Damper achieving low-yield-point steel energy dissipation and particle energy dissipation

A low-yield point steel and damper technology, which is applied in the direction of building components, building types, and earthquake resistance, can solve the problems of reducing energy consumption performance, and the damper does not play the role of consumption and shock absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

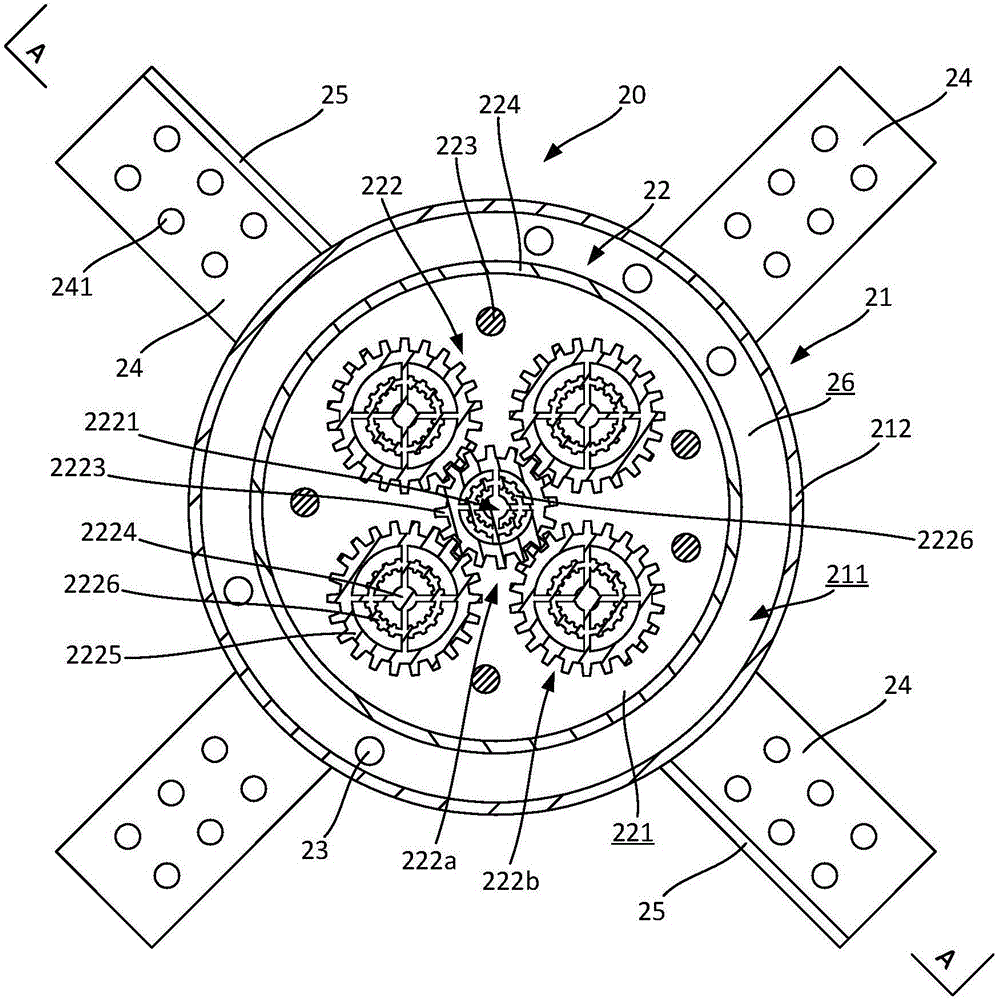

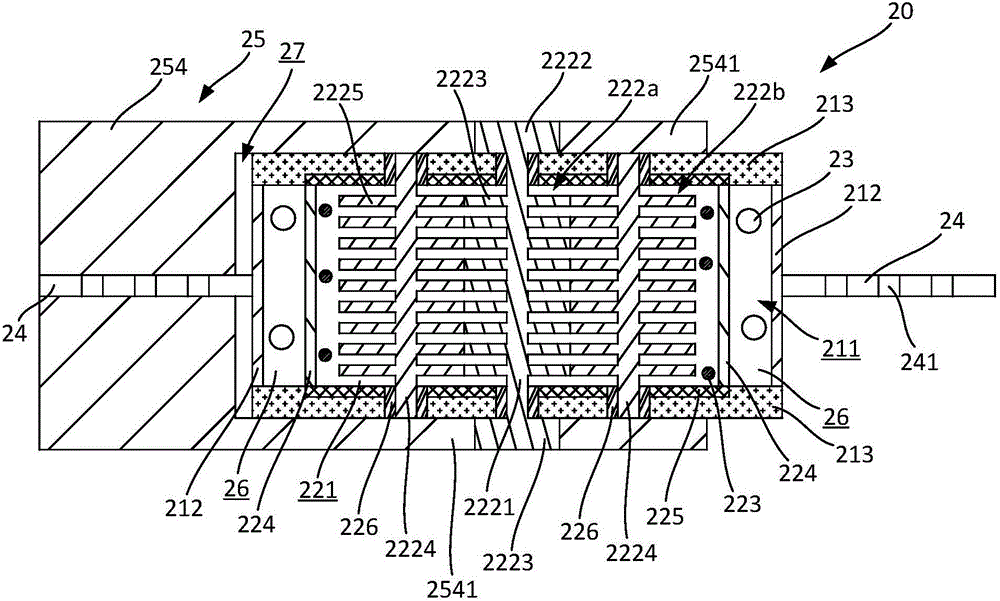

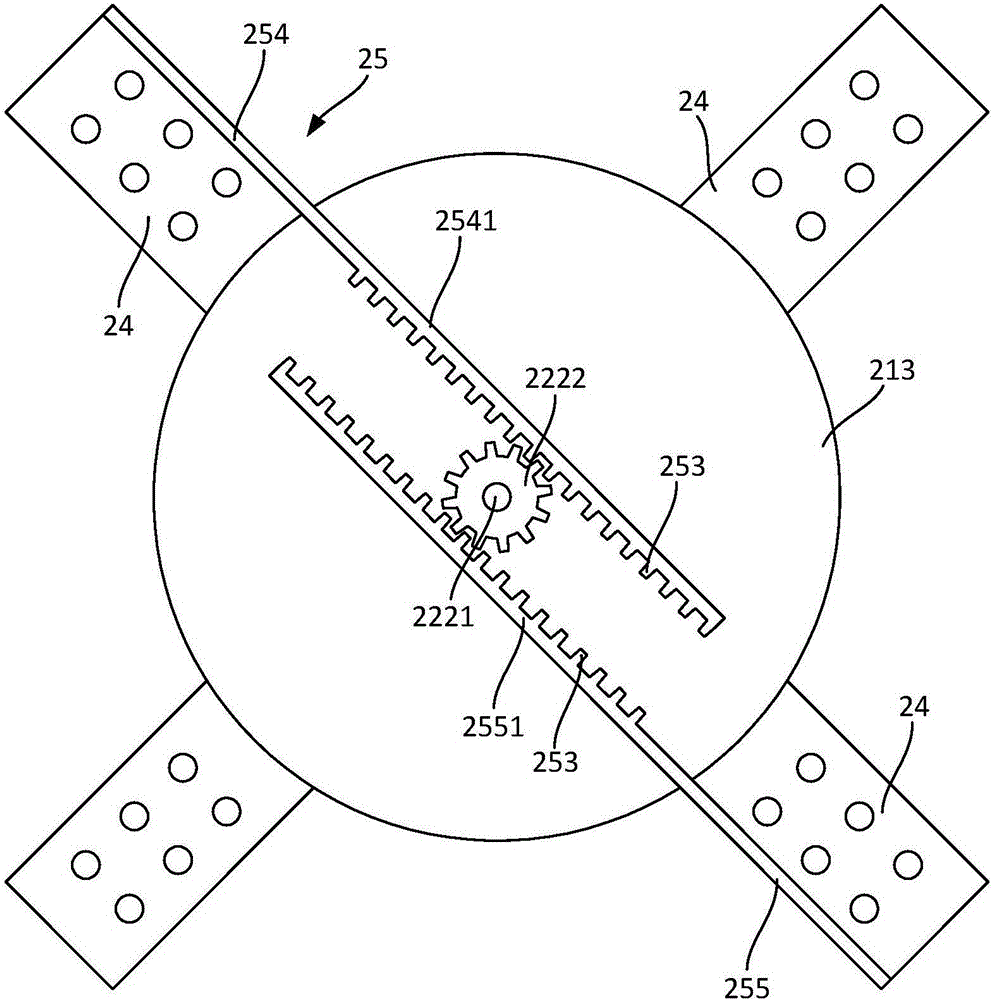

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] The invention provides a low yield point steel energy consumption and particle energy consumption damper, which is used for shock absorption and energy consumption of building structures. When the structure is in the elastic stage, the energy consumption mode of the damper is mainly low yield point steel yield energy consumption . When the structure enters the elastoplastic stage, the yield energy dissipation of the metal damper under small earthquakes is compensated by the particle energy dissipation. Particle energy dissipation is a passive energy dissipation shock absorption control technology, which has the advantage of widening the shock absorption frequency band of the damper, and its shock absorption performance does not decrease over time. The principle of the particle damper is: when the particle damper is in a relatively stron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com