Rotating wheel type scraper

A wheel-type, scraper technology, applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of labor and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

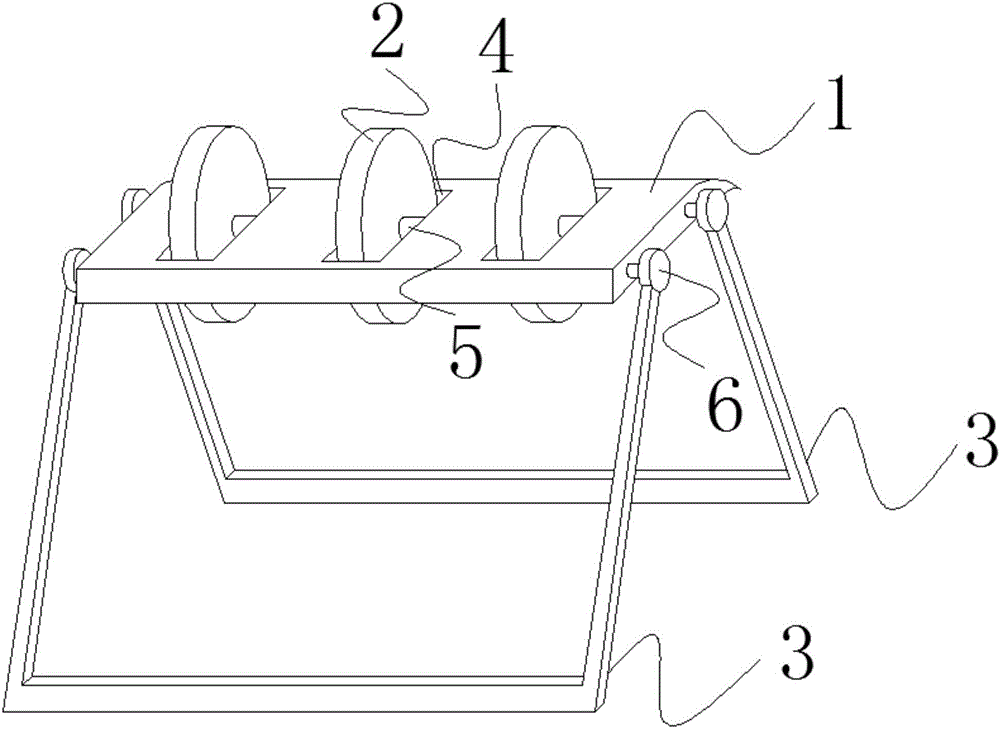

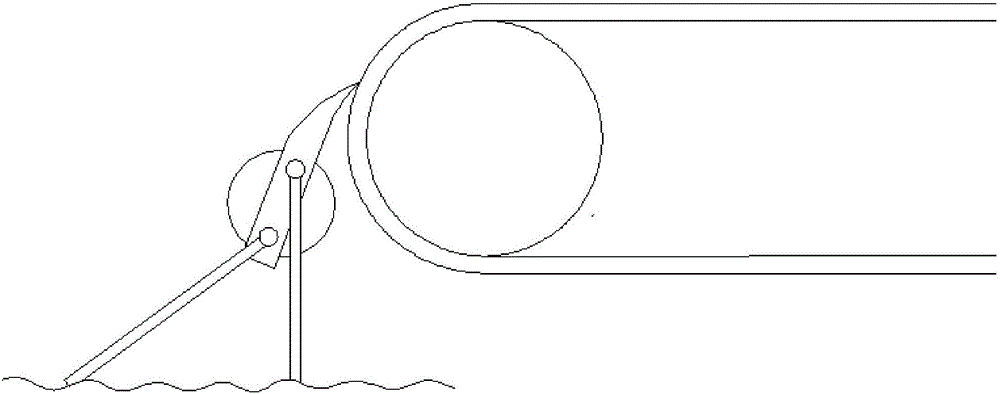

[0015] Such as figure 1 As shown, the rotary scraper includes a scraper 1, several runners 2 and brackets 3, the runners 2 are installed on the scraper back of the scraper 1, and the brackets 3 are installed on both sides of the scraper 1.

[0016] Some runners 2 are set on the scraping back of the scraper 1, and it is more convenient and labor-saving to drag the belt head to the runners 2 and then to the belt stand when changing a new belt by utilizing its carrying capacity. Several brackets 3 are installed on the two side wings of the scraper 1 to play a supporting role.

[0017] Since the positions of the belt conveyors from the ground are different, the height of the runner-type scraper is adjusted by setting the bracket 3. Specifically, the bracket 3 includes two vertical rods and a connecting rod, and the connecting rod is connected between two Between the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com