Patents

Literature

83results about How to "Turn control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

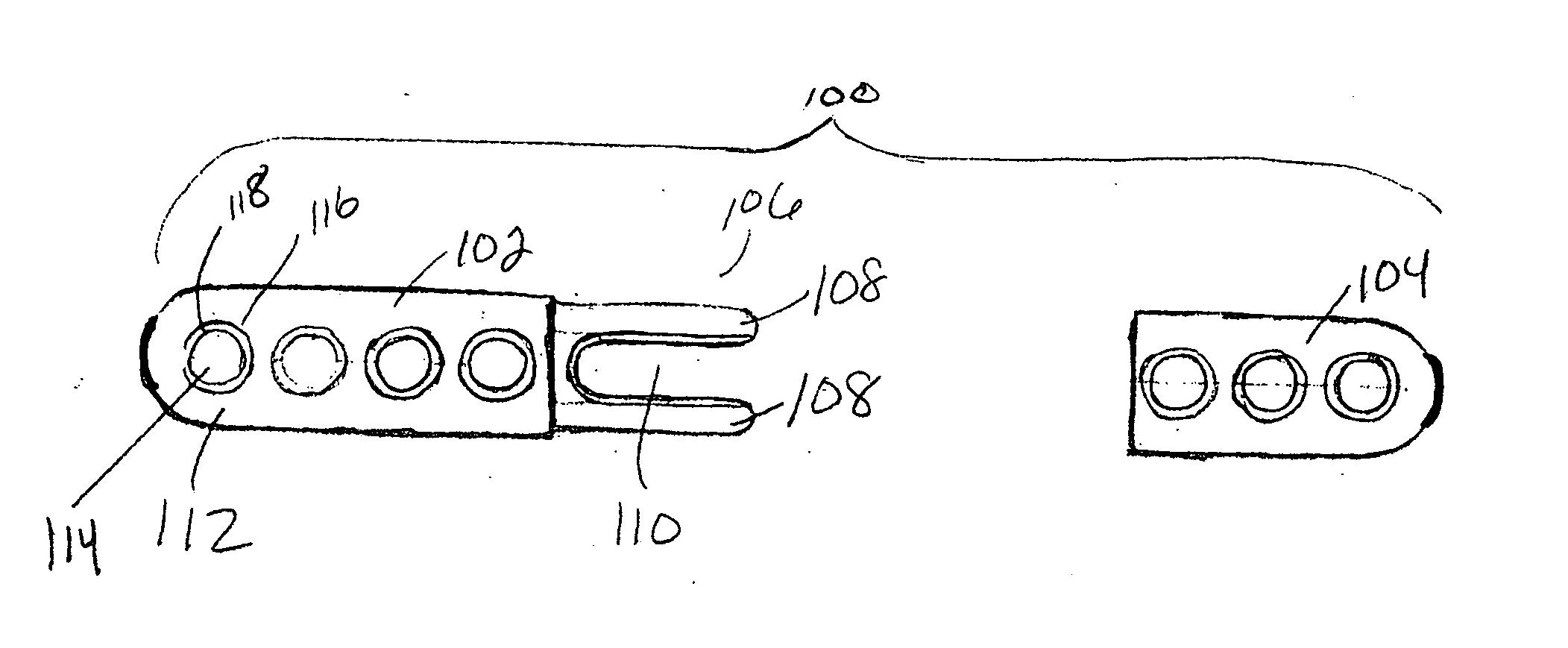

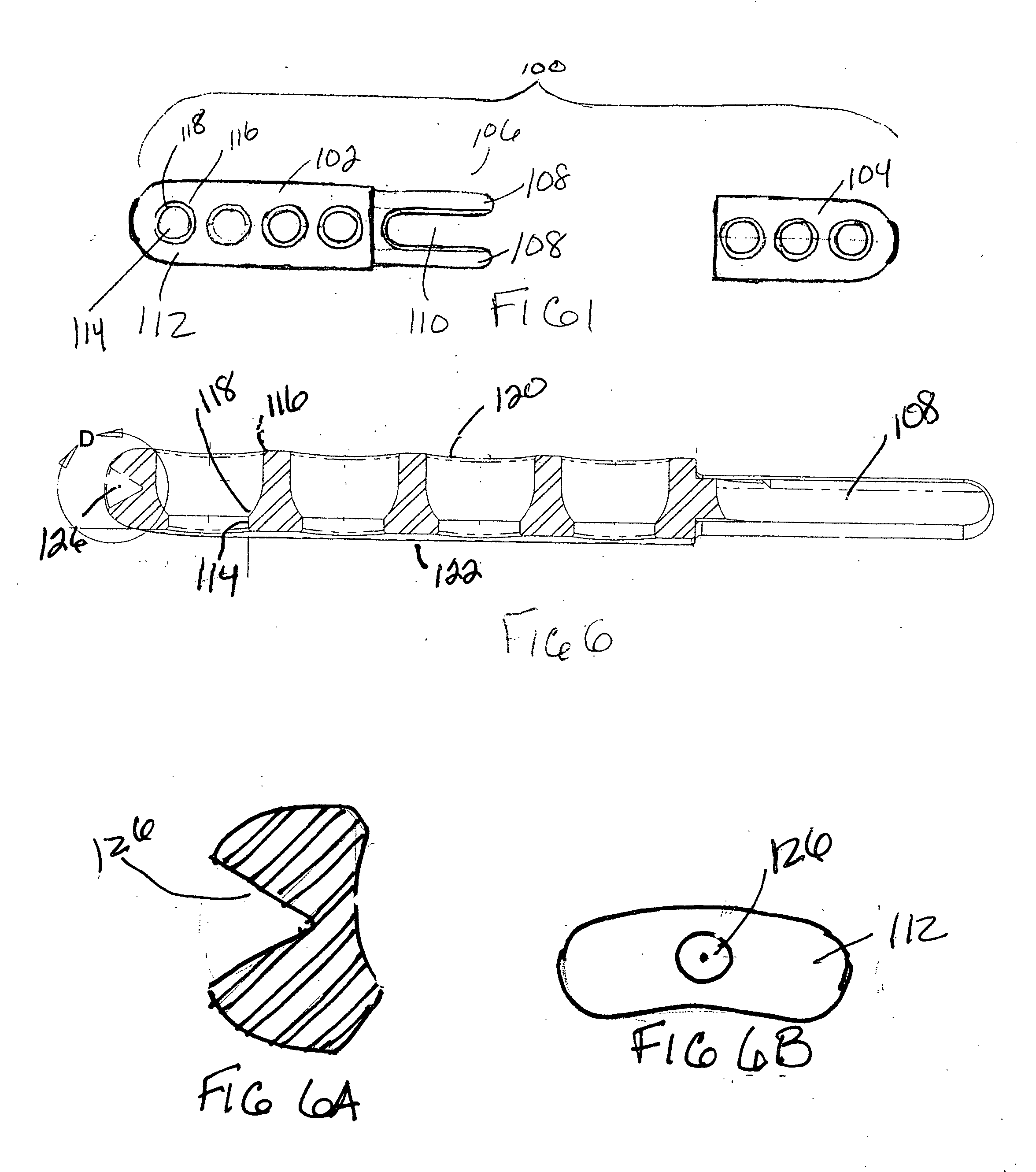

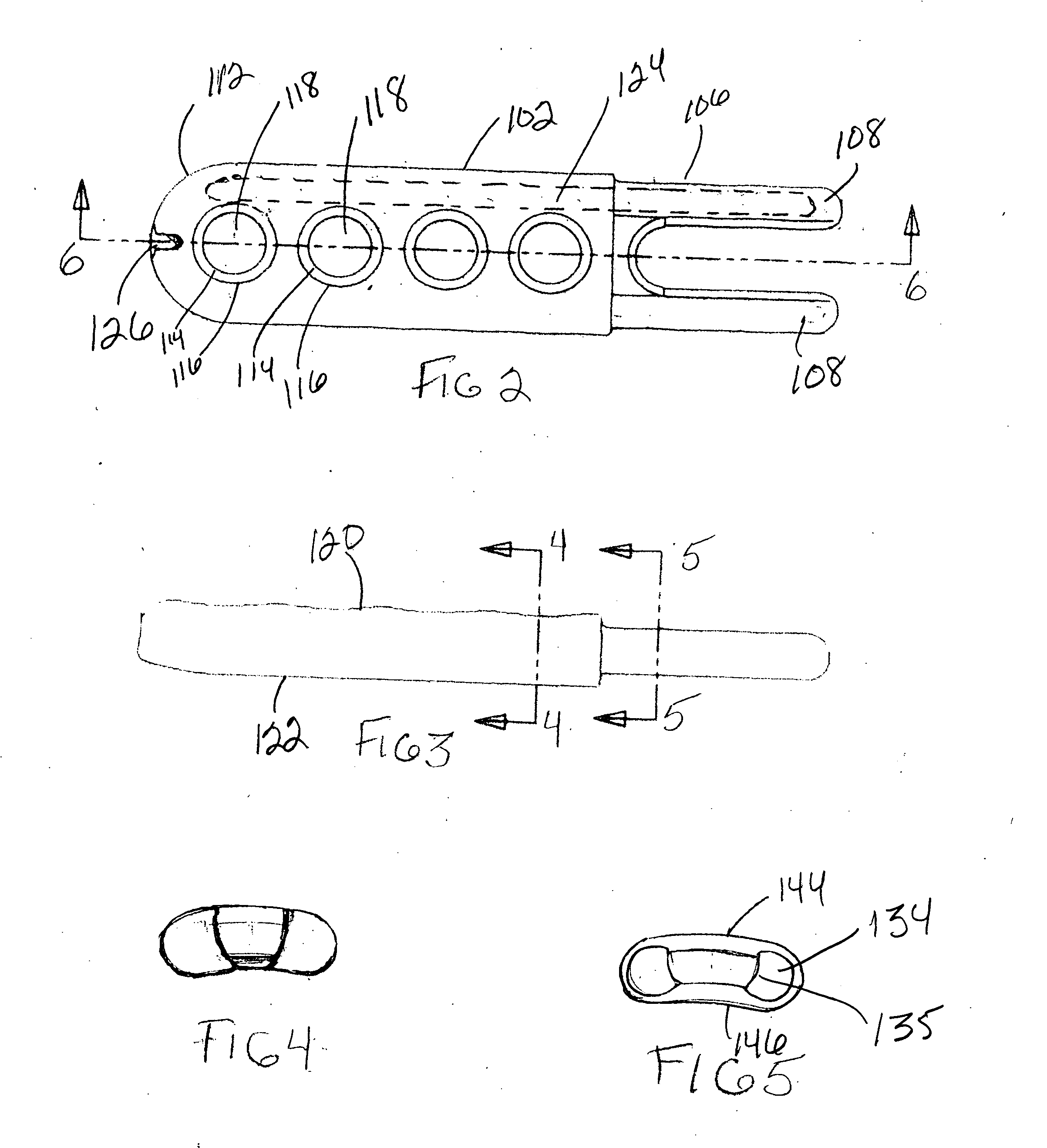

Adjustable bone plate

InactiveUS20060100625A1Resistant to bendingStrong lock mechanismInternal osteosythesisJoint implantsEngineeringMechanical engineering

A longitudinally curved adjustable bone plate comprising name to play how will the first plate having an end defined by at least two spaced prongs, and an end having means to fasten the plate to a body structure, e.g., the bone; and a second plate having an end defined by at least two straight bores for receiving the prongs, and an end having means to fasten the plate to a body structure, e.g., a bone; and a locking assembly for locking the prongs in the bores and fixing the overall length of the plate.

Owner:FIRST COMMERCE BANK

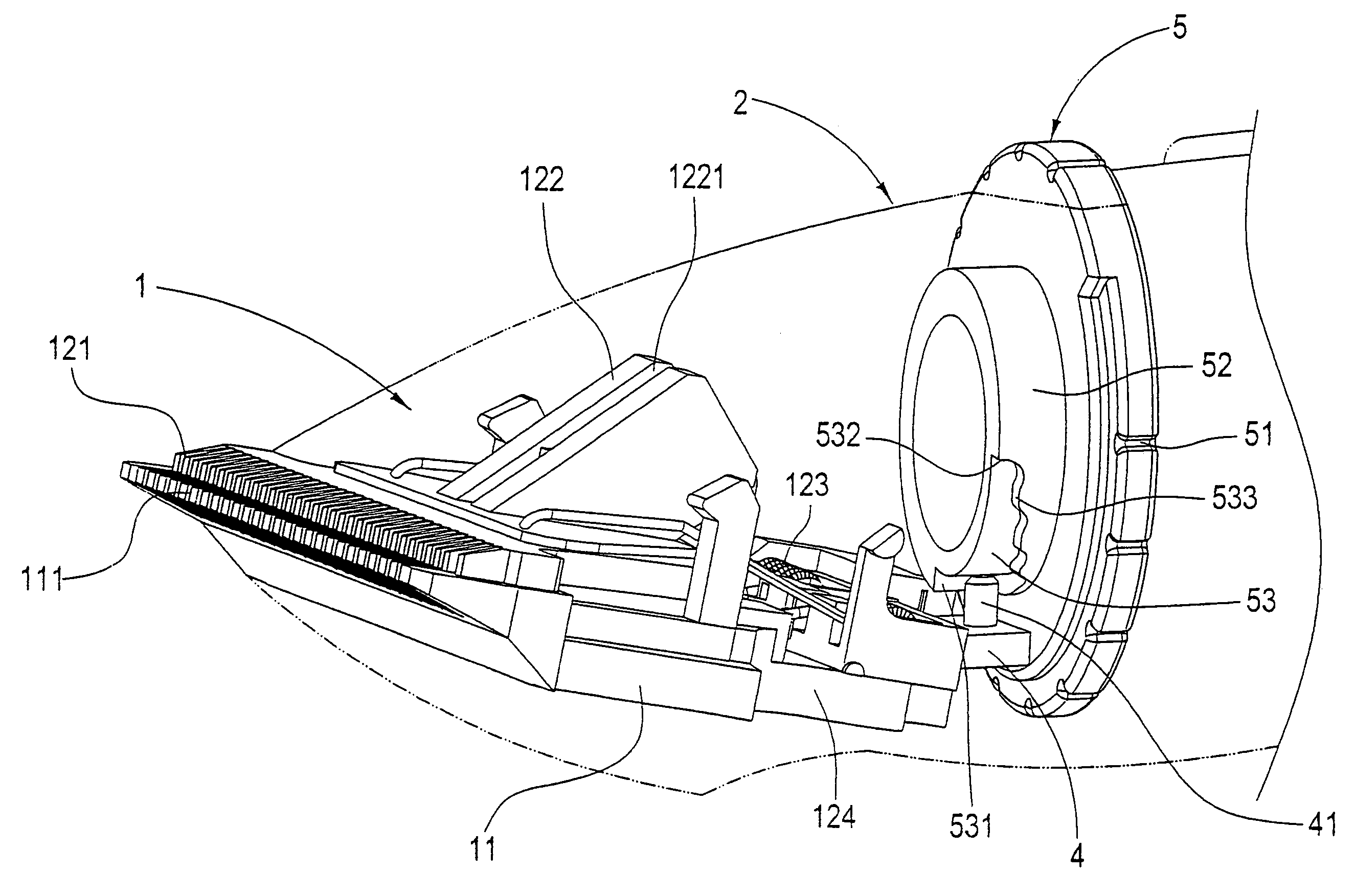

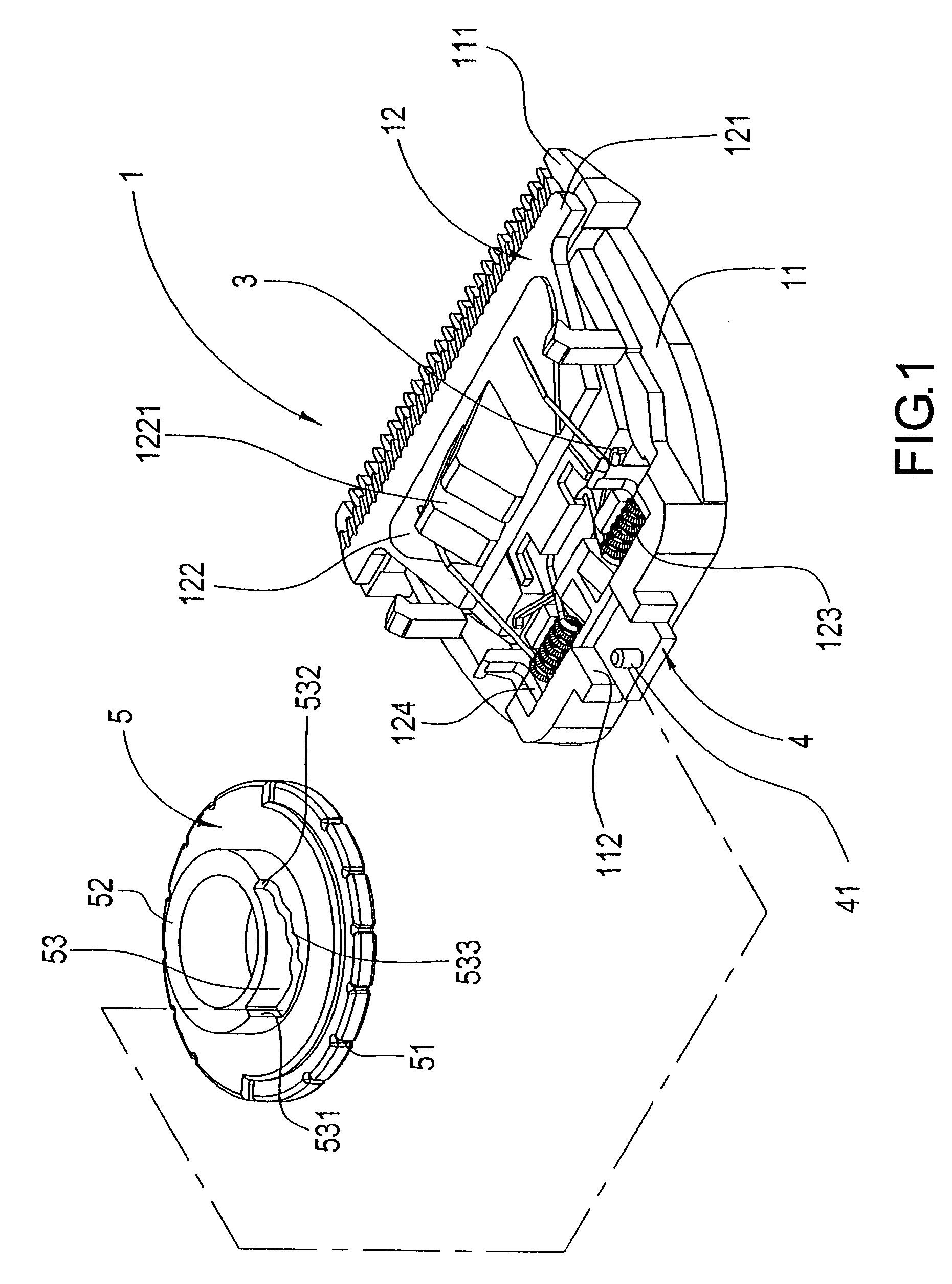

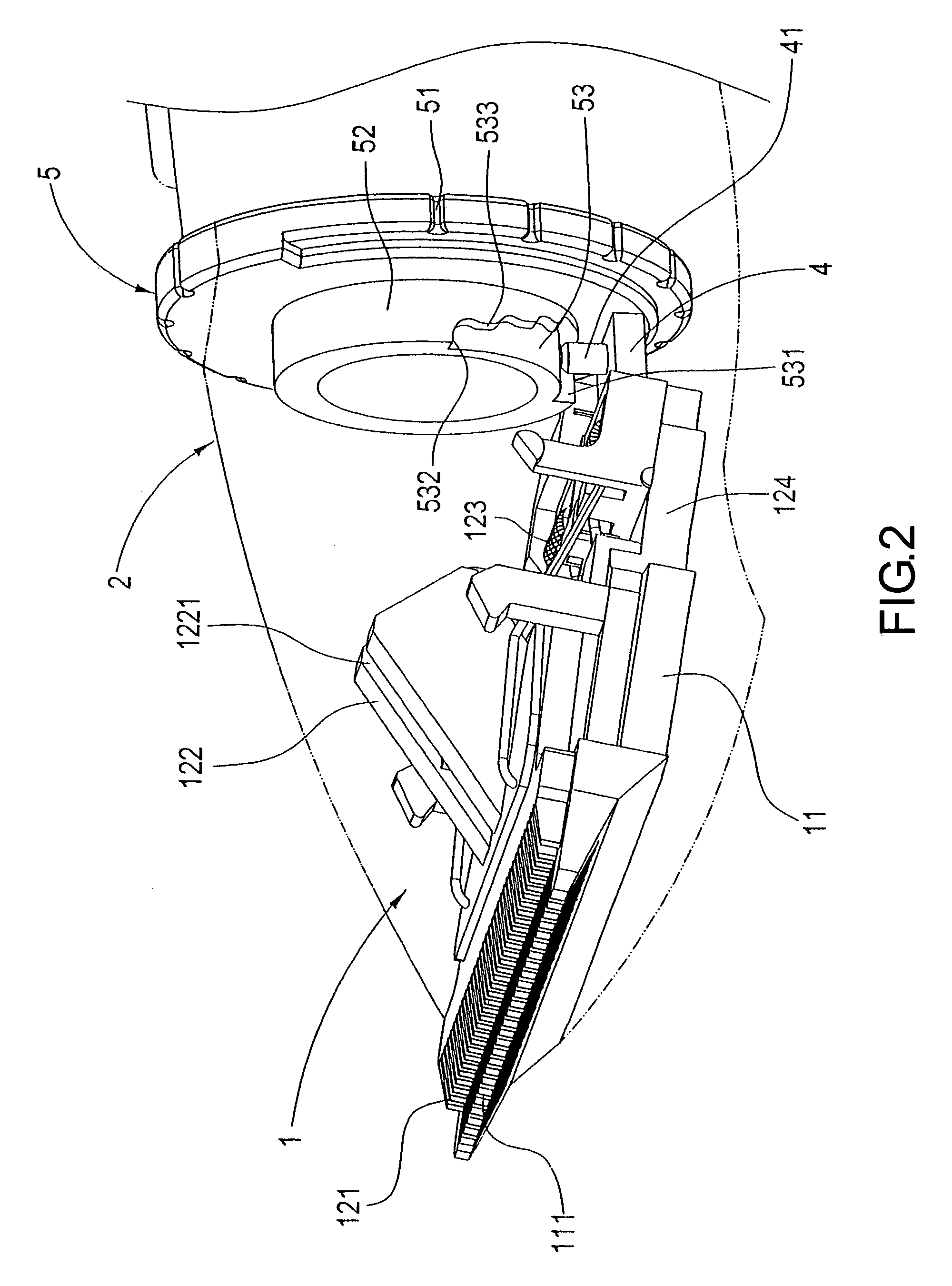

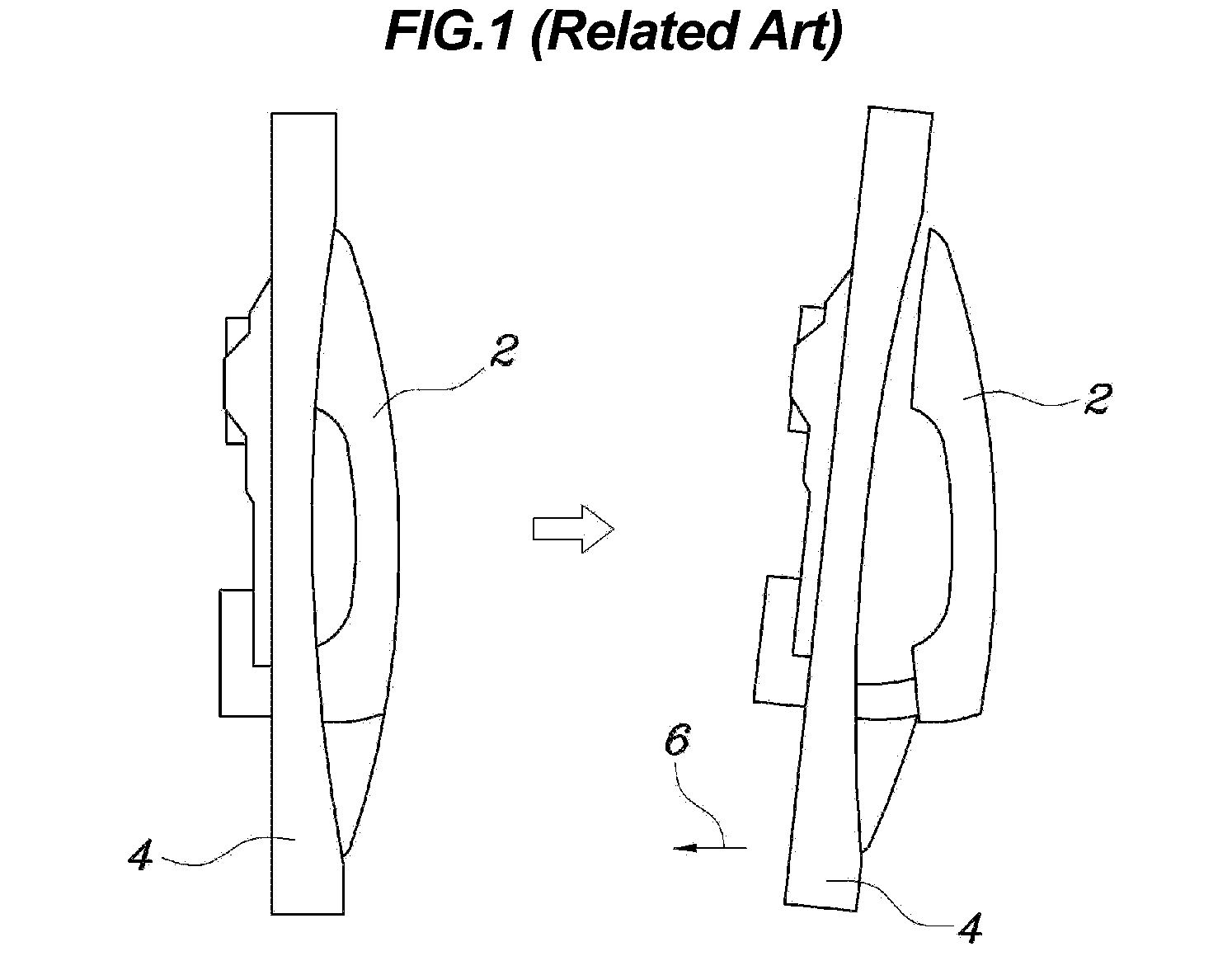

Adjustable apparatus for hair clipper

ActiveUS7234242B2Easy to operateSimple processMetal working apparatusAgricultural engineeringKnife blades

The invention discloses an adjustable apparatus for adjusting an upper blade position of a hair clipper to further adjust the hair cut length. The upper blade is connected to a blade spring. The blade spring is placed in a spring housing. The spring housing is connected to a pushing block. The pushing block is connected to a rotary wheel. Therefore, the position of the upper blade is adjustable by moving the rotary wheel.

