A method and system for controlling pins of an FPC connector

A technology of connectors and pins, which is applied in the field of FPC smart pins, can solve the problems of low precision and slow pin insertion speed, and achieve the effect of ensuring accuracy, ensuring smooth progress, and avoiding command recognition errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

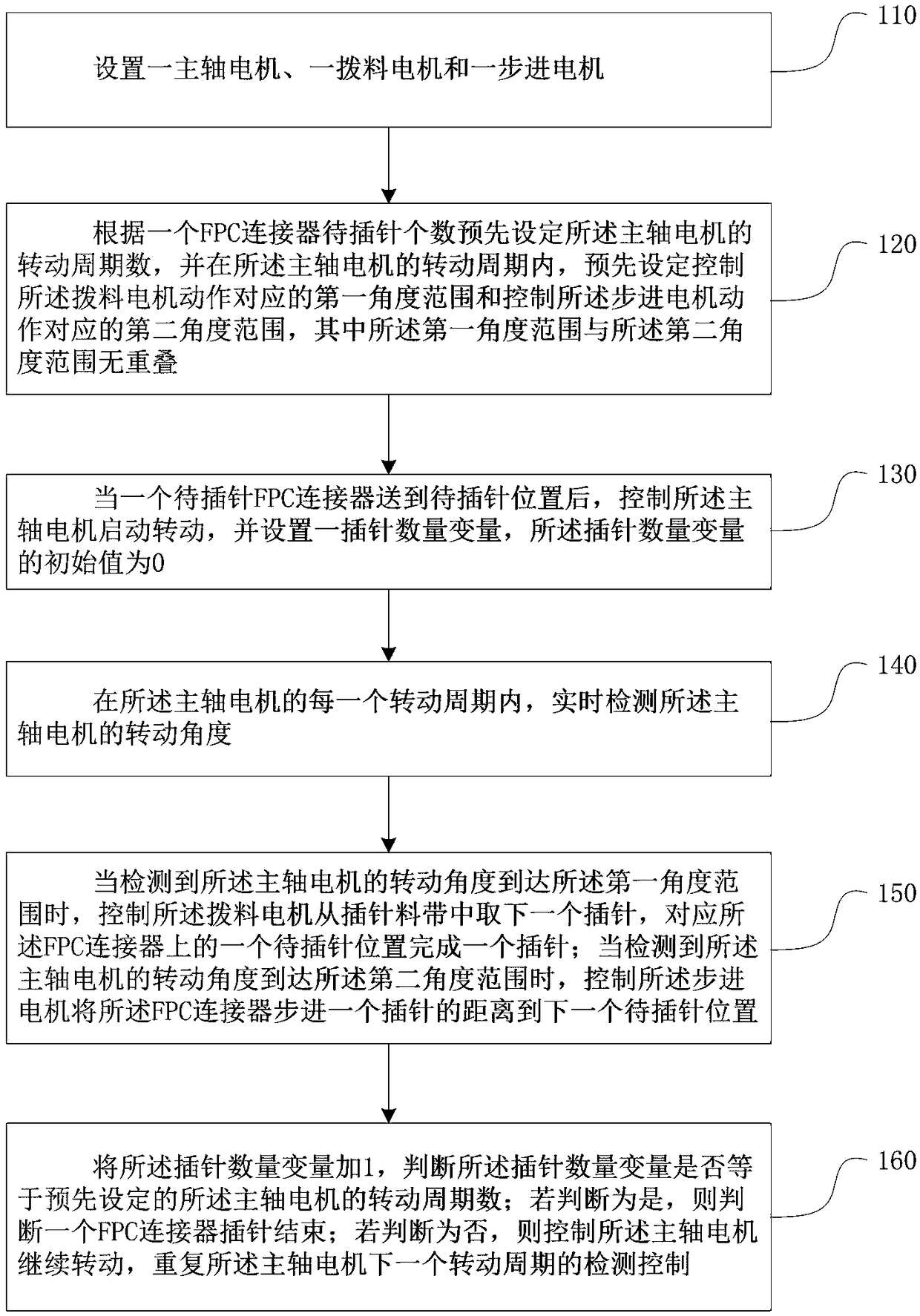

[0036] figure 1 It is a flowchart of a method for controlling FPC connector pins according to an embodiment of the present invention; as figure 1 As shown, the method includes:

[0037] In step S110, a spindle motor, a feed motor and a stepping motor are set.

[0038] In step S120, the number of rotation cycles of the spindle motor is preset according to the number of pins to be inserted in an FPC connector, and within the rotation cycle of the spindle motor, the number of rotations corresponding to the control of the action of the feeding motor is preset. An angle range and a second angle range corresponding to controlling the action of the stepping motor, wherein the first angle range does not overlap with the second angle range.

