Memory-alloy-wire sternum fixer with three pairs of encircling arms

A memory alloy wire and fixator technology, used in the field of sternum fixators and medical devices, can solve the problems of fracture of the bone plate, long operation time, easy occurrence of infection, etc., to improve the toughness and fatigue resistance, increase the strength of the dorsal arch and Stability, favorable effect on sternal revascularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

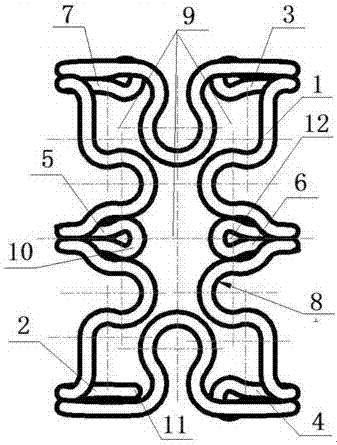

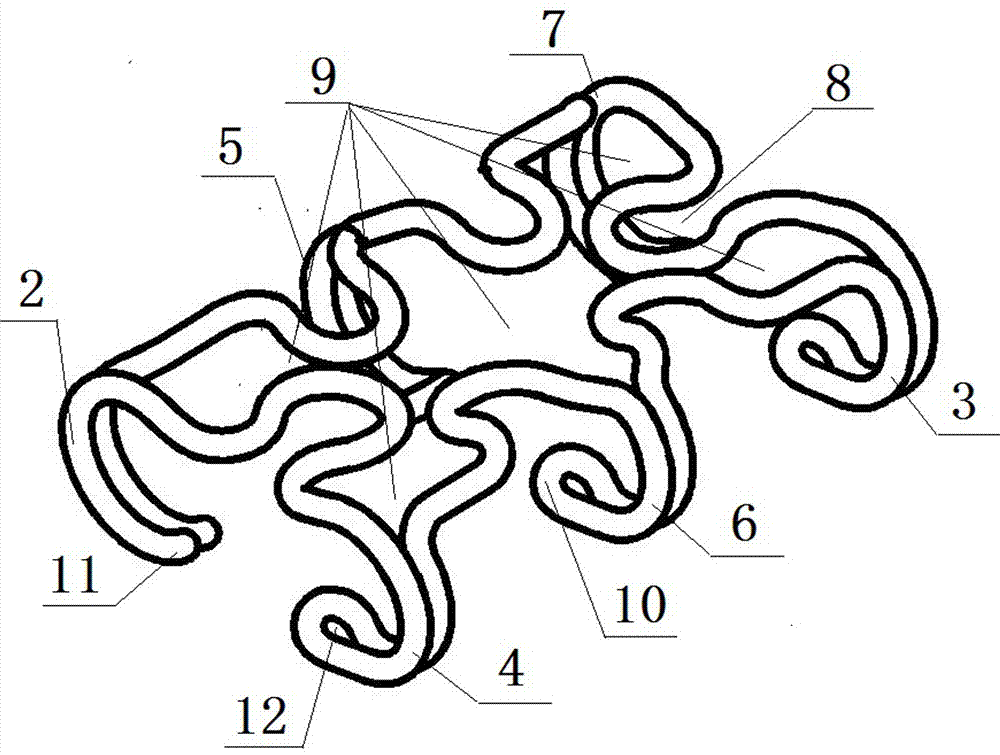

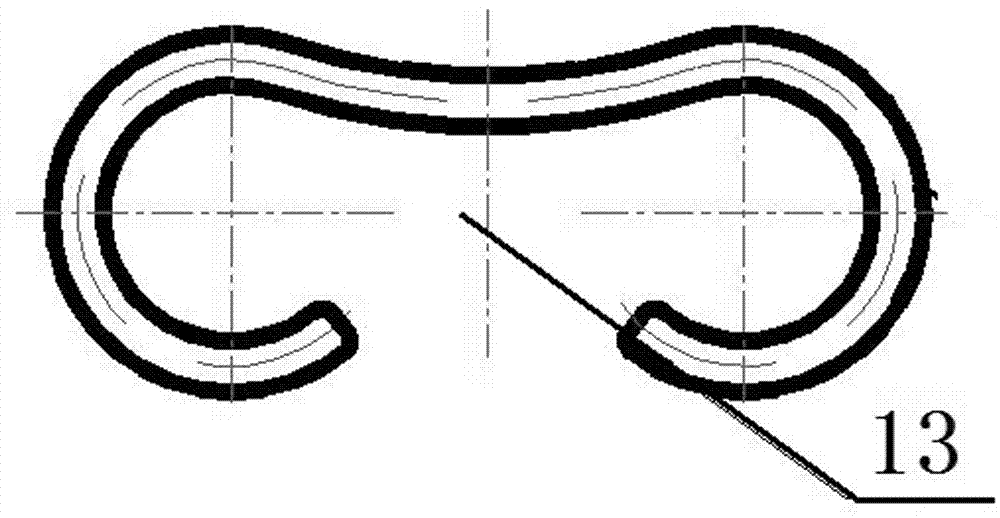

[0030] Such as figure 1 , As shown in 2, a memory alloy wire sternum fixer containing three pairs of embracing arms is made of a memory alloy wire to form an integrated structure containing three pairs of embracing arms, and the two embracing arms in each pair are all bent inwards towards each other An open ring structure is formed. Three open ring structures are arranged parallel to each other. Each embracing arm is formed by bending two memory alloy wires side by side. The middle section of the arched arm single beam between the tops of two adjacent encircling arms is extruded inward to form an arc-shaped pressure ring, and all the pressure rings are located on the same plane.

[0031] Such as figure 1 As shown, among them, three pairs of embracing arms are made of a memory alloy wire single beam 1 which is equally folded at both ends to form a double beam. Arm 3, two memory alloy wires at 1 / 3 and 2 / 3 between the two ends of the double beam are respectively bent downwards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com