Owner:YAO WOODY

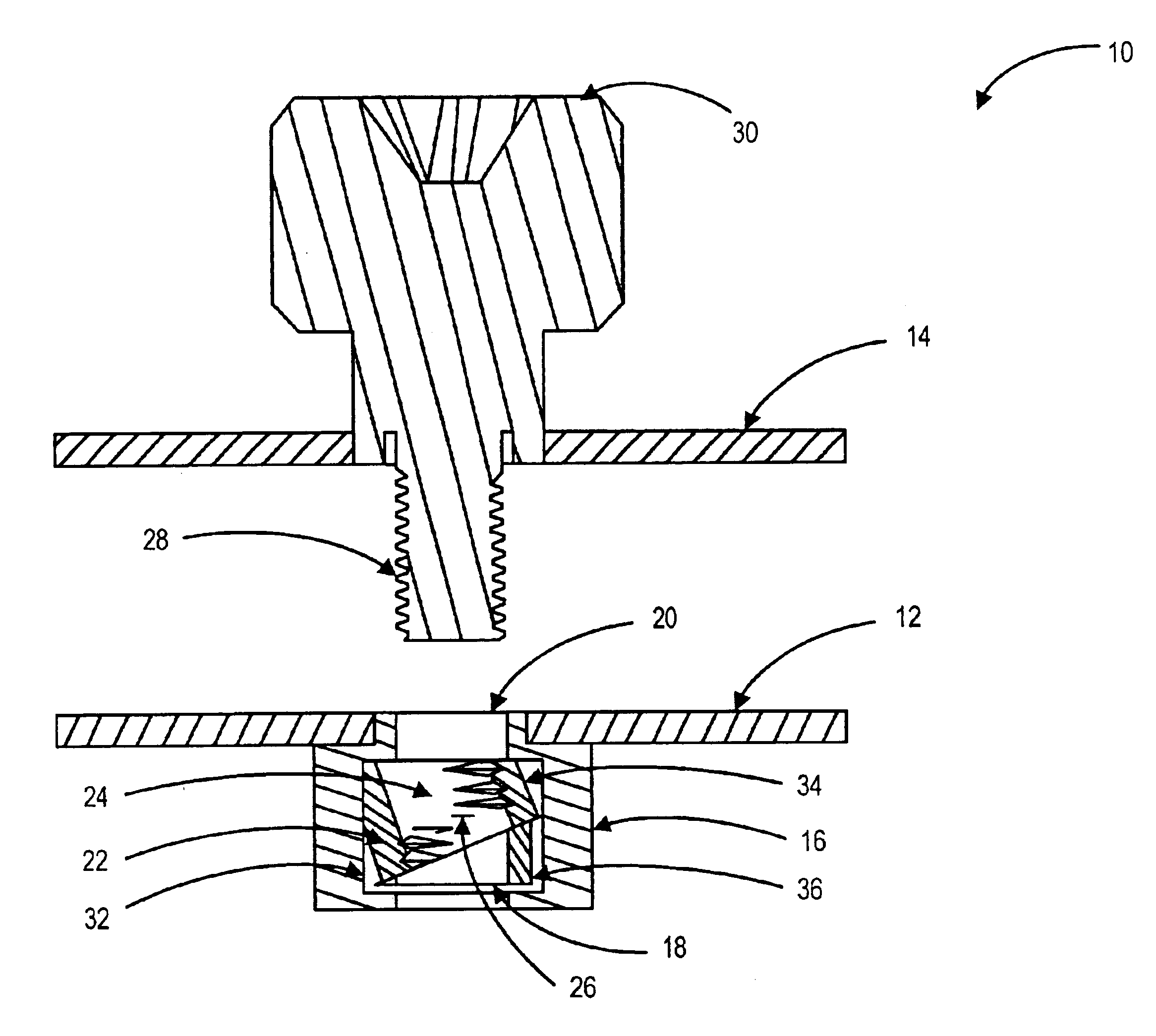

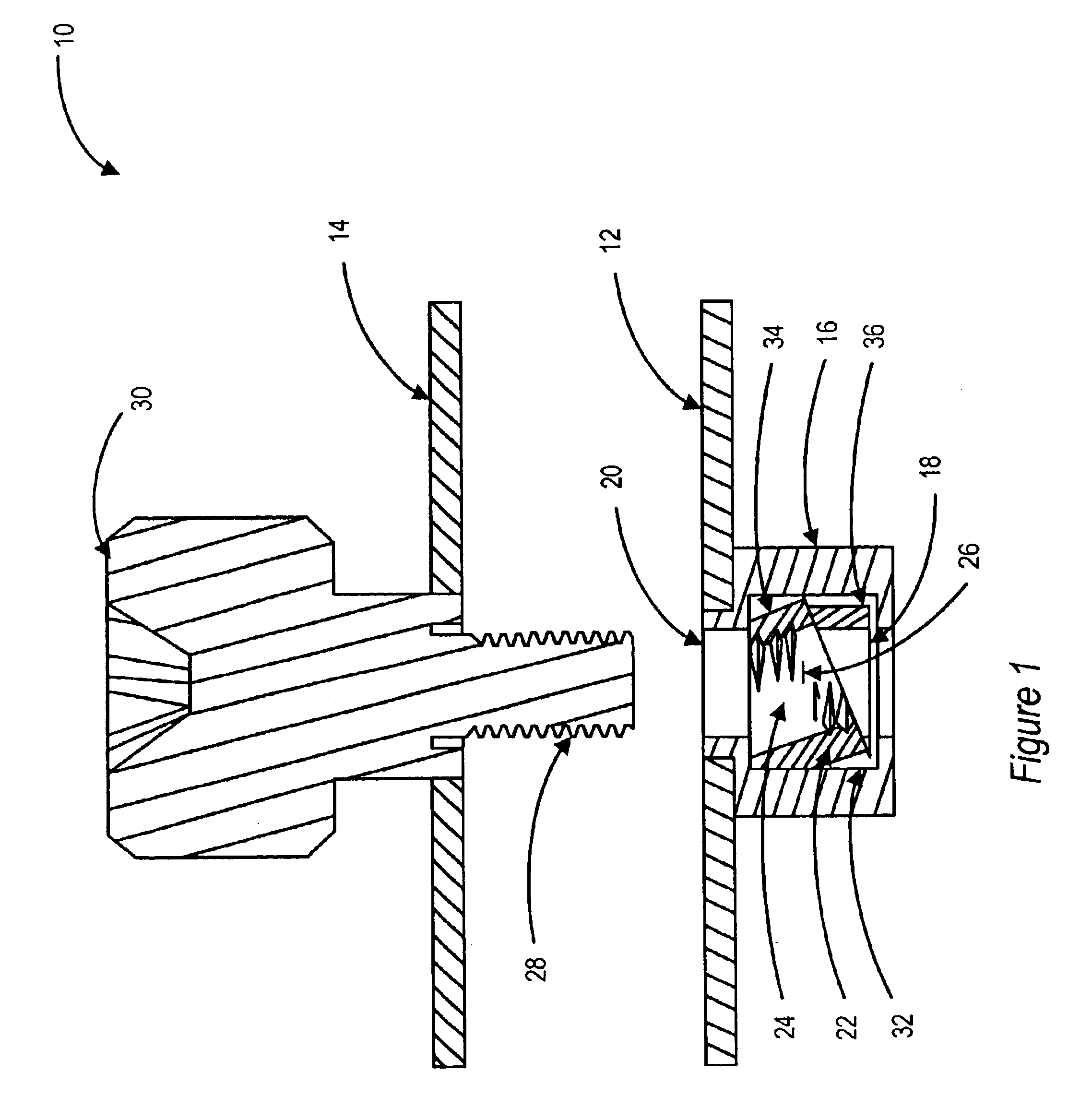

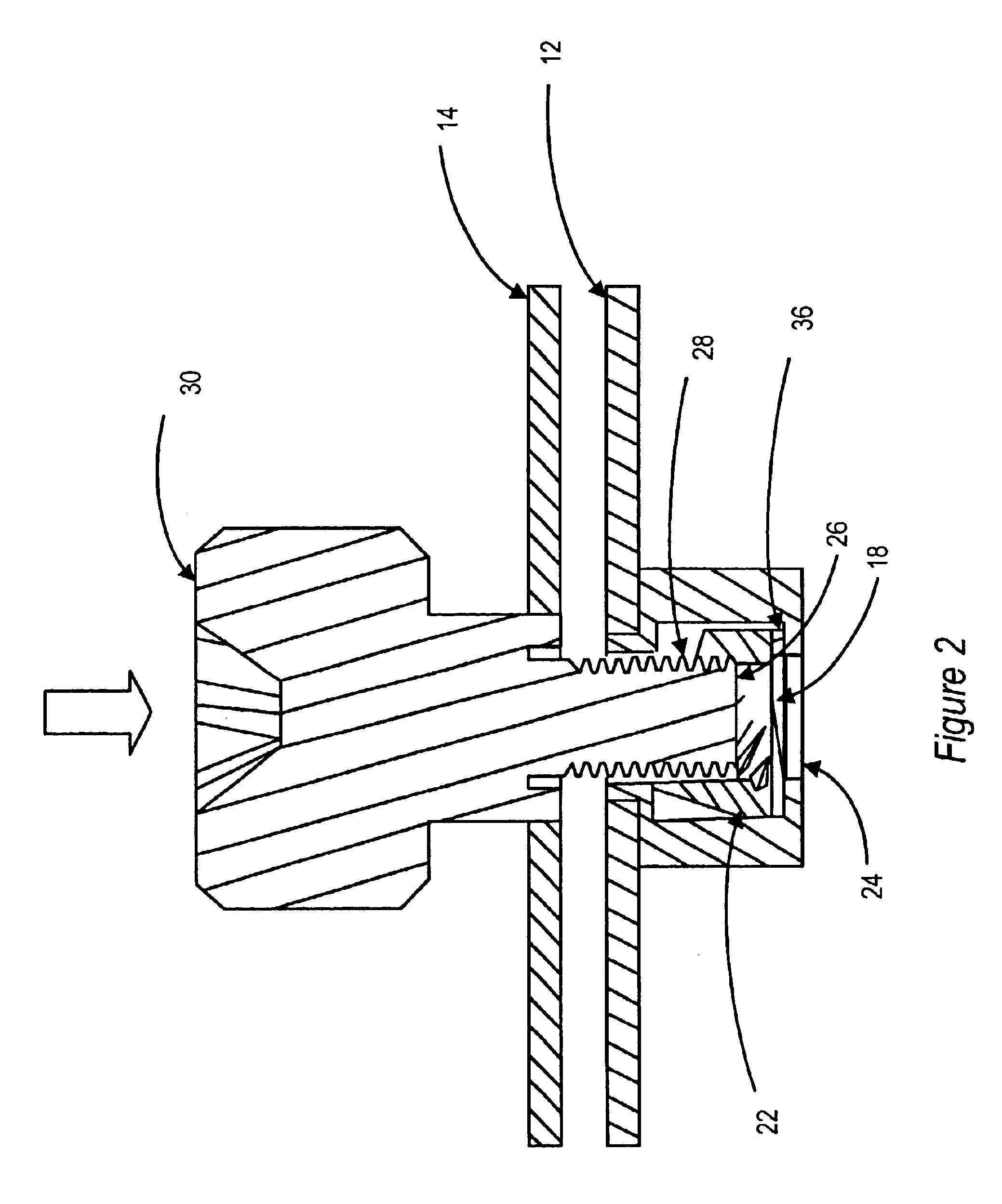

Rapid fastening screw apparatus and method

InactiveUS6860693B2Slow and tool-only disassemblyEasily and quickly securedNutsBoltsEngineeringInformation handling system

A press-in fastening apparatus and method couples a screw with a nut by pushing the screw through an opening of the nut along a slip axis and rotating the nut to align a lock axis with the inserted screw. The opening of the nut along the slip axis has a diameter greater than the diameter of the screw and the opening of the nut along the lock axis has a diameter that engages screw threads with nut threads. In one embodiment, the nut is disposed in a housing coupled to an information handling system and biased to align with the lock axis so that a module is secured to the information handling system by aligning a screw coupled to the module with the nut and pushing the screw into the nut. The module is removed from the information handling system by unscrewing the screw with engagement of the screw threads and nut threads.

Owner:DELL PROD LP

Polyester composite fiber with intelligent surface, and preparation method and application thereof

InactiveCN109385893ASpecial surface structureImprove hydrophilicity and hydrophobicityPhysical treatmentLiquid repellent fibresOil waterPolyester composite

The invention discloses a polyester composite fiber with an intelligent surface, and a preparation method and application thereof. The polyester composite fiber comprises a polyester fiber matrix andparticles covering the polyester fiber matrix, wherein the particles and the polyester fiber matrix are chemically bonded; preferably, the particles are polymer particles; more preferably, the particles are polymer particles with environmental response; thus, covering of the surface of the polyester fiber matrix with the particles can improve the hydrophilicity and hydrophobicity of the fiber andendows the fiber with certain environmental response. The preparation method comprises the following steps: preparing the polyester fiber matrix having reactive groups on the surface at first; then preparing the particles having reactive functional groups; and finally, mixing the polyester fiber matrix and the particles for a reaction so as to obtain the polyester composite fiber. The polyester composite fiber of the invention can be used for smart textiles, non-woven fabrics, porous films, composite materials and oil-water separators, preferably for smart textiles and oil-water separators.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

