Brake cylinder maintaining reference

A brake cylinder, brake cylinder pressure technology, applied in the direction of brakes, brake components, control valves and bleed valves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

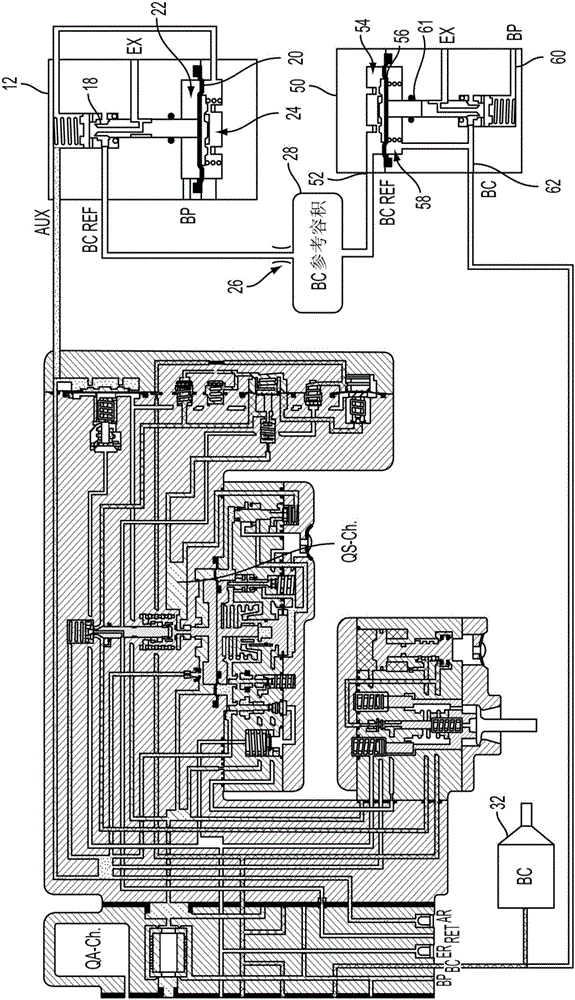

[0014] Referring now to the drawings, in which like reference numerals represent like parts throughout, in figure 1 A schematic illustration of a brake cylinder holding system 10 according to the invention is seen in . The system 10 provides reference pressures for brake cylinder hold in an independent and redundant manner such that the brake cylinder hold reference is not affected by any pre-existing leaks in the brake system, thereby resulting in brake cylinder BC pressure Provides higher pressure regulation accuracy in many different situations of loss.

[0015] The system 10 includes a brake cylinder reference pressure valve 12 that operates in response to the action of a master working piston 14 of a working portion 16 of a railcar braking system, figure 1 A detailed schematic of the working section of a DB-10 commercially available from New York Airlock Co., Watertown, NY is shown in . More specifically, the brake cylinder reference pressure valve 12 has an actuator 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com