High-speed 3D printing parallel drive mechanism

A technology of 3D printing and driving mechanism, which is applied in the direction of processing driving device, additive processing, processing platform/substrate, etc., can solve the problems of printing space fault or dislocation, and achieve the effect of low production cost, simple structure and improved printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is described in detail below in conjunction with accompanying drawing:

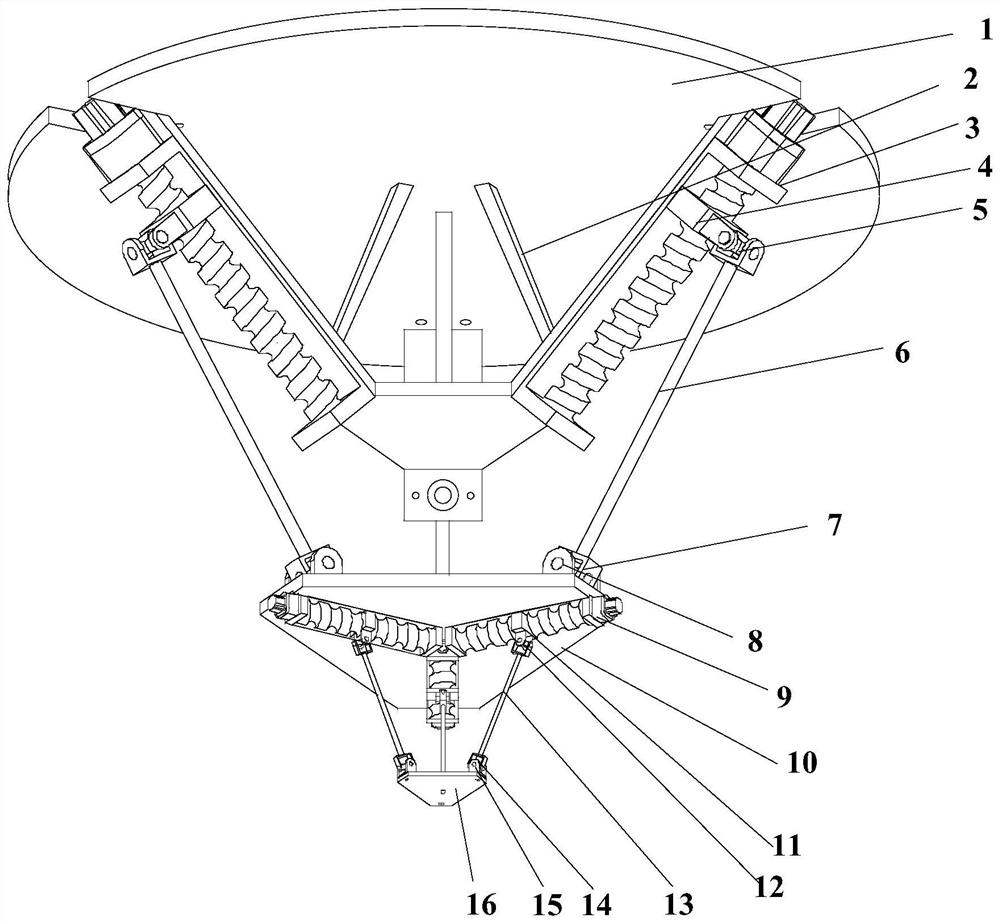

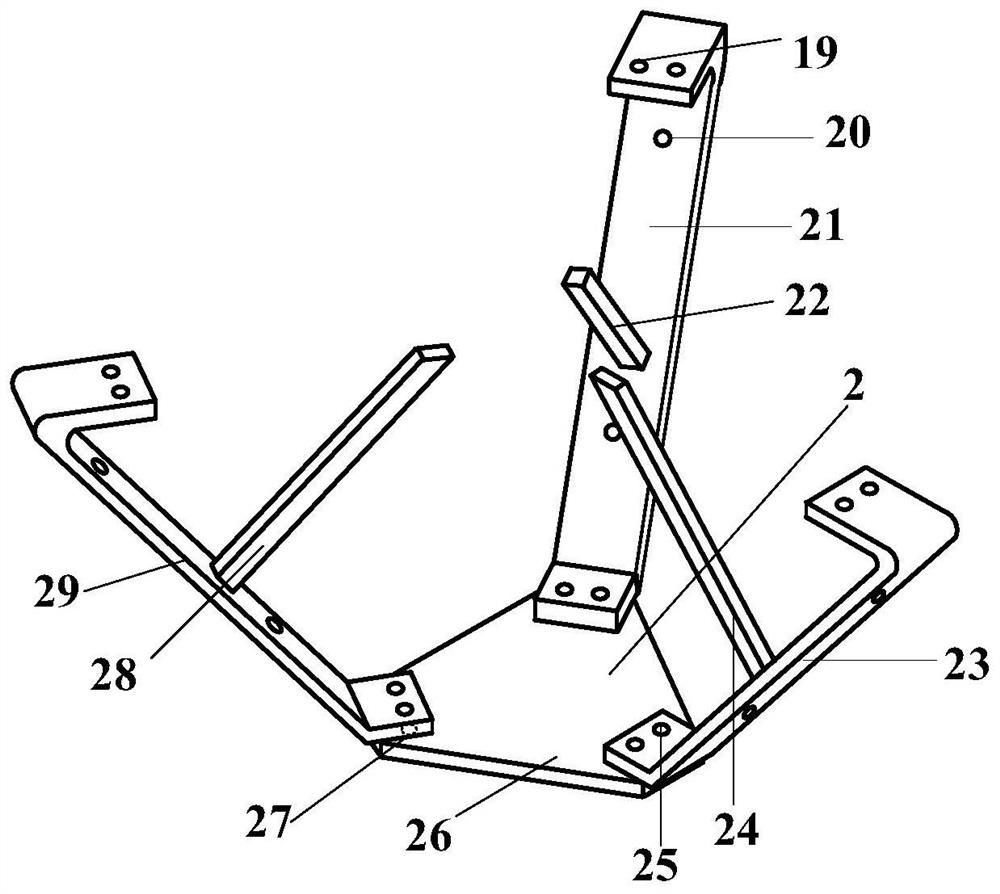

[0045] refer to figure 1 , a high-speed 3D printing parallel driving mechanism described in the present invention includes a fixed platform 1, a bracket 2, a first moving platform 10, a second moving