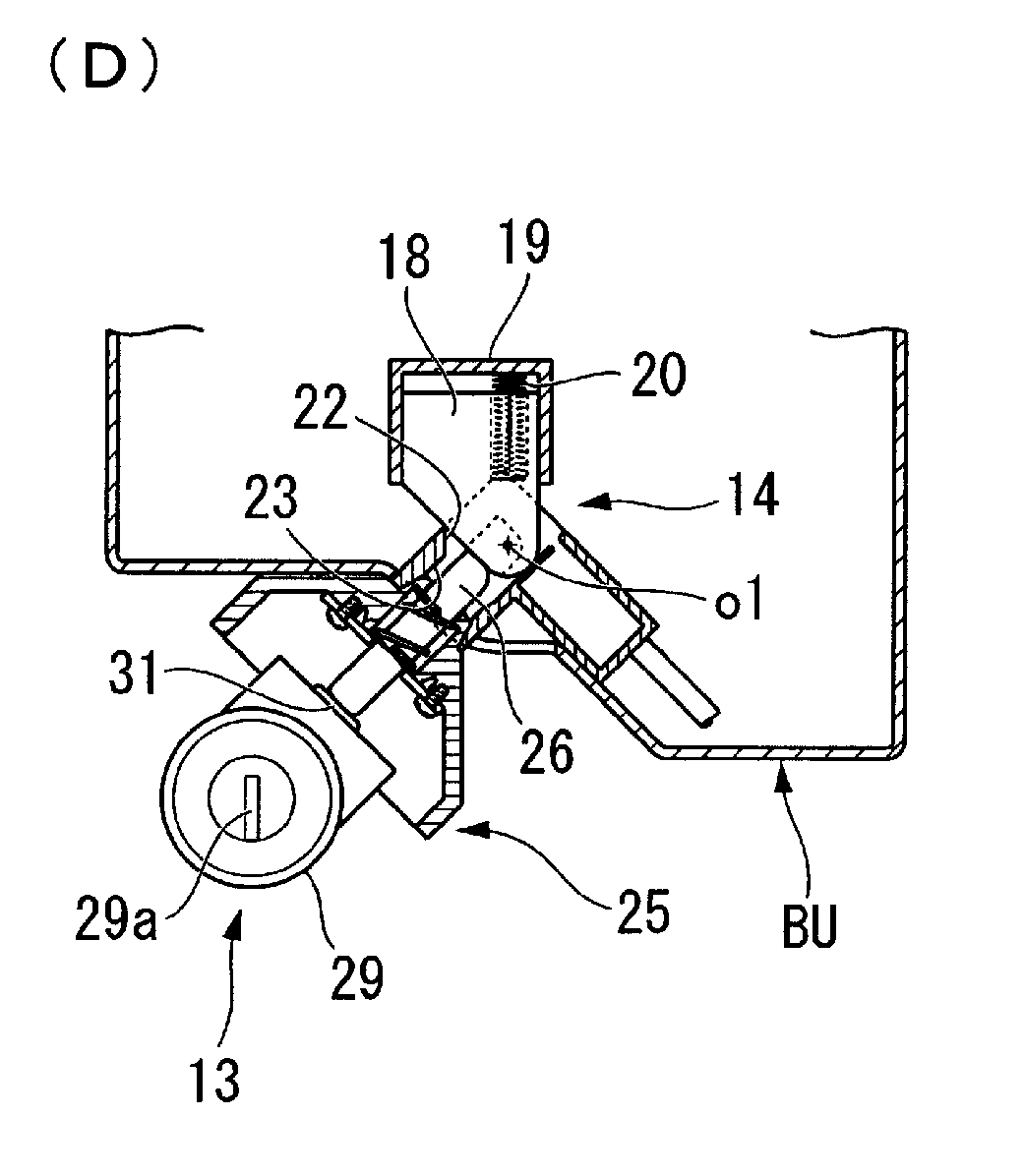

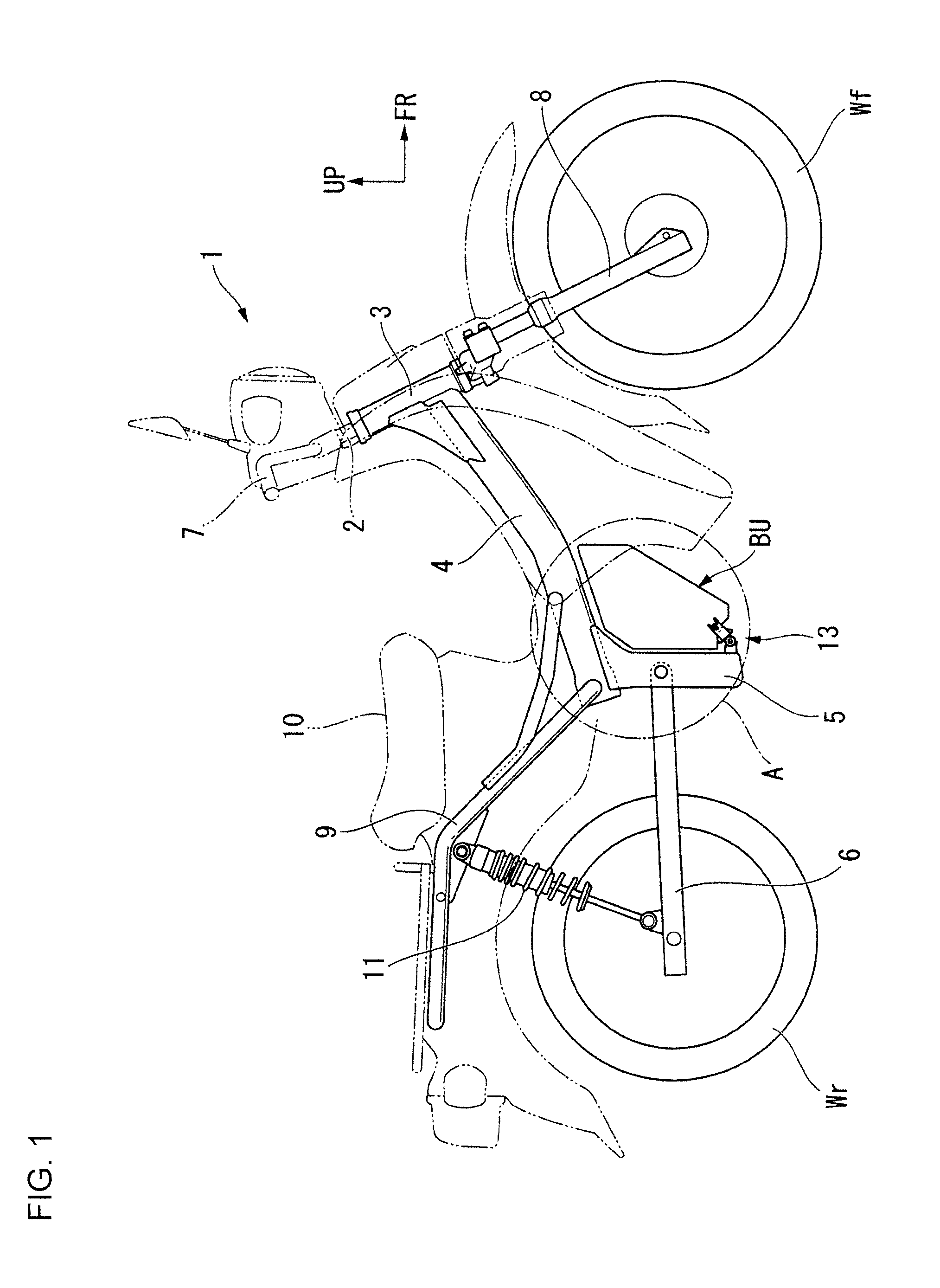

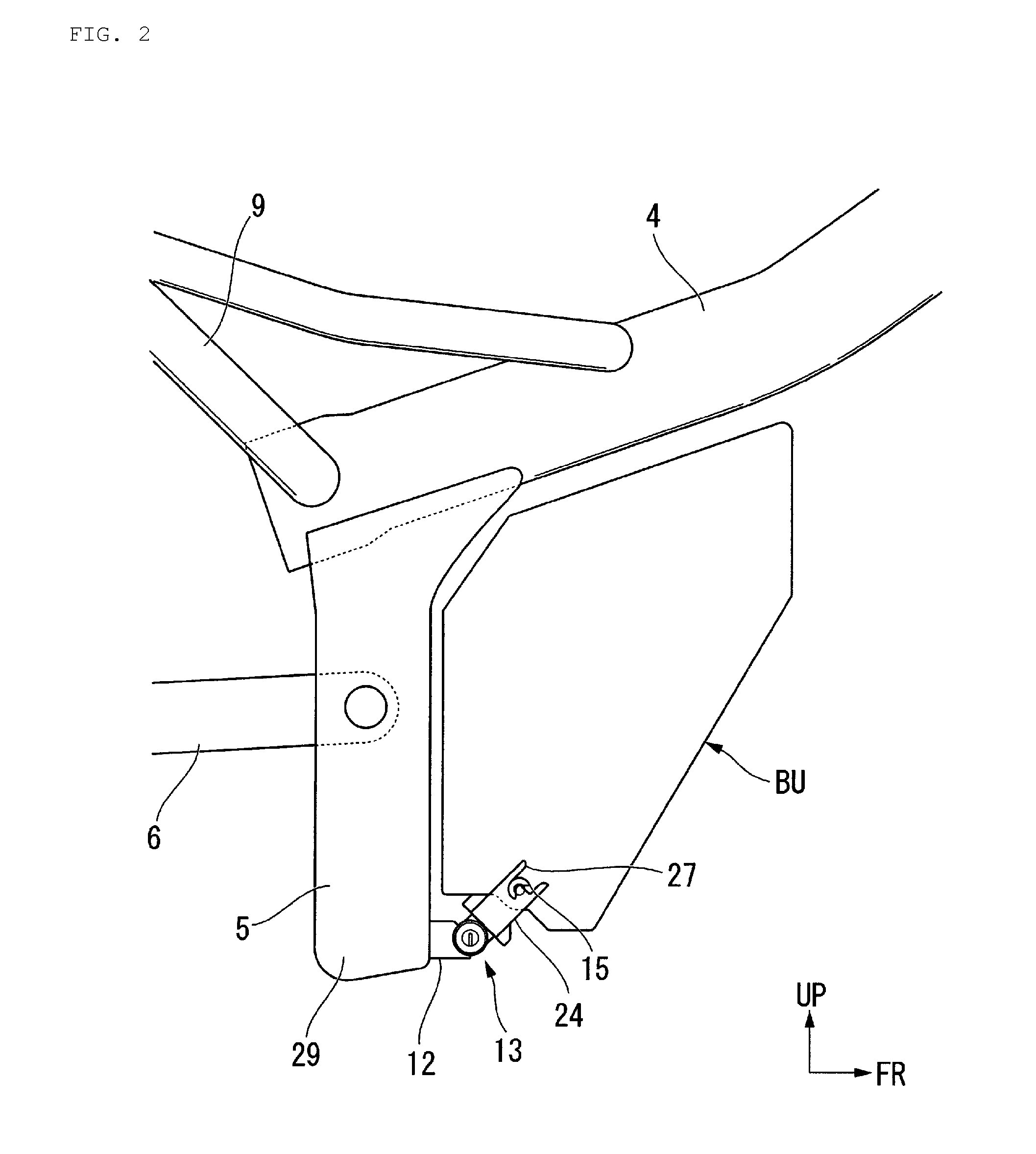

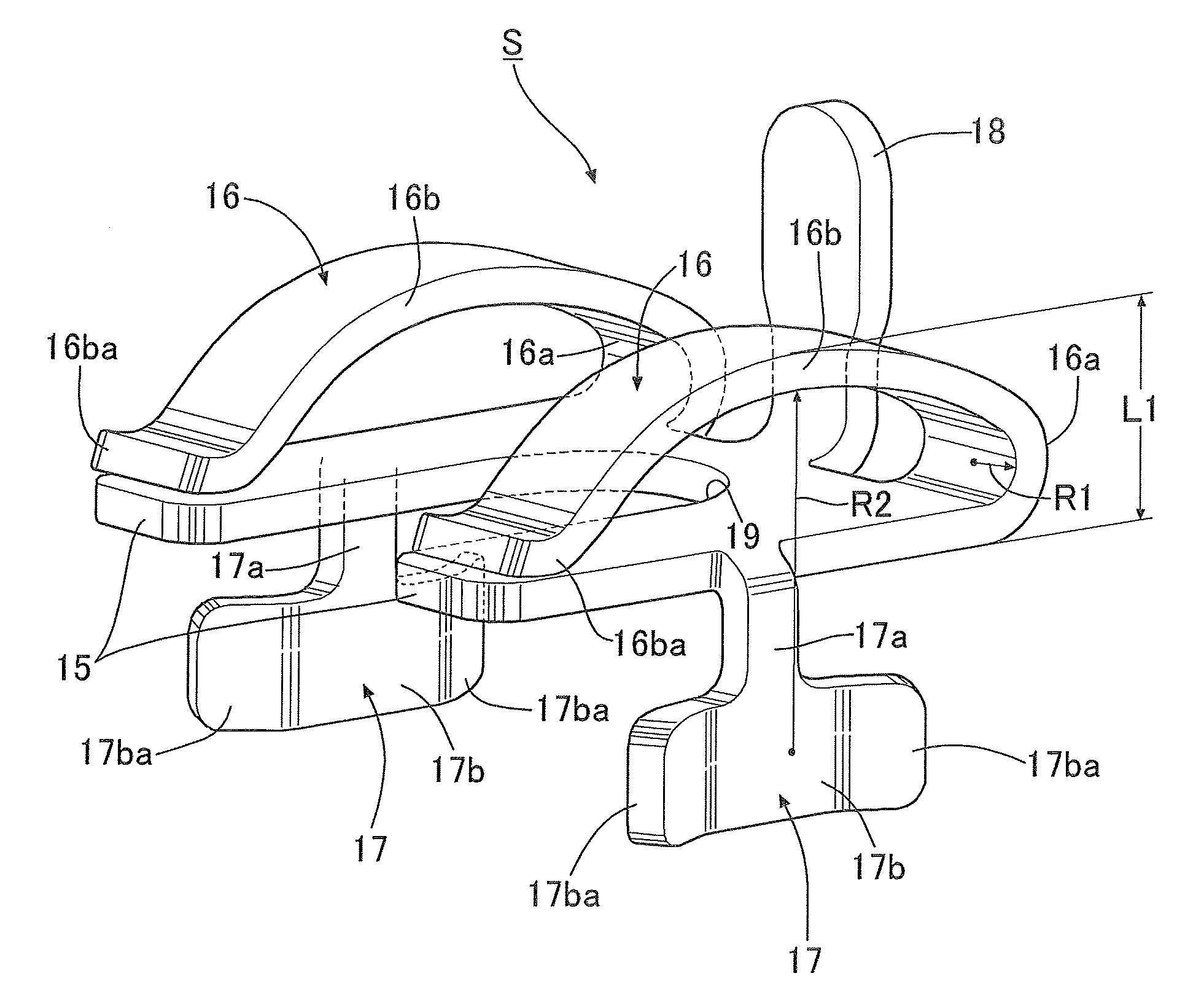

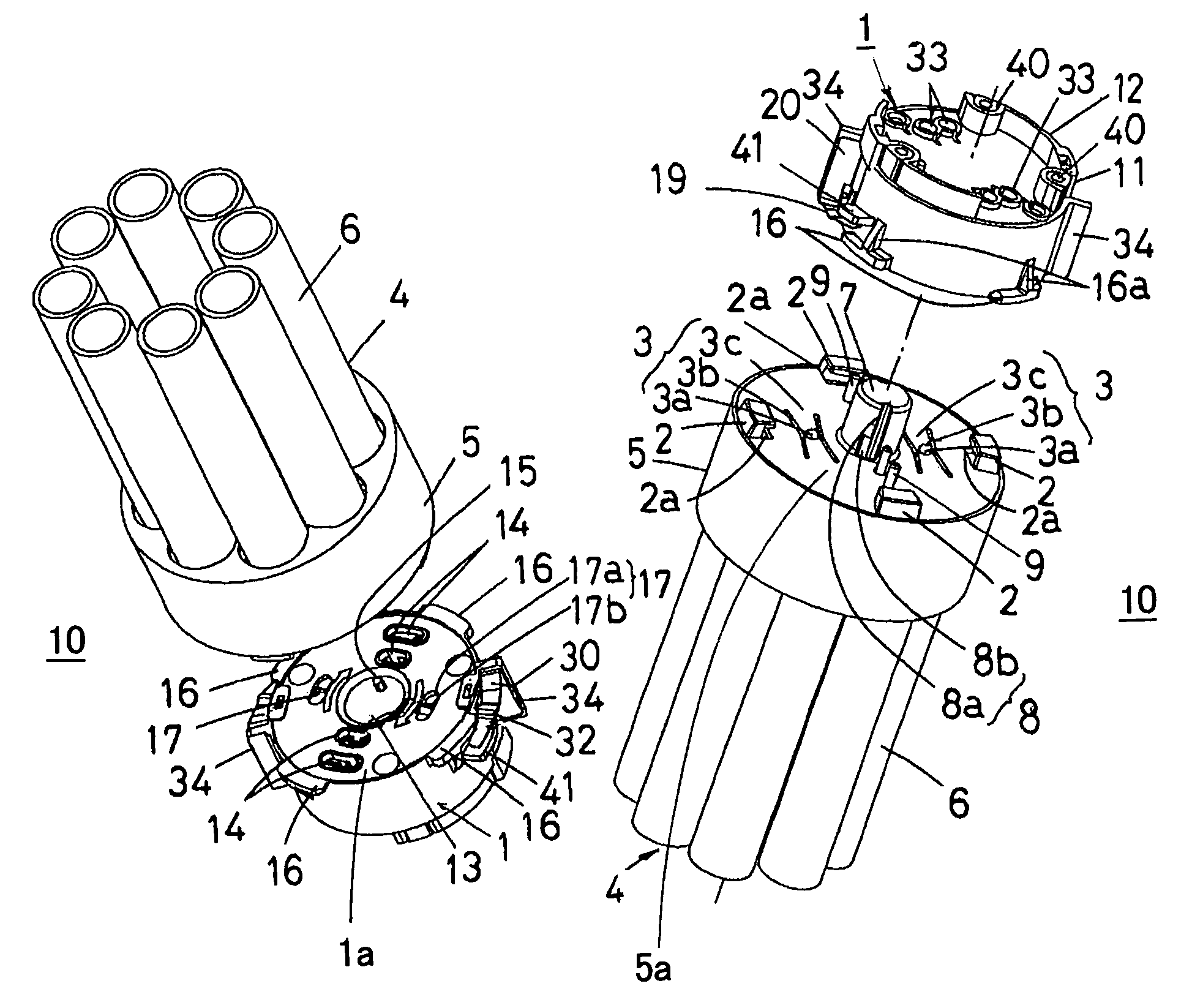

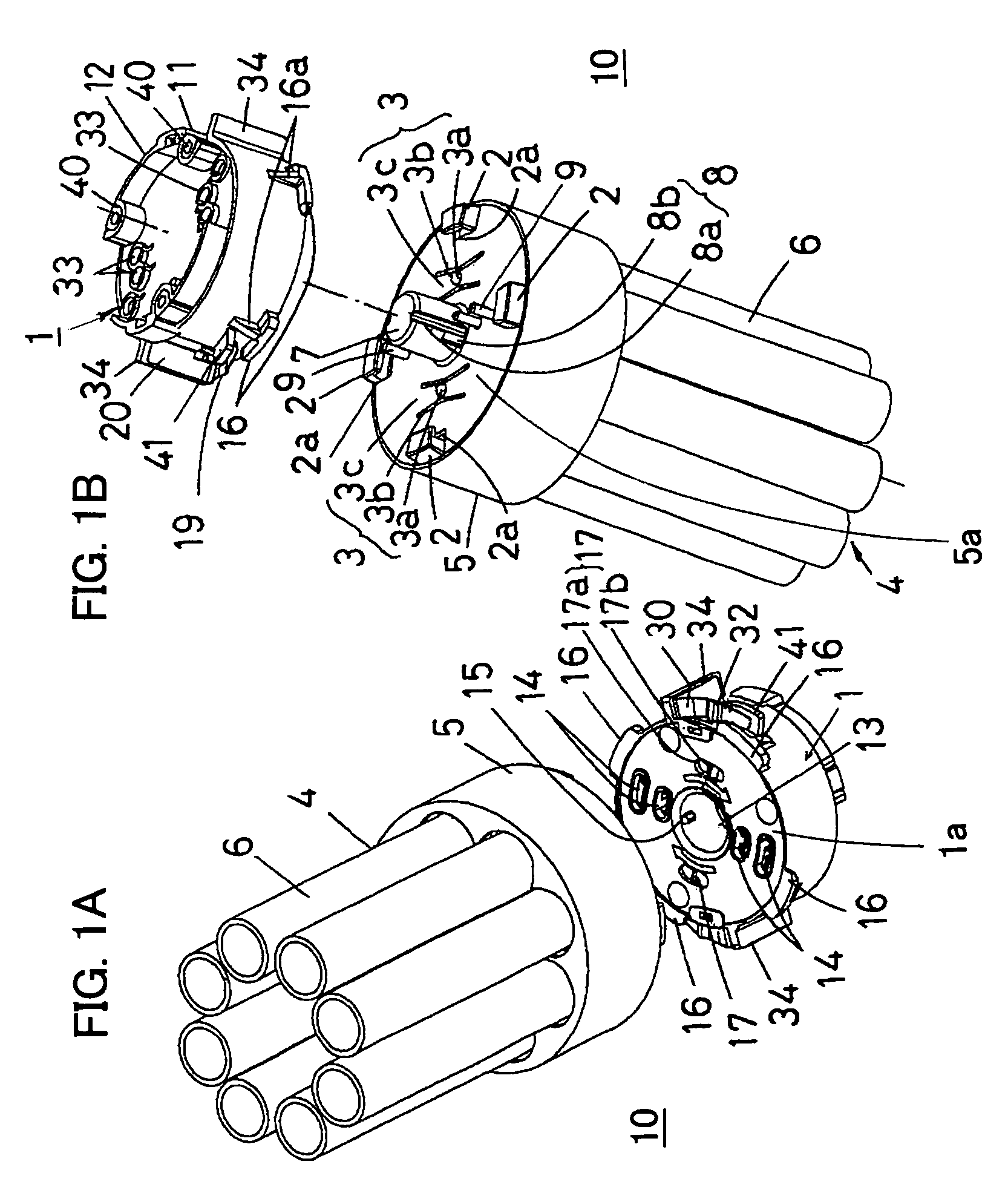

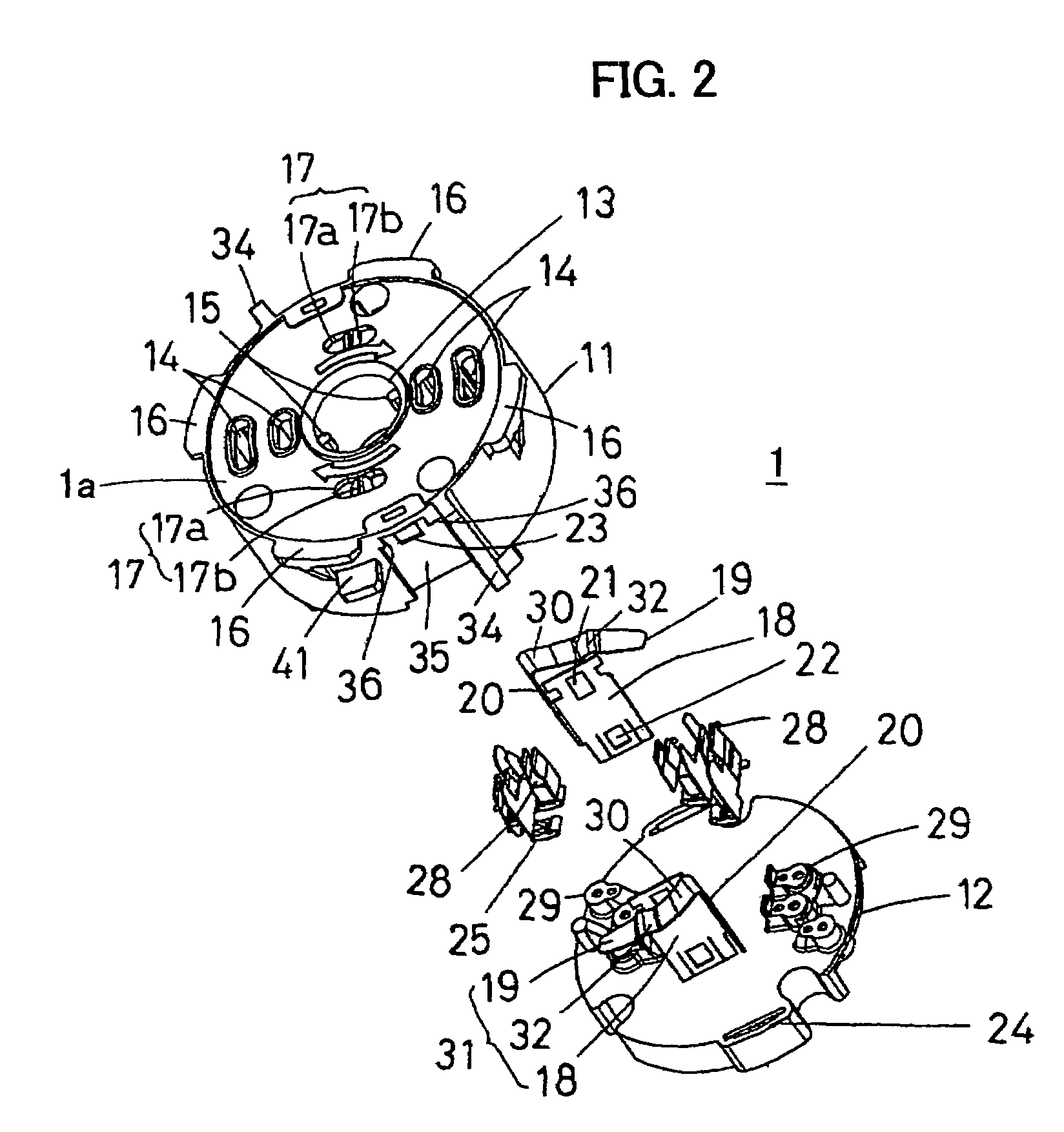

Battery unit connection structure of electric vehicle

InactiveUS20130280572A1Easy and accurate connectionImprove workabilityCharging stationsMotorised scootersEngineeringElectric vehicle

