Adjustable type slide way cover plate

An adjustable and slideway technology, applied in sorting and other directions, can solve problems such as machine failure, blockage, and different sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

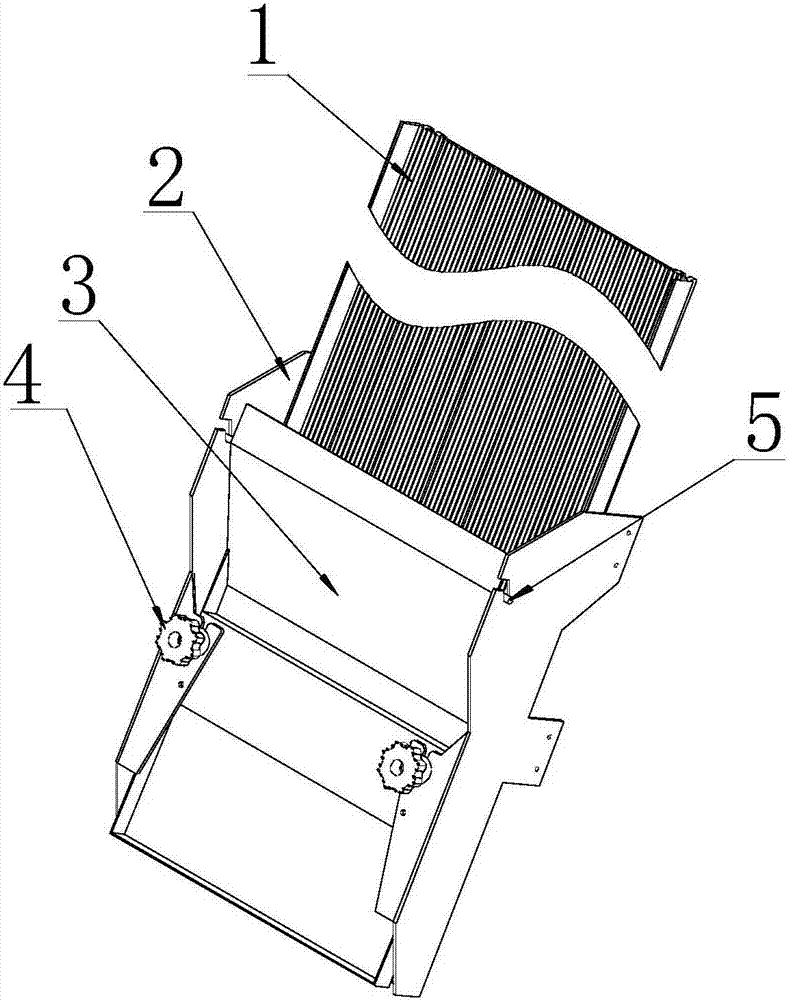

[0010] Such as figure 1 As shown, the purpose of the present invention is to provide an adjustable slideway cover, including a slideway 1, and the slideway cover side brackets 2 are arranged on both sides of the slideway 1, and the slideway cover side brackets 2 supports a rotating shaft 5, and the rotating shaft 5 drives an adjustable cover plate 3 covering the top of the slideway 1, and the adjustable cover plate 3 and the side bracket 2 of the slideway cover plate are arranged below the joint. There is adjustment knob 4.

[0011] The above content is only an example and description of the present invention. Those skilled in the art will make various modifications or supplements to the described specific embodiments or replace them in similar ways, as long as they do not deviate from the concept of the invention or go beyond the T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap