Electronic expansion valve and its refrigeration system

A technology for electronic expansion valves and valve ports, which is applied to components with teeth, valve operating/release devices, valve lifts, etc., which can solve the problem of increasing the volume of gear reducers, increasing the outer diameter of large gears, and failing to achieve high Accuracy, miniaturization and other issues to achieve the effect of improving stroke control accuracy and increasing the flow adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

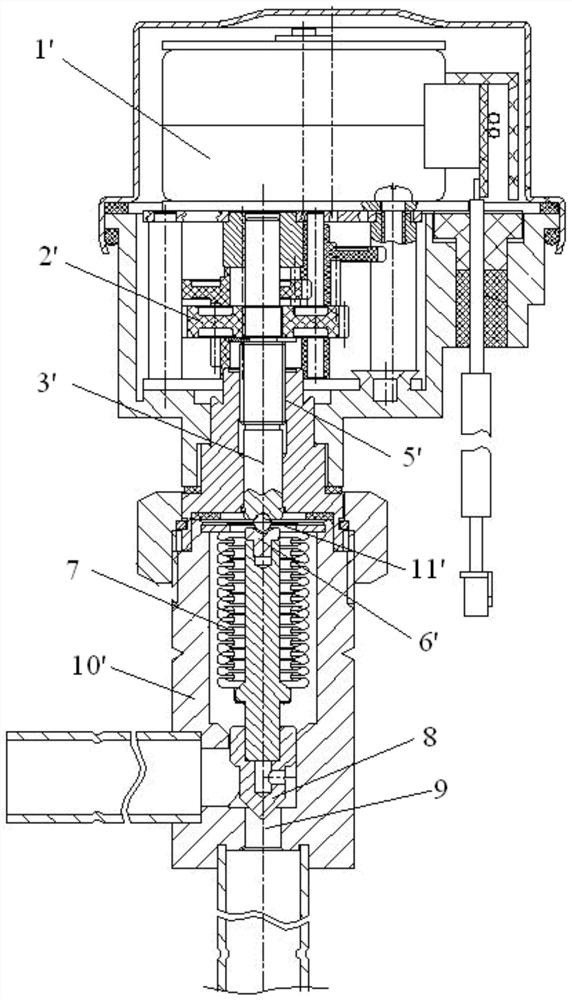

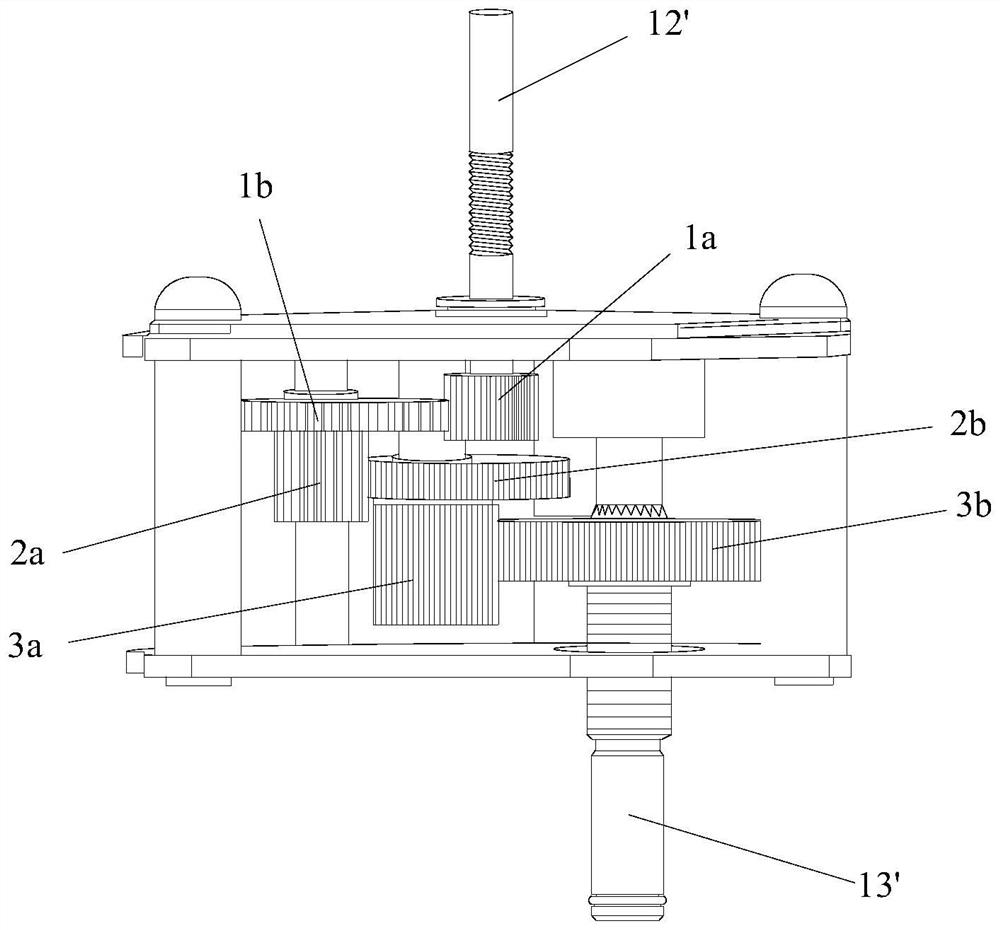

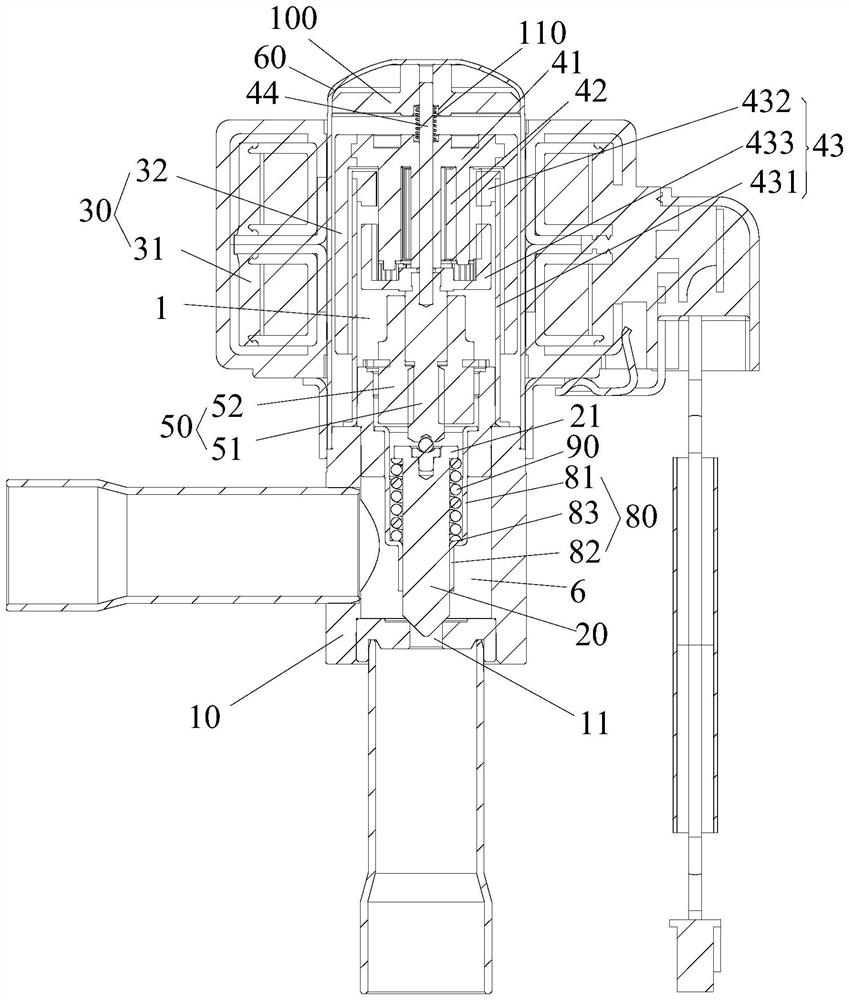

[0026] Such as Figure 3 to Figure 10 As shown, the electronic expansion valve of this embodiment includes: a valve seat 10, a valve needle 20, a drive mechanism 30, a planetary gear reduction mechanism 40, and a transmission mechanism 50, wherein the valve seat 10 has a cavity 6 and a valve communicating with the cavity 6 Valve port 11. The valve needle 20 is movably disposed in the cavity 6 , and the valve needle 20 has an open position for opening the valve port 11 and a closed position for blocking the valve port 11 . The driving mechanism 30 includes a rotor 32 and a coil 31 surrounding the outer side of the rotor 32 . Planetary gear reduction mechanism 40 comprises planet carrier 41, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com