Structural optimum design method for relieving cam

A technology of optimizing design and cam, applied in the direction of design optimization/simulation, calculation, special data processing application, etc., can solve the problems of vibration and noise of shovel mechanism and reduce the machining accuracy of workpiece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

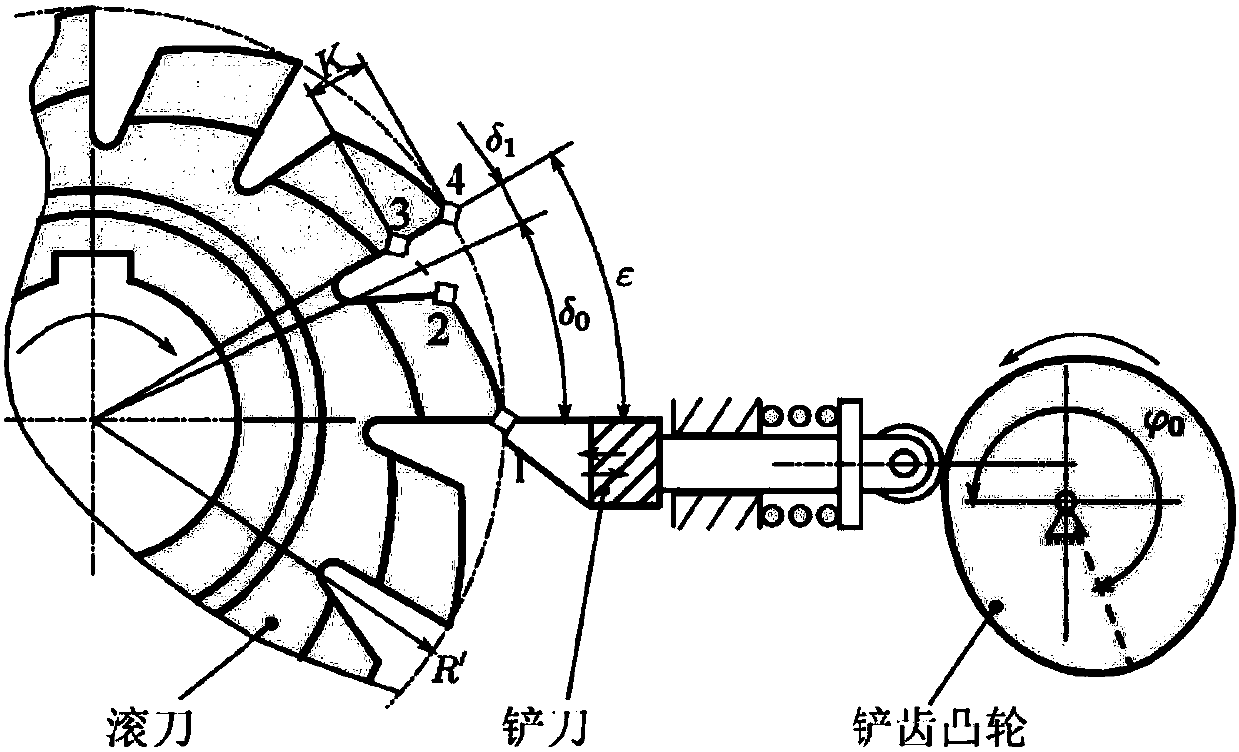

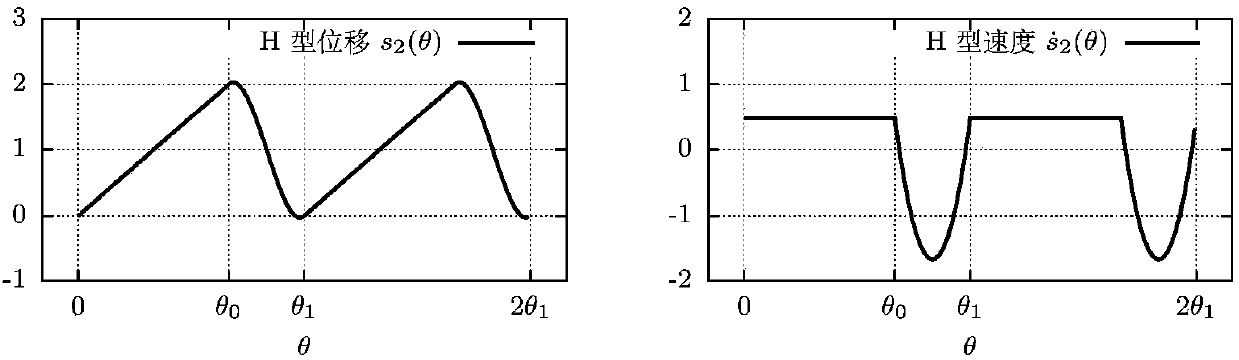

[0100] Example 1: Three-lift cam design

[0101] In this example, the three-lift H-type shovel tooth cam is used as the optimal design object. Such as Figure 8 As shown, the follower of the three-lift H-type shovel cam has three rising strokes in one revolution cycle. Different from the traditional single-lift shovel cam, the working profile of the three-lift shovel cam is rotationally symmetrical, and its geometric center coincides with the center of rotation. At high speeds, the tri-lift cams have less spindle load. The design constraints of the three-lift H-type shovel cam are listed in Table 3, in which the cam theoretical profile curvature, pressure angle distribution, initial displacement of the follower and the value range of the offset ensure the rationality of the design solution.

