A Pseudorandom Island Scanning Path Planning Method Based on Quadrant Region Guidance

A scanning path, pseudo-random technology, applied in the field of additive manufacturing, can solve the problem of inability to effectively manage and control input heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

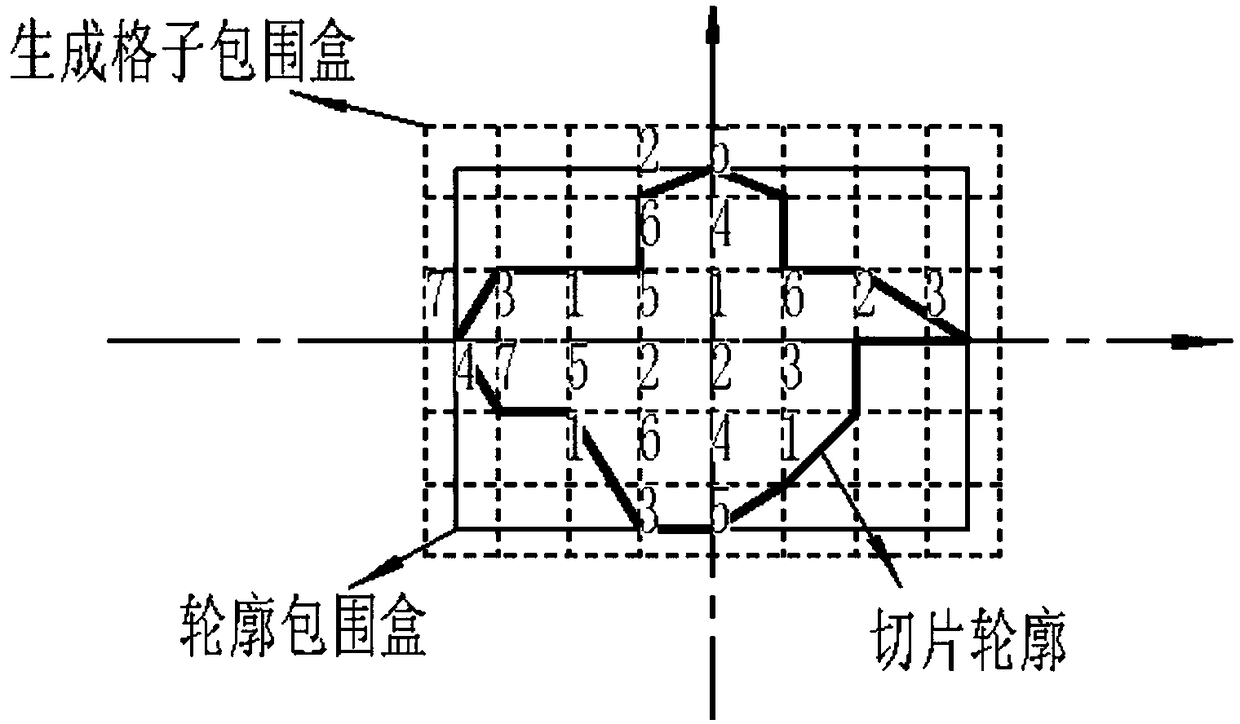

[0027] combine figure 1 , a pseudo-random island scanning path planning method based on quadrant area guidance, including the following steps:

[0028] Step 1, establish a Cartesian coordinate system and place the slice in the Cartesian coordinate system to obtain the slice contour coordinate information and obtain the slice contour bounding box, where the boundary of the bounding box is defined by the maximum and minimum values of the slice contour in the Cartesian coordinate system on the x and y axes Composed of straight lines parallel to the x and y axes;

[0029] Step 2, arrange square grids to cover the bounding box, and the set of square grids is denoted as {S ij} p×q , where p and q are the number of rows and columns of the square grid respectively, i∈p, j∈q;

[0030] Step 3, the collection {S ij} p×q The grids in the slice contour are performed with the Boolean intersection operation one by one to obtain the discrete slice set {C1 ij} p×q ;

[0031] Step 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com