Explosion-proof union and its connection nut installation method

A technology for connecting nuts and installation methods, which is applied in the direction of sealing surface connections, pipes/pipe joints/fittings, passing components, etc., which can solve the problems of high production costs, large production materials, and large parts sizes and specifications, and achieve saving production materials , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

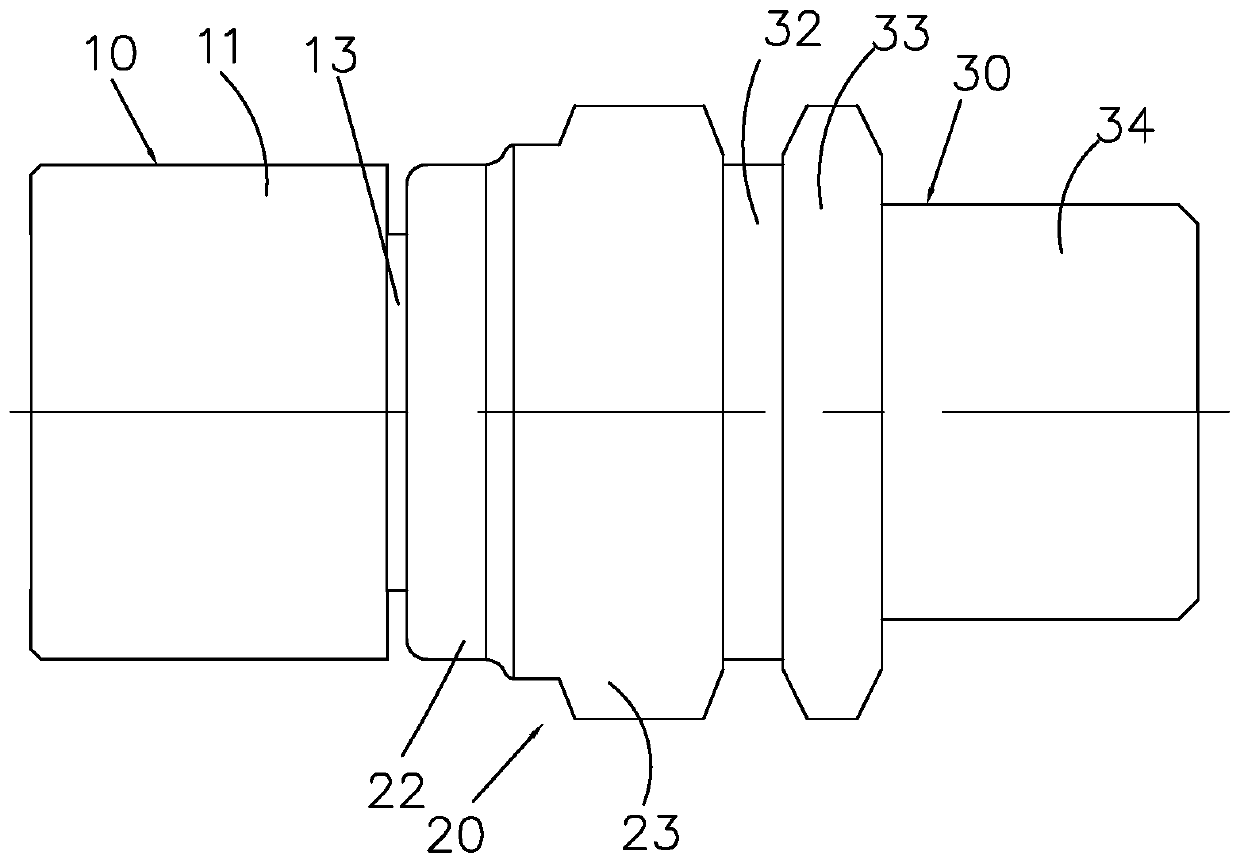

