Waste oil sealing cover mechanism in integrated stove

A technology of integrated stove and oil seal cover, which is applied in the field of machinery, can solve the problems of affecting cooking mood, integrated stove dirty, waste pollution of oil storage box, etc., and achieve the effect of improving collection stability and avoiding waste oil overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

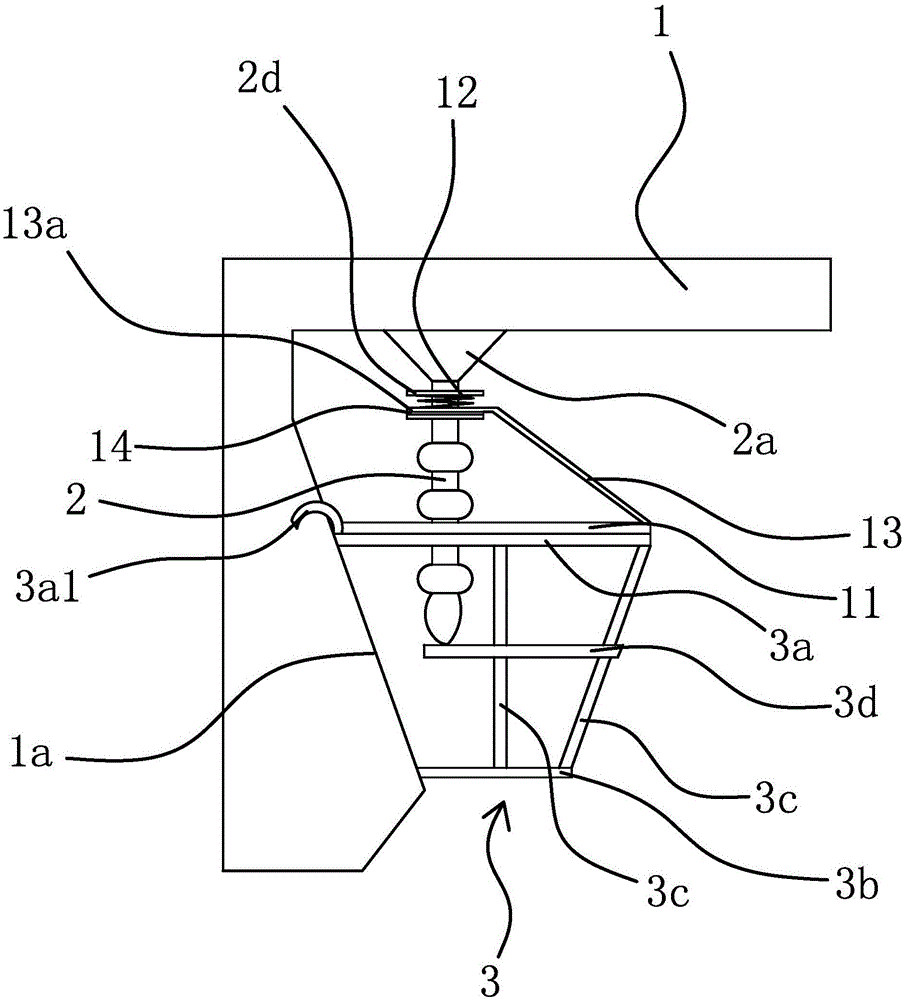

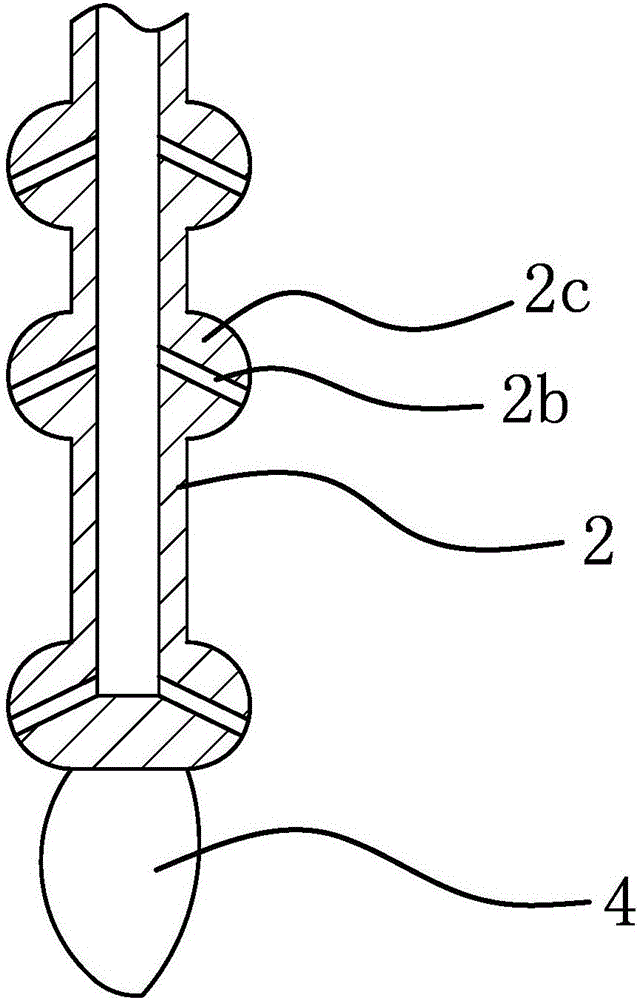

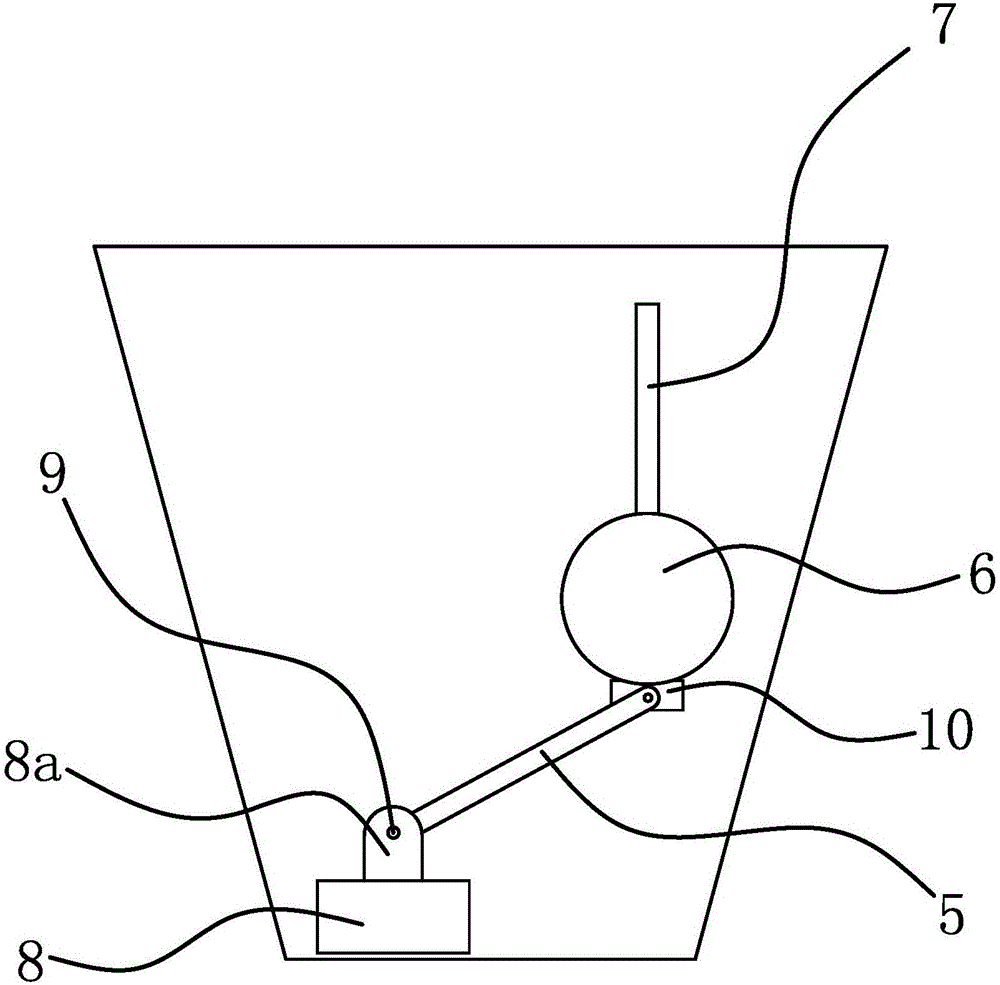

[0097] Such as figure 1 and figure 2 and image 3 and Figure 4 and Figure 5 and Figure 6 As shown, the waste oil collection mechanism in the integrated cooker, the integrated cooker includes a shell 1 with a cavity inside, the shell 1 has an oil discharge channel, and the shell 1 has an oil collecting pipe 2 outside and the oil collecting pipe 2 The inner end is connected with the oil discharge channel, and the housing 1 also has a bracket 3 located at the lower part of the oil collecting pipe 2, and the bracket 3 has a positioning part for positioning the disposable cup inside, and the bracket 3 It is connected with the casing 1 through a detachable connection structure, and the outer end of the oil collecting pipe 2 extends into the positioning portion.

[0098] The size of the oil collecting pipe 2 is smaller than that of the oil discharge channel, and the inner end of the oil collecting pipe 2 has a funnel-shaped introduction portion 2a.

[0099] The introduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com