Owner:HONDA MOTOR CO LTD

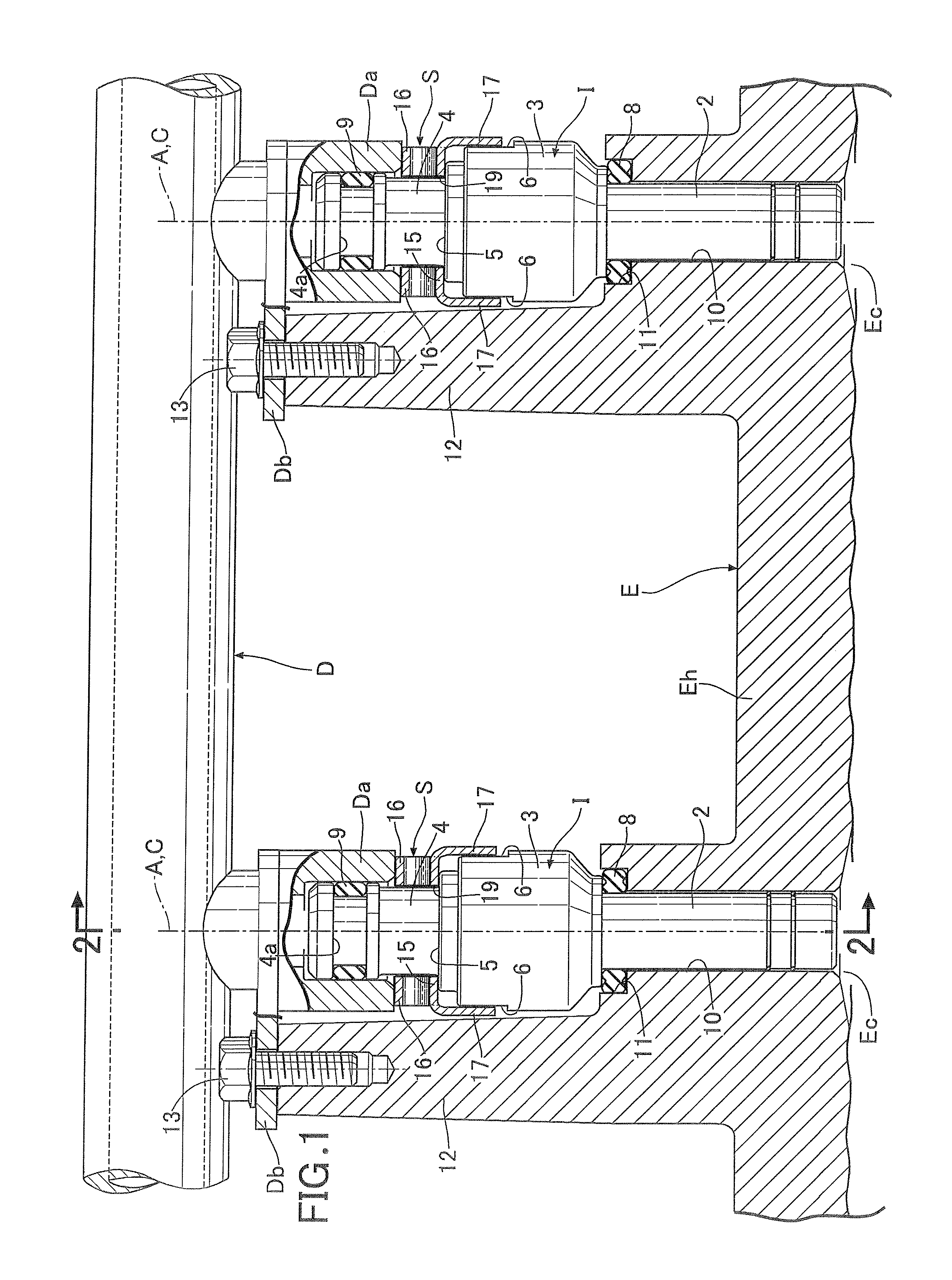

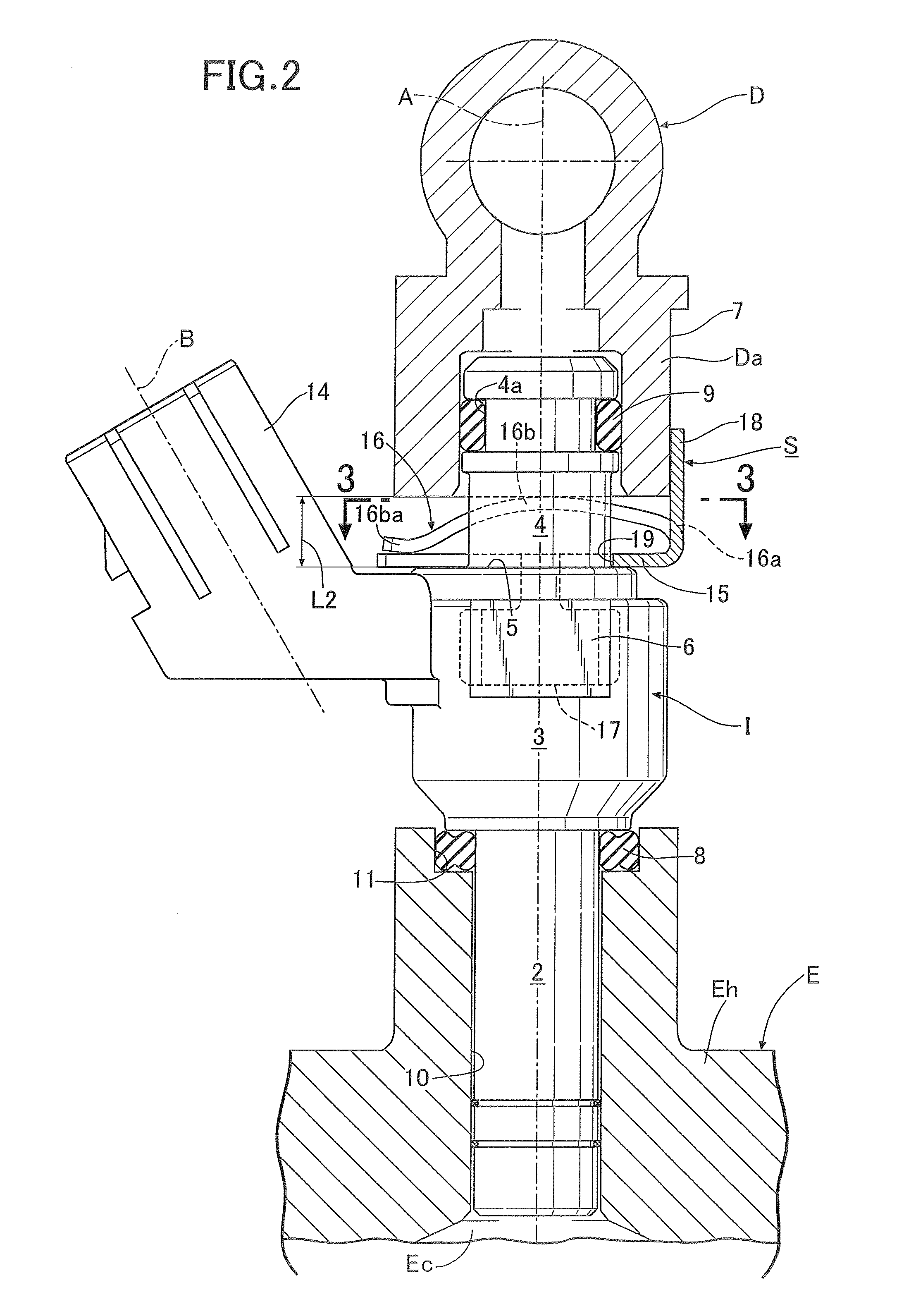

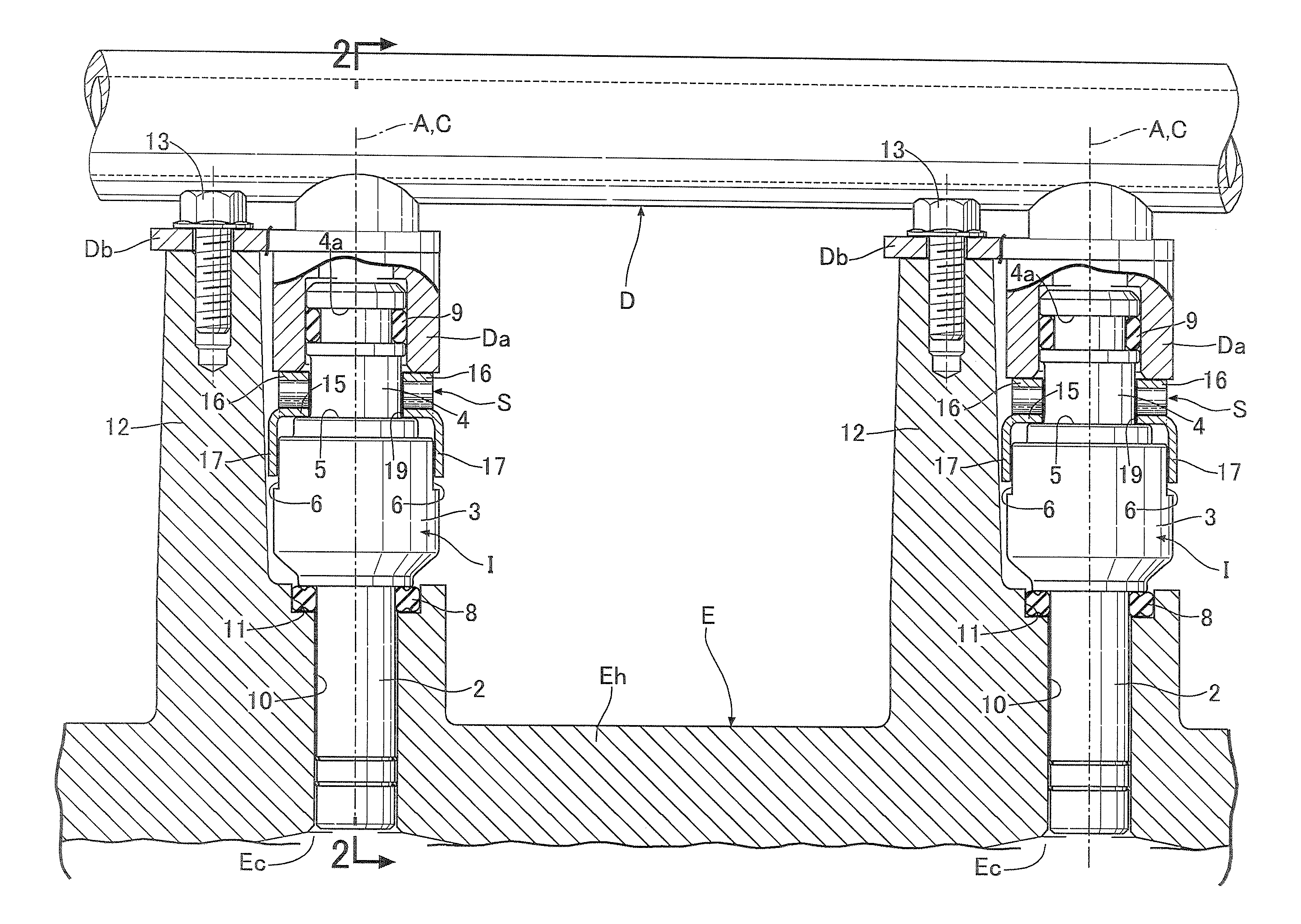

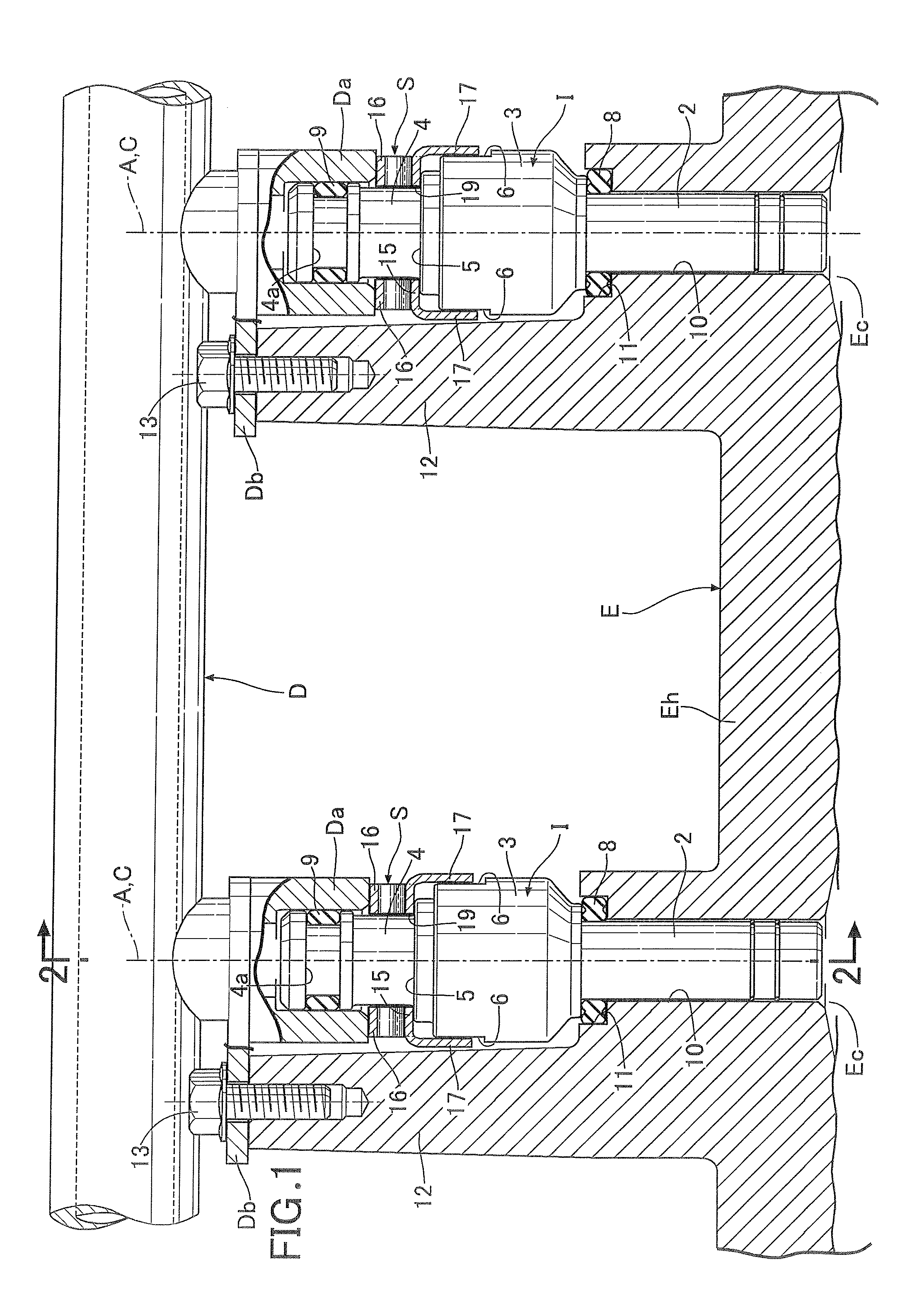

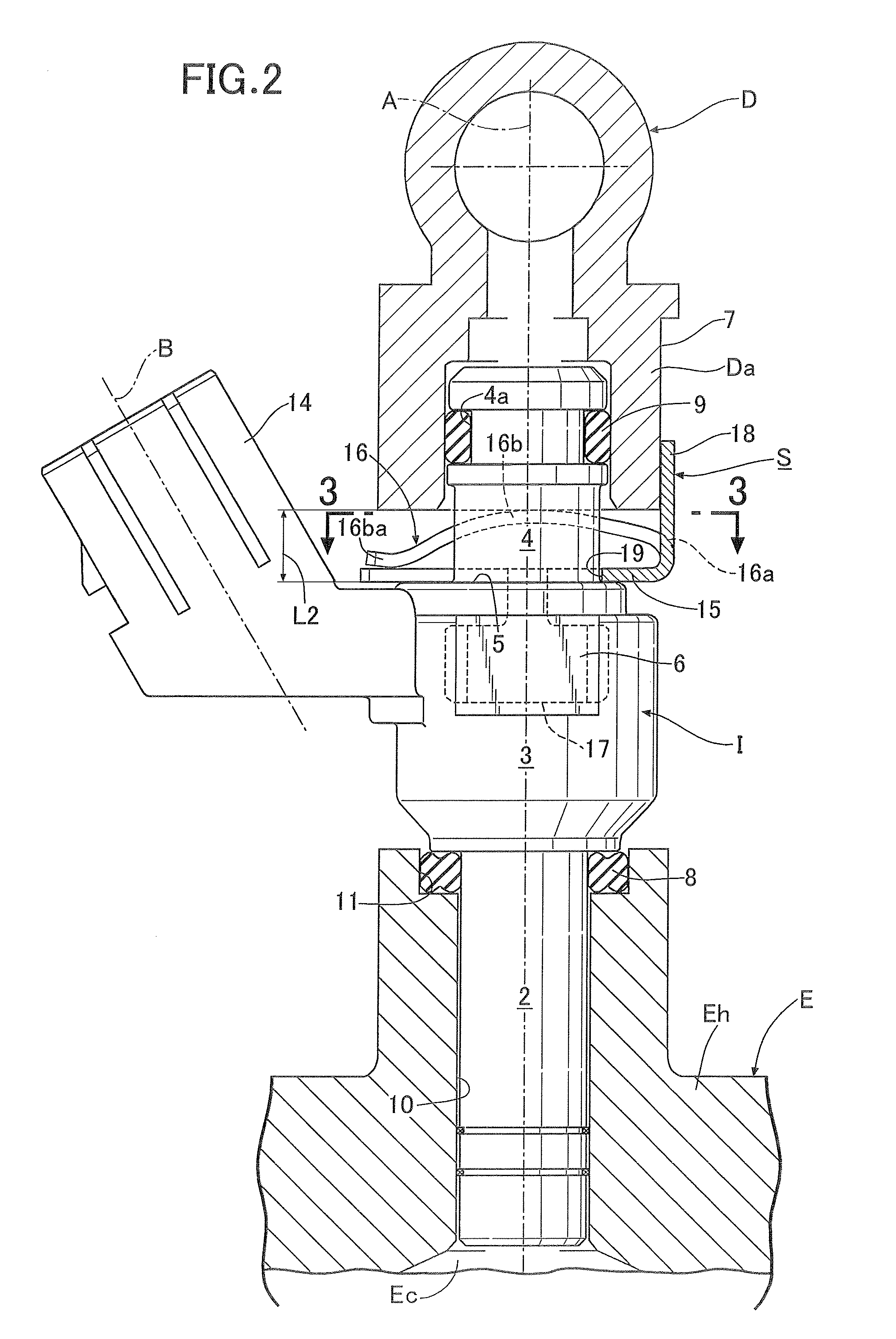

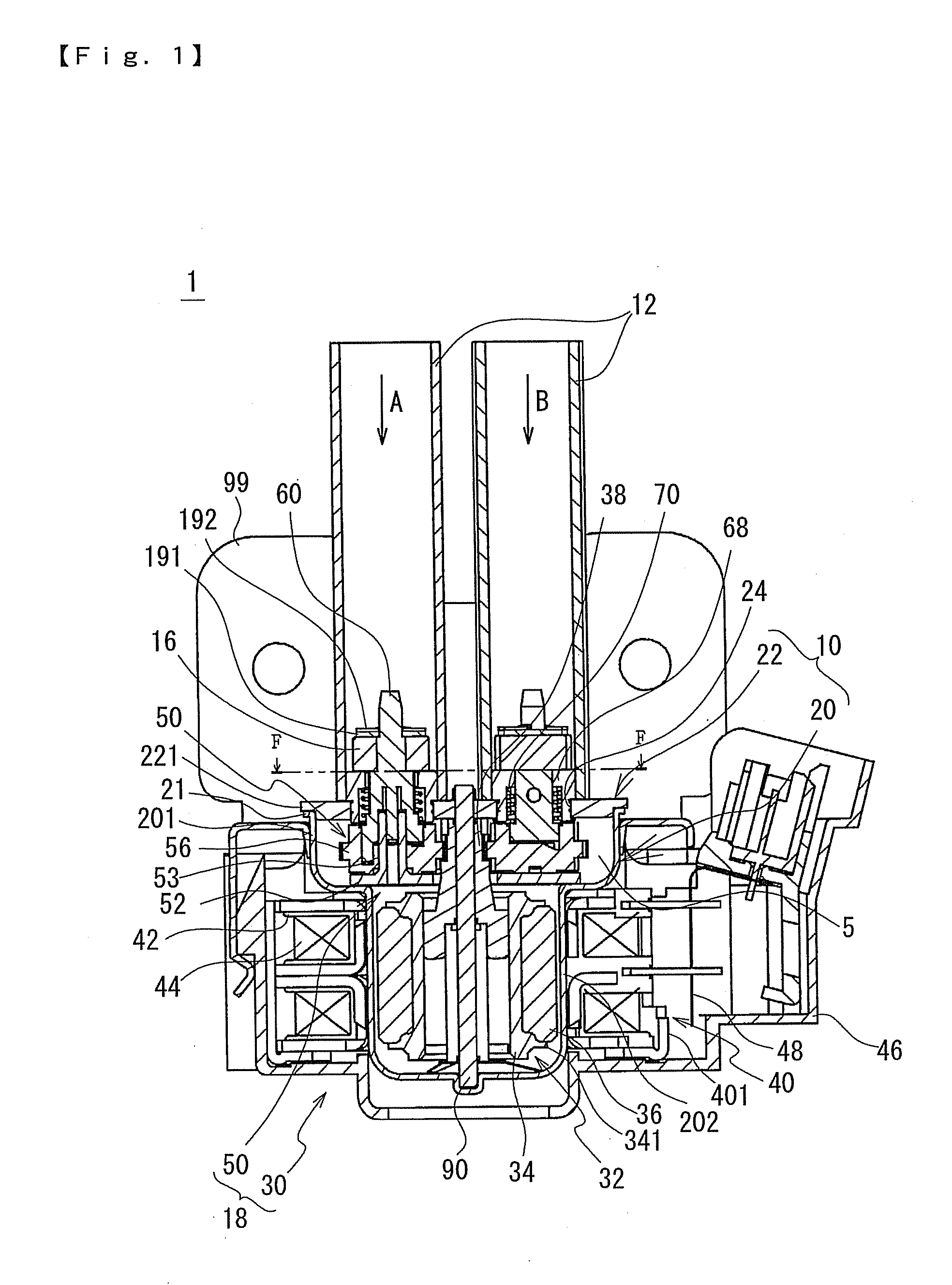

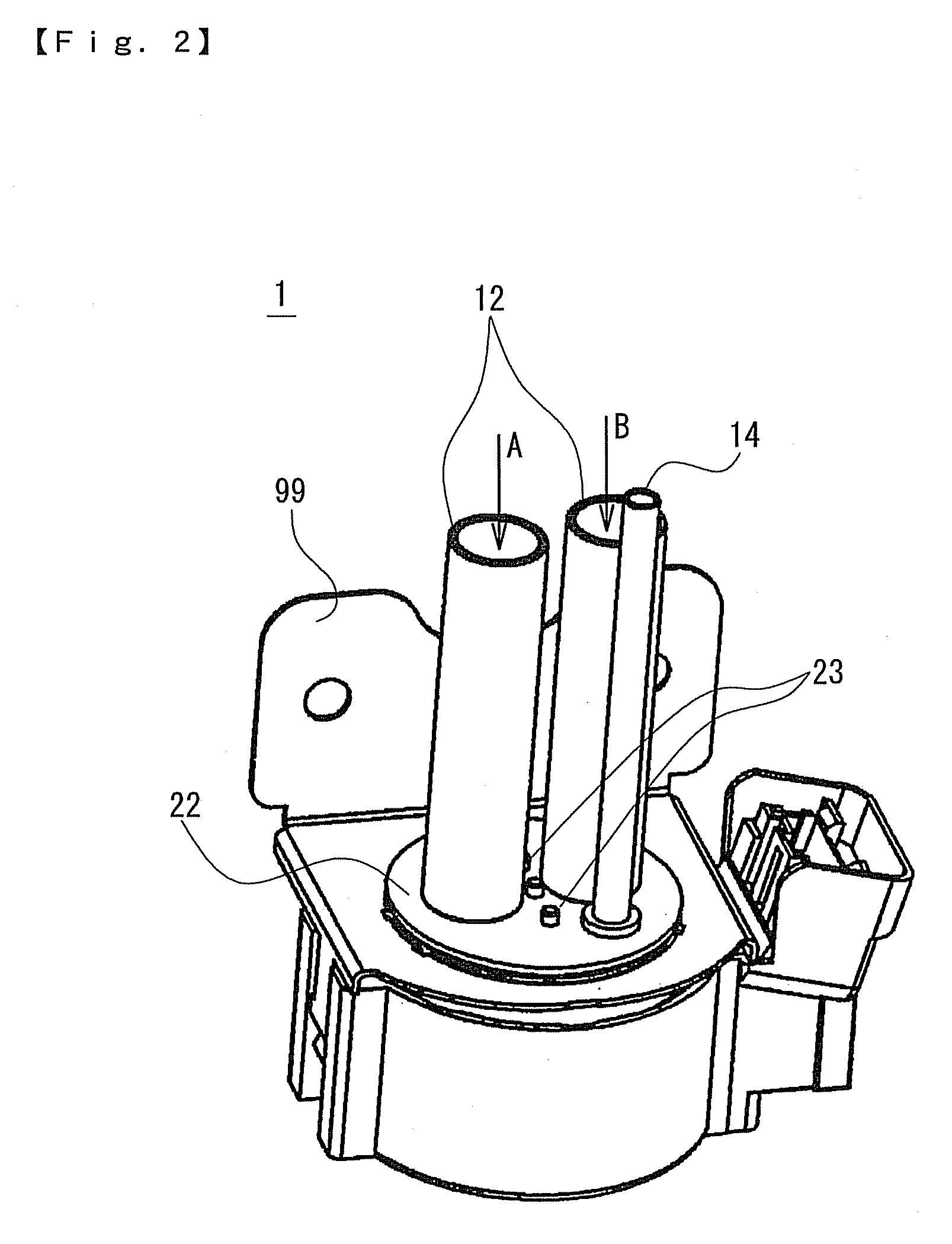

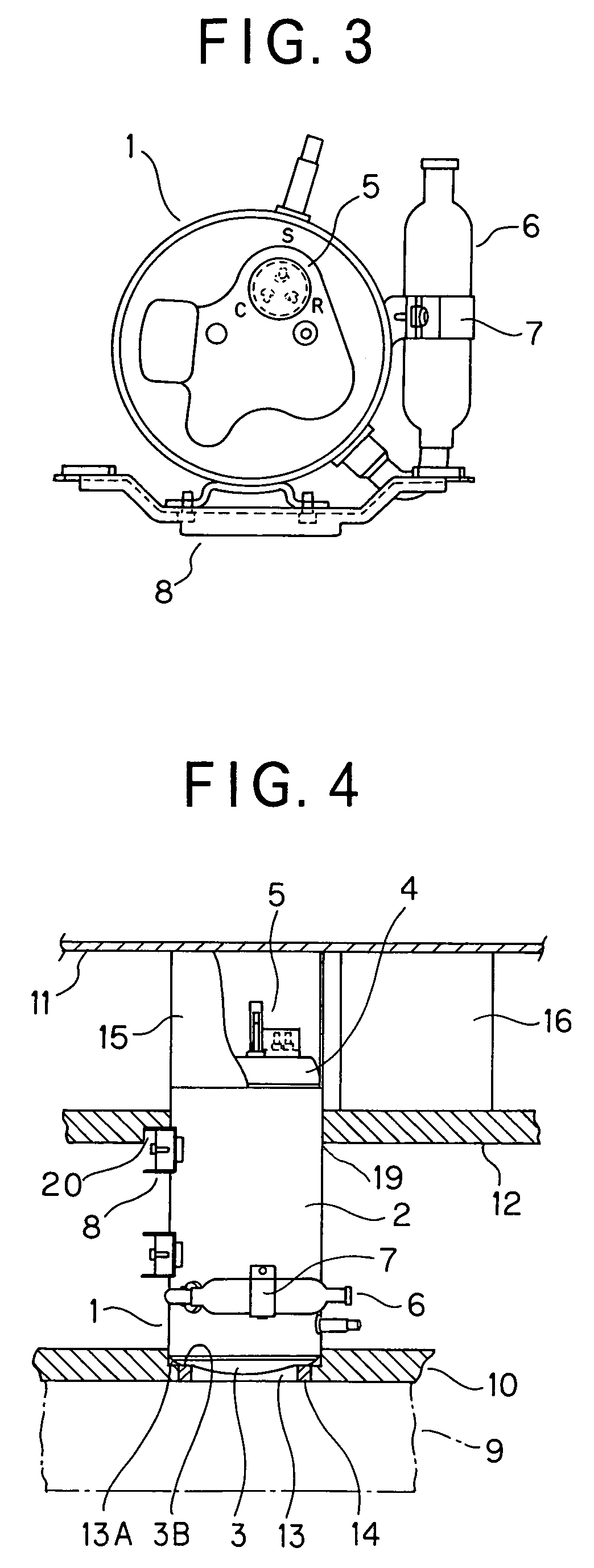

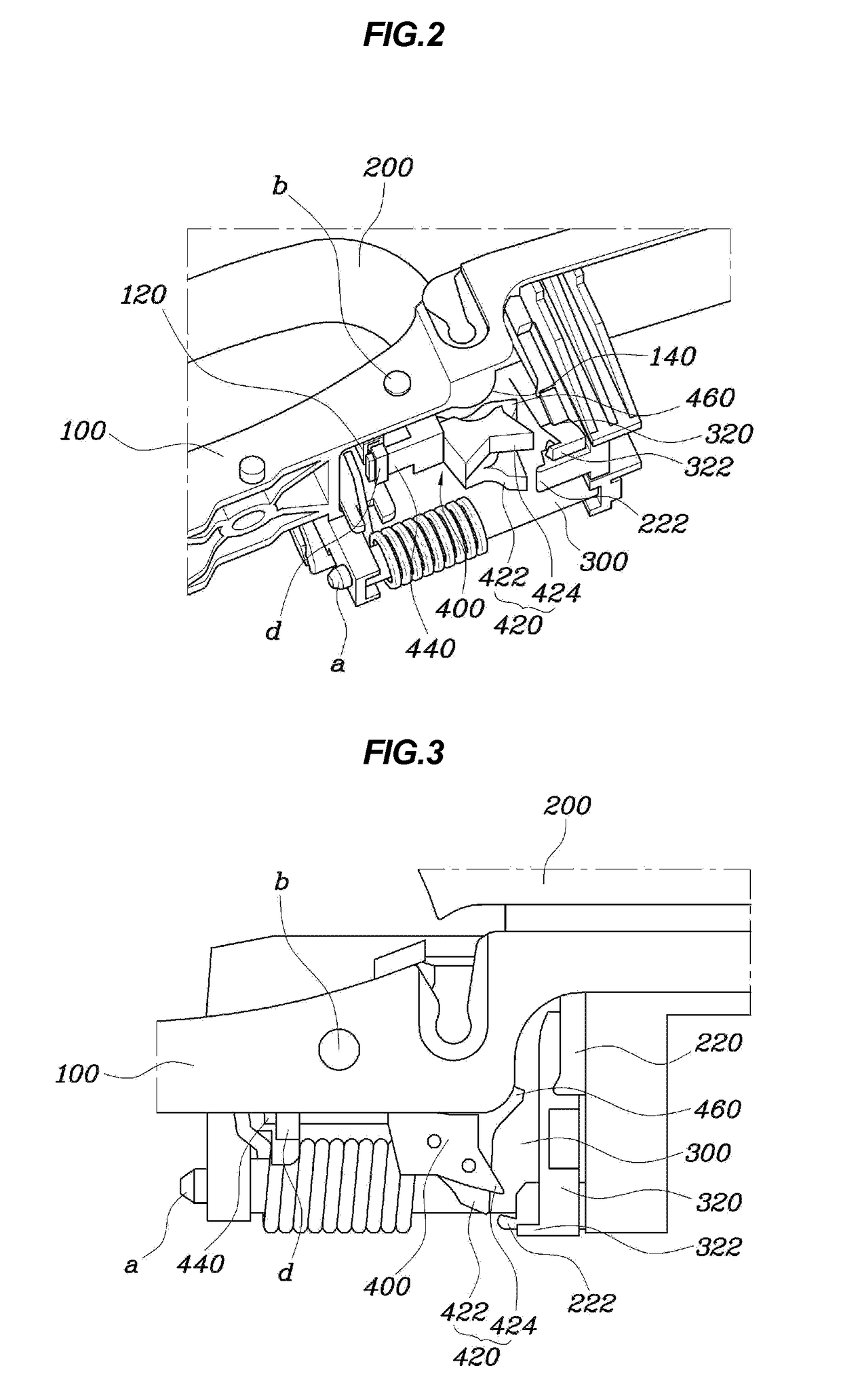

Fuel injection valve supporting structure

ActiveUS9032934B2Easily restricting turnTurn controlLow pressure fuel injectionMachines/enginesEngineeringFuel supply

In a fuel injection valve supporting structure, a first contact surface being orthogonal to a center axis of a fuel injection valve and opposed to a fuel supply cap and paired second contact surfaces opposed to each other with a plane, including the center axis and a center line of a coupler, in between are formed in an intermediate portion of the fuel injection valve, and a supporting member includes: a base plate set on the first contact surface; an elastic piece extending from the base plate to elastically come into pressure contact with the fuel supply cap and bias the fuel injection valve toward an injection valve attachment hole by its reaction force; and paired turn stopper pieces each extending from the base plate to abut against the second contact surface and restrict a turn of the fuel injection valve about the center axis.

Owner:HITACHI ASTEMO LTD

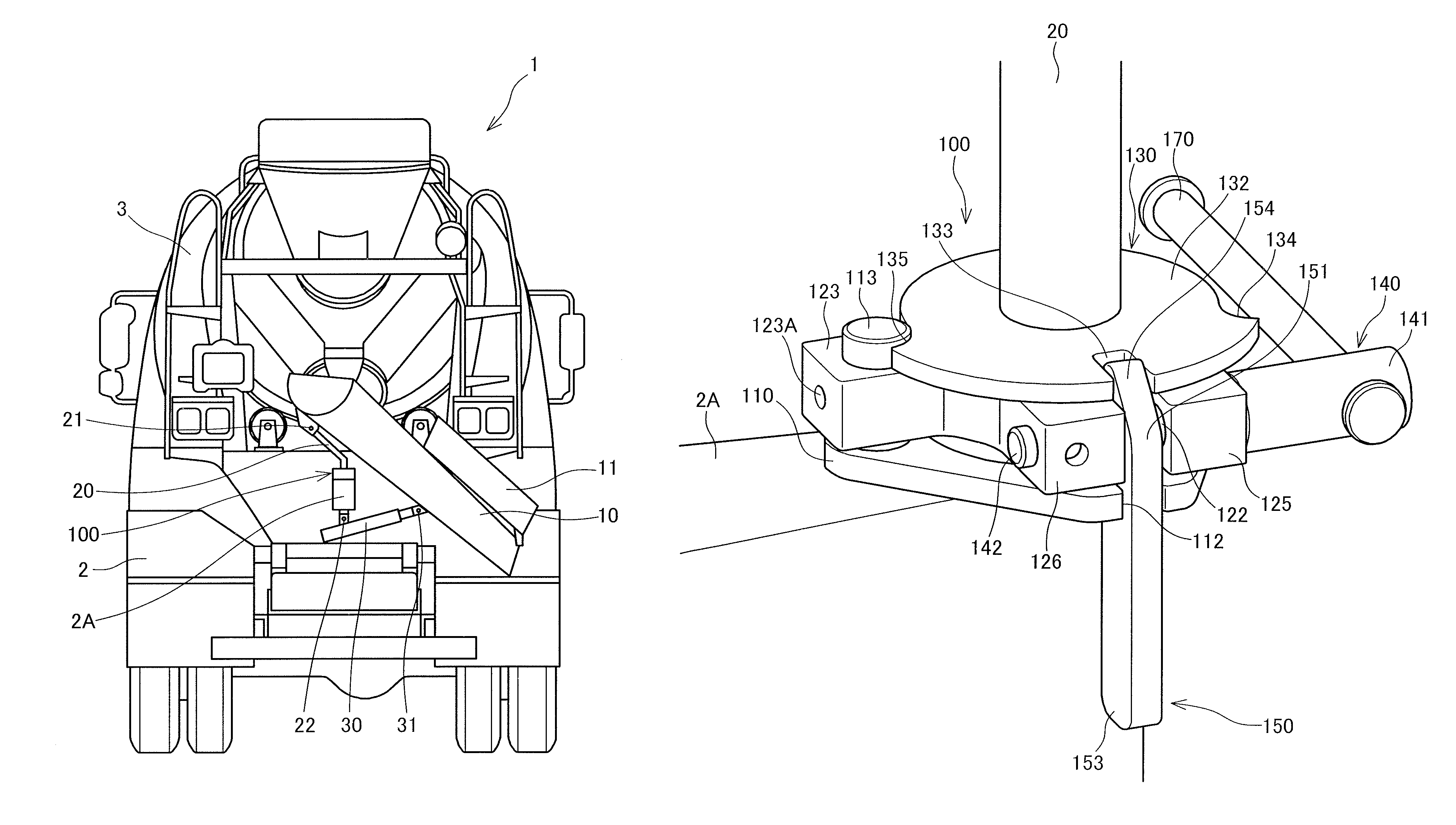

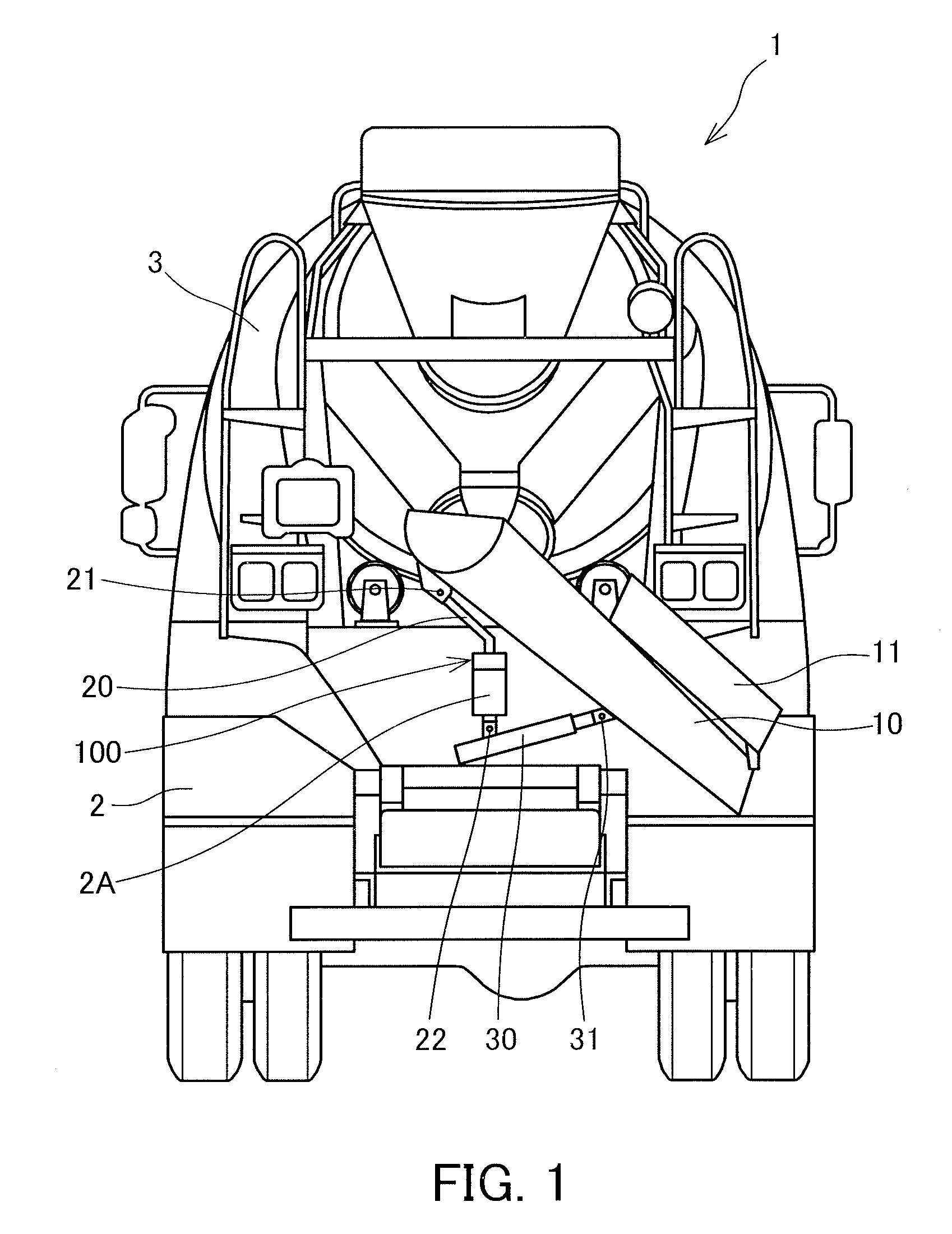

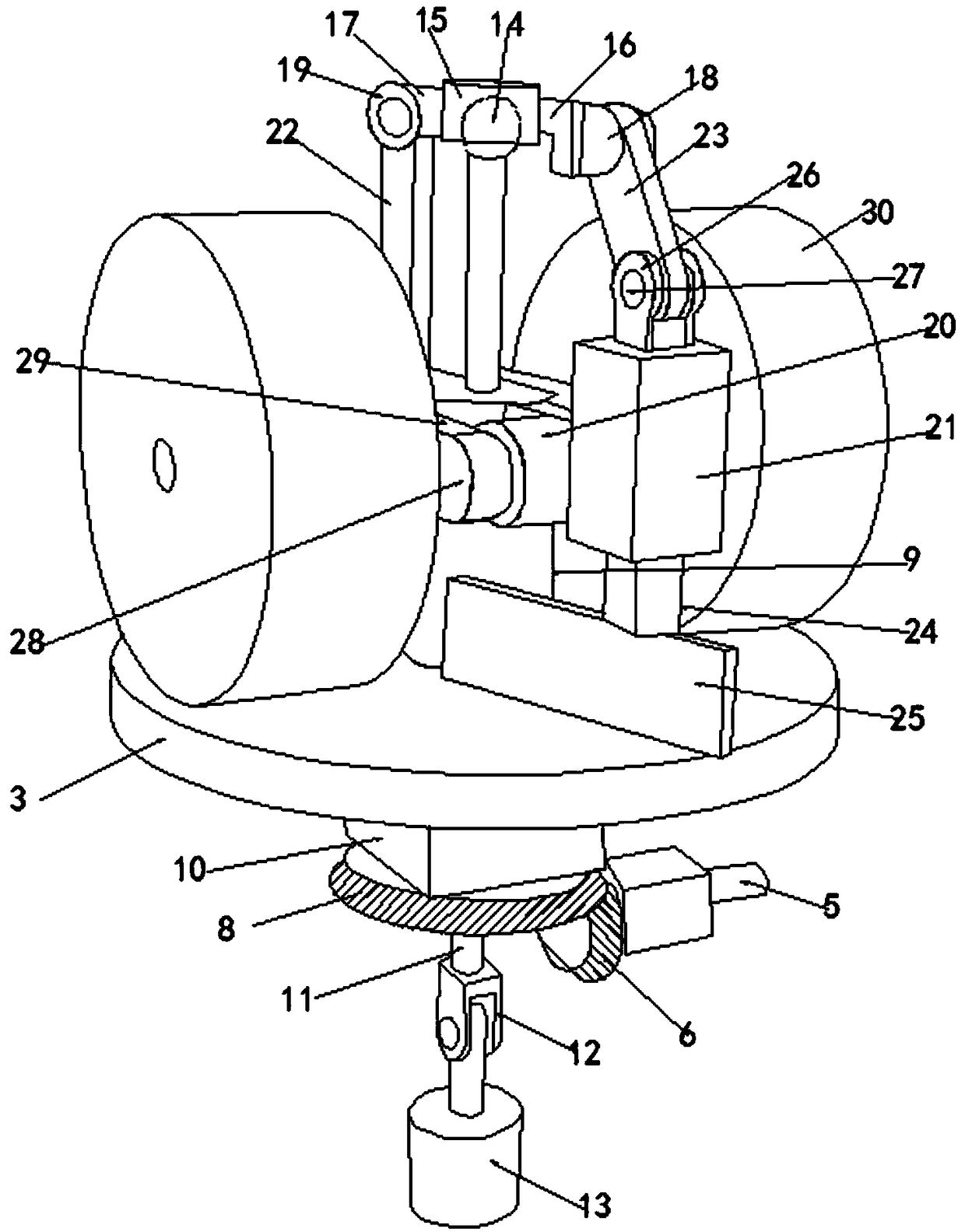

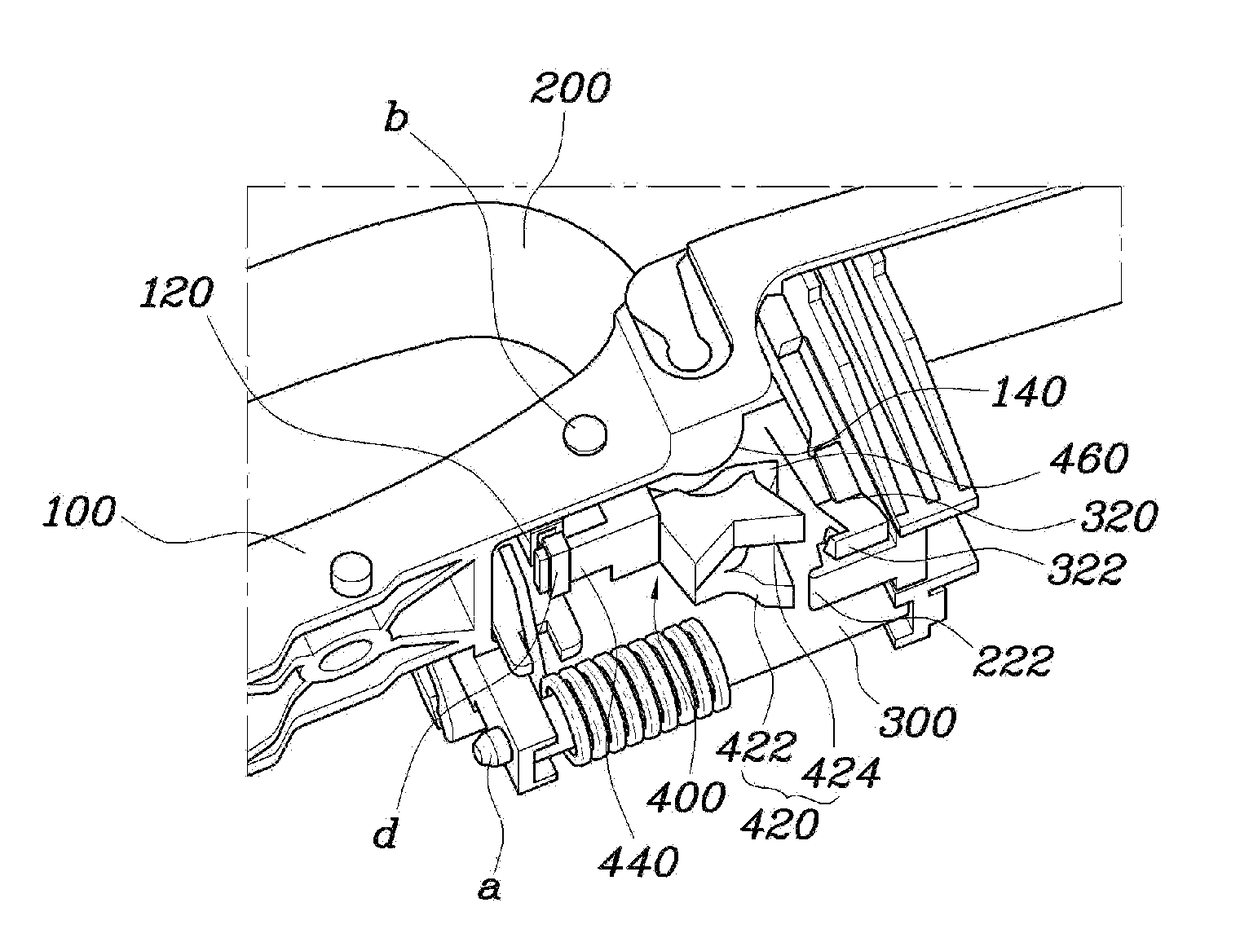

Chute turning restriction mechanism

InactiveUS8967358B2Simple configurationTurn controlConcrete transportationSupporting framesEngineeringTruck

