Machine clip body automatic adjustment device

An automatic adjustment and clamping technology, applied in packaging and other directions, can solve the problems of narrow application scope, complex structure, and many restricted factors, and achieve the effect of simple structure and flexible application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

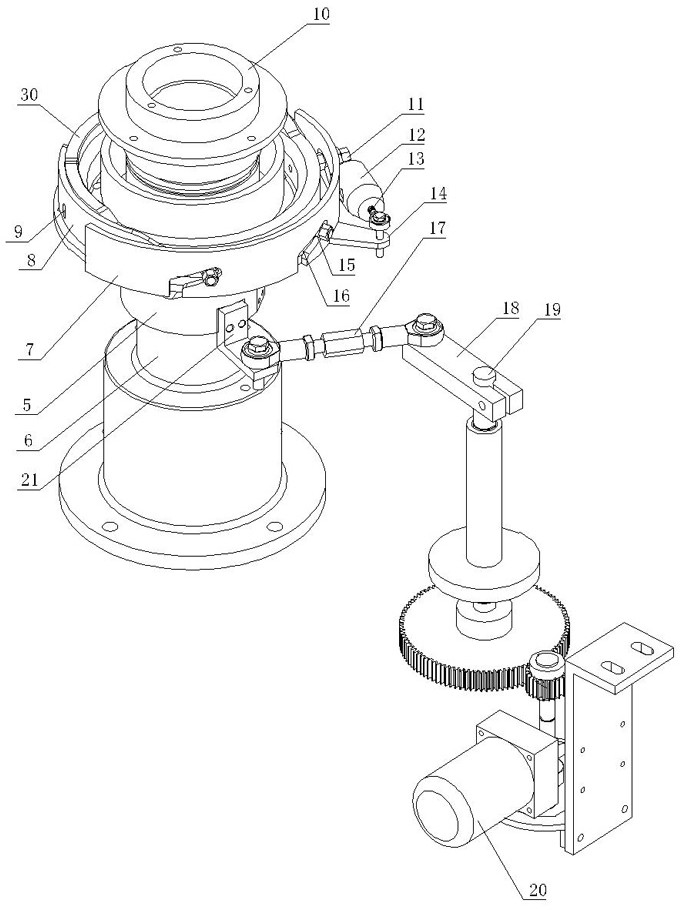

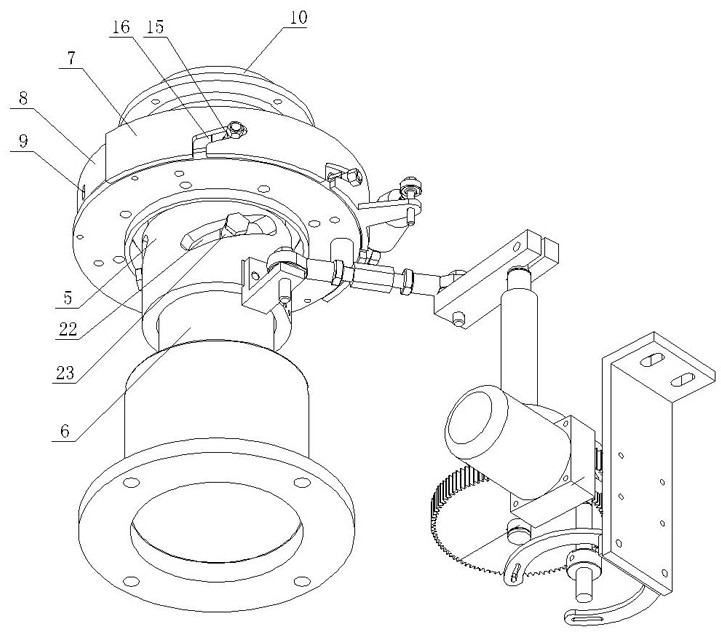

[0013] As shown in the figure, the automatic adjusting device of the clip body of the present invention includes a vertical column 6 fixed on the upper surface of the main table. The outer circular movable sleeve of the vertical column 6 is provided with a spiral lifting seat 5 and is fixedly provided with a guide wheel 23. The spiral lifting seat The circumference of 5 is provided with a plurality of first helical grooves 22, the guide wheel 23 is rolled in the first helical groove 22, the screw lifting seat 5 is connected with the clamping limit seat 30, and the clamping limit seat 30 is rotated and arranged in the screw lifting and lowering. The outer circle of the seat 5, the screw lift seat 5 drives the clamp-opening limit seat 30 to perform a synchronous up-and-down movement when the screw lift seat 5 moves up and down, and the clamp-opening limit seat 30 does not rotate during the lifting action. The upper end surface is the working surface for adjusting the clamping bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com