Trapezoidal part fixing device

A fixing device and trapezoidal technology, which is applied in the field of trapezoidal parts fixing devices, can solve the problems of relatively high requirements on the hole spacing of the support bars, labor hours, and failure to install bolt holes correctly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

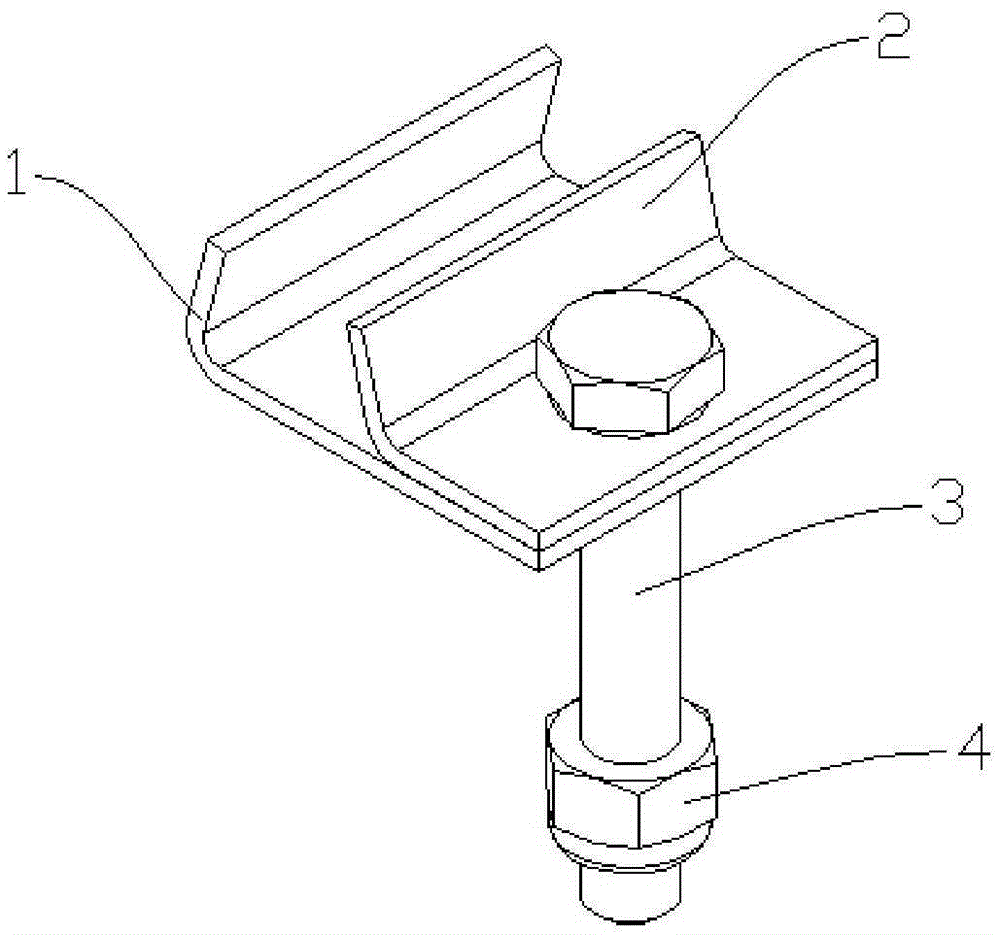

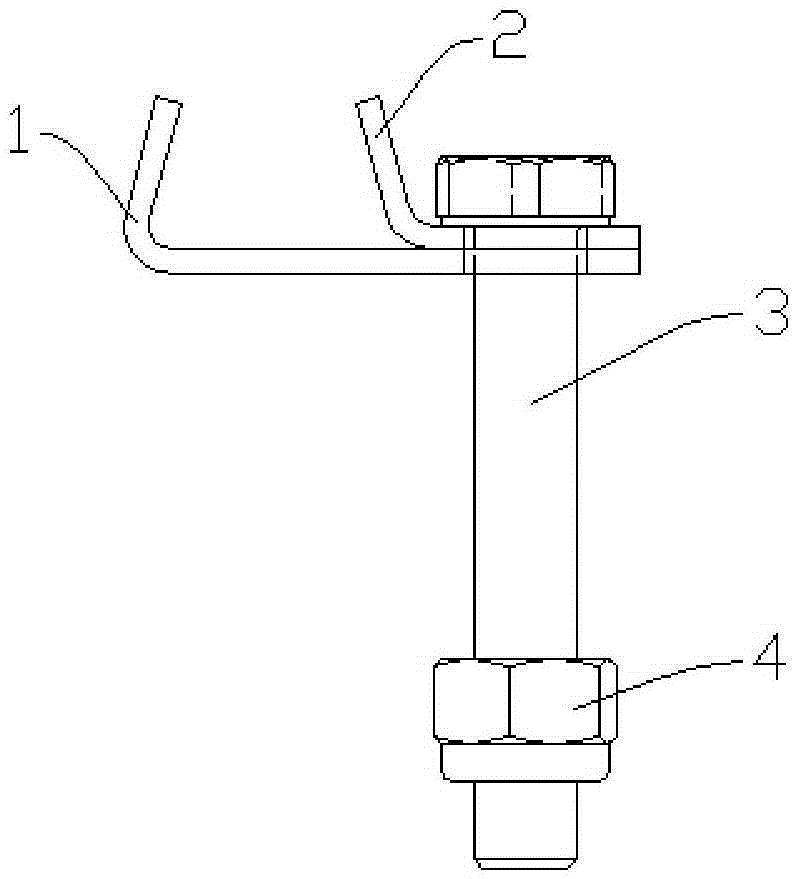

[0012] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0013] A fixing device for a trapezoidal piece, comprising a long clip gasket 1, a short clip gasket 2, a bolt 3 and a nut 4, the long clip gasket 1 and the short clip gasket 2 are stacked together, and the bolt 3 passes through The long-clamp washer 1 and the short-clamp washer 2 are stacked together, the head of the bolt 3 is provided with a nut 4 , and a frame is provided between the long-clamp washer 1 and the nut 4 .

[0014] The above descriptions are only preferred embodiments of the present invention, and are not intended to limit the present invention. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall be included in the scope of the present invention. within the scope of protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com