A chute turning restriction mechanism includes: a rotary shaft on which a chute is disposed and which is provided to be capable of rotating relative to a vehicle body of a mixer truck; a bracket that is provided on the vehicle body and includes an insertion hole into which the rotary shaft is inserted and a cutaway portion formed by cutting away a part of the insertion hole; an inner diameter adjustment shaft provided across the cutaway portion to be capable of adjusting an inner diameter of the insertion hole, and configured to restrict rotation of the rotary shaft by reducing the inner diameter of the insertion hole; a rotary body that is provided to rotate together with the rotary shaft and includes an engagement groove; and a lock lever that is provided to be capable of rotating about the inner diameter adjustment shaft, and that restricts the rotation of the rotary shaft by engaging with the engagement groove.

Owner:KYB CORP

Fuel injection valve supporting structure

ActiveUS20130220276A1Easily restricting turnTurn controlLow-pressure fuel injectionMachines/enginesEngineeringFuel supply

In a fuel injection valve supporting structure, a first contact surface being orthogonal to a center axis of a fuel injection valve and opposed to a fuel supply cap and paired second contact surfaces opposed to each other with a plane, including the center axis and a center line of a coupler, in between are formed in an intermediate portion of the fuel injection valve, and a supporting member includes: a base plate set on the first contact surface; an elastic piece extending from the base plate to elastically come into pressure contact with the fuel supply cap and bias the fuel injection valve toward an injection valve attachment hole by its reaction force; and paired turn stopper pieces each extending from the base plate to abut against the second contact surface and restrict a turn of the fuel injection valve about the center axis.

