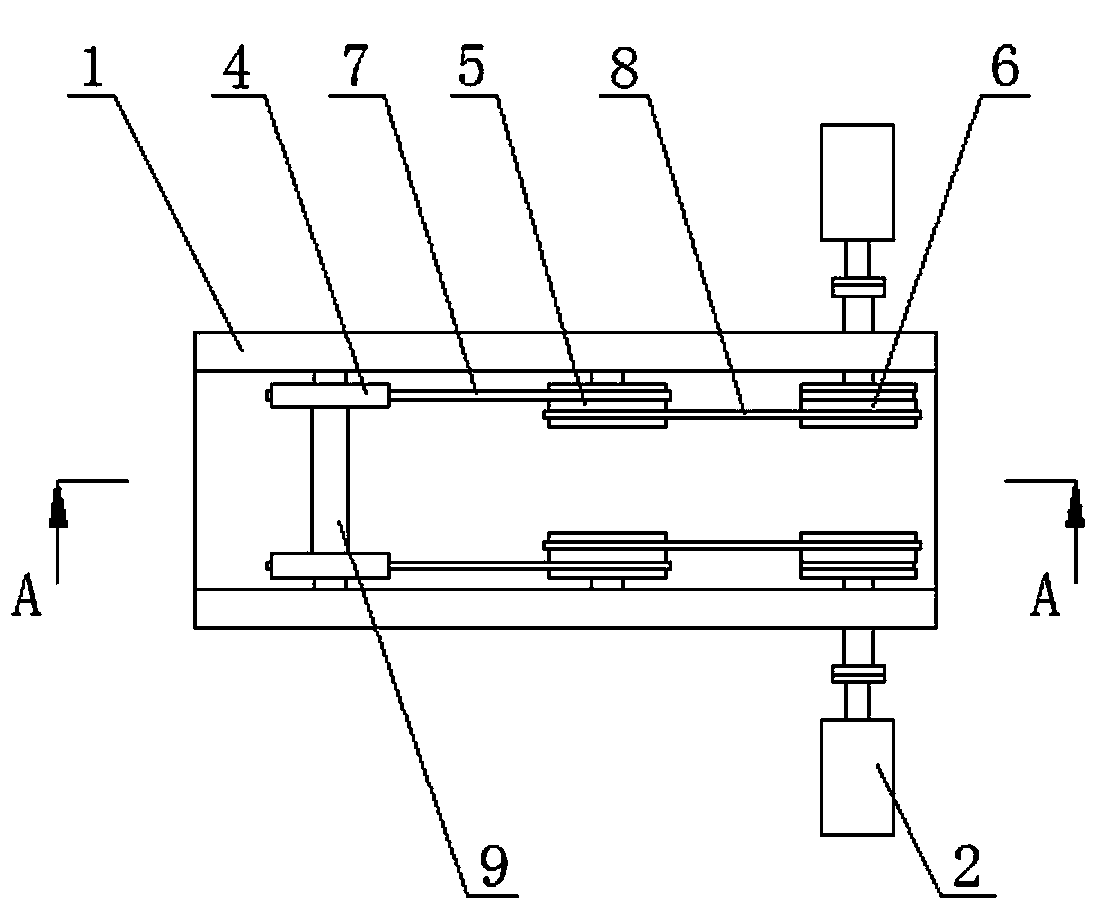

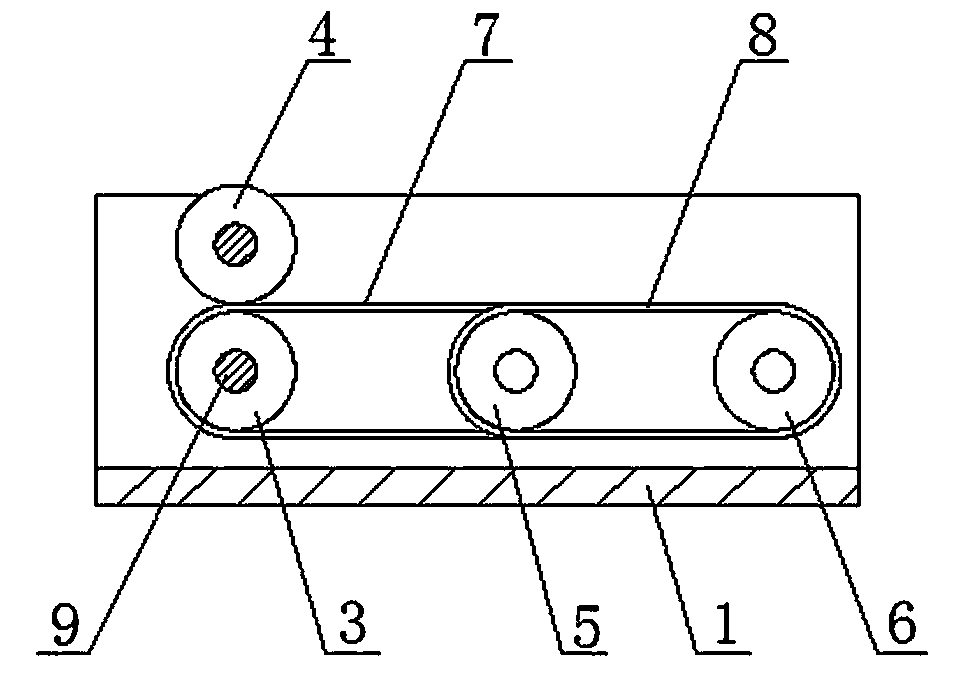

[0014] Such as figure 1 and figure 2 Shown, a kind of lead frame transmission device, it comprises channel steel 1, motor 2 and transmission mechanism, described transmission mechanism is made up of pinch wheel I3, pinch wheel II4, pulley I5 and pulley II6, described pinch wheel I3, Belt pulley I5 and belt pulley II6 are installed on the inner wall of channel steel 1 along one end of channel steel 1 to the other end rotating shaft of channel steel 1. Such as figure 1 and figure 2 As shown, a belt I7 is installed between the pressure pulley I3 and the pulley I5, a belt II8 is installed between the pulley I5 and the pulley II6, and a pressure pulley II4 is installed on the inner wall of the channel steel 1 for rotation, and the pressure pulley II4 is set on the pressure pulley I3 Above and presse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com