A tapered memory alloy breastbone fixer

A technology of memory alloy and memory alloy wire, which is applied in the field of sternum fixer and medical equipment, can solve the problems such as difficulty in fixing the sternum, achieve the effect of not being easy to rotate and shift, less contact area, and increasing the strength and stability of the back arch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

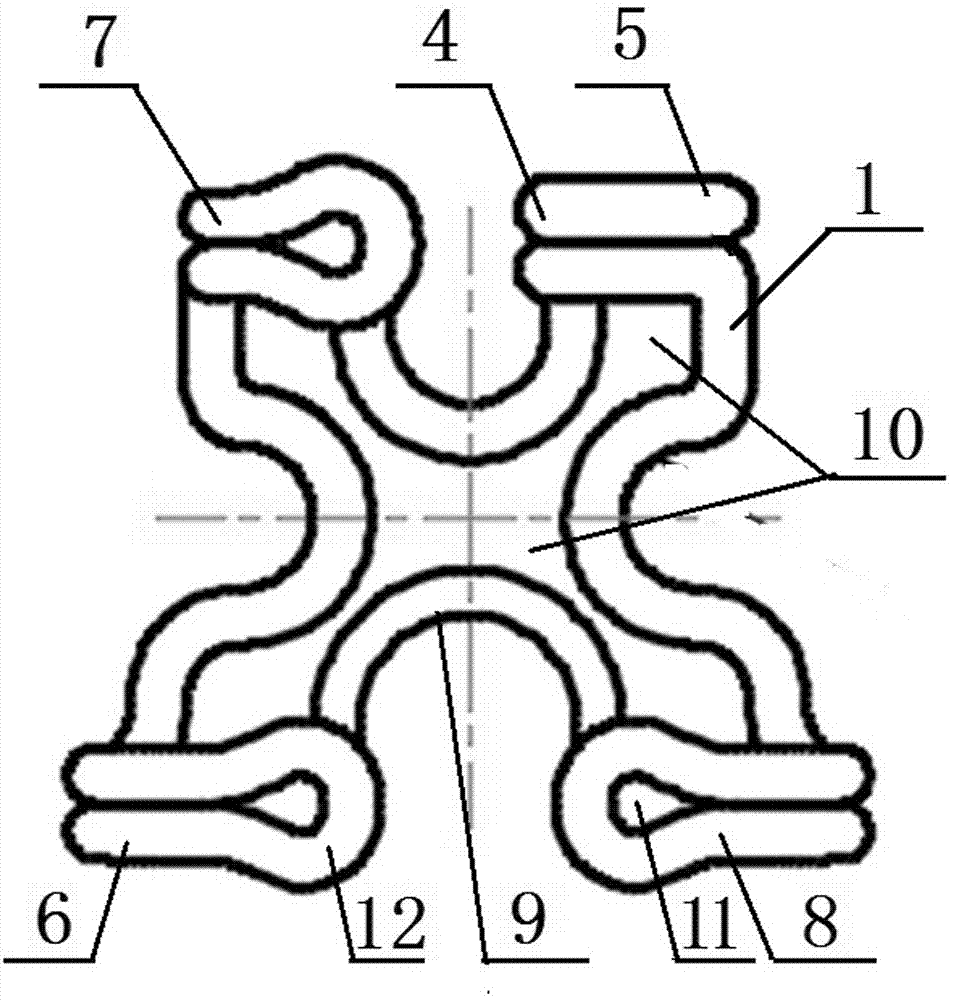

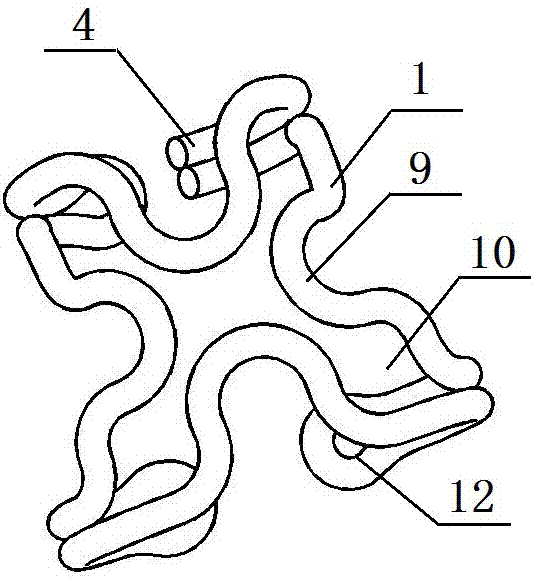

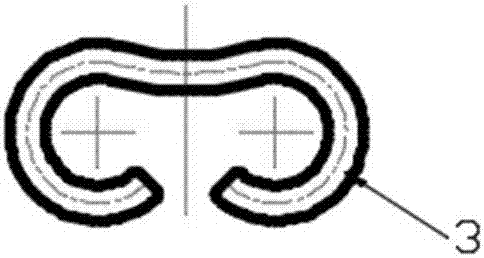

[0031] Such as Figure 1-3 As shown in the figure, a tapered memory alloy sternum fixer is made of a double beam formed by folding both ends of a memory alloy wire in equal alignment. It includes two open annular structures, one large and one small, which are parallel to each other. The top surface of the two open annular structures is an arched back with a narrow upper part and a wider lower part. Among them, the small open annular structure 3 is formed by two short encircling arms bent inward towards each other. , the ring structure 2 with a large opening is formed by two long encircling arms bent towards each other and inward. The ends of the embracing arms located at the openings in the two open ring structures are bent inward. Among the four encircling arms, the tops of two adjacent encircling arms are sequentially connected by arched arm single beam 1 to form an arched back with a narrow top and a wide bottom.

[0032] Among them, the four embracing arms are formed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com