[0102] Table 3 Design constraints of the three-lift shovel cam

[0103]

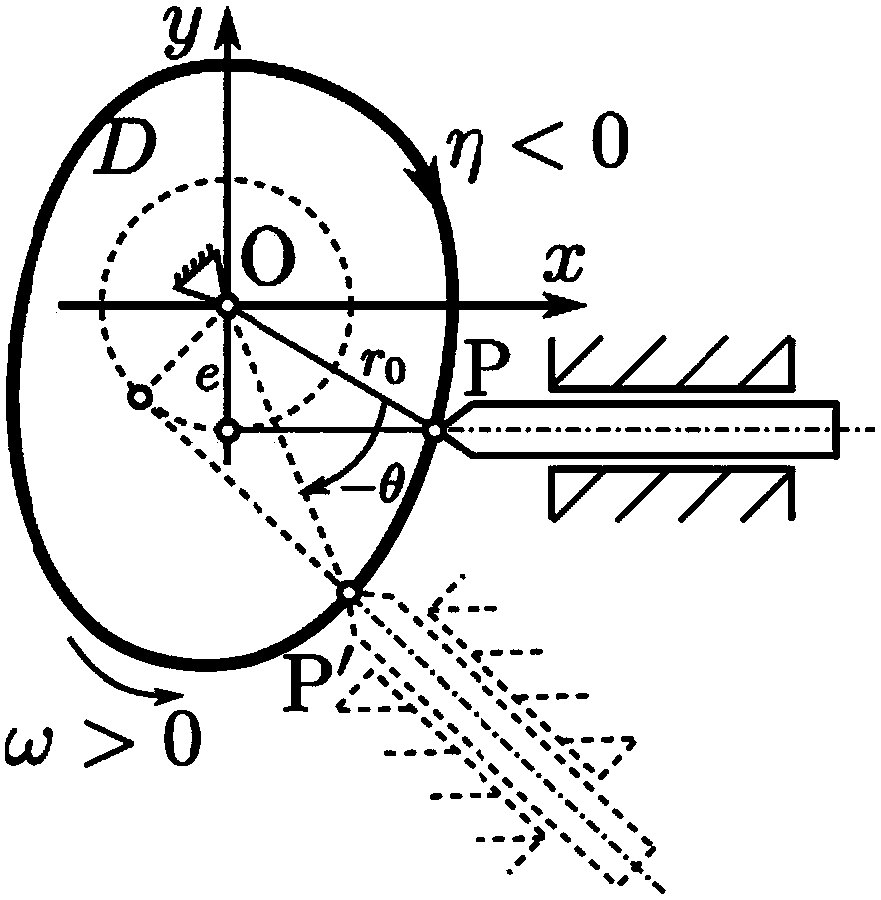

[0104] The optimal design model of the three-lift H-type shovel cam is established by formula (11), and th...

example 2

[0110] Example 2: Four-lift cam design

[0111] In this example, the four-lift H-type shovel tooth cam is used as the optimal design object. Such as Figure 12 The cam shown has four follower strokes. Similar to the three-lift cam, the working profile of the four-lift cam is rotationally symmetrical, its geometric center coincides with the center of rotation, and the inertial force is small in high-speed situations. A four-lift cam performs four feed movements per revolution. The design constraints of the four-lift shovel cam are listed in Table 6. The value ranges of cam theoretical profile curvature, pressure angle, follower initial displacement and offset ensure the rationality of the design solution. The area of the four-lift cam is larger than that of the three-lift cam. Under the condition of a certain size of the shoveling mechanism, the upper limit of the initial displacement of the follower in the four-lift scheme is slightly lower.

[0112] Table 6 Design param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com