Crop control model driven intelligent greenhouse system control method

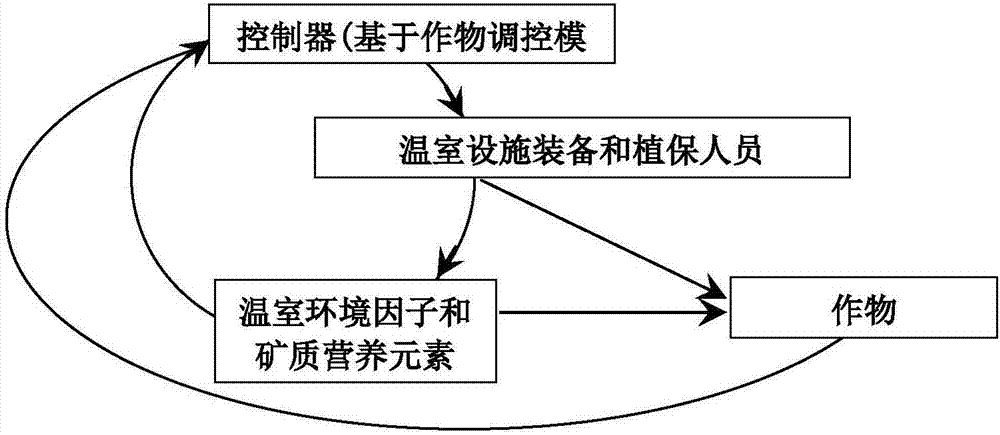

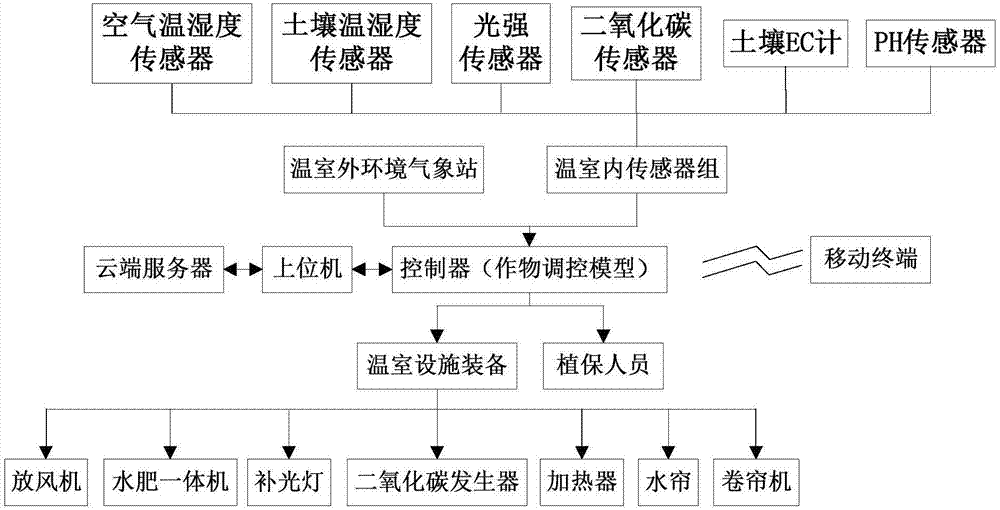

A model-driven, greenhouse technology, used in control/regulation systems, non-electric variable control, and simultaneous control of multiple variables, etc., can solve the problem of ignoring the interaction of environmental factors, difficult to ensure the control effect of the greenhouse control system, and not considering other factors. Changes and influences, etc., to achieve the effect of strong theoretical and difficult to promote and disseminate tacit knowledge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Determine the quantitative model of interaction

[0035] (1) Determine the temperature during tomato growth. Different growth and development stages of tomato have different temperature requirements.

[0036] Seed germination stage: determine the optimum temperature is 25°C to 30°C, when the temperature is lower than about 12°C (biological starting point temperature) or exceeds 40°C (biological upper limit temperature), it will be difficult to germinate;

[0037] Seedling stage: determine that the suitable temperature during the day is 20°C-25°C, and the suitable temperature at night is 10°C-15°C. When the temperature reaches 40°C (biological upper limit temperature), stop growing. When the temperature drops below 10°C, the growth is slow, and at 5°C (biological starting temperature), the plant stops growing;

[0038] Flowering period: Make sure that the suitable temperature during the day is 20°C-26°C, and the suitable temperature at night is 15°C-20°C. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com