[0039]In practical applications, the number of rotations of the spindle motor can be arbitrarily positioned according to the diversified needs of the FPC connector industry market, and any number of FPC connectors can be inserted, which greatly ...

Embodiment 2

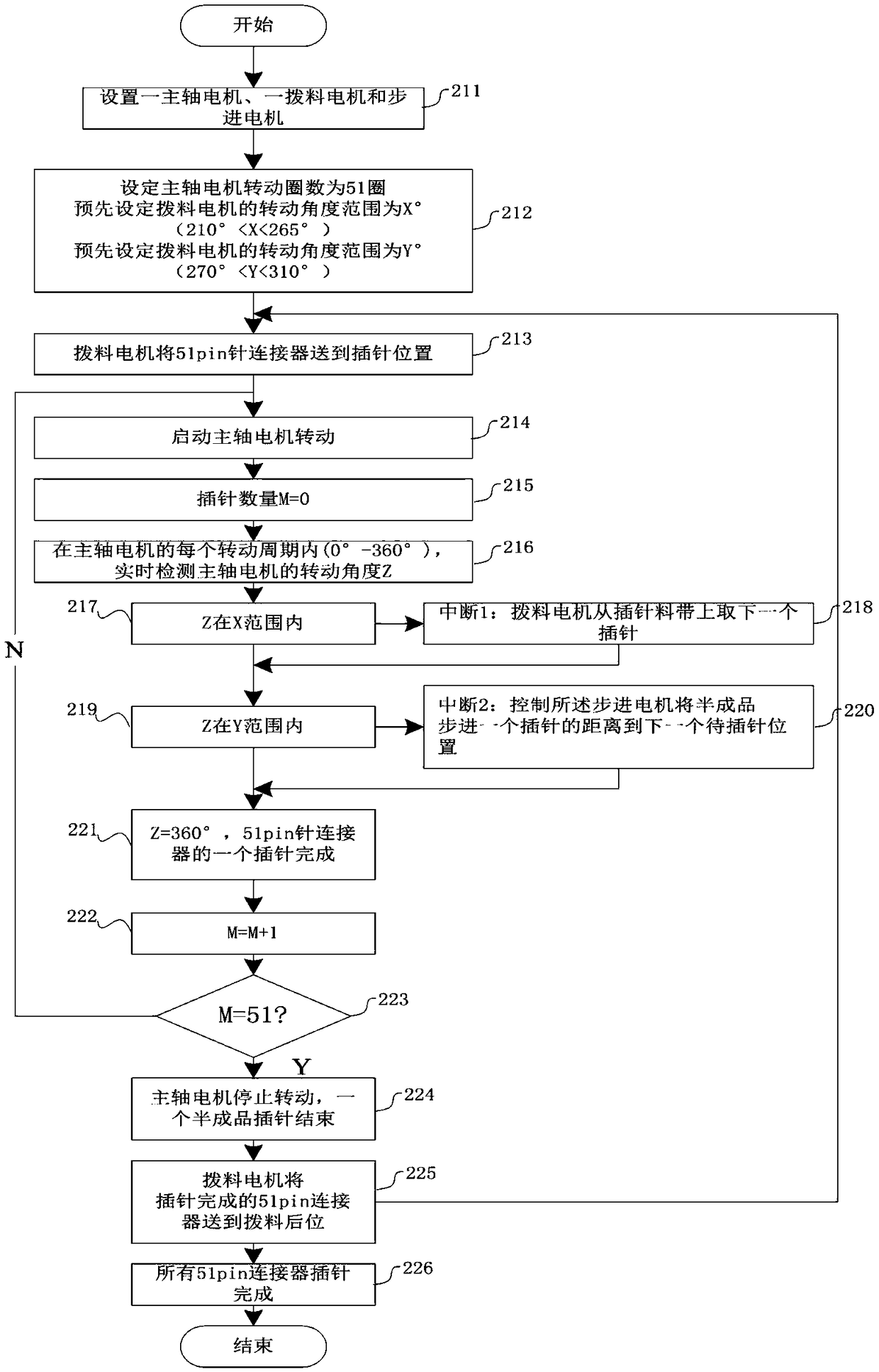

[0059] In order to make the solution of the present invention more clear, a specific example will be used for description below. figure 2 It is a flowchart of a pin insertion method of a 51-pin FPC connector according to an embodiment of the present invention, such as figure 2 As shown, the specific method of controlling the pins of the 51-pin FPC connector is as follows:

[0060] S211, setting a spindle motor, a feeding motor and a stepping motor.

[0061] In this embodiment, in order to realize the intelligent pin insertion of the FPC connector, firstly, a spindle motor, a feeder motor and a stepping motor must be set. It should be noted that the gains of these three motors have been adjusted to the best state. In order to reduce the scratches on the 51-pin connector when inserting the pins, it also ensures the best motion performance and life of the three motors.

