Fiber decomposition device

A fiber decomposition and transmission technology, which is applied in the field of mechanical equipment, can solve the problems of brown rope broken and brown rope fiber not meeting production needs, and achieve the effect of improving untwisting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is illustrative, not restrictive, and the protection scope of the present invention cannot be limited thereby.

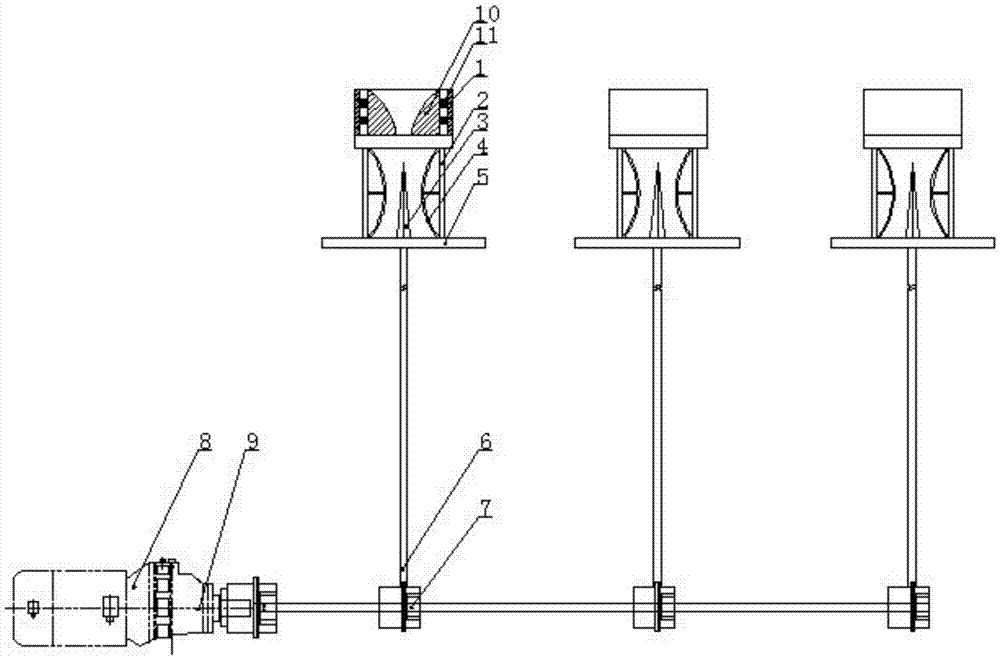

[0012] A fiber disintegration device, which is composed of multiple untwisting devices and transmission devices. The untwisting device is composed of a transmission baffle 5, a feeding positioning sleeve 1 and a detwisting bin 2. One side of the transmission baffle is coaxial The untwisting bin and the feeding positioning sleeve are fixedly installed, and the other side of the transmission baffle is connected with the transmission device through the transmission shaft 6. The inner wall of the feeding positioning sleeve is connected with a plurality of positioning pressing blocks through the compression spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com