A breastbone fixer with a memory alloy wire sing beam provided with a pair of embracing arms

A technology of memory alloy wire and memory alloy, which is applied in the field of medical devices and sternal fixers, can solve the problems of fractured bone plate, easy infection, sternal tear, etc., and achieves improved toughness and fatigue resistance, firm fixation and not easy to break, Increased strength and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

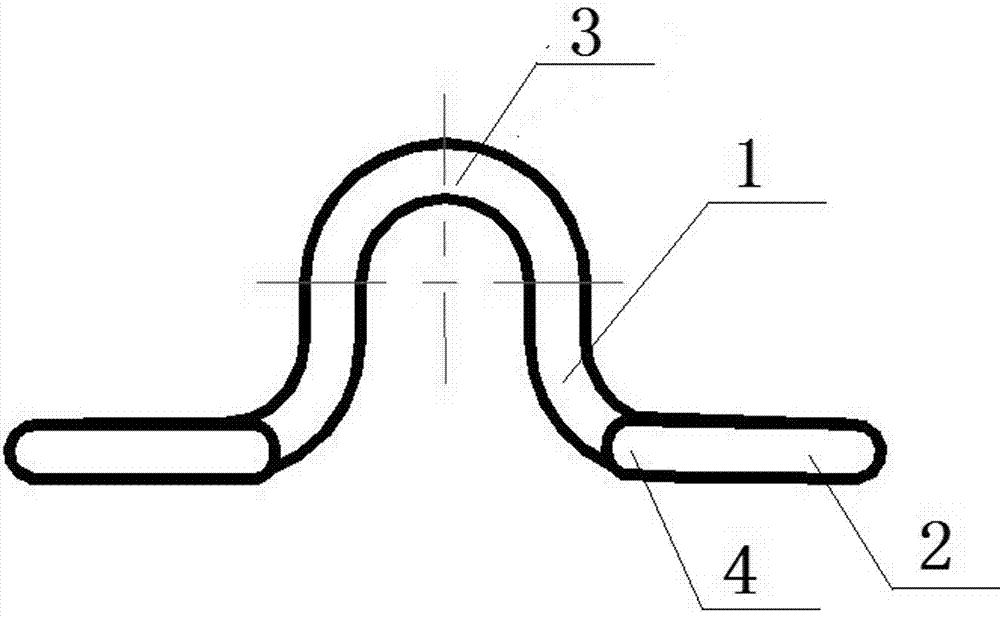

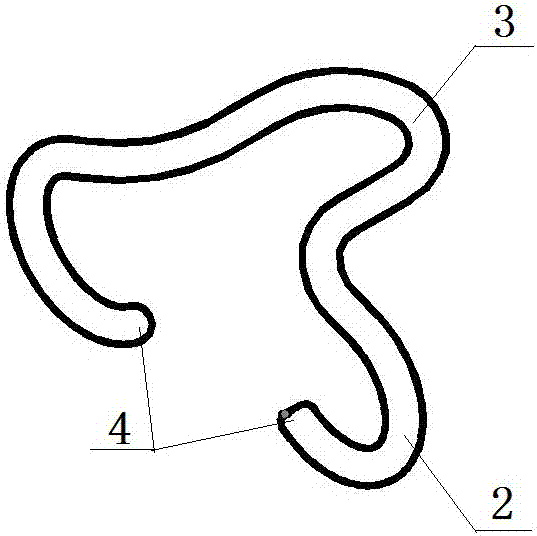

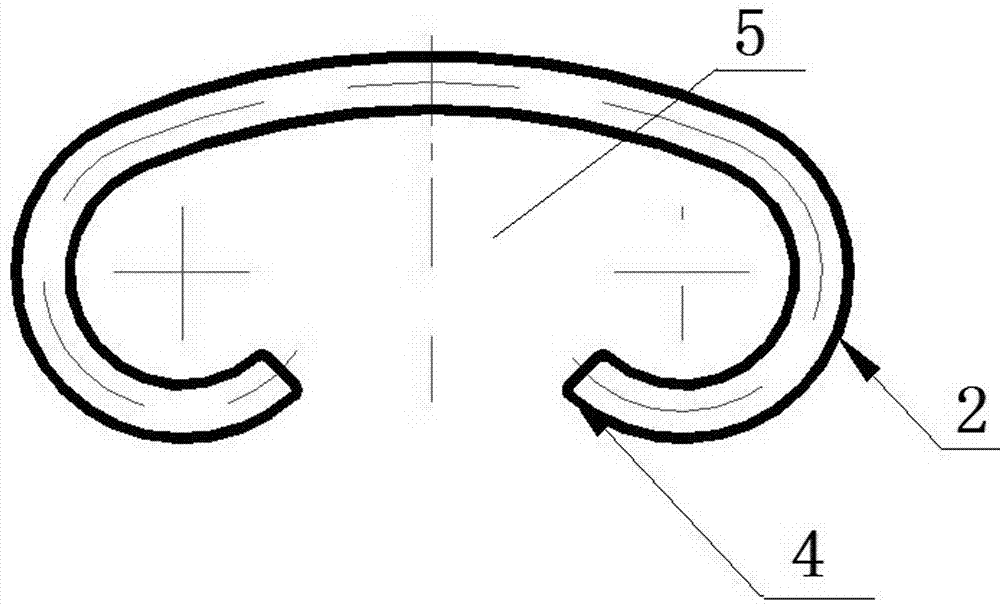

[0025] A sternum fixer with a pair of surrounding arms on a memory alloy wire single beam, including a single beam 1 made of a memory alloy wire, the two ends of the single beam 1 are relatively inwardly bent to form a surrounding arm 2, two The encircling arm 2 forms an open ring structure 5 on the longitudinal plane, and the middle section of the single beam is extruded and bent along the horizontal plane to form an arc-shaped pressure ring 3 on the horizontal plane. The plane where the pressure ring 3 in the middle section of the single beam is located is perpendicular to the plane where the open ring structure 5 is located. The ends of the surrounding arms 2 located at the opening in the open ring structure are bent inward. The end of the surrounding arm 2 located at the opening in the open ring structure has a rounded corner 4 .

[0026] A memory alloy wire single beam with a pair of sternal fixation arms surrounding the arms, its preparation process:

[0027] 1. Cut th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com