Owner:HITACHI ASTEMO LTD

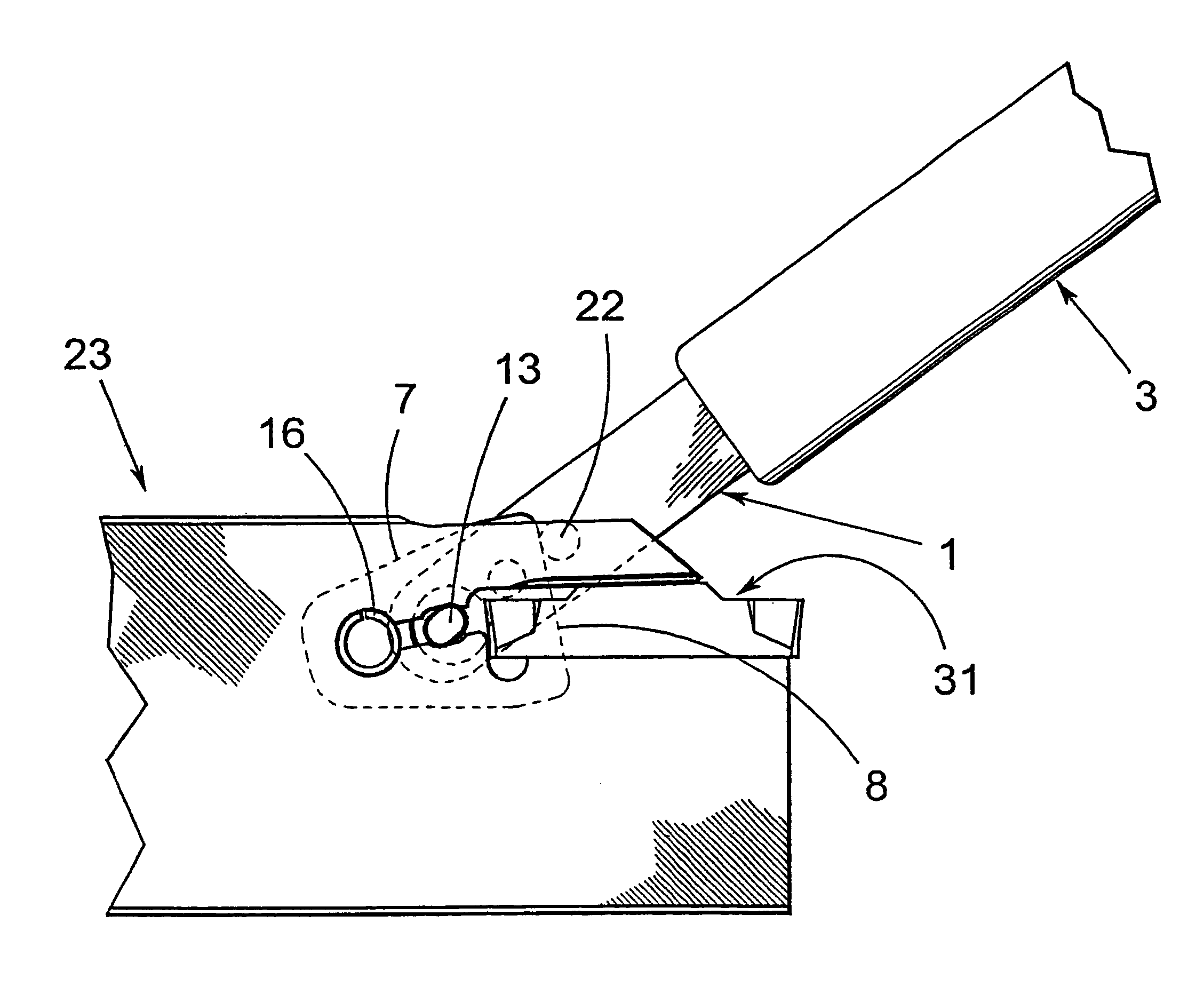

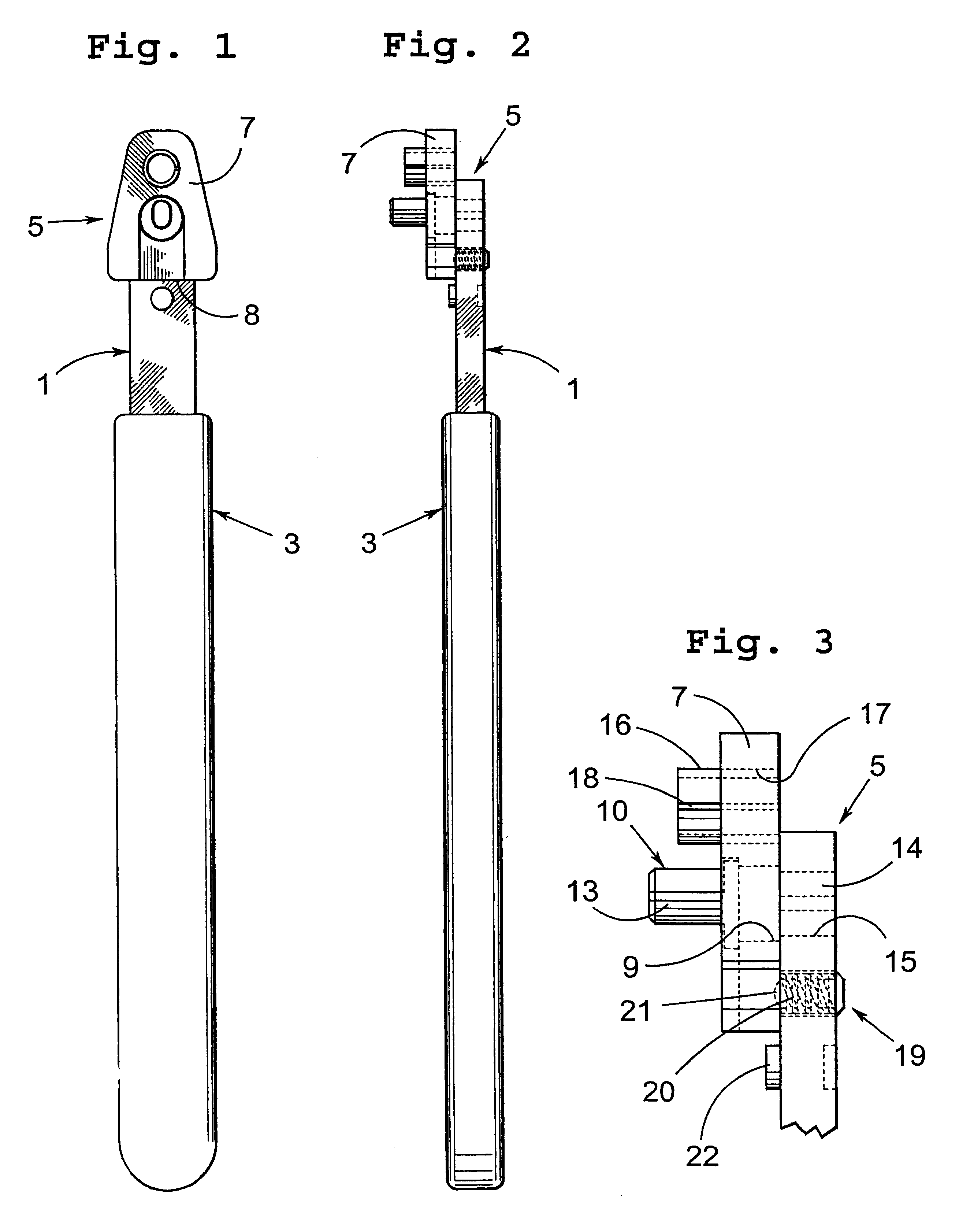

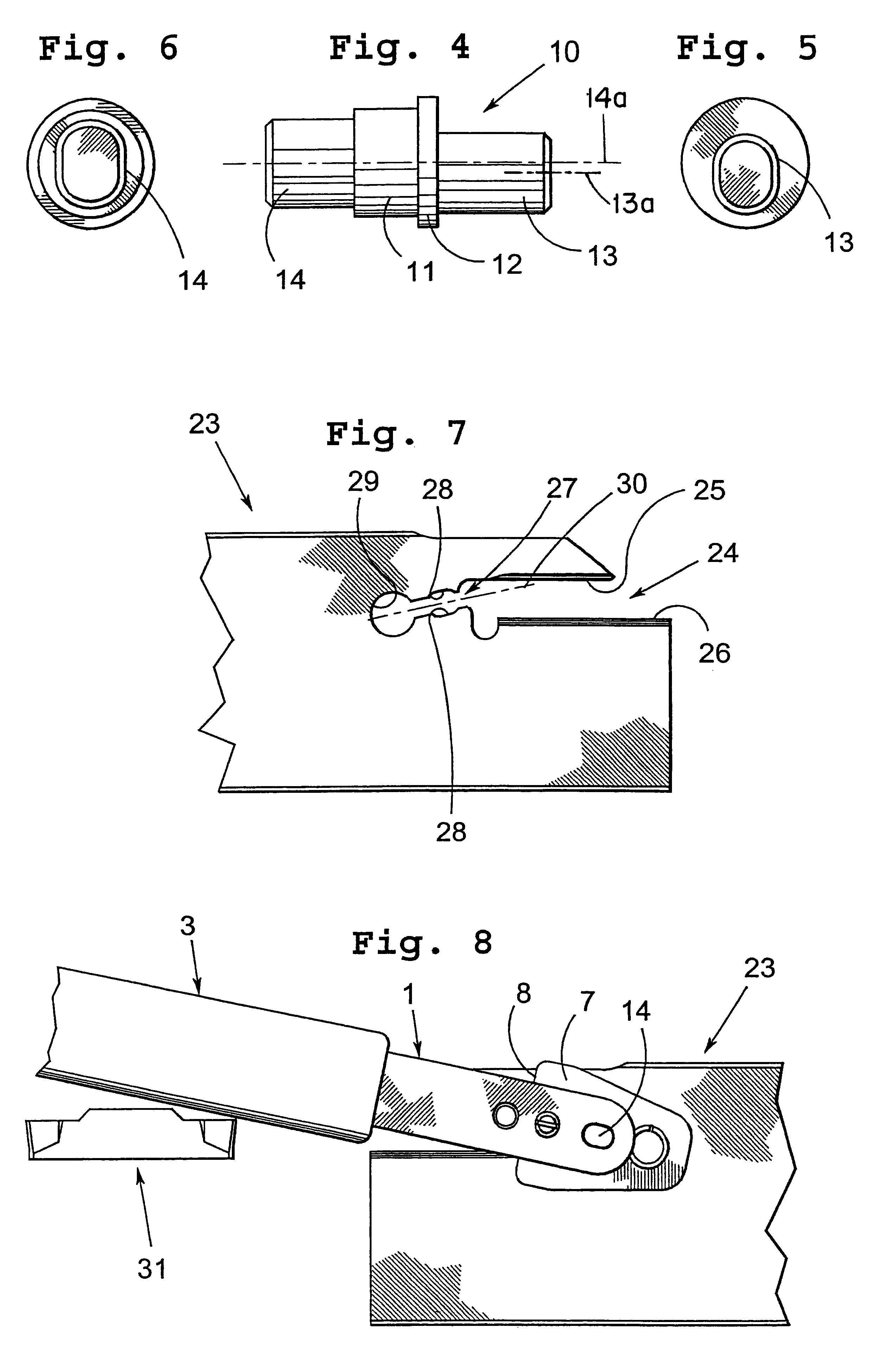

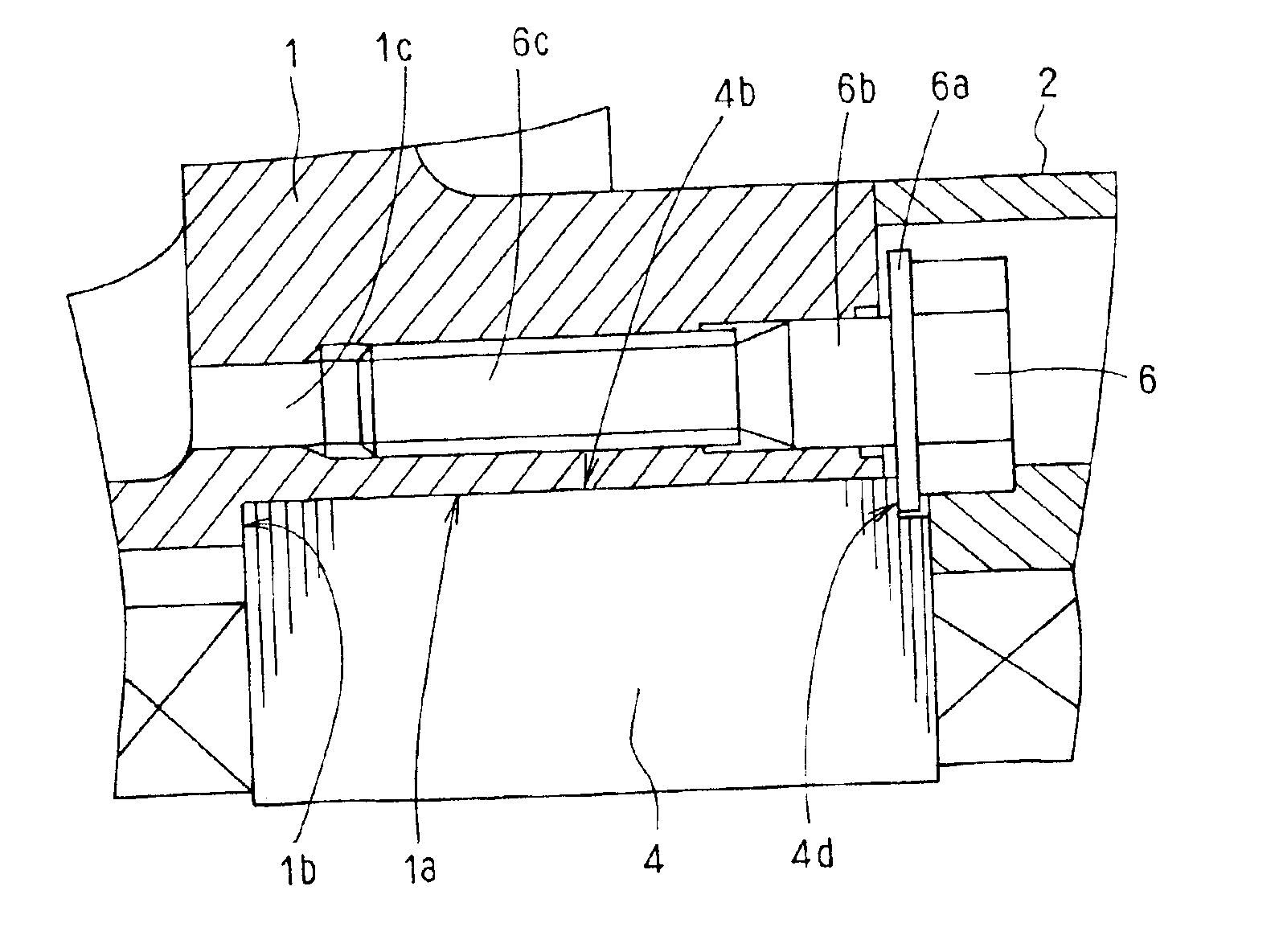

Key for widening an insert seat of a holder

InactiveUS6572309B2Turn controlForce is smallAuxillary equipmentCutting insertsEngineeringMutual engagement

A holder includes a seat which removably carries a cutting insert for chip removing machining. The seat can be widened by the manual application of a force to enable the insert to be replaced. The force is applied by a manually actuable key which includes a shaft and an expansion mechanism mounted on an end of the shaft. The expansion mechanism includes a plate which is mountable to the holder in a manner enabling a projection pin of the shaft to enter a slot which constitutes an extension of the insert seat. The portion of the pin entering the slot has an out-of-round cross sectional shape. By rotating the shaft relative to the plate, the pin rotates to widen the slot, and thus to widen the seat. Rotation of the shaft relative to the plate is terminated after a predetermined amount of rotation, in response to mutual engagement between stop surfaces disposed on the shaft and the plate, respectively.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