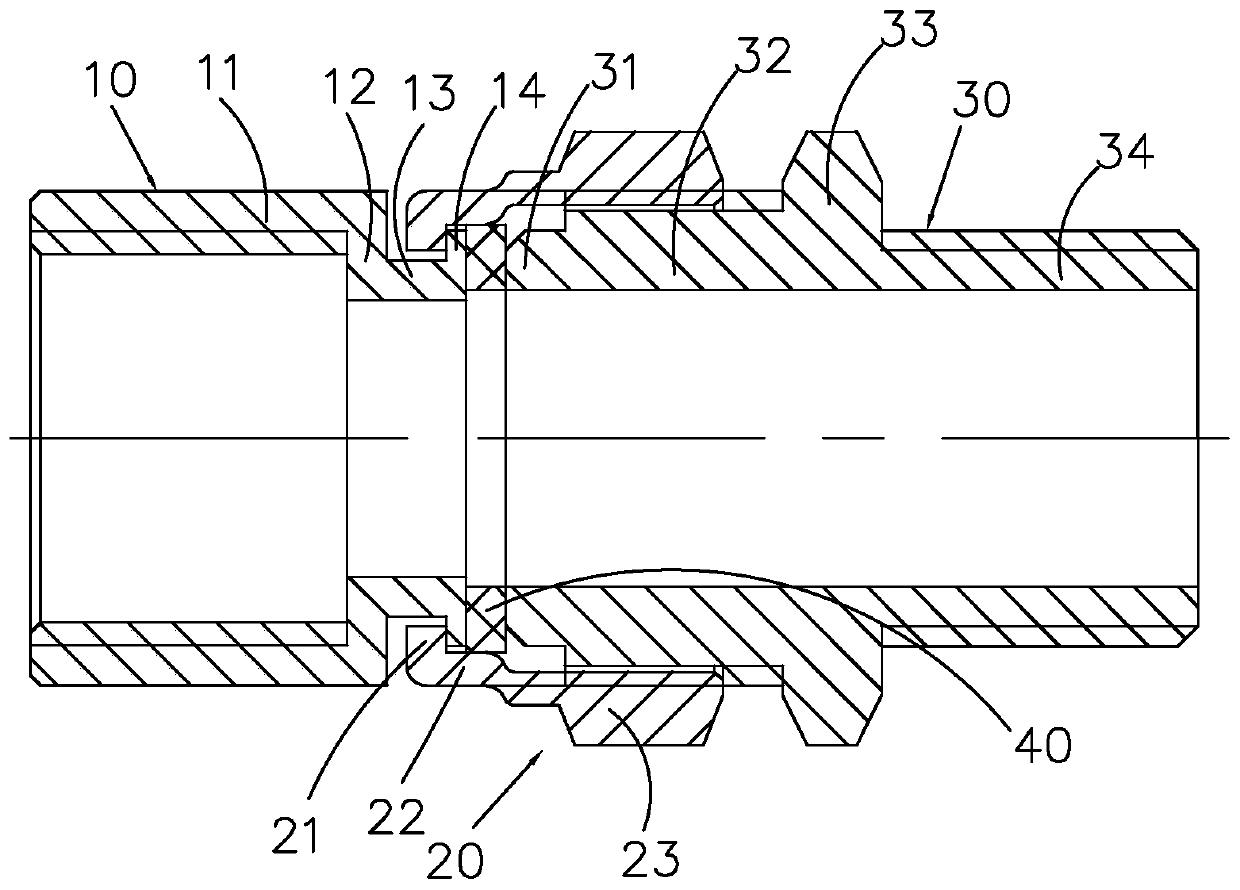

[0014] as attached figure 1 , 2 shown. An explosion-proof joint, comprising a first joint 10, a connecting nut 20 arranged on the first joint 10, a second joint 30 threadedly connected with the connecting nut 20, a joint between the first joint 10 and the second joint 30 Gasket 40.

[0015] In this example, the first connector 10 is a power connector connected to a power supply terminal, and the second connector is a lamp connector 30 connected to a lamp.

