A retractable blast furnace tapping main ditch steel structure

A blast furnace tapping and steel structure technology, applied in the discharge device and other directions, can solve the problems of open welding and fracture of the iron main channel steel structure, achieve good telescopic function, avoid open welding and fracture, and compensate for the effects of axial thermal expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

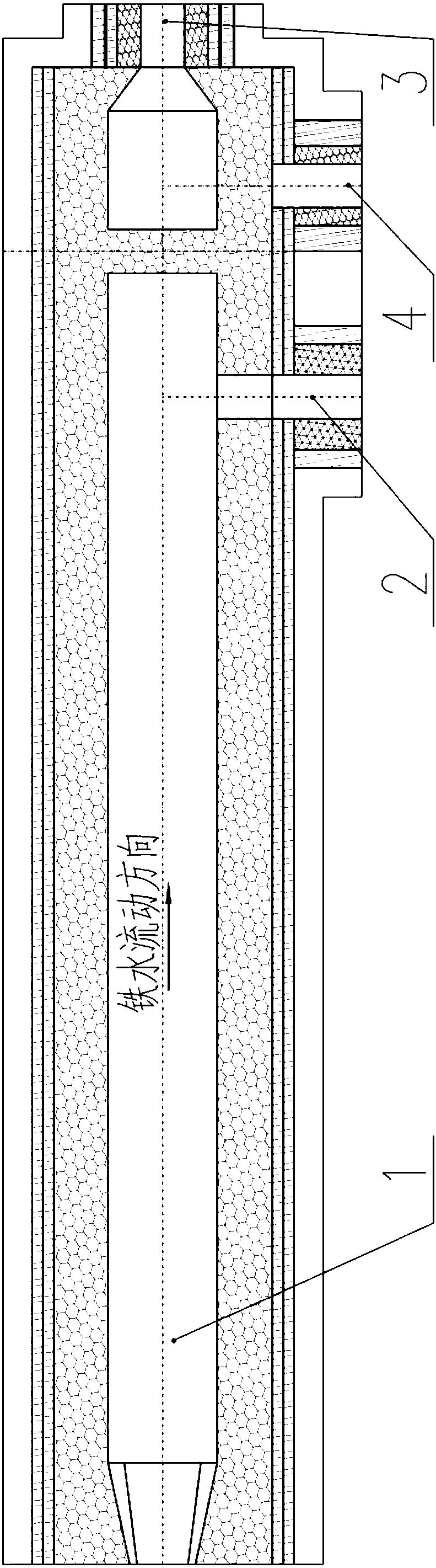

[0019] Such as figure 1 As shown, after the slag and iron discharged from the blast furnace are separated in the tapping main ditch 1, the molten slag is introduced into the blast furnace slag treatment system through the slag ditch 2, and the molten iron flows into the molten iron tank through the iron ditch 3, and the residual iron in the tapping main ditch can pass through the residual Iron ditch 4 flows into ladle.