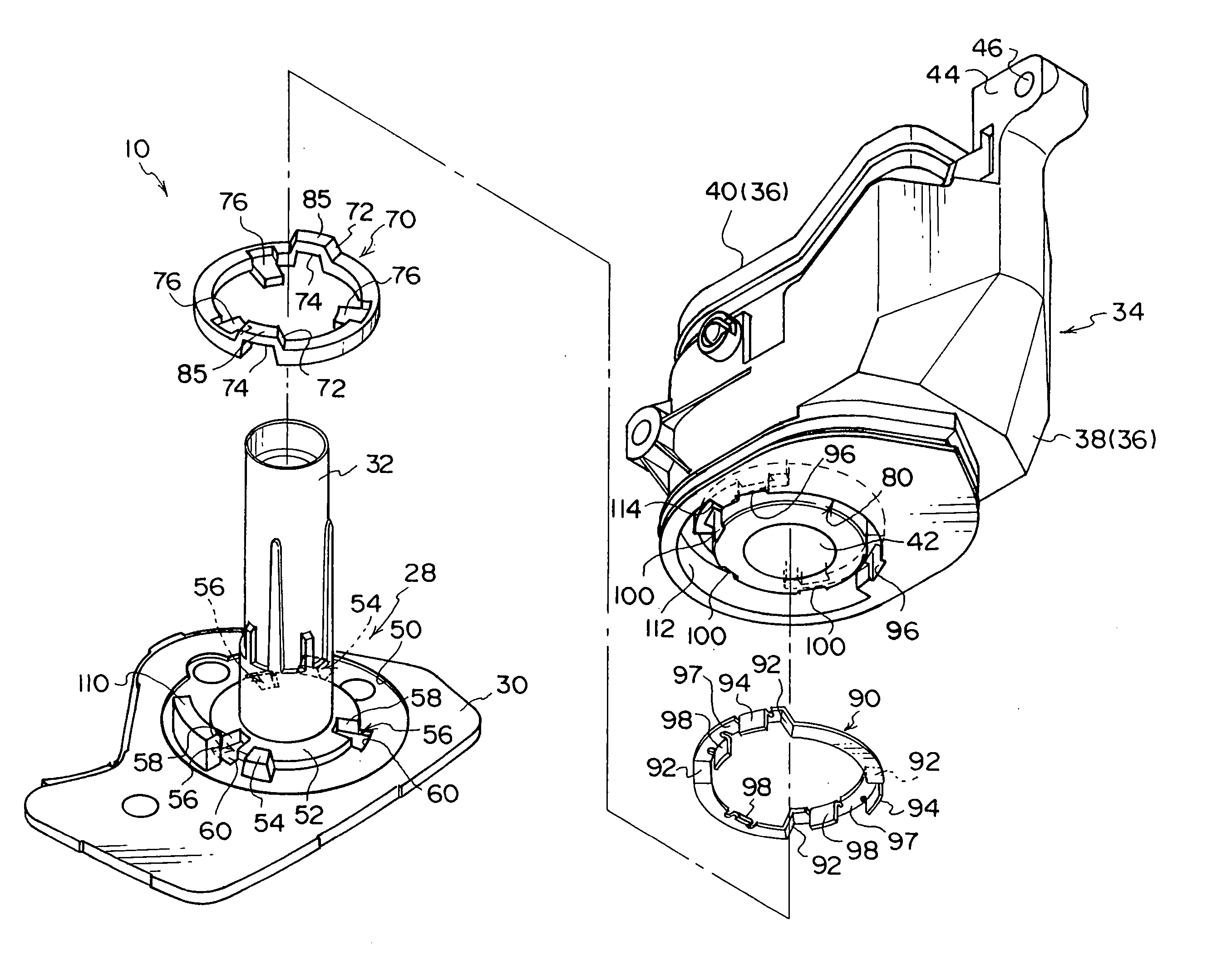

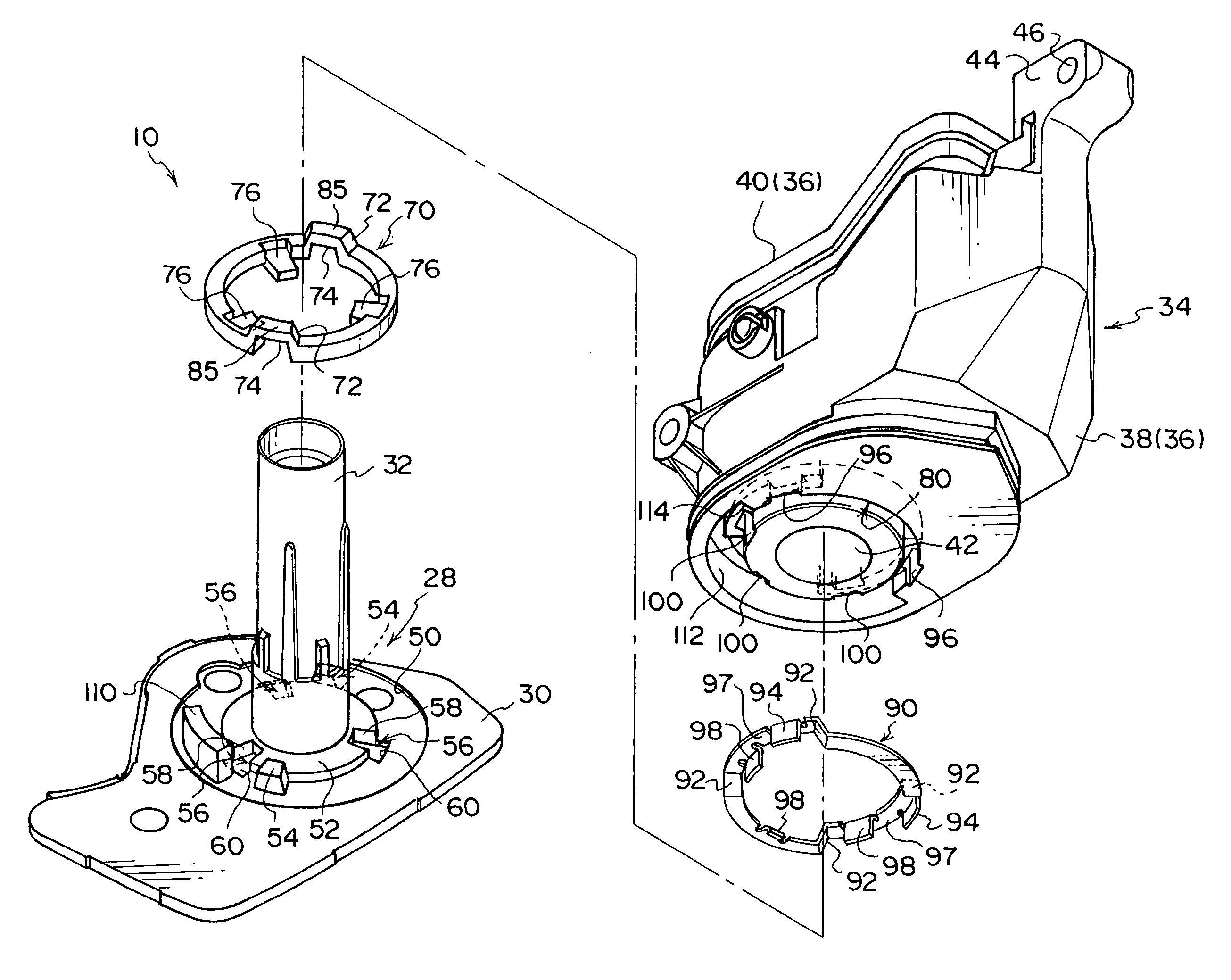

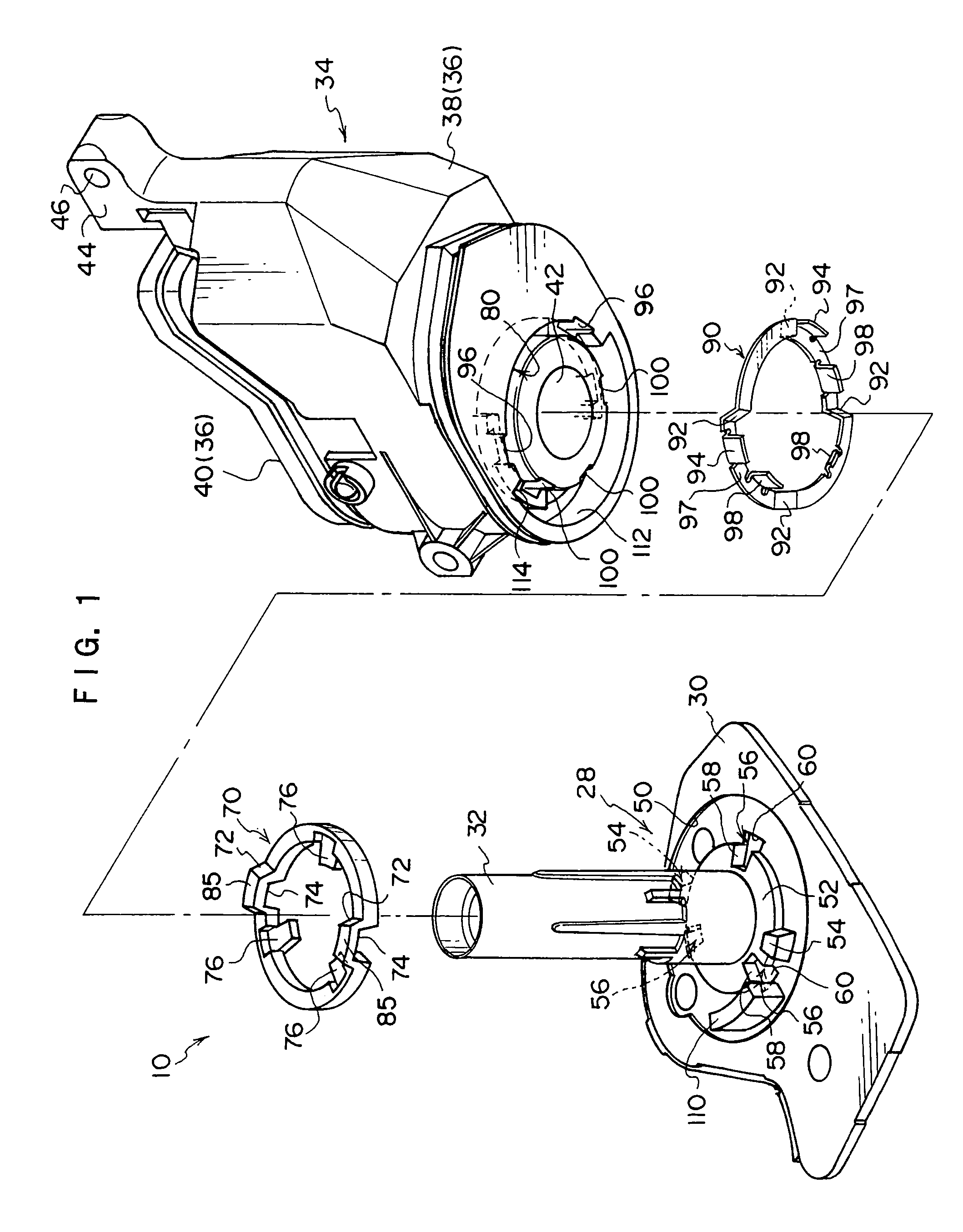

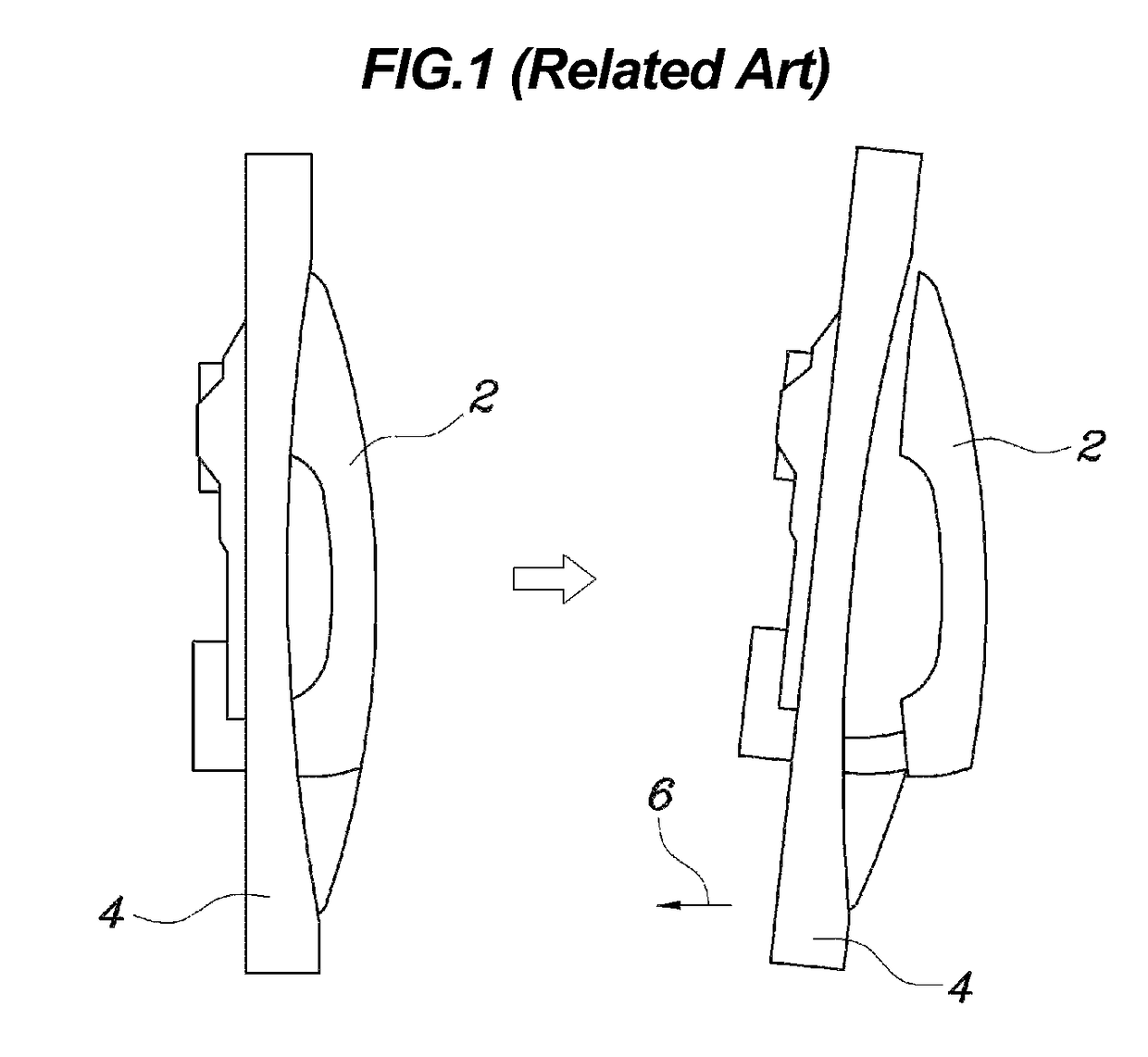

Vehicle door mirror device

A vehicle door mirror device has a detent plate which is provided in the bottom of a housing having a motor actuator therein and a detent piece which is arranged at a stand or a stay. Depressions are formed in the detent plate, protrusions are formed on the detent piece, and a stopper is provided on the stand. A restricting wall is provided at the bottom portion of the housing. The range of the turning angle of the housing is set from the state where the stopper is in contact with the restricting wall to where the protrusion on the detent piece comes into contact with the depression on the detent plate. The same detent piece can be used while changing the rotation angle of the housing by changing the position of the detent piece relative to the stand, whereby the types of parts used can be reduced.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

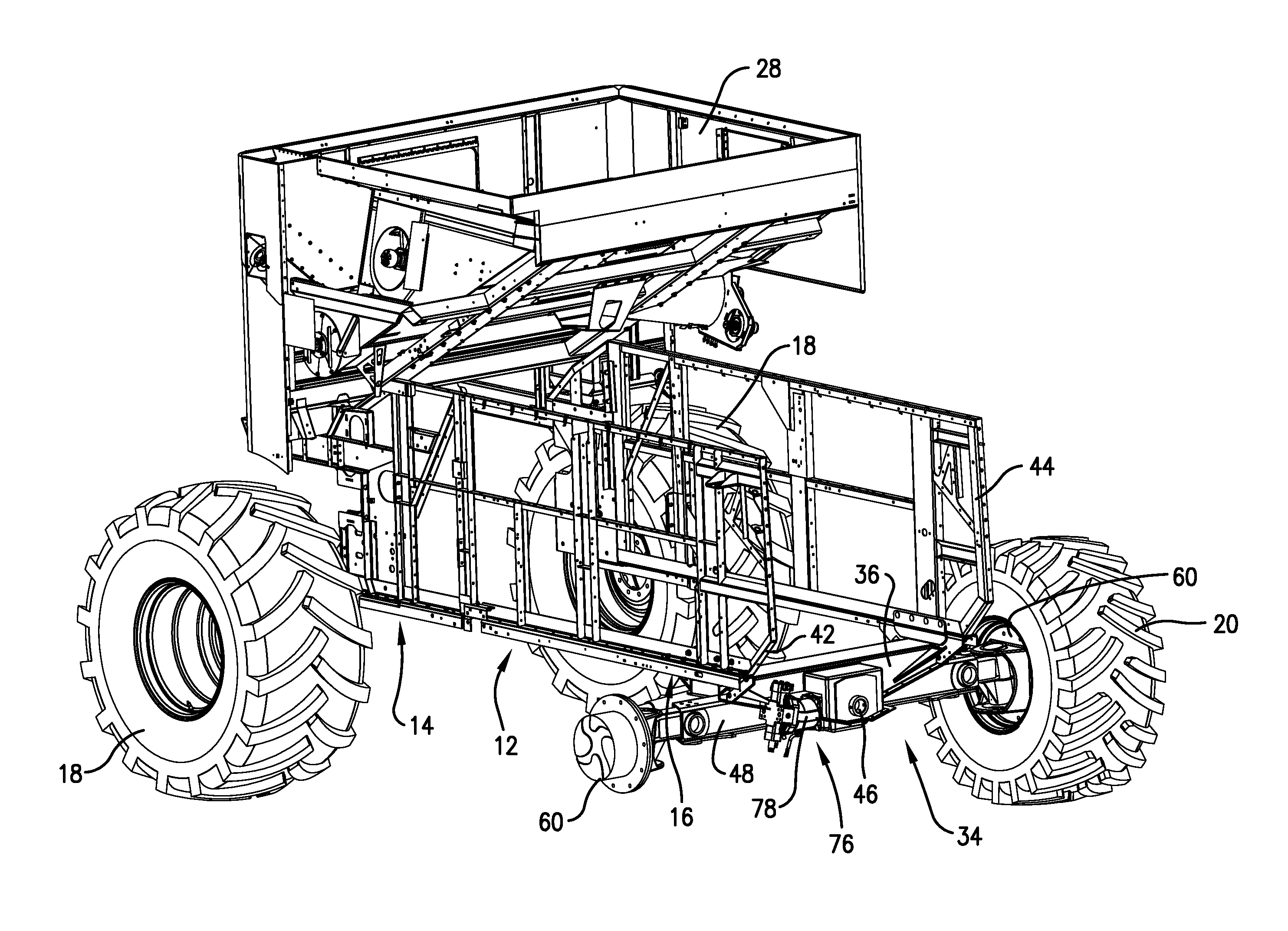

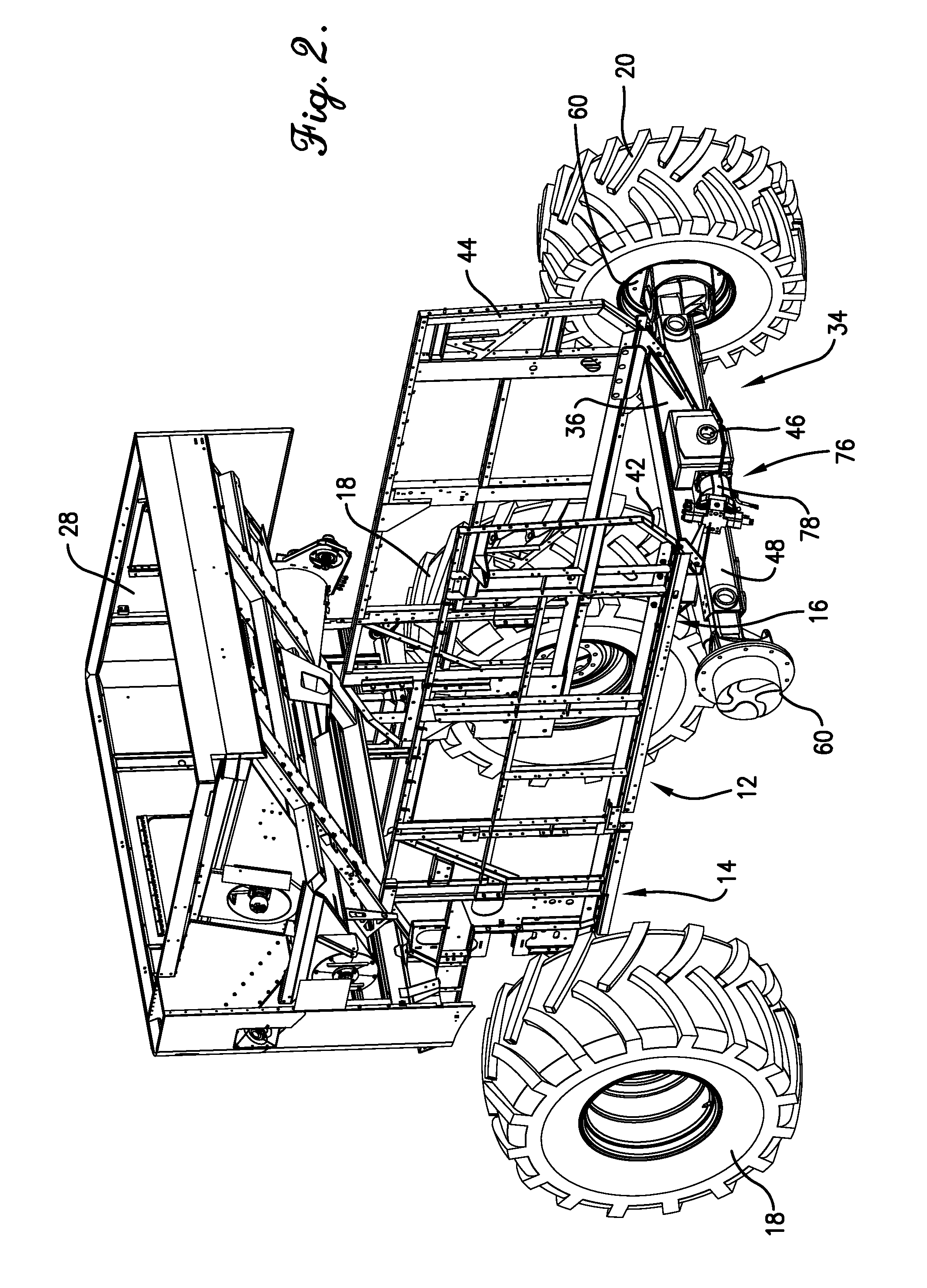

Harvester with extendable rear axle

InactiveUS20140260158A1Turn radius be compromiseFacilitate maneuveringMowersAxle unitsDriver/operatorCombine harvester

A combine harvester has a rear axle that can be extended on-the-go to enable its ground wheels to be turned more sharply during steering operations without striking nearby portions of the chassis. Extension may be carried out manually by the driver or automatically in response to a predetermined input, such as the commencement of a turn by the harvester. In one embodiment the rear ground wheels are powered, such as by a single hydraulic or electric motor, while in another embodiment they are non-powered.

