Washing machine counterweight, washing machine and washing machine counterweight method

A washing machine and counterweight technology, which is applied to the control device of the washing machine, other washing machines, washing devices, etc., can solve the problem of vibration and noise increase of the whole drum washing machine, inconvenient handling and distribution of the drum washing machine, and increase in the quality of the drum washing machine. and other problems, to achieve the effect of good vibration suppression, convenient handling and distribution, and reducing the quality of the counterweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

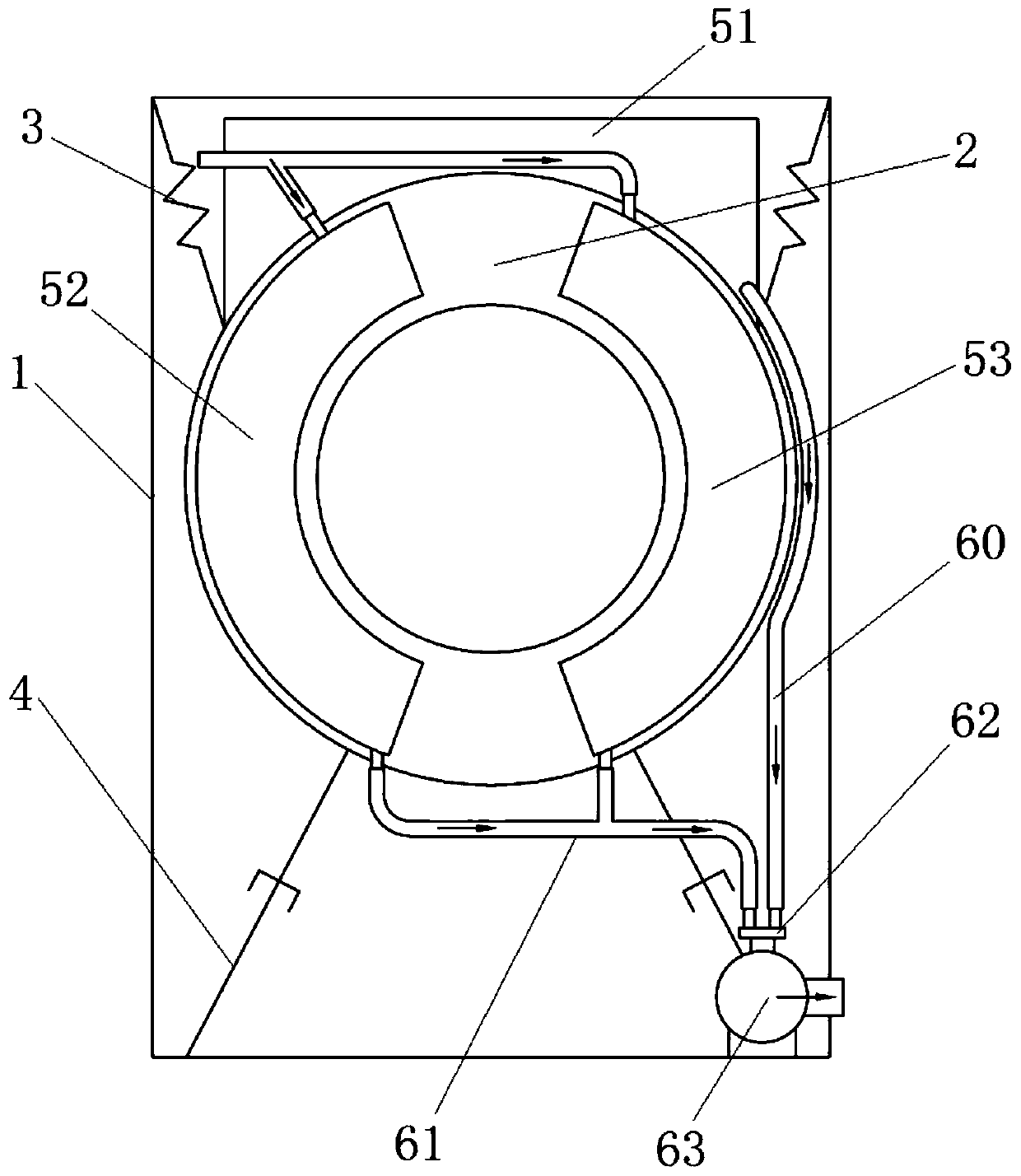

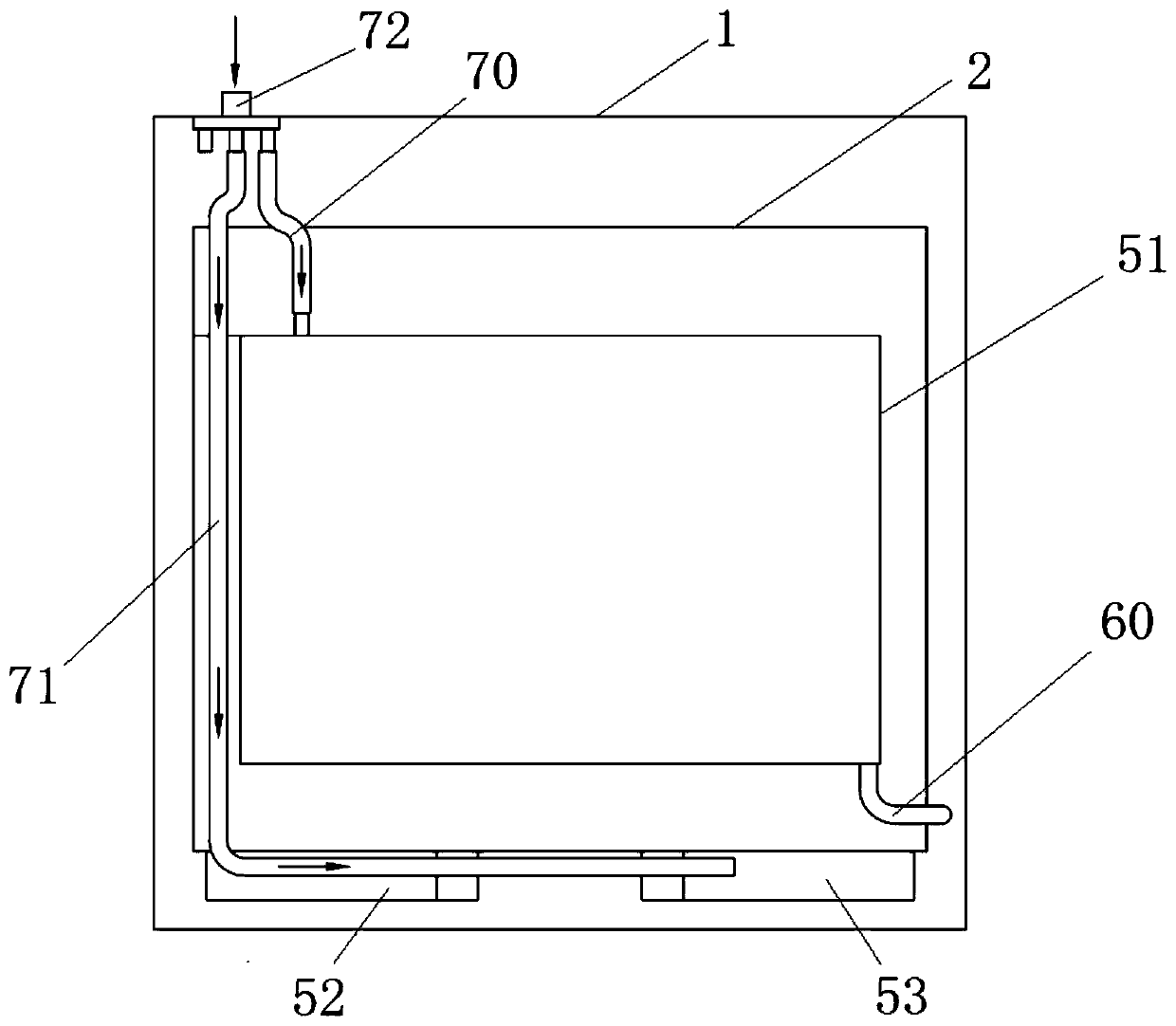

[0052] This embodiment provides a counterweight for a washing machine, which is used to be fixed on the water tank of the washing machine. Taking a drum washing machine as an example, it is mainly used to adjust the drum center of mass of the drum washing machine, and to increase the outer drum (water drum) and inner drum of the drum washing machine. The quality of the drum washing machine is suppressed. Specifically, as Figure 1 to Figure 3 As shown, the counterweight of the washing machine in this embodiment includes at least one counterweight cavity (see figure 1 with image 3 The first counterweight chamber 51, the second counterweight chamber 52 and the third counterweight chamber 53) and the pressurized water structure (see image 3 Press water plate 501 and spring 502 in). Wherein, the counterweight chamber is a closed cavity, and the counterweight chamber is provided with a water inlet for connecting the water inlet pipe and a water outlet for connecting the water ...