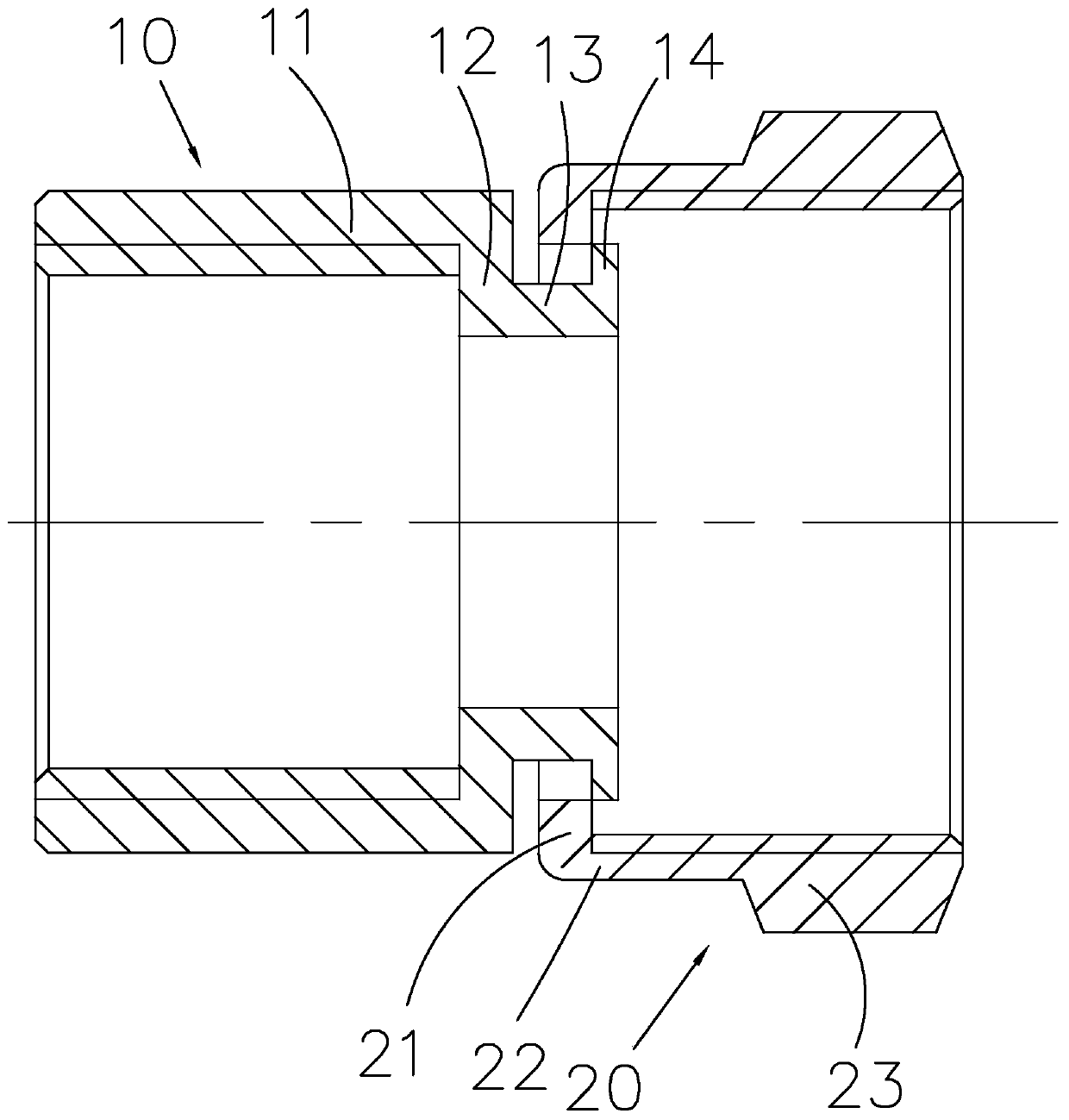

[0016] Such as figure 2 As shown, the first joint 10 includes a first joint body 11, a connecting wall 12 formed by extending radially inward from one end edge of the first joint body 11, and extending axially outward from the end of the extended connecting wall 12. The formed connecting neck 13, the joint snap ring 14 formed by extending radially outward from the end of the connecting neck 13, one end of the connecting nut 20 has a nut snap ring 21 extending radially inward, and the nut snap ring 21 is sleeved on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com