Winding mechanism of superconduction coil

A winding mechanism and superconducting coil technology, applied in the direction of superconducting magnets/coils, electrical components, magnetic objects, etc., can solve the problems of increasing manufacturing costs, achieve the effects of reducing production costs, reducing manufacturing costs, and preventing spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

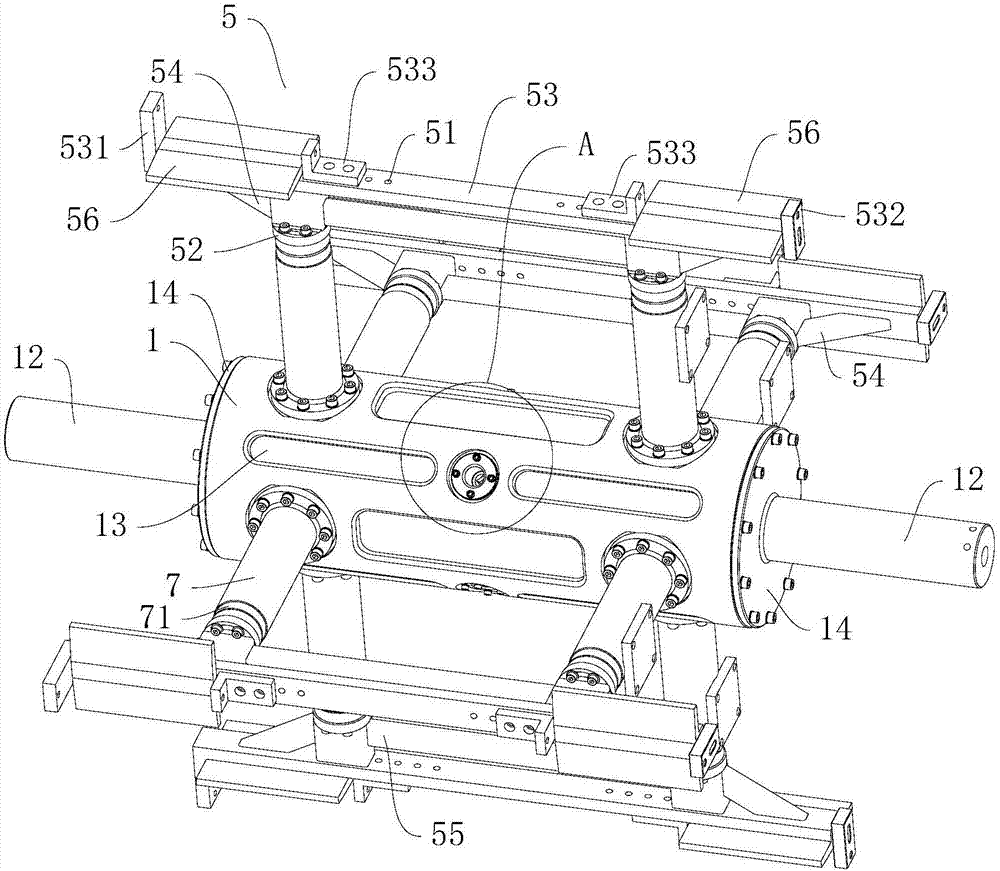

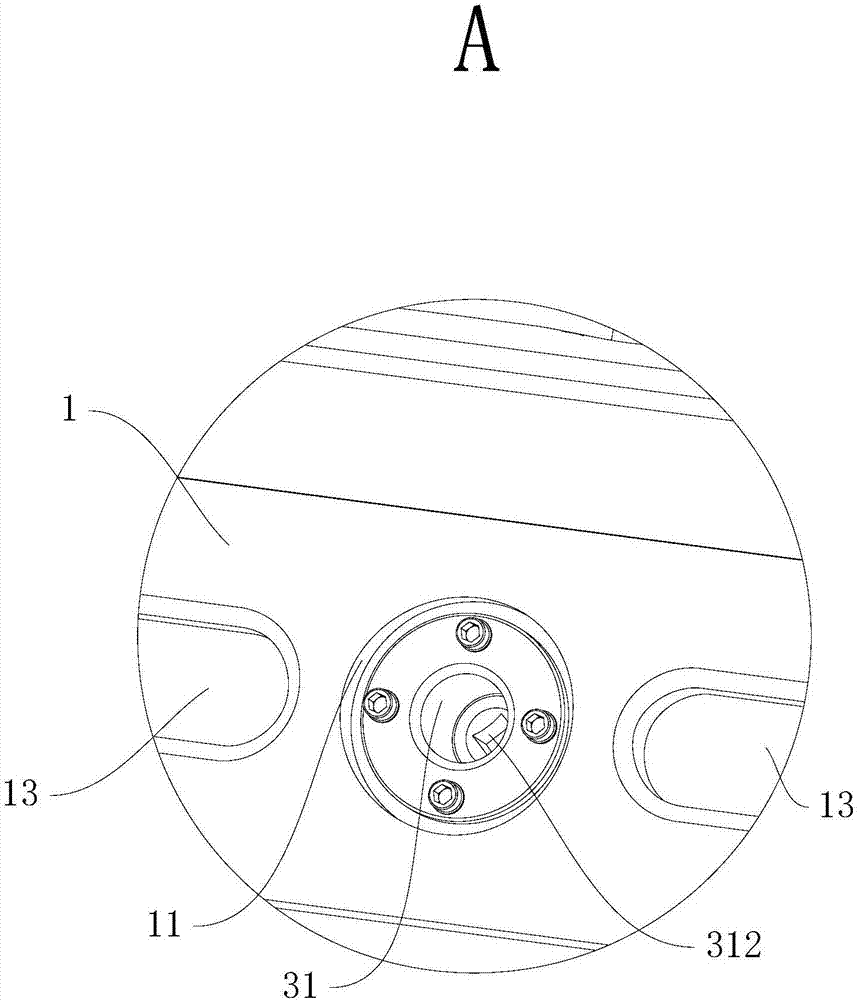

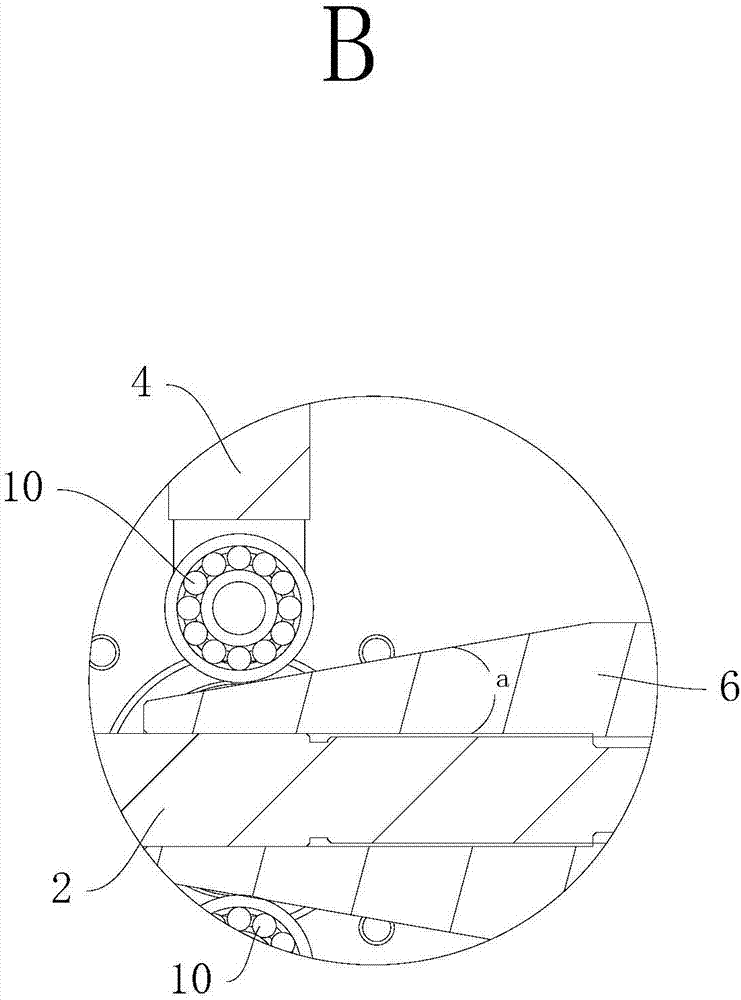

[0041] A kind of winding mechanism of superconducting coil, see figure 1 , figure 2 , image 3 and Figure 4 , including the main housing 1, the main housing 1 is a hollow cylinder, the central shaft 2 is arranged in the axial direction inside the main housing 1, and the two ends of the central shaft 2 are movably installed on the two ends of the main housing 1, which can be passed through the bearing connection, the central shaft 2 can rotate freely around its own axis; the central shaft 2 is provided with two tapered sleeves 6, and the two ends of the central shaft 2 are respectively provided with positive threads and reverse threads, and the two tapered sleeves 6 are threaded. On the central shaft, when the central shaft 2 rotates, the two tapered sleeves 6 are close to the middle section of the central shaft 2 or away from the middle section of the central shaft 2 at the same time; the two ends of the outer wall of the main housing 1 are respectively symmetrically provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com