Washed-glass air-drying frame used in experiment

A glass cleaning and drying rack technology, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as scratches, inconvenient operation, limited desktop, etc., to improve efficiency, facilitate operation, reduce Effect of drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

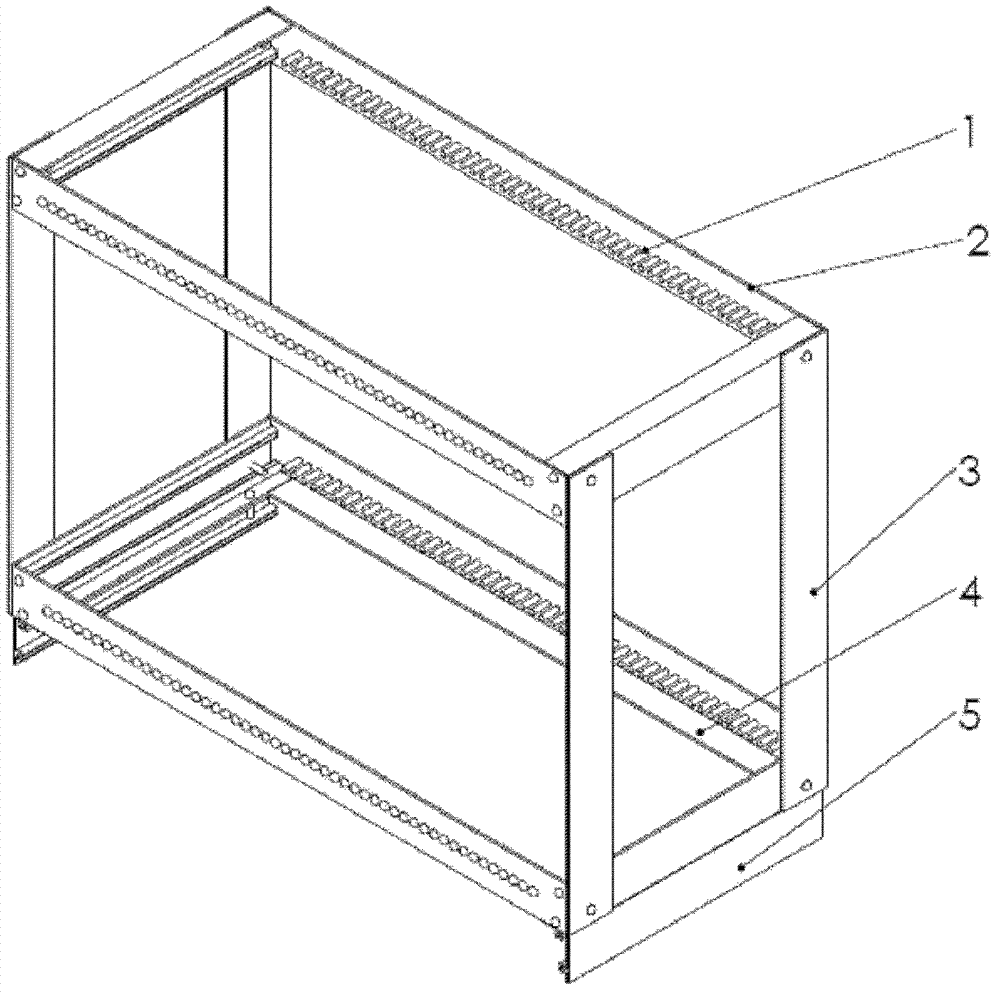

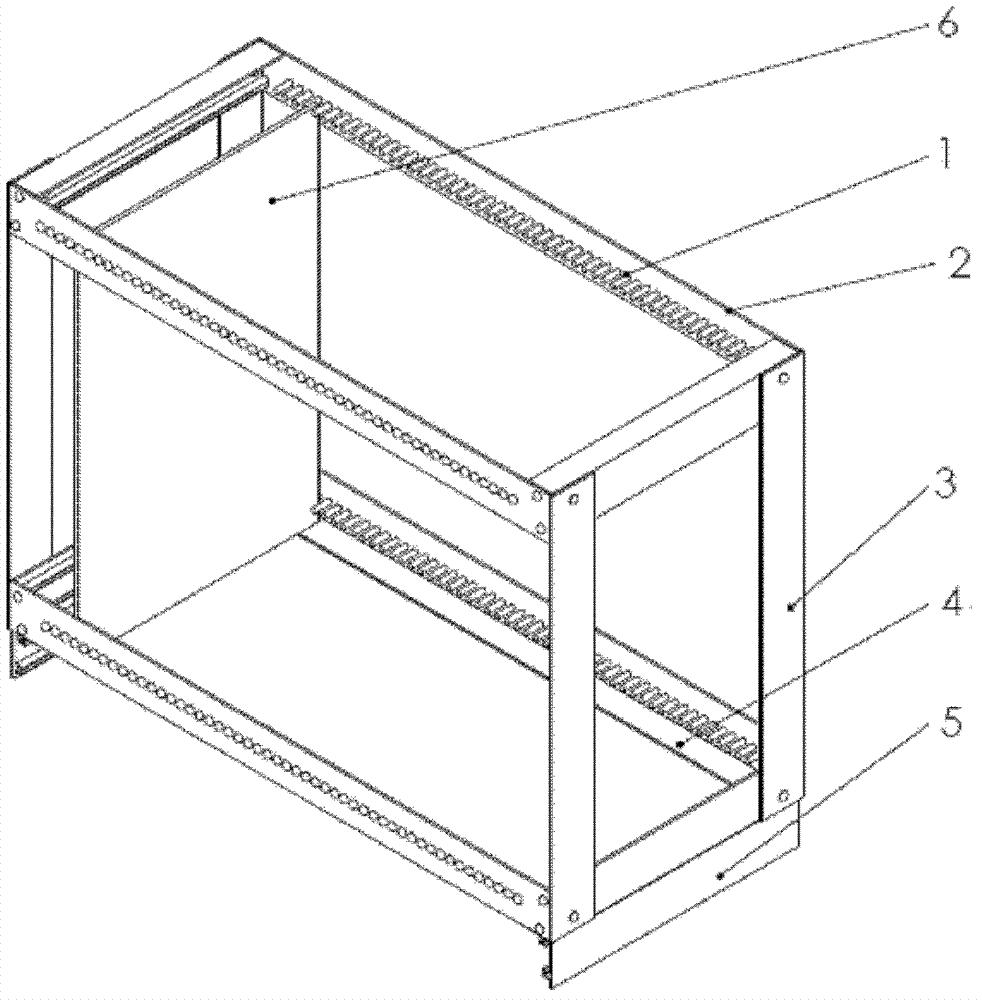

[0014] Such as Figure 1-2 Shown, a kind of glass cleaning drying rack for experiment, this drying rack is cuboid structure, comprises positioning post 1, baffle plate 2, support plate 3, support plate 4 and bearing 5, support plate 4 and support plate 3 are set On the support 5 , the baffle 2 is set on the support plate 3 , the positioning column 1 is set on the baffle 2 , and the glass 6 for experiment is placed vertically on the positioning column 1 .

[0015] Baffle plate 2 is that 4 baffle plates are fixed on the support plate to form a cuboid support structure, and each baffle plate is provided with 25 positioning columns 1, and the positioning columns on the 4 baffle plates are all set correspondingly. The spacing is 5mm.

[0016] When the above-mentioned experimental glass cleaning and drying rack is working, the experimental glass 6 is placed upright during the placement process, and each piece of glass is stuck by the positioning column 1 inside the drying rack, wit...

Embodiment 2

[0018] refer to Figure 1-2 As shown, a glass cleaning drying rack for experiments, the drying rack is a cuboid structure, including a positioning column 1, a baffle plate 2, a support plate 3, a supporting plate 4 and a support 5, and the baffle plate 2 is 4 baffle plates It is fixed on the support plate to form a cuboid support structure, and 30 positioning columns 1 are arranged on each baffle plate. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com