Cylindrical coordinate type robot

A technology of cylindrical coordinates and robots, applied in the field of robots, can solve the problems of reducing production efficiency, wasting energy, and not being able to meet the continuous change of production varieties, so as to achieve the effect of improving production efficiency and avoiding continuous empty grasping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

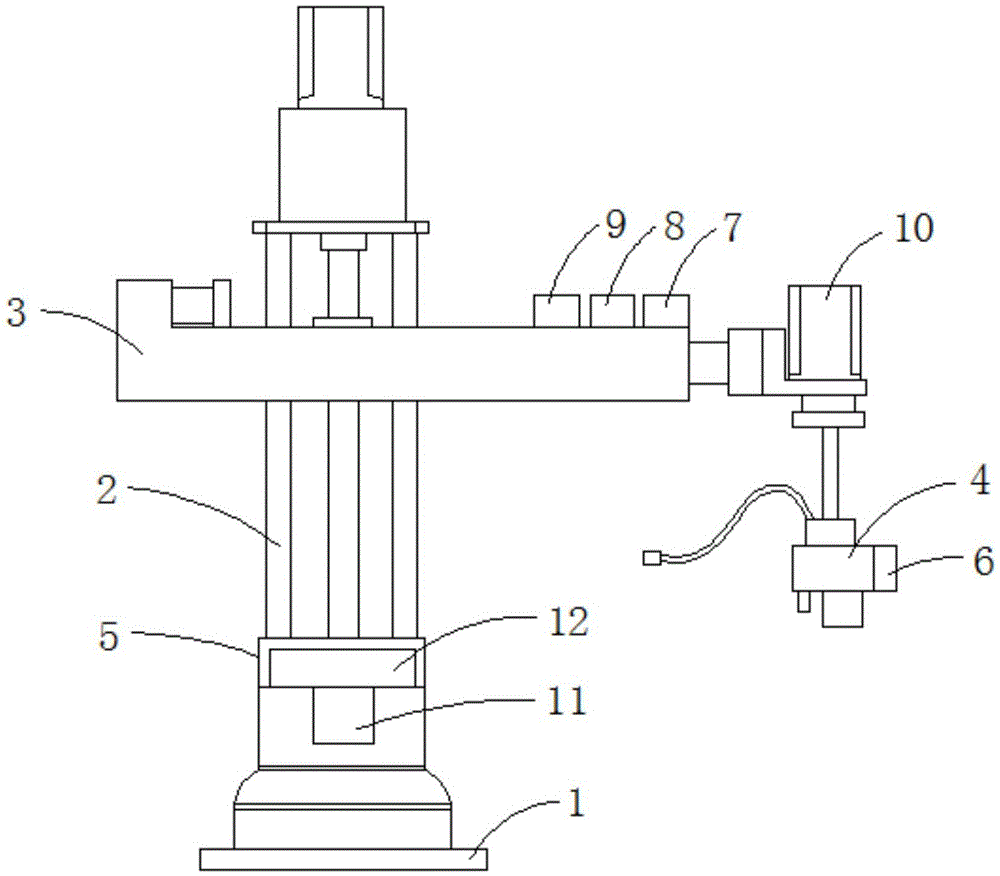

[0014] Such as figure 1 As shown, a cylindrical coordinate robot includes a base 1 and a guide mechanism 2 vertically arranged on it, and an arm telescopic mechanism 3 that can move horizontally and telescopically is connected to the guide mechanism 2 and can move up and down along it. The front end of the arm telescoping mechanism 3 is connected to the grasping mechanism 4, and the base 1 is provided with a base rotation mechanism 5 that drives the overall rotation; one side of the grasping mechanism 4 is fixedly provided with an infrared sensor 6, and the Infrared sensor 6 is connected with counter 7 by line, and described counter 7 is connected with controller 8 by line, and described controller 8 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com