Module type permanent magnet motor rotor with radial ventilation channel and motor

A technology of radial ventilation and permanent magnet motors, applied in the direction of magnetic circuit rotating parts, electrical components, electromechanical devices, etc., can solve the problem that it is difficult for permanent magnets to form gaps, permanent magnets cannot be repaired or replaced, and the contact area between cooling air and motors Limited and other problems, to reduce maintenance costs and improve the effect of internal ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

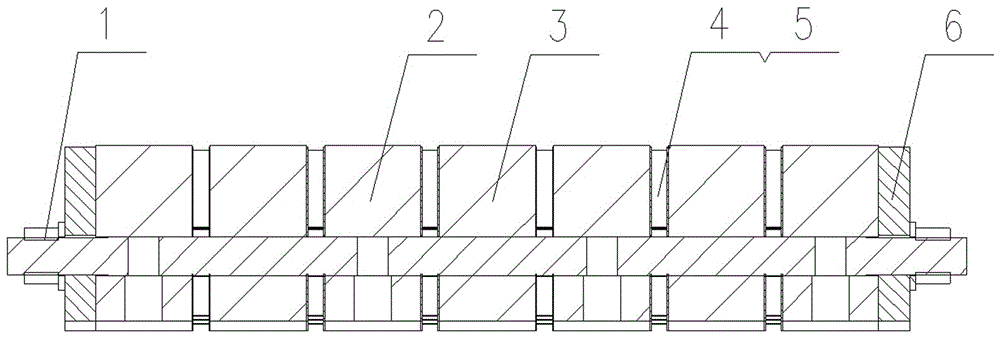

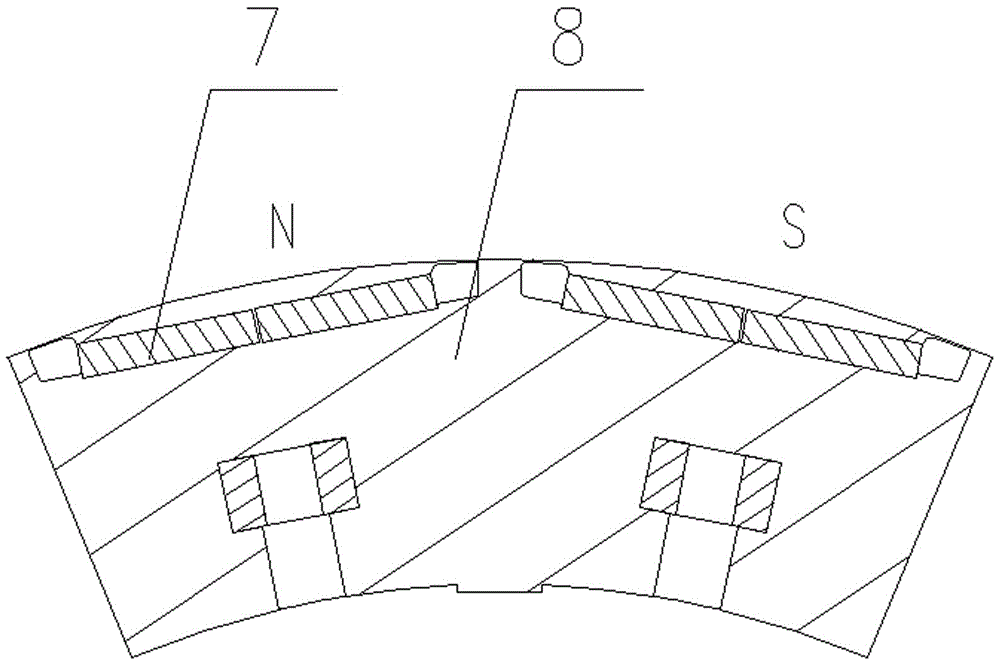

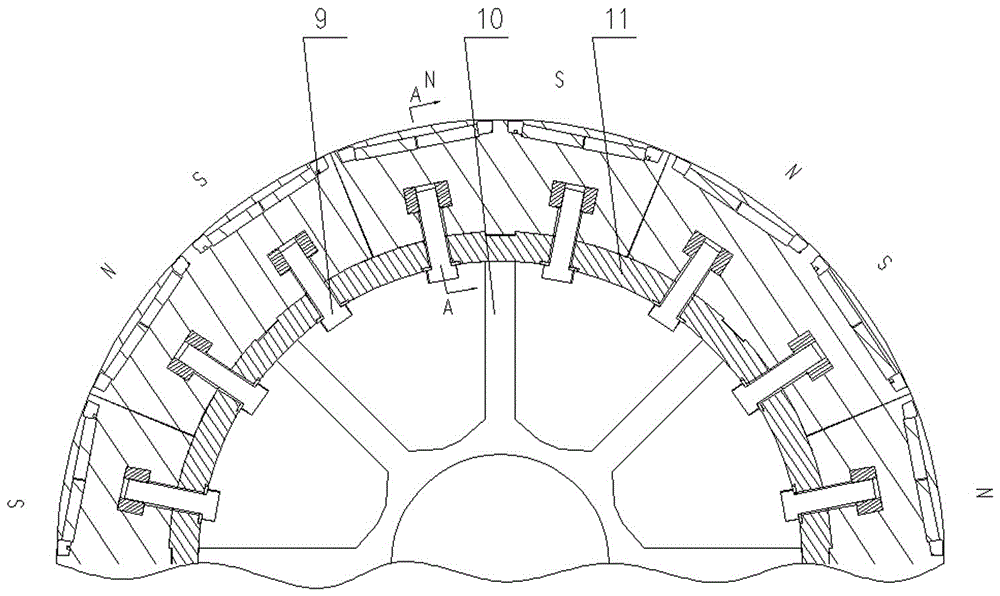

[0017] With reference to the accompanying drawings, a modular permanent magnet motor rotor with radial ventilation ducts includes magnetic poles, a rotating shaft 10 with ribbed plates, and a magnetic pole fixing ring 11. The magnetic poles include a magnetic pole core 8, a permanent magnet 7, and a magnetic pole fixing ring 11. Set on the outer circle of the rotating shaft 10 of the ribbed plate, the magnetic pole is divided into eight modular magnetic poles from the radial direction, and the modular magnetic pole includes a magnetic pole, a magnetic pole pressure plate 6, a tension screw pair 1, and a ventilation groove plate 4. The pole core 8 is divided into seven pole core units in the axial direction, including four pole core units 2 with installation holes and three pole core units 3 without installation holes. Adjacent poles Ventilation slots 4 and ventilation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com