Dynamic transmission error prediction method based on gear integrated error

A technology of transmission error and overall error, which is applied in machine gear/transmission mechanism testing, mechanical component testing, machine/structural component testing, etc. It can solve problems such as measurement environment interference and complex structure of dynamic transmission error measurement equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

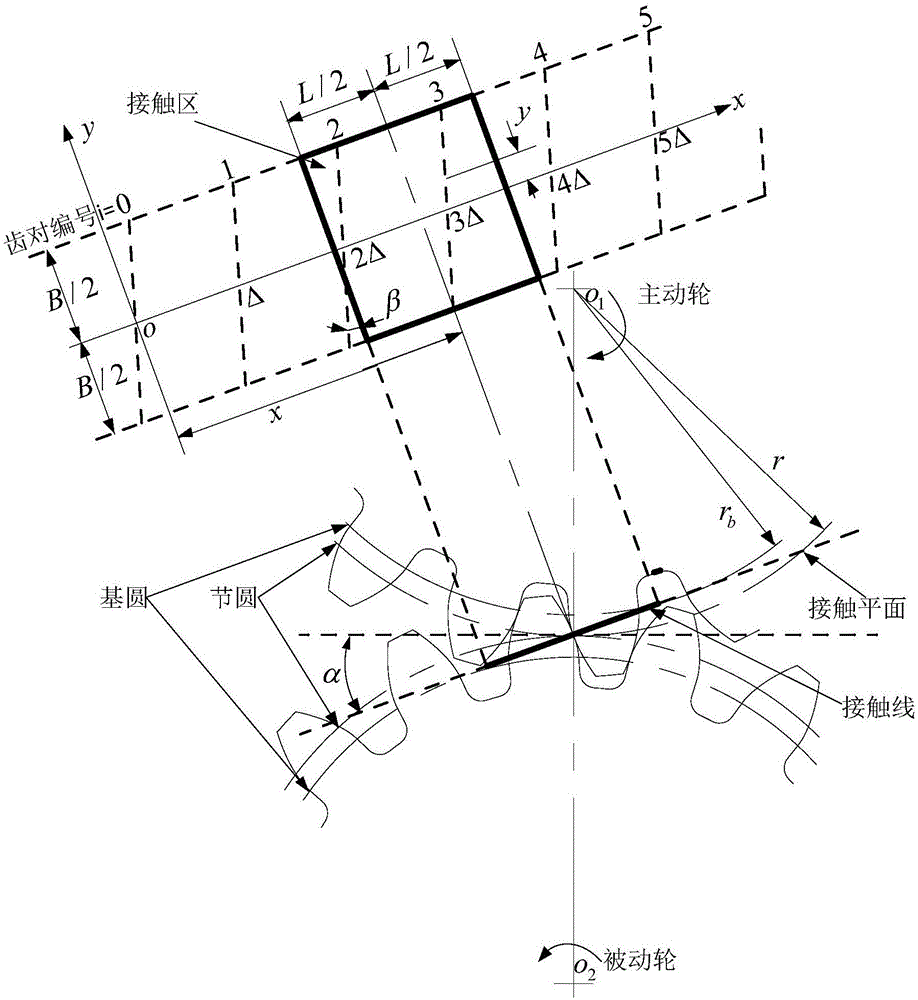

[0044] 1) Construct a coordinate system; construct such as figure 1 In the gear contact coordinate system shown, B represents the tooth width, B / 2 represents the half tooth width; L represents the length of the actual contact line of a pair of teeth, L / 2 represents the general length of the connection, and also represents the width of the contact area; Δ represents The normal tooth pitch of the gear along the meshing direction; β indicates the helix angle; α indicates the pressure angle; o 1 ,o 2 represent the centers of gear 1 and gear 2 respectively; r b Indicates the radius of the base circle; r indicates the radius of the pitch circle; i indicates the serial number of the contact gear pair, i (i=1,2,...,n, is a positive integer); the value of the coordinate x indicates the position of the centerline of the contact area relative to i (i=1,2,...,n, positive integer) is the position of the middle plane of the contact line of the tooth, which is one of the base circles with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com