An auxiliary switch control structure and a switch cabinet having the same

An auxiliary switch and installation structure technology, applied in the direction of electrical switches, electrical components, circuits, etc., can solve the problems of unable to form stable cooperation, affecting the safety of equipment, etc., and achieve the effects of stable cooperation, good linkage and high installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

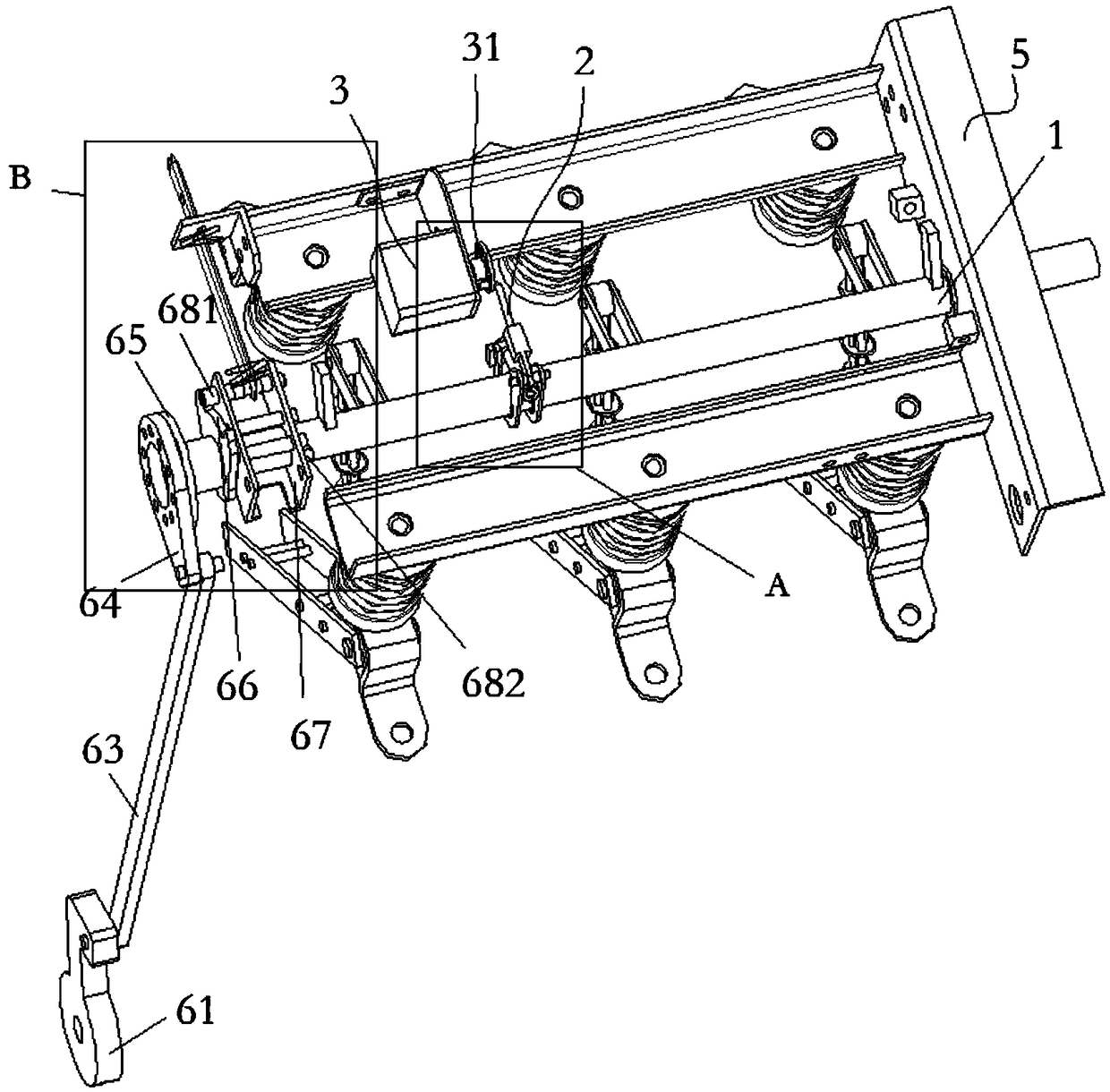

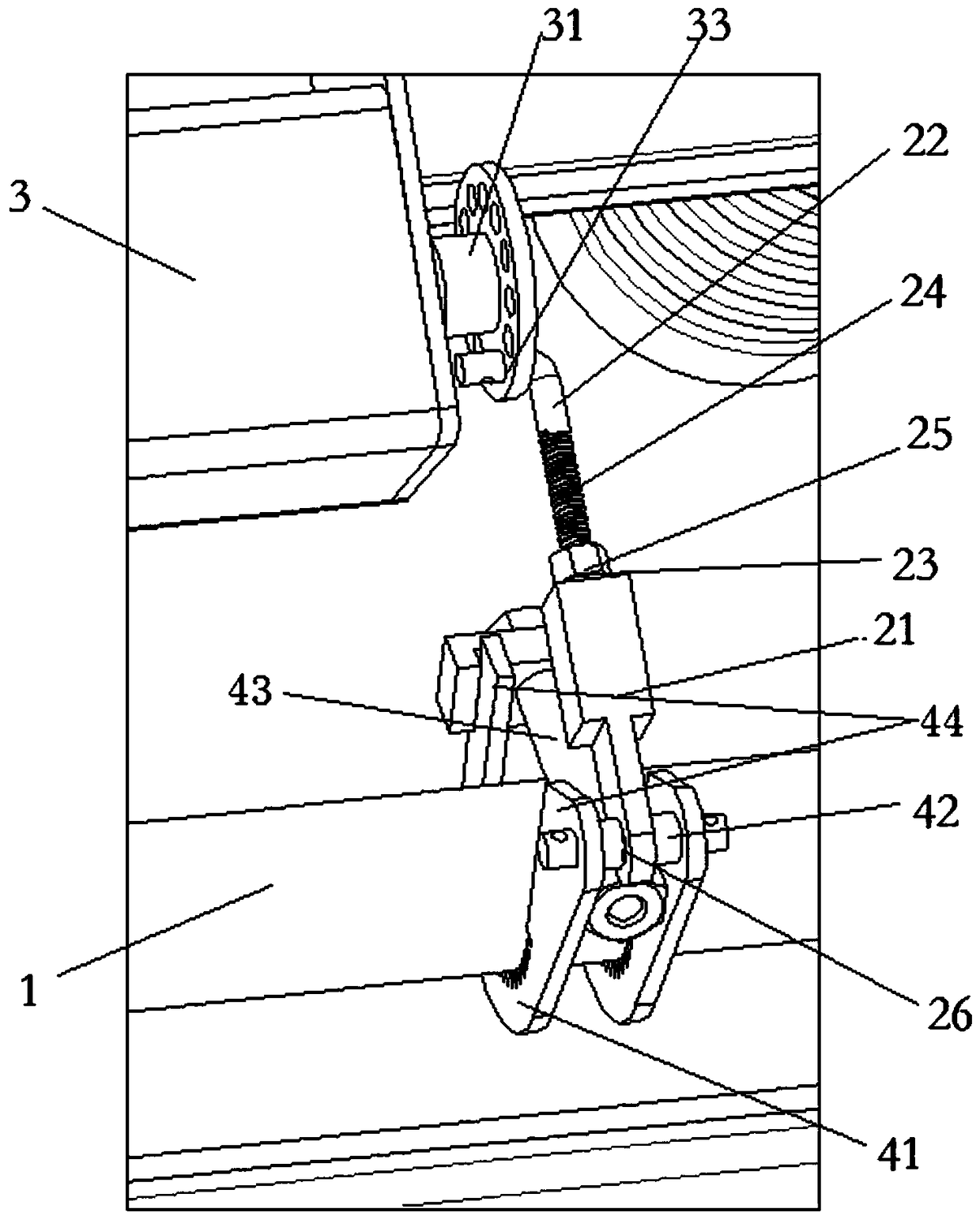

[0057] This embodiment provides an auxiliary switch control structure, such as Figure 2-3 As shown, it includes: a driving rod 1, which can rotate around its own axis under the action of an external force; a linkage rod 2, whose axial length is adjustable, one end is rotatably connected to the driving rod 1 through a mounting structure, and the other end is connected to the opening and closing gate. The turntable 31 is connected, and the opening and closing turntable 31 is used to drive the auxiliary switch 3 to connect the closing circuit or the opening circuit; when the driving rod 1 rotates, it drives the movement of the linkage rod 2, and then drives the opening and closing circuit. The turntable 31 rotates to control the auxiliary switch 3 to connect the closing circuit or the opening circuit.

