Combined grain harvester for threshing before cutting

A technology of grain harvester and thresher, which is applied in the direction of harvester, threshing equipment, cutter, etc., can solve the problems of complex structure, high power consumption and high loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

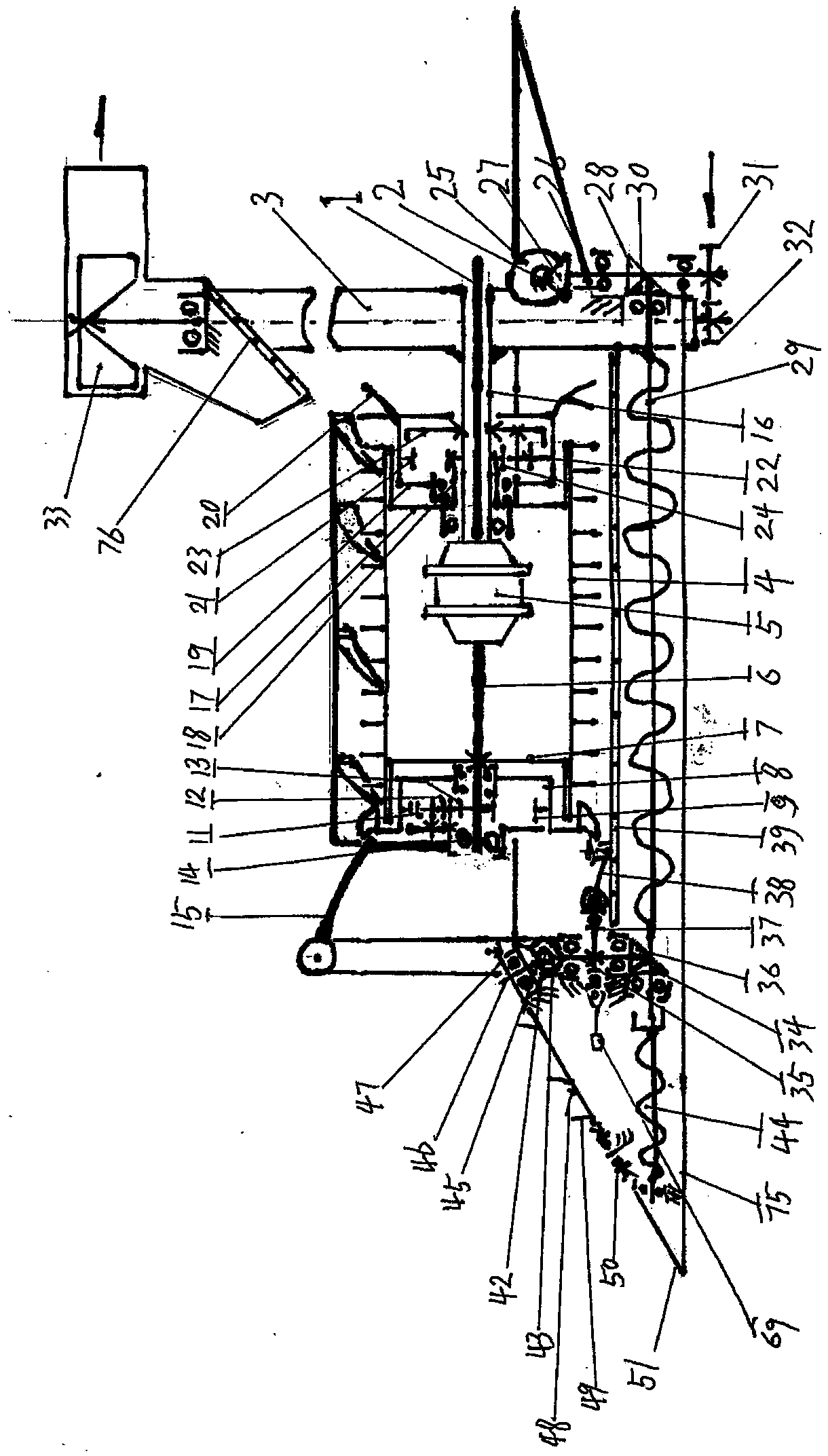

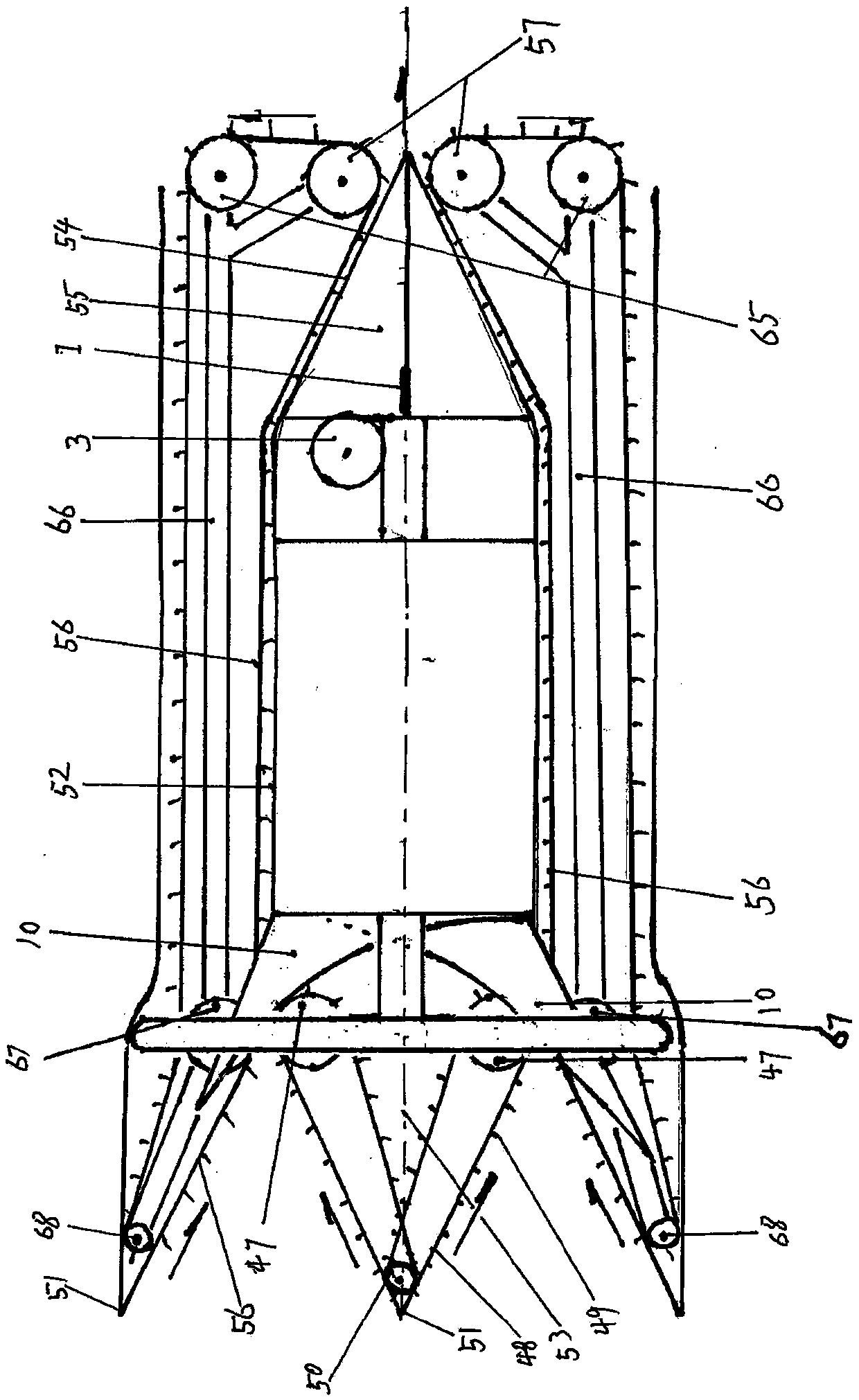

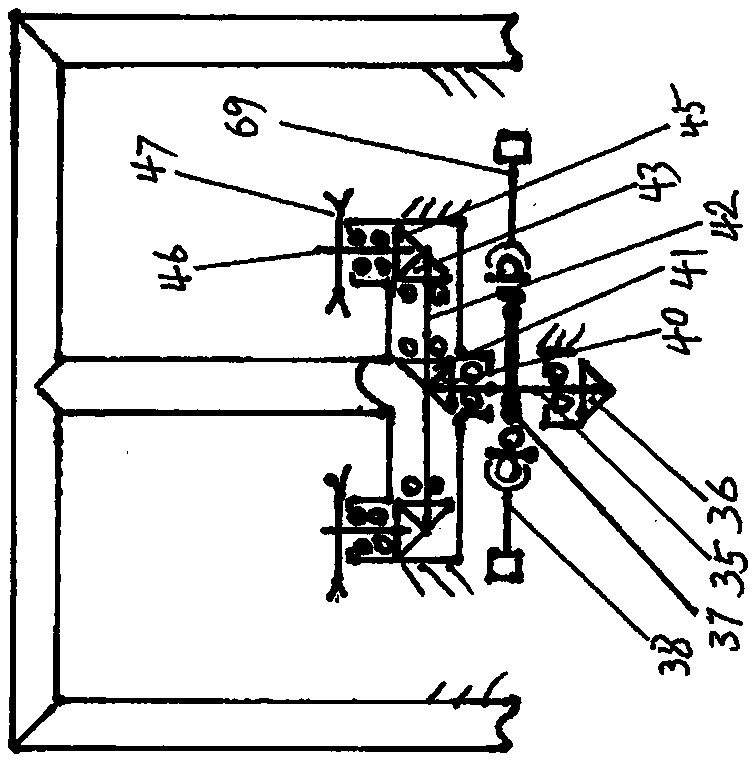

[0024] Structural framework of the present invention, in order to explain more thoroughly, expresses from the order of power transmission: , threshing structure: figure 1 The rear end of the grain harvester shown is connected by a power machine (not shown in the figure) (special for threshing) constant-speed transmission force input shaft 1, which is inserted into the rear end of the threshing machine drum 4 from the side of the vertical grain conveying pipe 3 In the center, it becomes the power input shaft of the cycloidal pinwheel reducer 5, the power input shaft and the power output shaft 6 of the cycloidal pinwheel reducer form an axis line under the control of the housing, and the power output shaft 6 is fastened The threshing drum front end cover 7 of the threshing drum 4, the power output shaft 6 is covered with the slanted tooth plate 8 for feeding the grain, and the gear ring 9 is fastened inside before the grain is fed into the slanted tooth plate 8, and the gear ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com