Suprasternal plate

A sternum and sternum technology, applied in the field of medical devices, can solve the problems of sternal plate easy retreat, lung inflammation, lung infection, etc., and achieve the effect of reducing the difficulty of surgery, reducing lung inflammation, and restoring the shape of the thorax

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

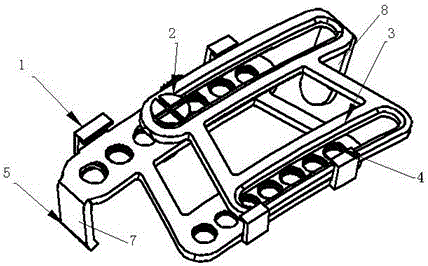

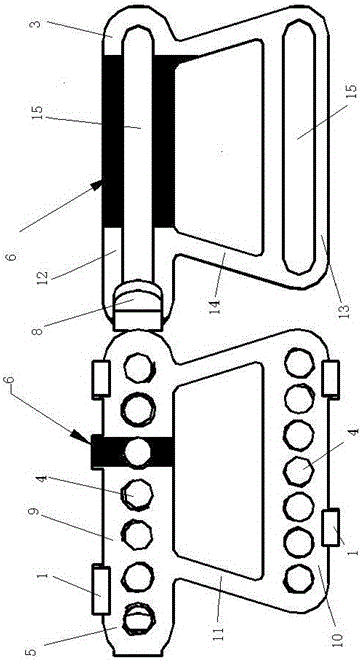

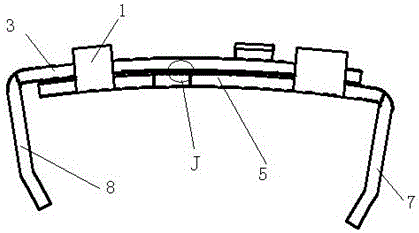

Embodiment 1

[0027] like Figure 1-4 As shown, a sternum plate includes an upper sternum 3, a lower sternum 5 and fixing nails 2; the upper sternum 3 includes a first upper sternal main body 12, a second upper sternal main body 13 and an upper sternal connecting portion 14; The breast plate main body 12 and the second upper breast plate main body 13 are connected together by two upper breast plate connecting parts 14; the first upper breast plate main body 12 and the second upper breast plate main body 13 are respectively provided with an upper breast plate hollow part 15; One end of the upper chest plate main body 12 is provided with a claw 8, and the bottom surface of the first upper breast plate main body 12 is provided with a stop tooth 6; the lower breast plate 5 includes a first lower breast plate main body 9, a second lower breast plate main body 10 and a lower Breast plate connection part 11; first lower breast plate main body part 9 and second lower breast plate main body part 10 ...

Embodiment 2

[0030] like Figure 8-9 As shown, a sternum plate includes an upper sternum 19, a lower sternum 16 and fixing nails 18; the upper sternum 19 includes an upper sternum main body 25, and the upper sternum main body 25 is respectively provided with an upper sternum hollow 24; the upper sternum main body 25 One end of the upper chest plate is provided with a claw 21, and the bottom surface of the upper breast plate main body 25 is provided with a back-stop tooth 23; the lower breast plate 16 includes a lower breast plate main body 26, and the top surface of the lower breast plate main body 26 is respectively provided with a plurality of threaded holes 20. The hole 20 is used for locking and fixing, and has a fastening effect; the side of the lower breast plate main body 26 is provided with a plurality of chute buckles 17, and the function of the chute buckles 17 is to limit the movement of the upper breast plate 19 and prevent it from eversion; The top surface of the lower sternum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com