[0058] In the auxiliary switch control structure of this embodiment, after the drive rod 1 and the auxiliary switch 3 are installed respectively, the linkage rod 2 is used to con...

Embodiment 2

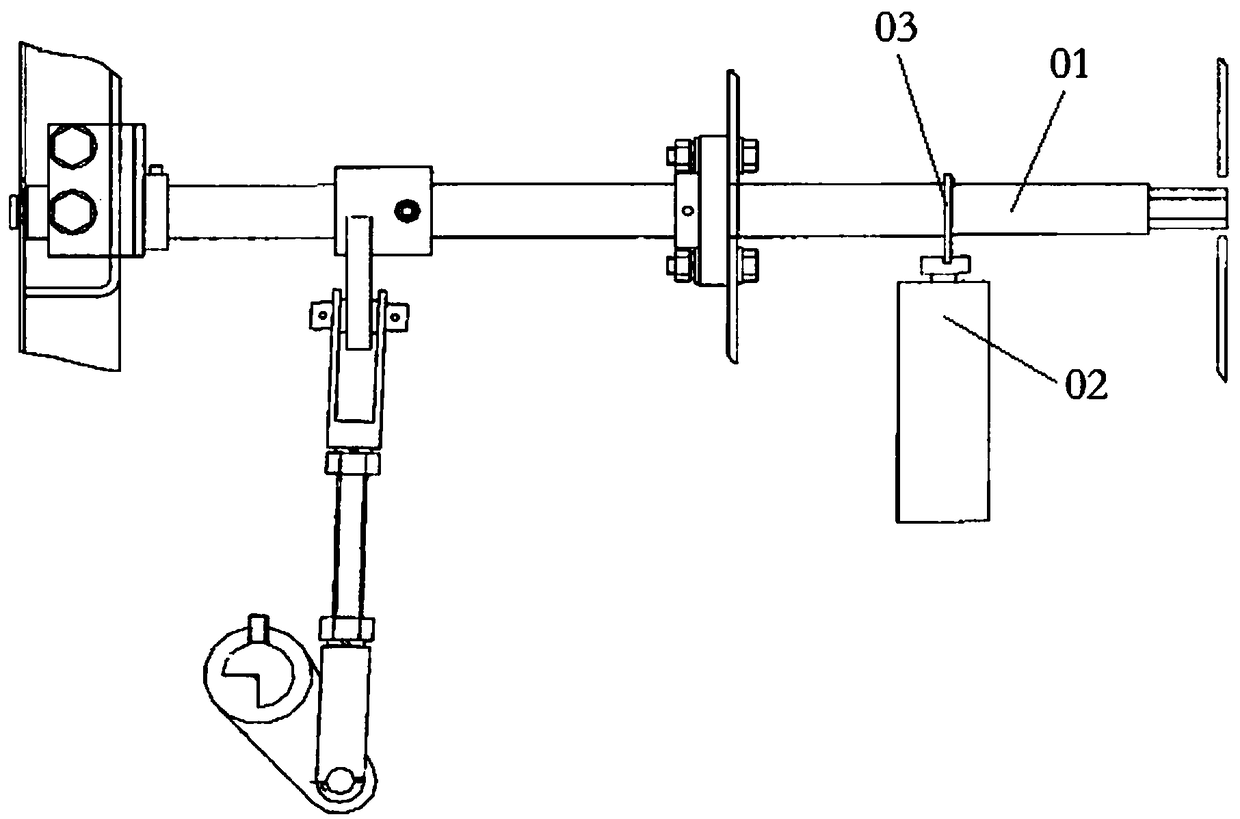

[0068] This embodiment provides a switchgear, such as Image 6 and refer to as Figure 1-5 As shown, the switchgear of this embodiment includes the auxiliary switch control structure as described in Embodiment 1.

[0069] Because the switchgear of this embodiment includes the above-mentioned auxiliary switch control structure, it naturally has all the advantages brought by the above-mentioned control structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com