[0062] S212, the number of rotations of the spindle motor is set to 51, the rotation range of the pre-set ...

Embodiment 3

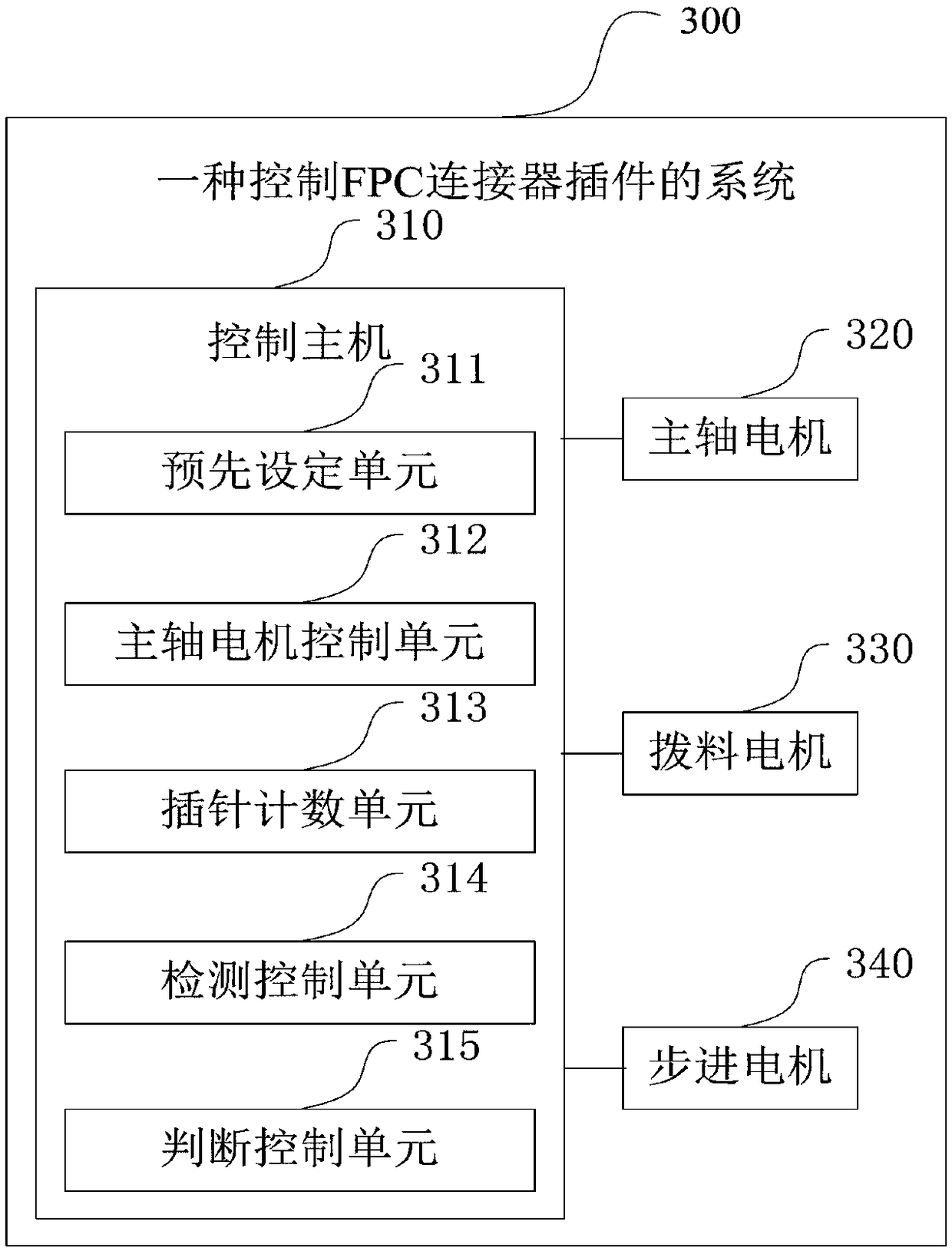

[0080] image 3 It is a schematic diagram of a system for controlling FPC connector pins according to an embodiment of the present invention; as image 3 As shown, the system includes: a control host 310, a spindle motor 320, a material pulling motor 330 and a stepping motor 340; wherein,

[0081] The main shaft motor 320 is used for rotation, and according to the angle range of rotation, the action timing between the described material-setting motor and the stepping motor is controlled, which is convenient for realizing the main shaft motor 320, the material-setting motor 330 and the stepping motor 340 The synergistic effect, thus ensuring the precise and fast insertion of the FPC connector.

[0082] The material pulling motor 330 is used to remove a pin from the pin strip, and complete a pin corresponding to a position to be inserted on the FPC connector, so as to further ensure accurate and fast pin insertion of the FPC connector.

[0083] The stepper motor 340 is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com