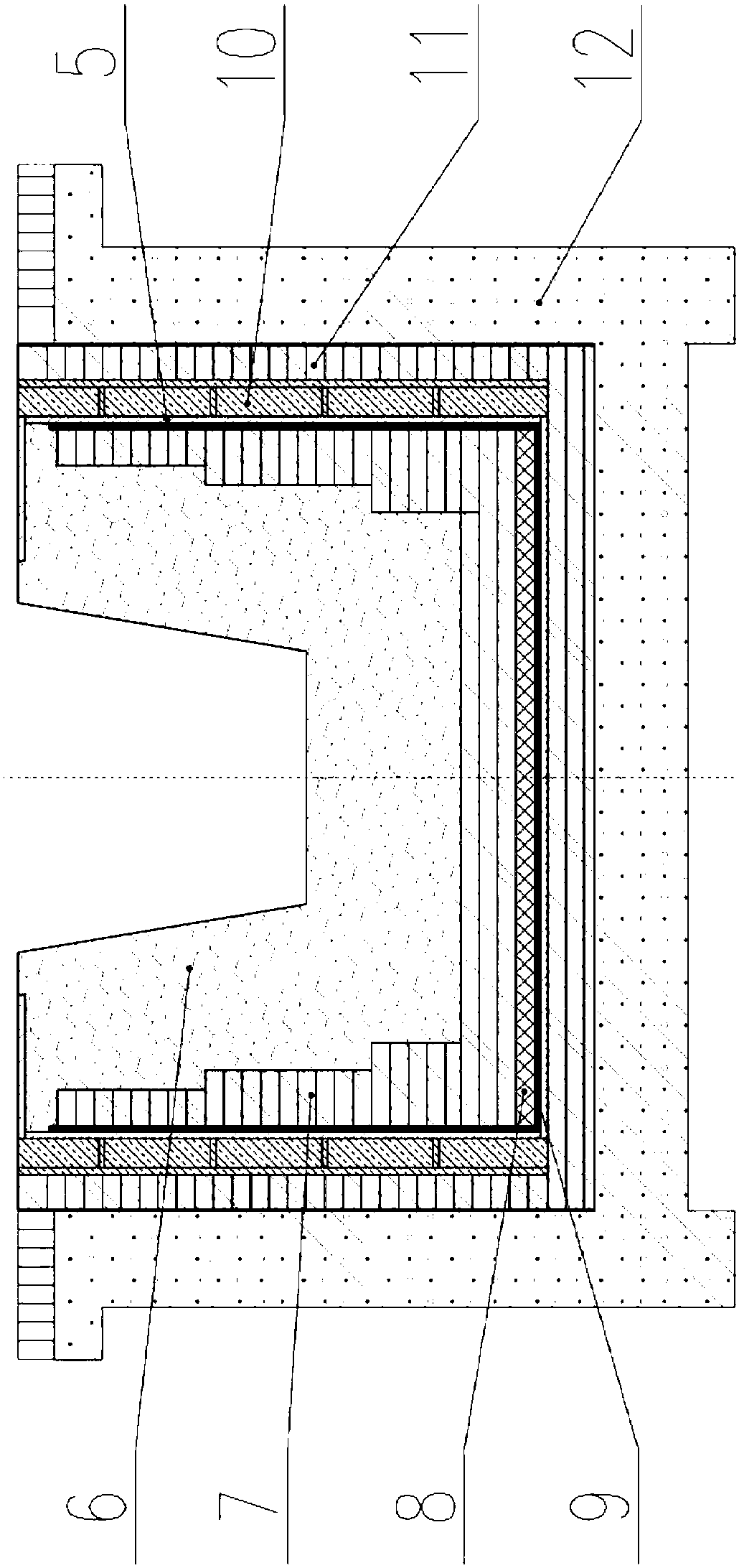

[0020] Such as figure 2 As shown, the tapping main ditch 1 is divided into inner and outer areas by the tapping main ditch steel structure 5 as the boundary; The thermal light clay brick layer 8 and the composite thermal insulation board 9 are composed; the exterior of the main ditch steel structure 5 is composed of a sand filling layer 10, a heat-insulating protection brick layer 11, and a civil heat-resistant concrete structure layer 12.

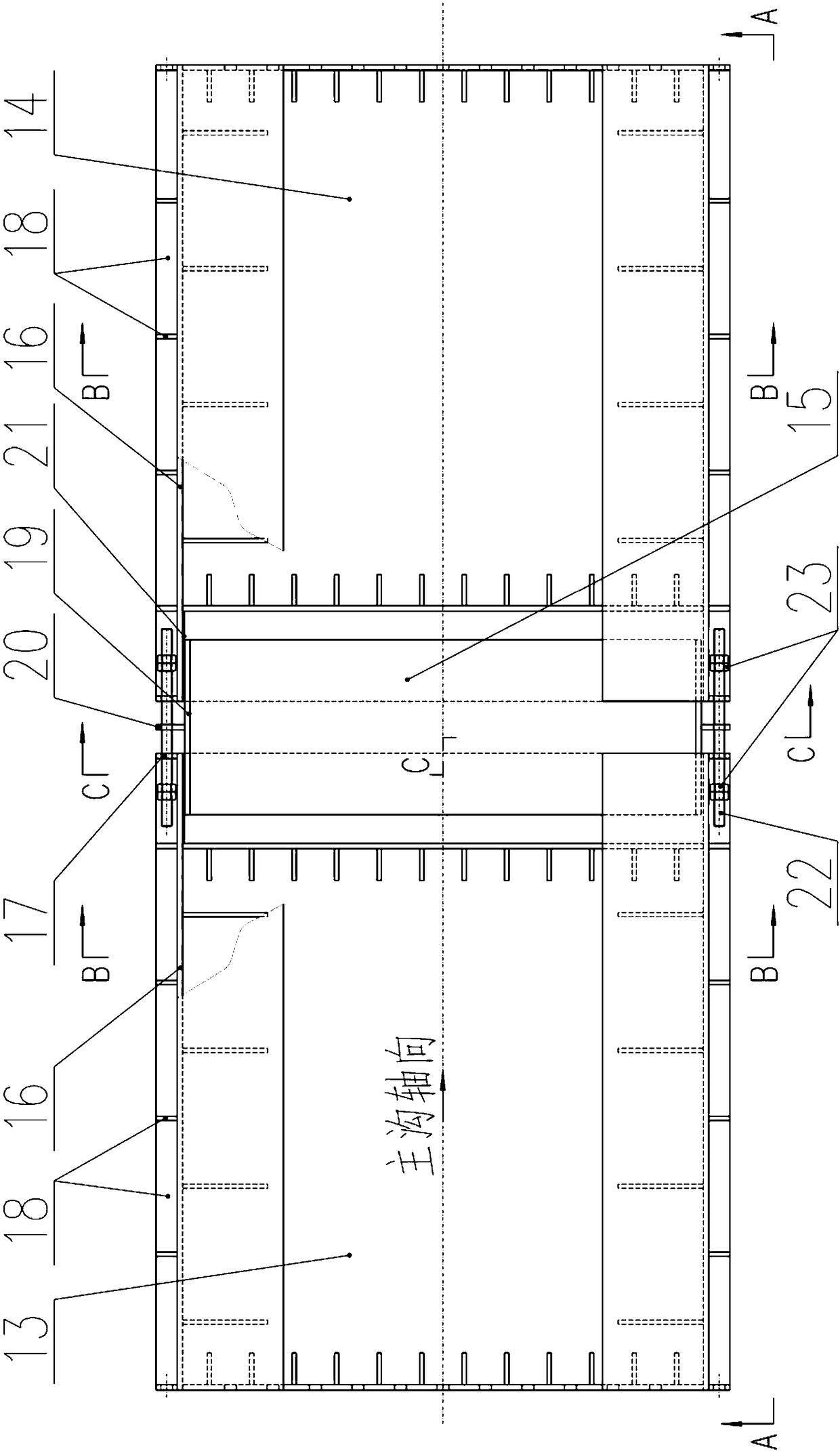

[0021] The blast furnace tapping main ditch steel structure 5 is a steel box with an open upper part, which can be di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com