Embodiment 2

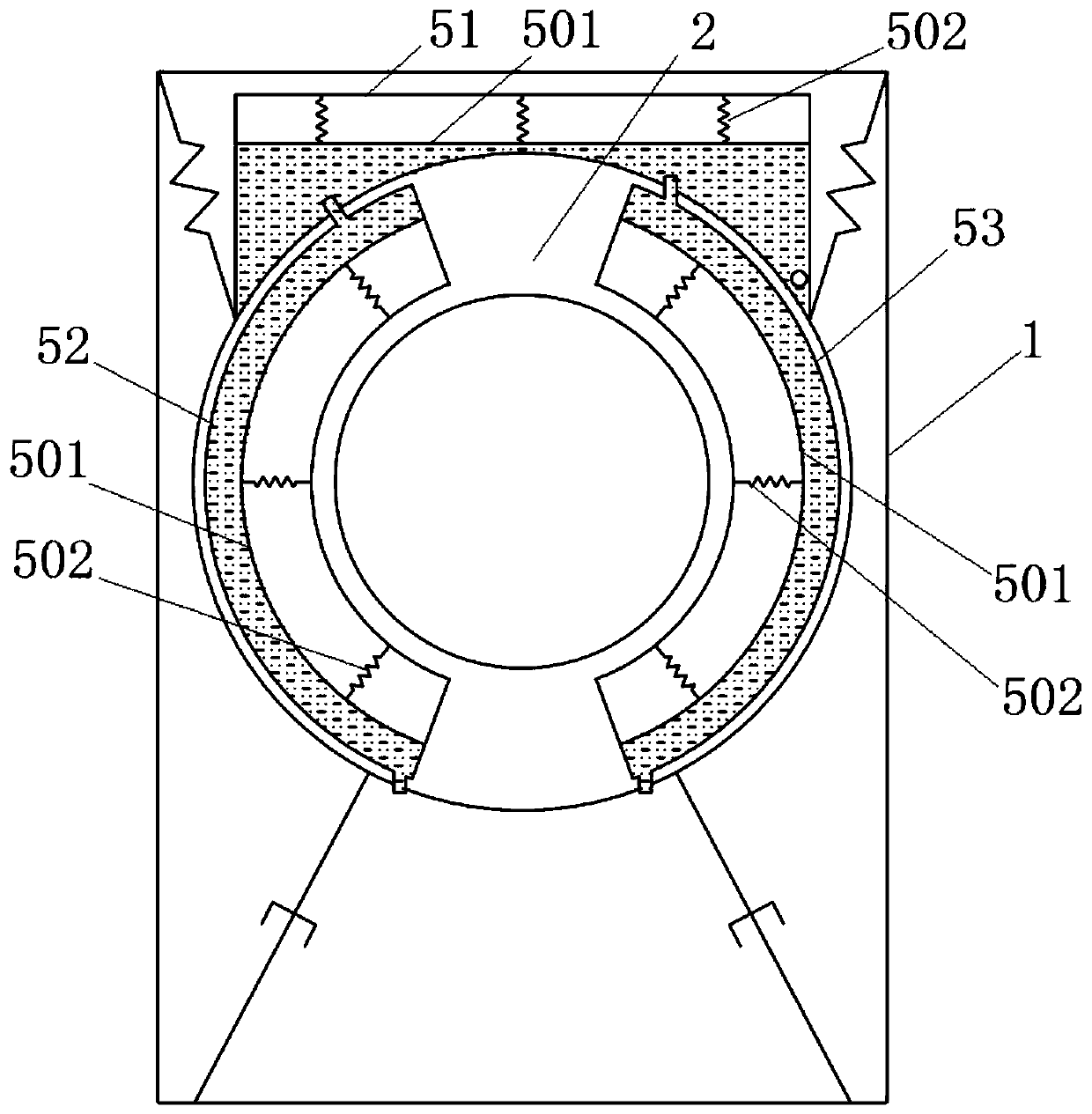

[0056] Preferably, this embodiment provides a washing machine counterweight, compared with the previous embodiment, as image 3 As shown, the water pressure structure of this embodiment includes: a water pressure plate 501 and a pressure assembly. Wherein, the pressure water plate 501 can move in the counterweight cavity, and divides the counterweight cavity into a first cavity and a second cavity with variable volume. Wherein, the water inlet and the water outlet are both communicated with the first cavity. Here, both the first cavity and the second cavity are closed cavities. The pressure assembly is arranged in the second cavity for applying pressure to the pressure water plate 501 (the pressure here refers to: a kind of elastic force whose pressure changes with the movement of the water pressure plate 501, specifically, the pressure The size is inversely proportional to the volume of the second cavity, and proportional to the volume of the first cavity), so that the pres...

Embodiment 3

[0061] Preferably, this embodiment provides a counterweight for a washing machine. Compared with Embodiment 2, the pressure assembly in this embodiment can be set to the following structure:

[0062] First, the pressure assembly in this embodiment may be high-pressure gas filled in the second cavity.

[0063] Specifically, when the counterweight cavity of the counterweight of the washing machine is in an anhydrous state, the volume of the first cavity is zero, and the high-pressure gas fills the counterweight cavity. When water is injected into the counterweight cavity, the water pressure plate moves to the direction of shrinking the second cavity under the action of water pressure, compressing the high-pressure gas. The volume of the first cavity increases continuously. When the high-pressure gas is compressed to the limit, stop the water intake. During the above whole process, the water intake into the counterweight cavity is carried out in the state of no air in the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com