Modulated dispersion dyeing microscopic object lens

A technology for dispersive dyeing and microscope objective lenses, applied in the field of modulated dispersive dyeing microscope objective lenses, can solve the problems of indeterminacy, blocking light beams, inability to transmit, and difficulty in distinguishing substances with similar characteristics, and achieves clear sample display, enhanced variation range, enhanced The effect of transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

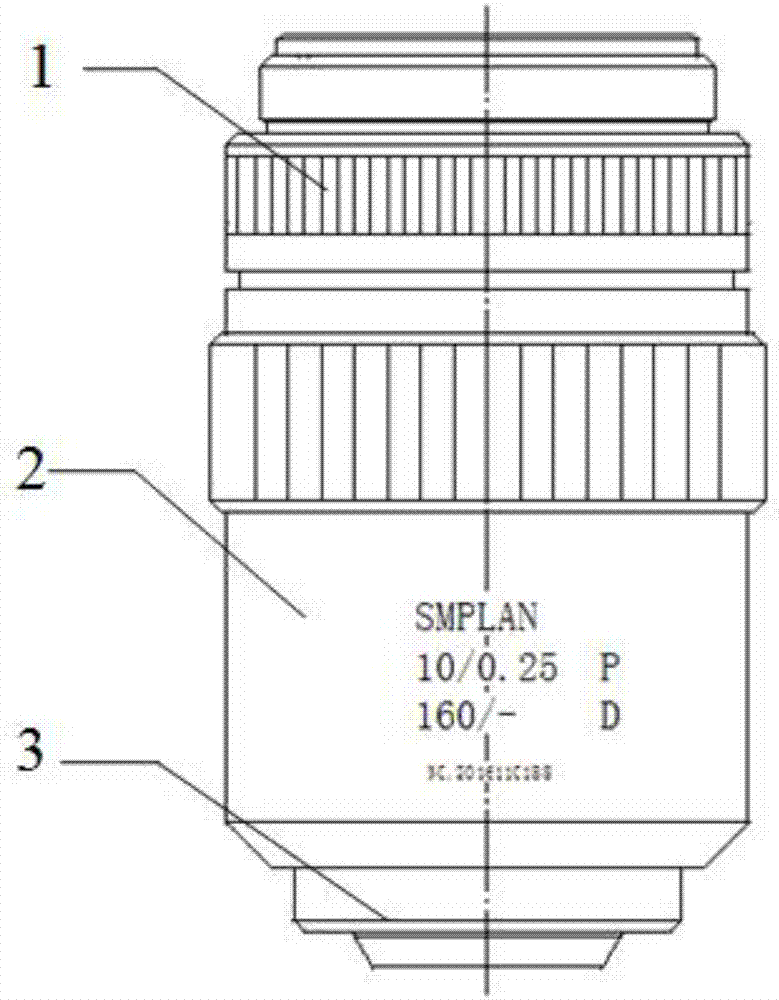

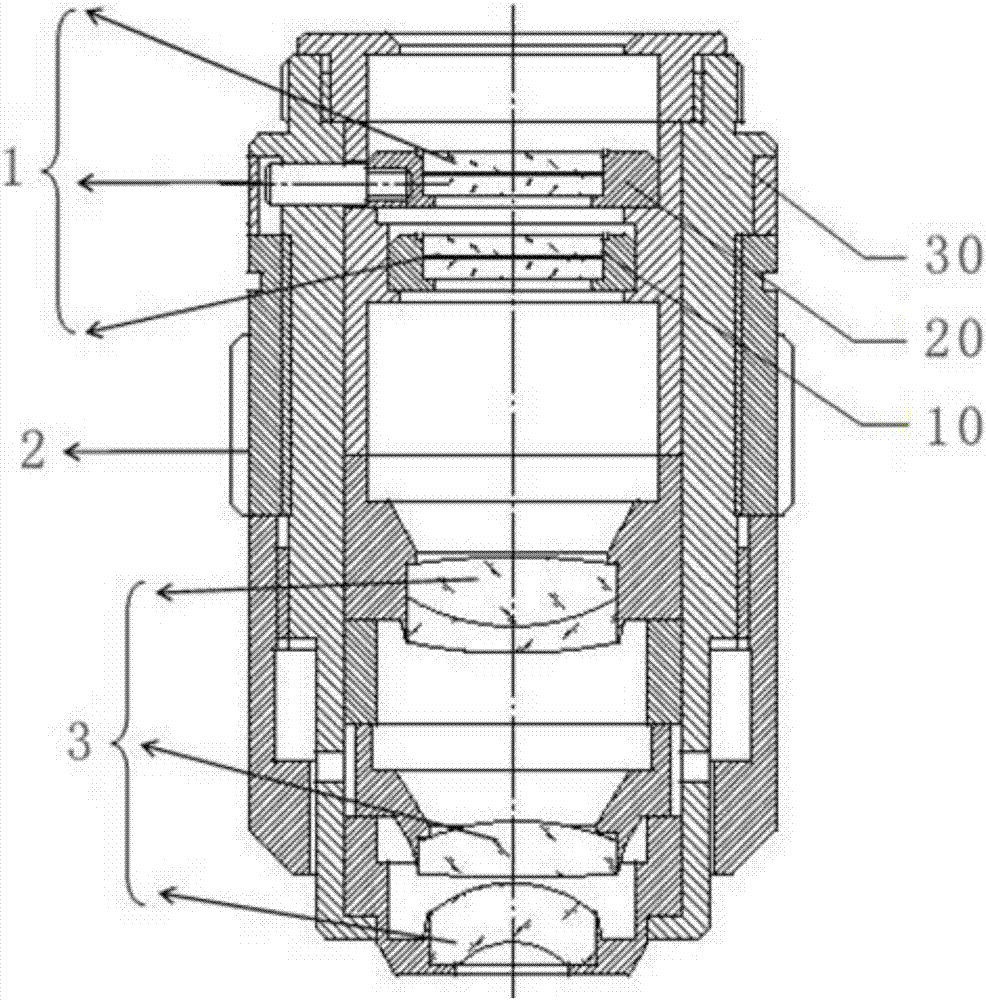

[0030] Embodiment: a kind of adjustable dispersion dyeing microscope objective lens.

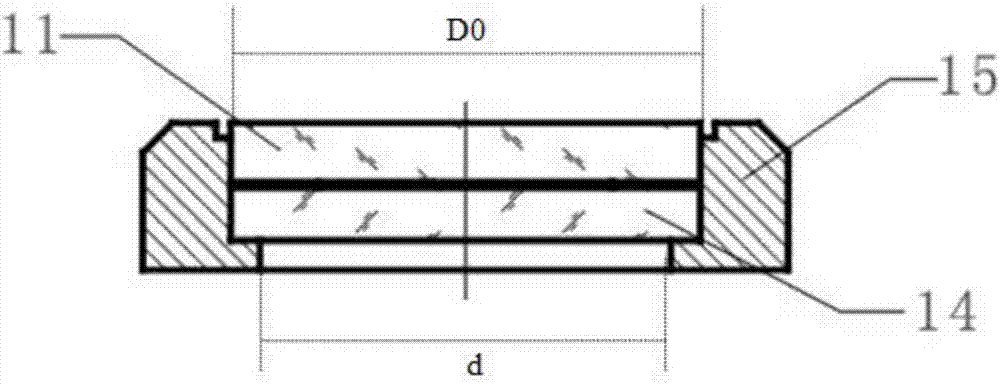

[0031] refer to figure 1 and figure 2 As shown, a kind of adjustable dispersion dyeing microscopic objective lens, metal mirror housing 2, the dispersion dyeing modulator group 1 installed on the inner top of the mirror housing 2, the optical lens group 3 installed on the inner bottom of the mirror housing 2, the dispersion dyeing The modulator group 1 includes a dispersion dyeing polarizer 10, a dispersion dyeing analyzer 20 and an adjuster 30, and the dispersion dyeing analyzer 20 and the dispersion dyeing polarizer 10 are installed side by side in the adjuster 30 up and down, and the dispersion The dyed polarizer 20 is installed directly above the dispersion dyed polarizer 10 . The adjustable dispersion dyeing microscopic objective adopts a 10X microscopic objective lens, and its main technical parameters are: numerical aperture 0.25, and the distance between the rear focal plane of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com