manual reversing valve

A manual reversing valve and spool technology, applied in fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of small electromagnet thrust, spool locking, high cost of use, etc., and achieve high stroke control accuracy , reduce wear and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

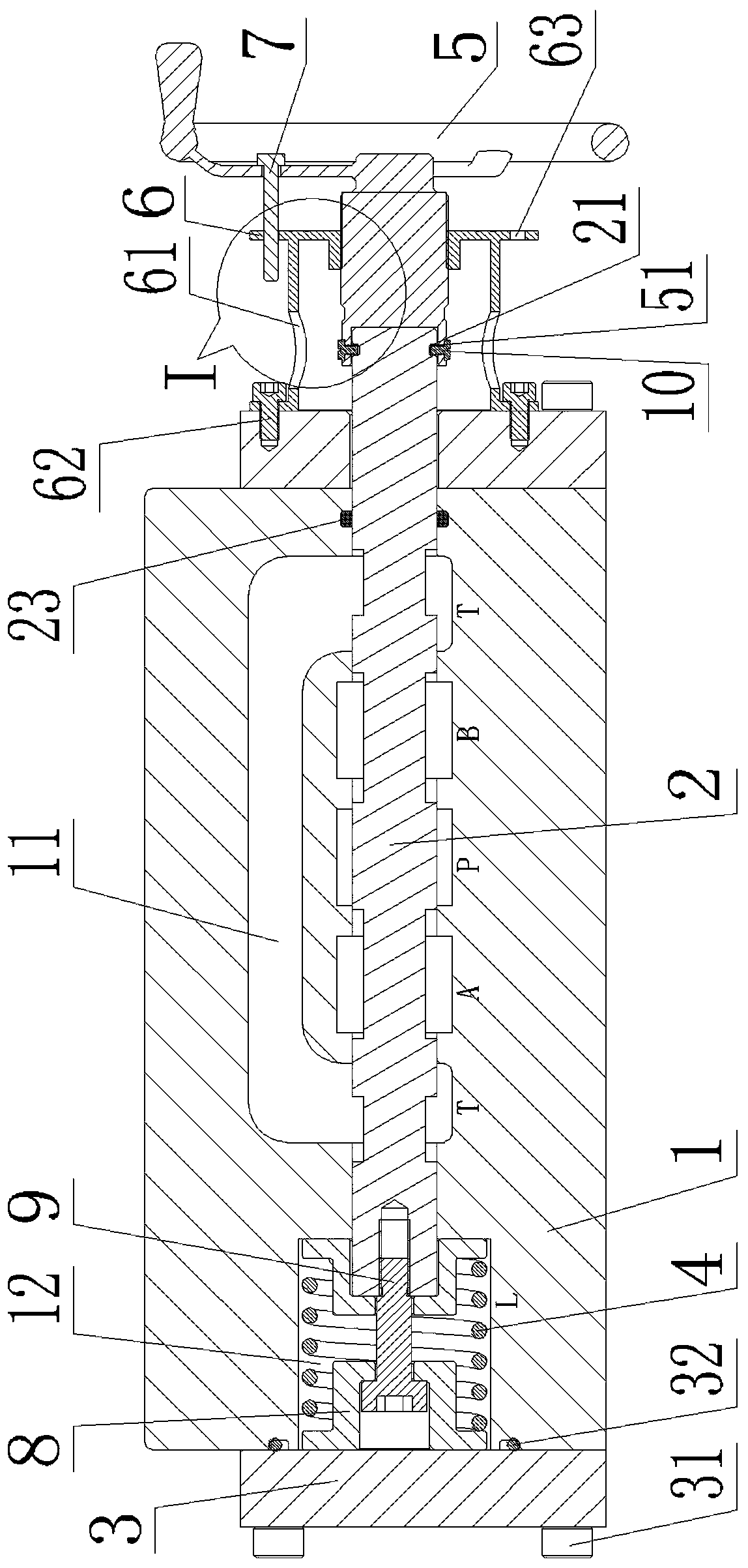

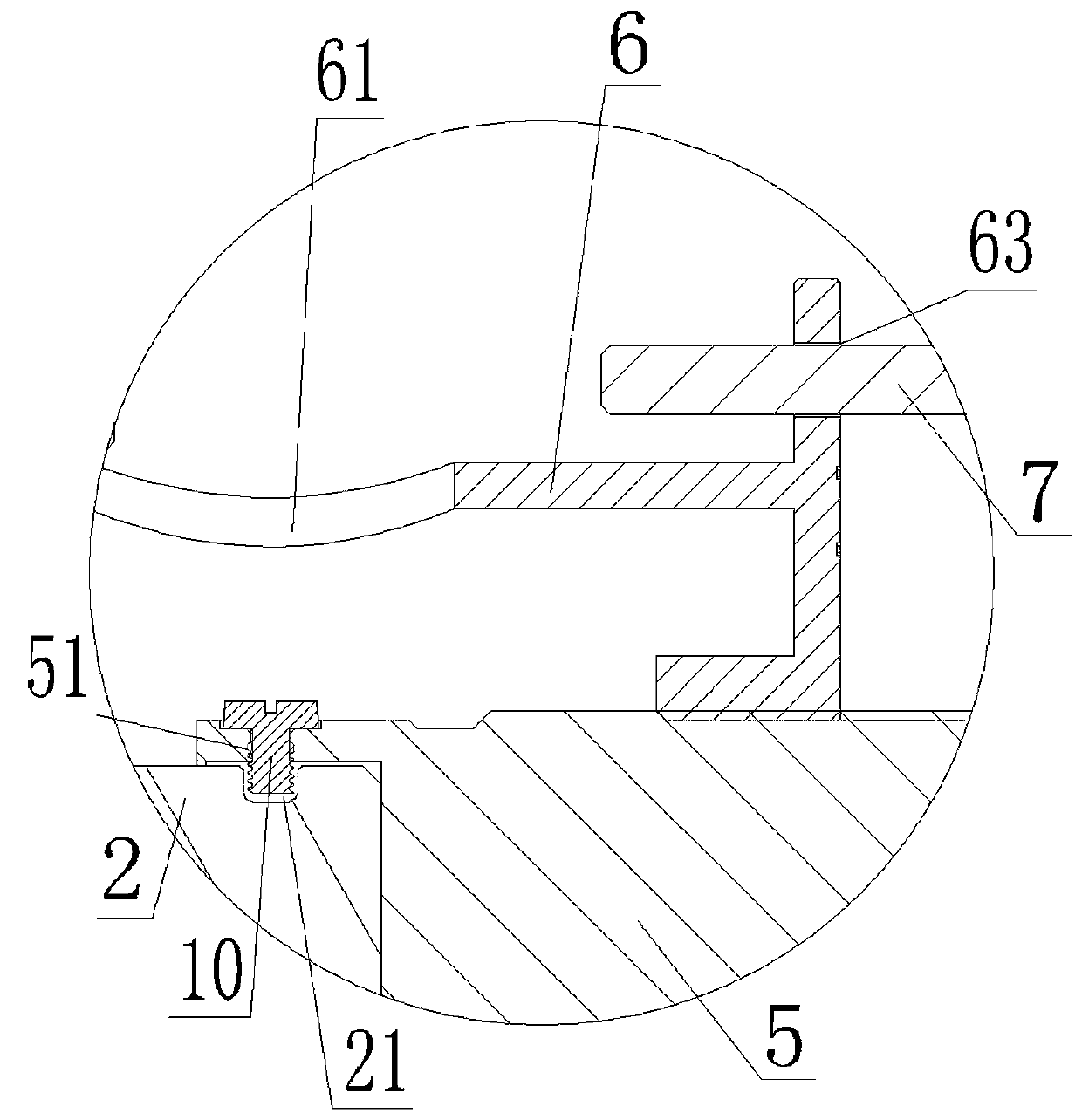

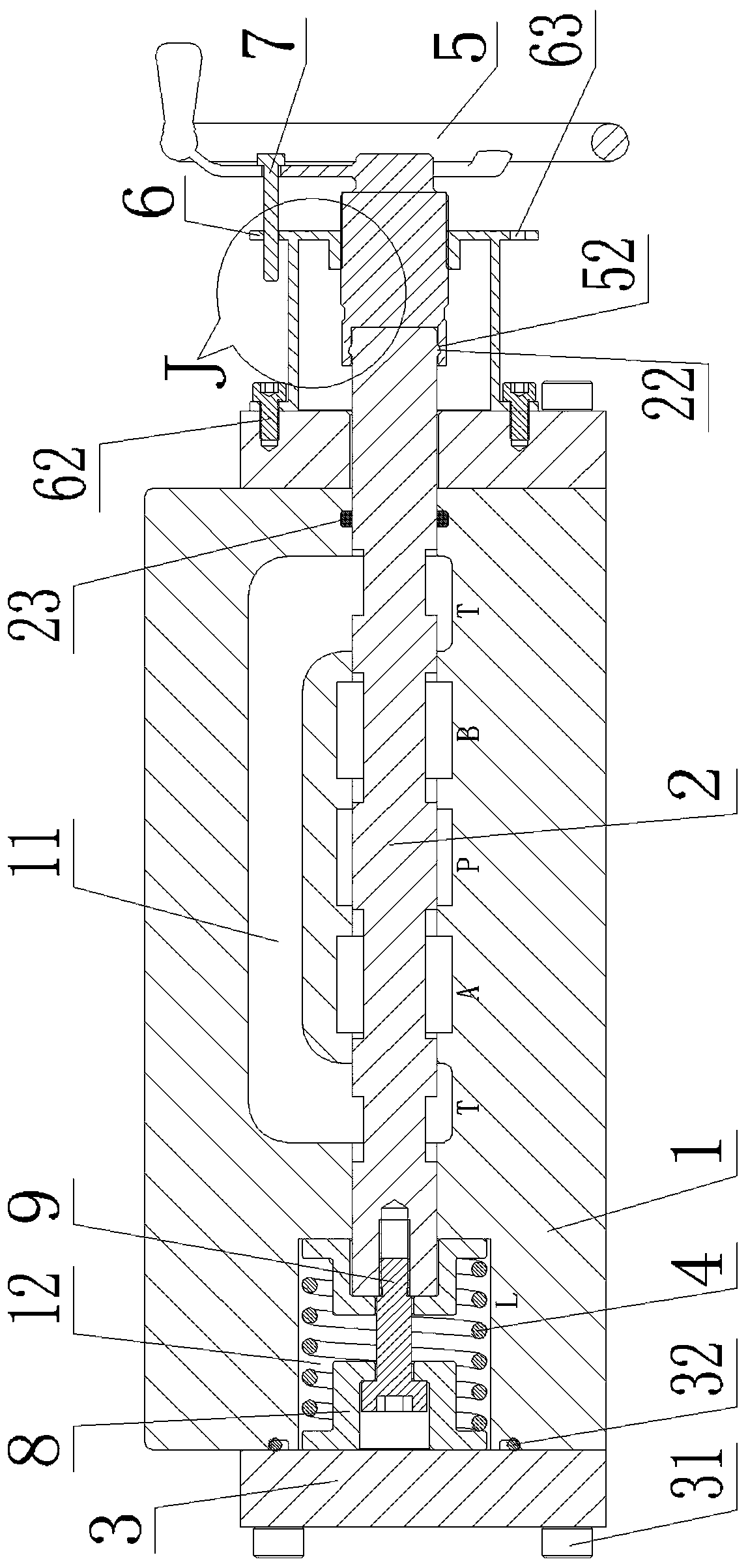

[0023] Taking the three-position four-way hydraulic valve as an example, from figure 1 and image 3 It can be seen that the manual reversing valve of the present invention includes a valve body 1, a valve core 2, an end cover 3, a return spring 4, an adjustment handle 5, a positioning disc 6, a positioning pin 7, a spring seat 8 and a fastening screw 9 , wherein, the end cap 3 includes a left end cap and a right end cap, the left and right end caps are all affixed to both ends of the valve body 1 through a number of end cap bolts 31, and the left end cap is sealed with the valve body 1 through an O-ring 32, in A control chamber 11 and a reset chamber 12 are opened in the valve body 1 along the axial direction from left to right. The valve core 2 is installed in the valve body 1 and runs through the control chamber 11 and the reset chamber 12. There are P port and T port on the top, and A port and B port are provided on the valve core 2 corresponding to P port and T port. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com