An Internet of Things intelligent dust removal equipment management and control system

A technology for dust removal equipment and management and control systems, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as the inability to solve the problem of the exact time when dust removal equipment is turned on, shorten the service life of dust removal equipment, and damage to physical health. Easy to build, implement and use, prevent explosion accidents, and ensure normal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

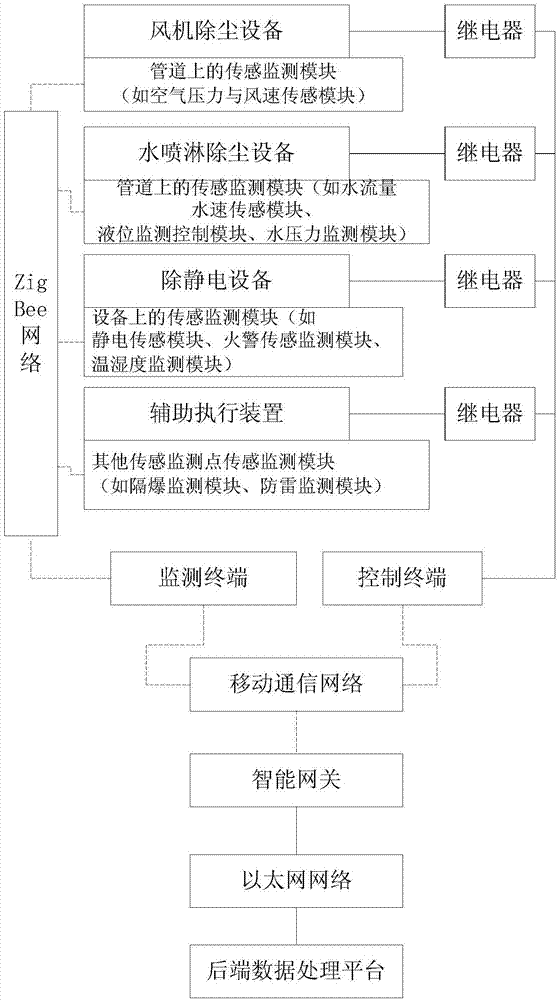

[0020] Embodiment 1: as figure 1 As shown, an intelligent dust removal equipment management and control system for the Internet of Things, especially dust removal equipment systems involving inflammable and explosive dust and safety explosion protection, spark detection, automatic fire extinguishing, automatic alarm, automatic opening and closing, and automatic inert injection in the production process The intelligent management and control system for gas, automatic explosion-proof and explosion-venting, etc., mainly includes the start-up and shutdown time sequence control device of dust removal equipment and the real-time on-line monitoring sensor device of the site environment, which specifically includes the dust removal equipment system and data sensor monitoring system , an intelligent automatic control system, a gateway communication system and a back-end data processing platform, the dust removal equipment system includes several dust removal nodes, dust removal equipmen...

Embodiment 2

[0021] Embodiment 2: as figure 1 As shown, as an improvement of the present invention, the monitoring terminal includes a power supply module, a monitoring main control board, a ZigBee transceiver module and a mobile communication module, the power supply module provides power for the monitoring terminal, and the ZigBee transceiver module passes through the SPI interface It is connected with the monitoring main control board, the mobile communication module is connected with the monitoring main control board through the URAT interface, and the ZigBee wireless module of the sensing monitoring module is connected with the ZigBee transceiver module through the ZigBee network for wireless communication. The monitoring main control board receives the sensing data and the heartbeat information of the sensor from the sensor monitoring module through the ZigBee transceiver module, and analyzes and judges the sensing data, packs the heartbeat information of the sensor, and finally passe...

Embodiment 3

[0022] Embodiment 3: as figure 1 As shown, as an improvement of the present invention, the back-end data processing platform includes a remote management and control platform based on WEB, an intelligent mobile terminal and a terminal server, the remote management and control platform adopts a PC computer or a computer workstation, and the intelligent mobile terminal Adopt mobile phone and / or palmtop computer, described terminal server comprises HBase distributed database server and WEB server, described HBase distributed database server connects WEB server, described remote control platform and intelligent mobile terminal all connect WEB server, described The HBase distributed database server is connected to the intelligent gateway through the firewall. The remote management and control platform and the smart mobile terminal are provided with a front page including the authority of the government supervision department, the authority of the user unit and the authority of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com