Conicity measuring instrument and application method thereof

A measuring instrument and taper technology, which is applied in the field of taper measuring instruments, can solve the problems of restricting the application and development of instruments and meters, unstable reliability of electronic equipment, and high maintenance costs, and achieve low maintenance costs, simple and easy-to-understand operating principles, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

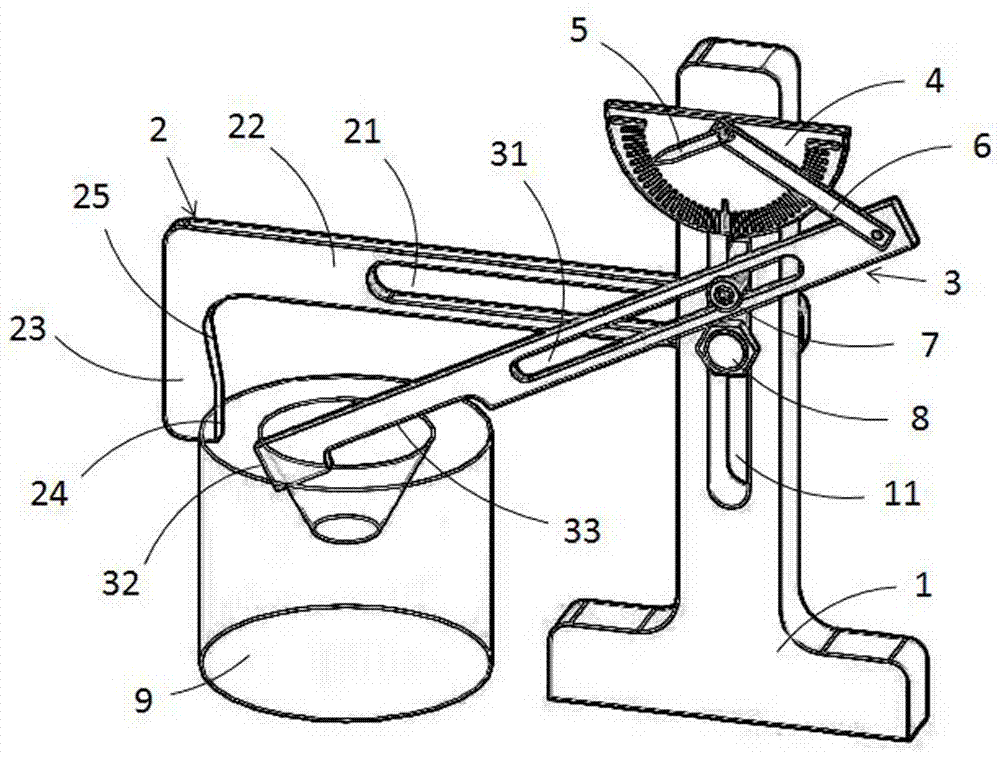

[0017] A kind of taper measuring instrument of the present invention, as figure 1 As shown, it includes a base frame 1, a fixed rod 2 arranged on the base frame 1, a measuring rod 3 and a dial 4, wherein the dial 4 is provided with a pointer 5, and the pointer 5 is rigid with the measuring rod 3 through a linkage rod 6. connected, and the pointer 5 is rotationally connected with the dial 4; the measuring rod 3 is hinged with the base frame 1; the middle part of the measuring rod 3 is provided with a first long hole 31, and the middle part of the base frame 1 is provided with a second long hole 11 , the measuring rod 3 and the base frame 1 are hinged through the first connecting piece 7, and the first connecting piece 7 passes through the first elongated hole 31 and the second elongated hole 11 in turn; one end of the fixed rod 2 is provided with a third elongated hole 21. The fixed rod 2 and the base frame 1 are fixedly connected through the second connecting piece 8 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com