platform 16, and three No. 1 parallel connections connecting the bracket 2 and the first moving platform 10. Branch chains, three No. 2 parallel branch chains connecting the first moving platform 10 and the second moving platform 16.

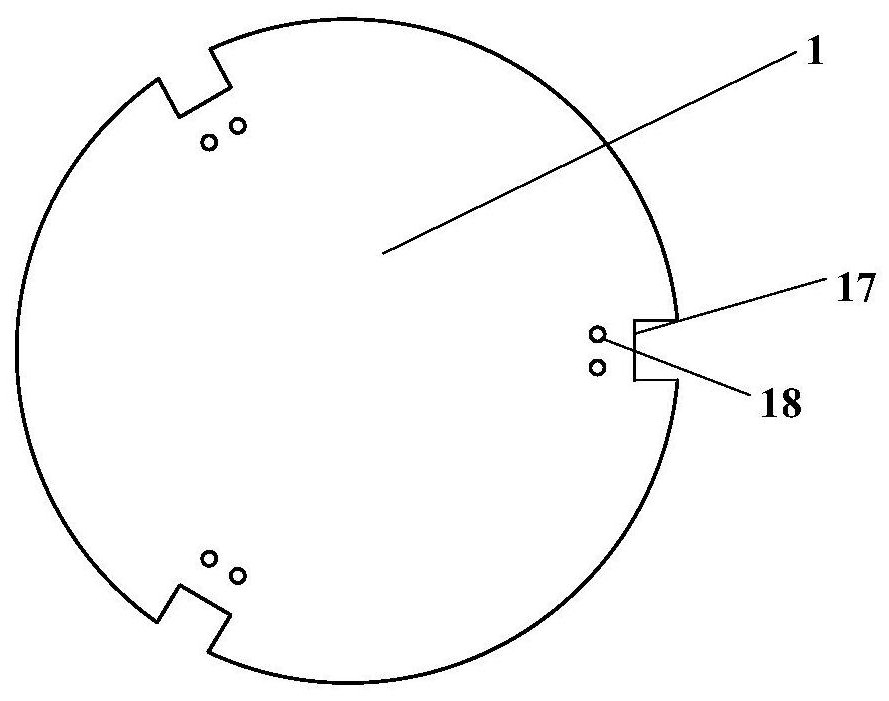

[0046] refer to figure 2 , the fixed platform 1 is a disc-shaped structural member, on which there are 3 gaps 17 with the same structure and 3 groups of support plate mounting holes 18, and the 3 gaps 17 with the same structure and 3 groups of support plate mounting holes 18 are Matching setting, three notches 18 are evenly arranged along the circumferential direction, the width of the notches 18 is equal to the width of the first support plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com