Owner:AGCO CORP

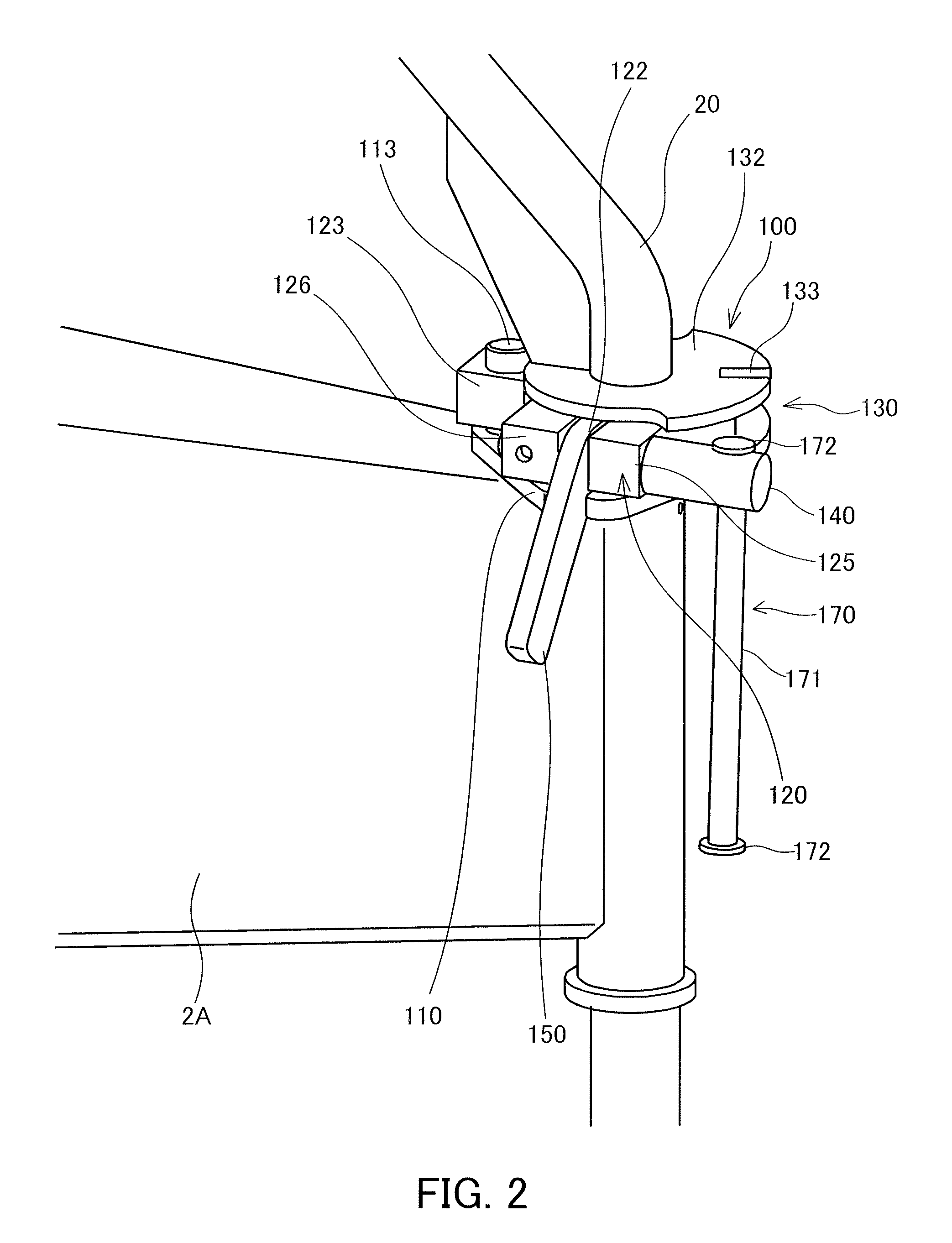

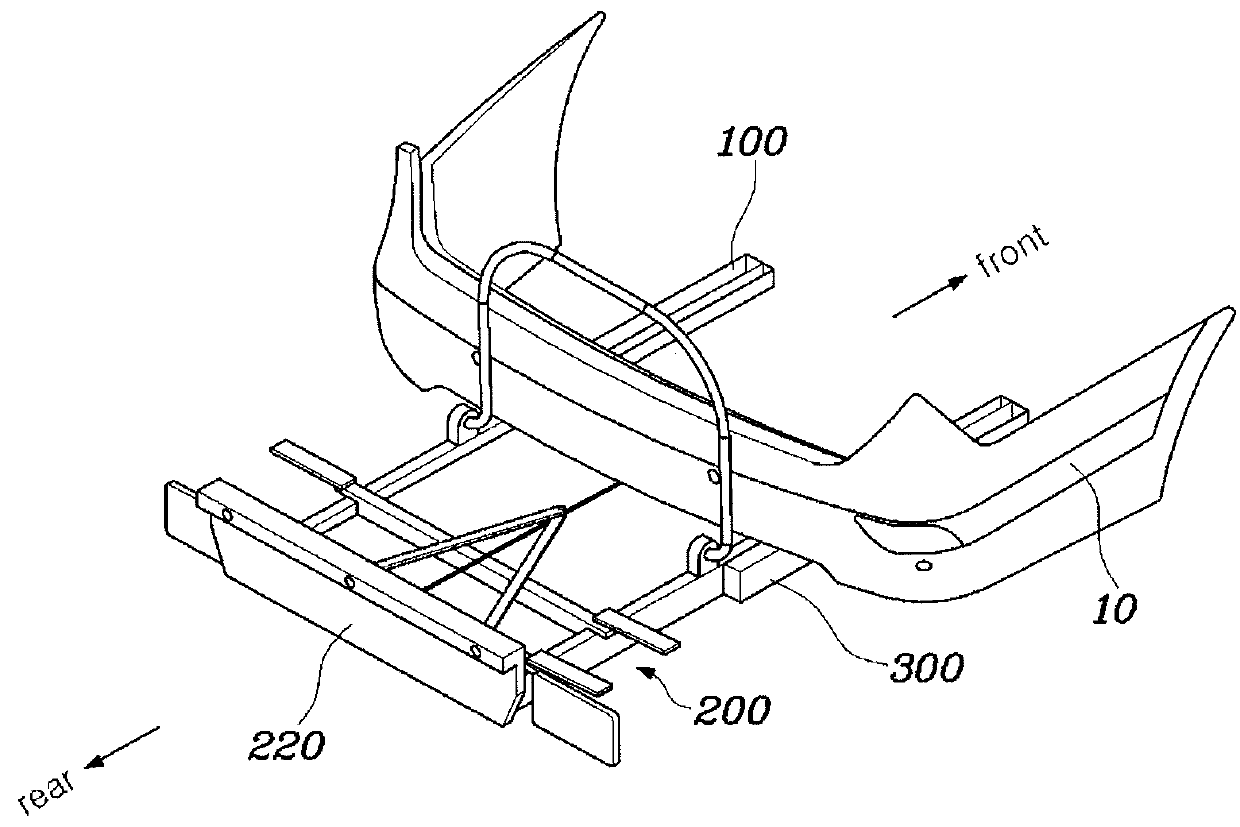

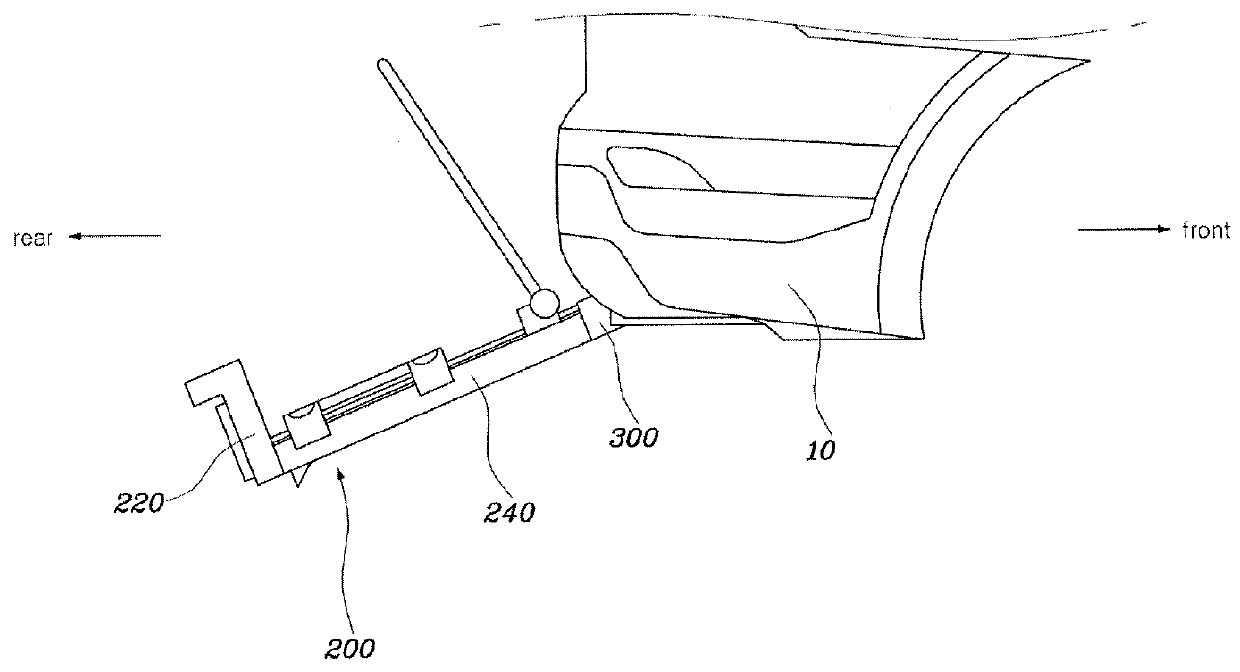

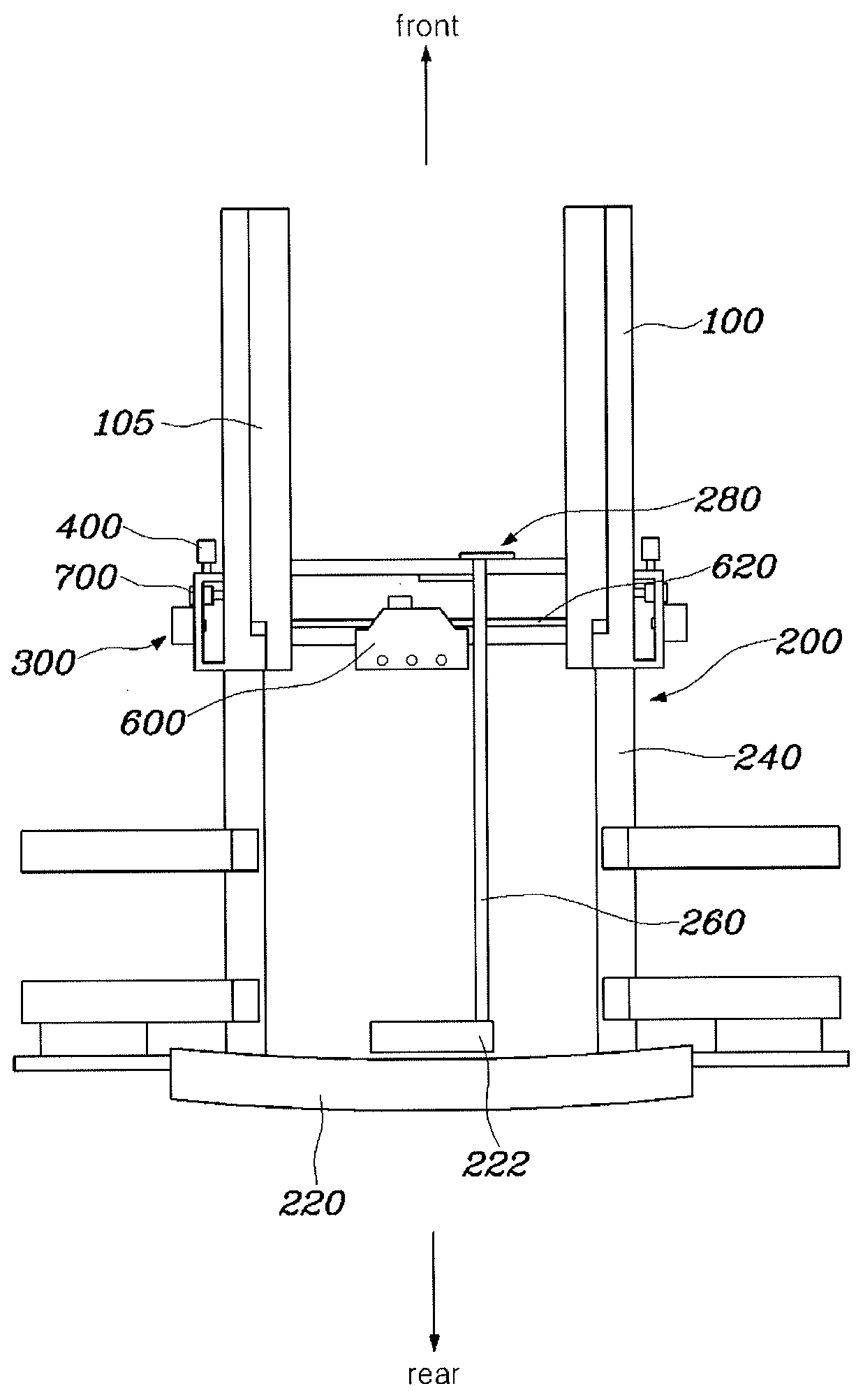

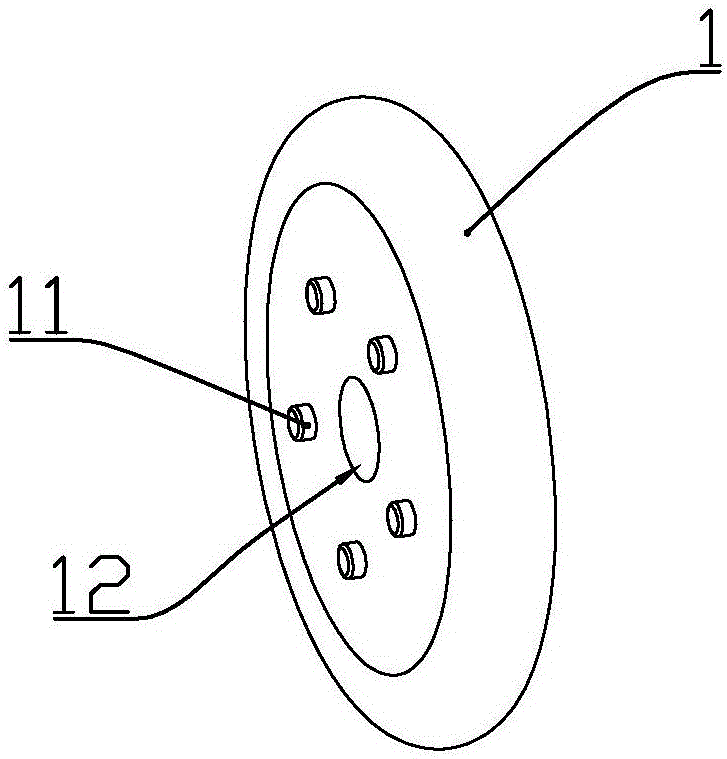

Carrier apparatus for vehicle

ActiveUS20160052458A1Improve convenienceTurn controlSupplementary fittingsOther load carrying vehiclesEngineeringMechanical engineering

Owner:HYUNDAI MOTOR CO LTD

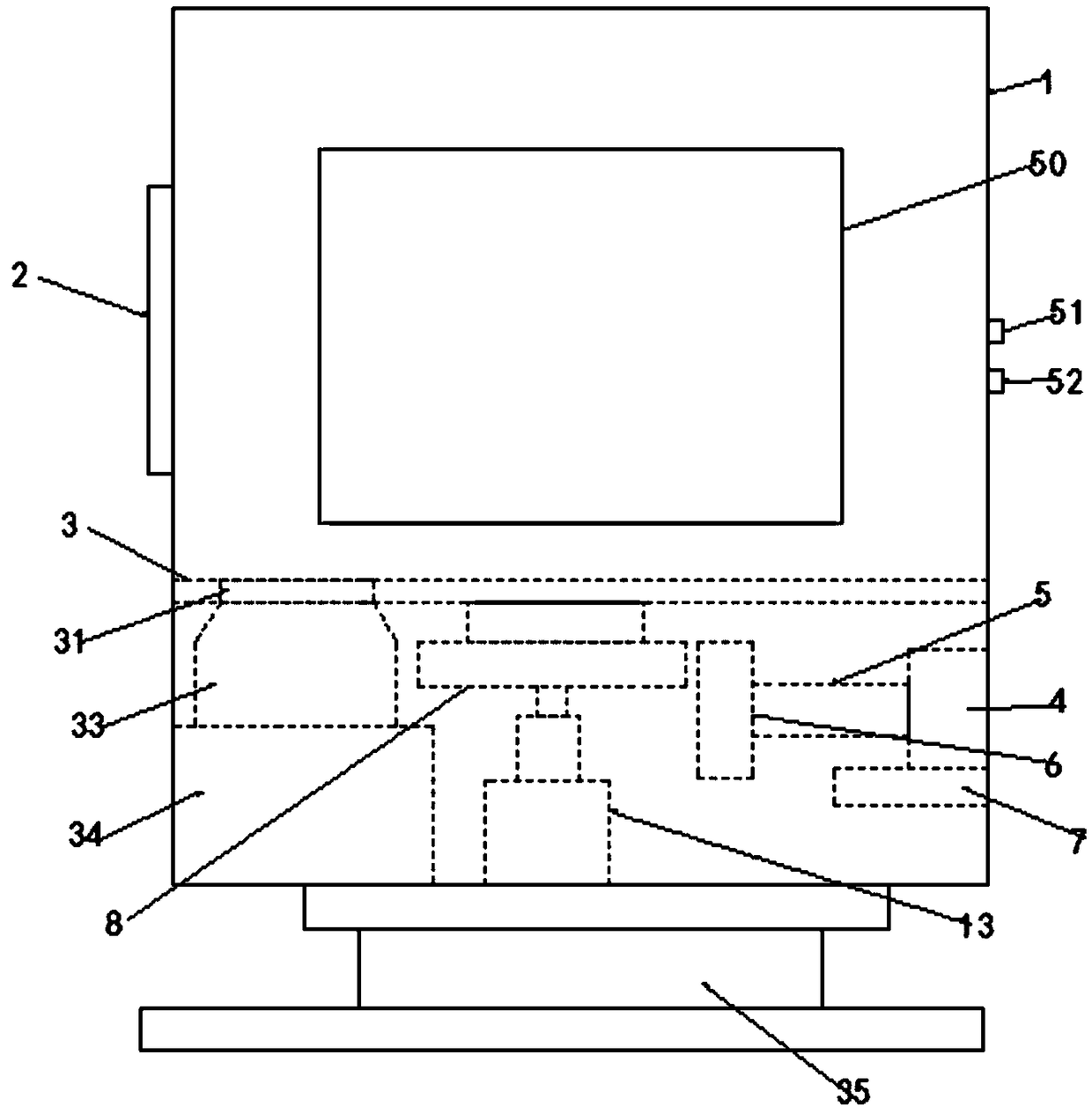

Powder grinding device convenient to operate

InactiveCN109465070AGood for grinding and extrusionEasy to scrape and collectGrain treatmentsEngineeringMechanical engineering

The invention discloses a powder grinding device convenient to operate comprising a fixing barrel. A feeding inlet is formed in the top of one side of the fixing barrel; a fixing plate is arranged atthe inner bottom of the fixing barrel; a first motor is arranged at the inner bottom of the fixing barrel and on one side below the fixing plate; an output shaft of the first motor is connected with afirst rotary shaft; a first conical gear is arranged at the end, away from the first motor, of the first rotary shaft; the bottom end of the first motor is fixed inside the fixing barrel through a supporting board; the side, away from the first motor, of the top end of the first conical gear is provided with a second conical gear matched with the first conical gear; a second rotary shaft is arranged at the top end of the second conical gear; the top end of the second rotary shaft penetrates through the middle of the top end of the fixing plate and extends to the upper portion of the fixing plate; a fixing block is arranged at the position, corresponding to the second rotary shaft, of the bottom end of the fixing plate; the interior of the second rotary shaft is of a hollow structure; a first connection rod is arranged inside the second rotary shaft in a penetrating mode; the bottom end of the first connection rod is located below the second conical gear; and first clamping boards arearranged on two sides of the bottom end of the first connection rod.

Owner:嘉善顺源金属制品有限公司

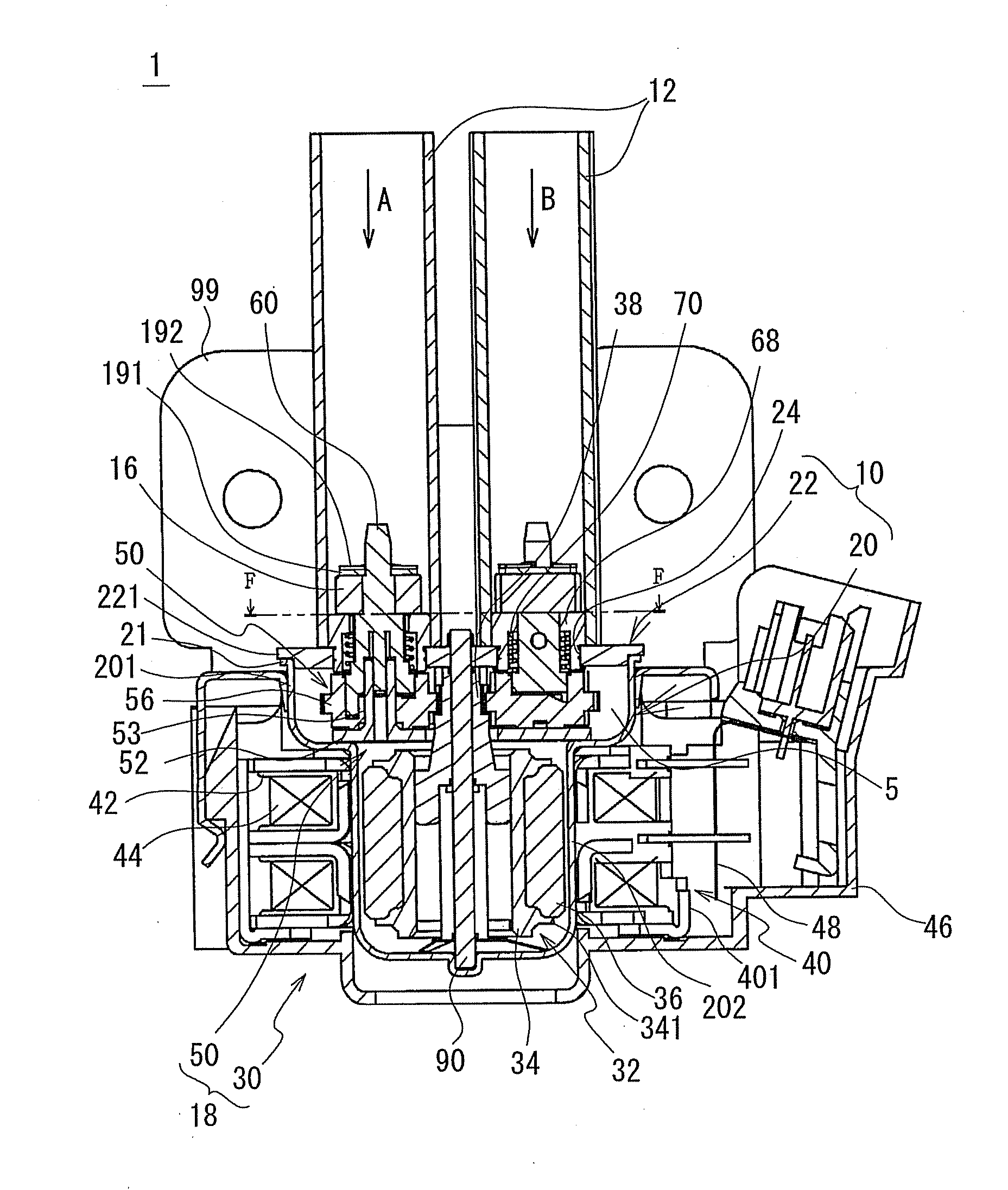

Valve element opening/closing device

InactiveUS20080251147A1Simple structureSmall sizeOperating means/releasing devices for valvesCheck valvesEngineeringVALVE PORT

A valve element opening / closing device may include a main body formed with a space, an inflow pipe and an outflow pipe which are connected to the main body, a valve element for opening and closing a flow passage, and a drive part for driving the valve element to open and close the flow passage. The valve element may be arranged on an inflow pipe side with respect an opening of the main body to which the inflow pipe is connected. The valve element is preferably arranged within the inflow pipe.

Owner:SANKYO SEIKI MFG CO LTD

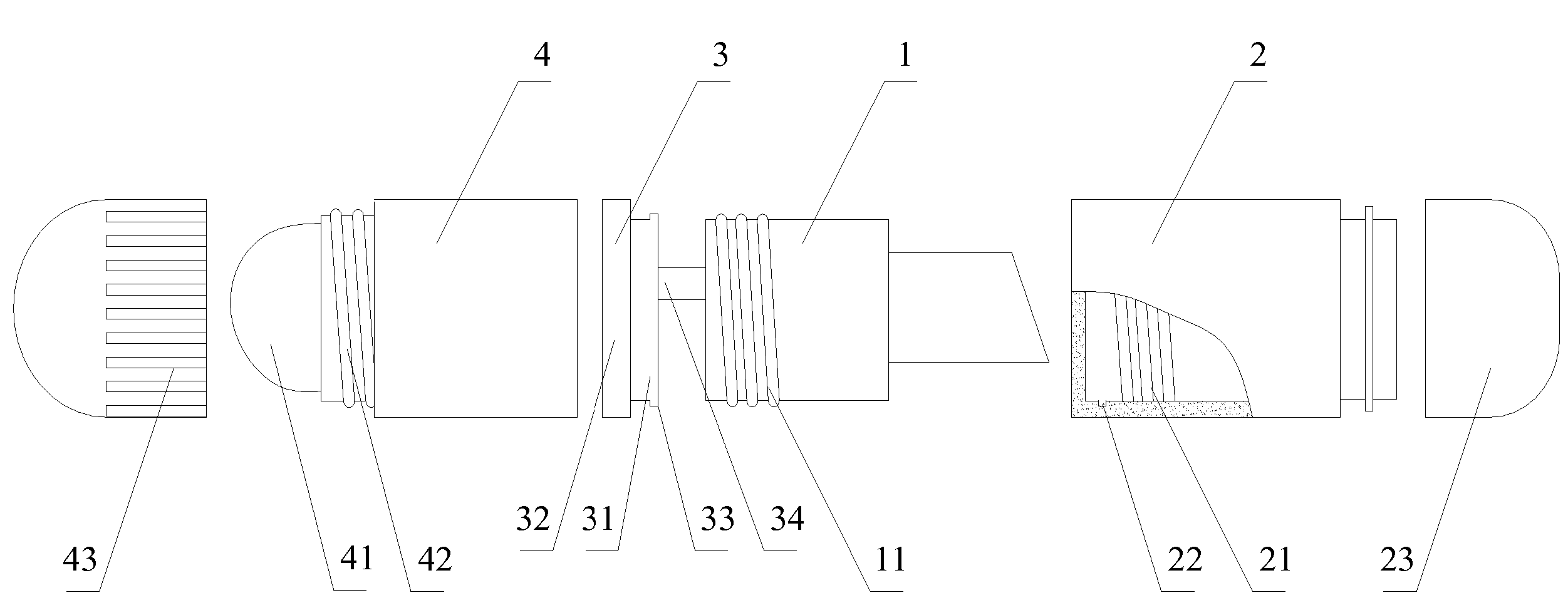

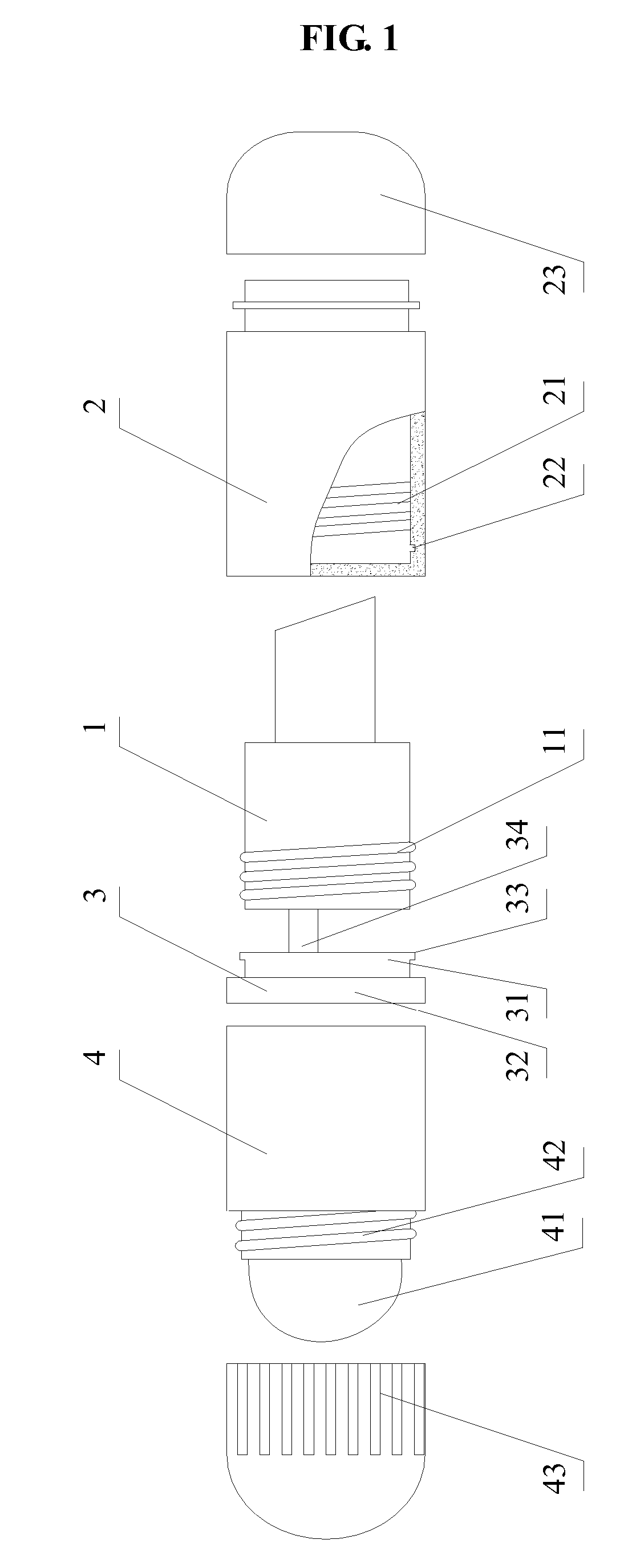

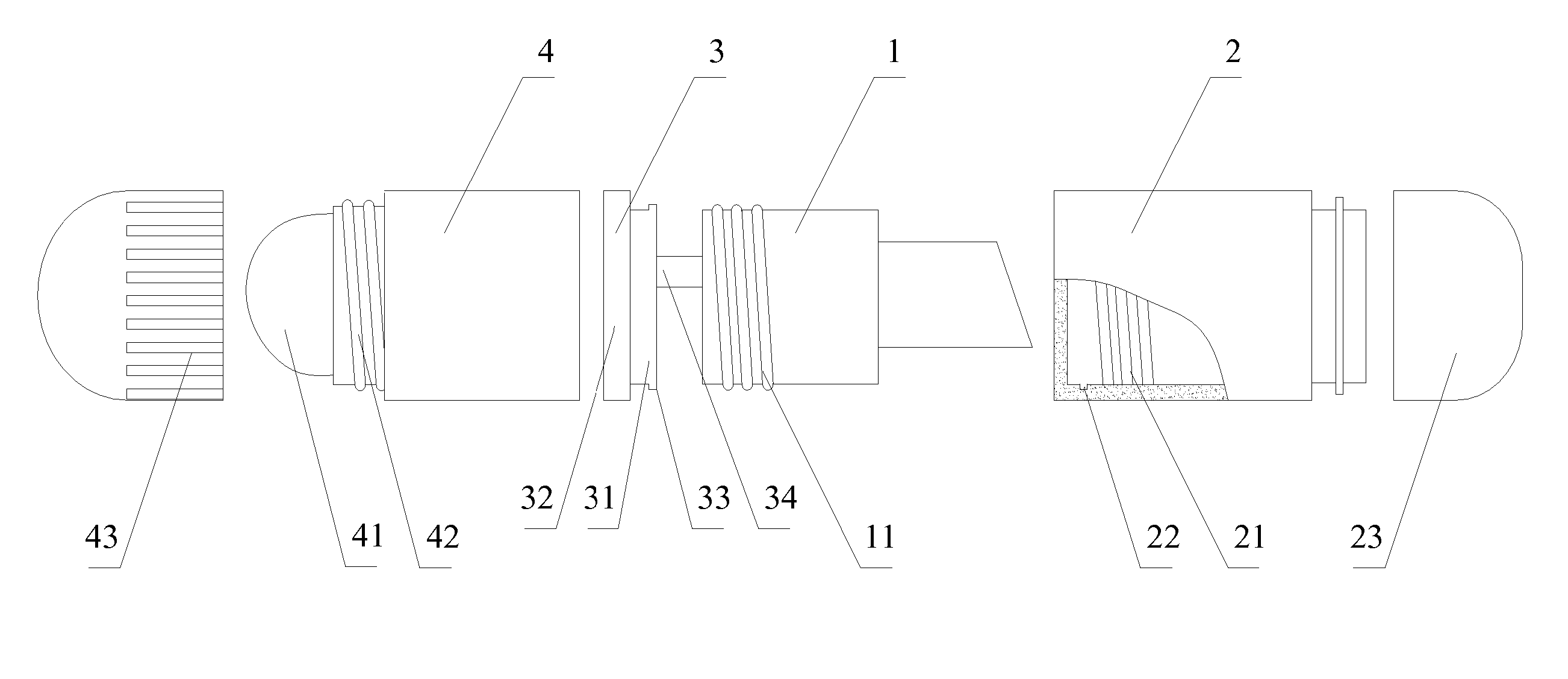

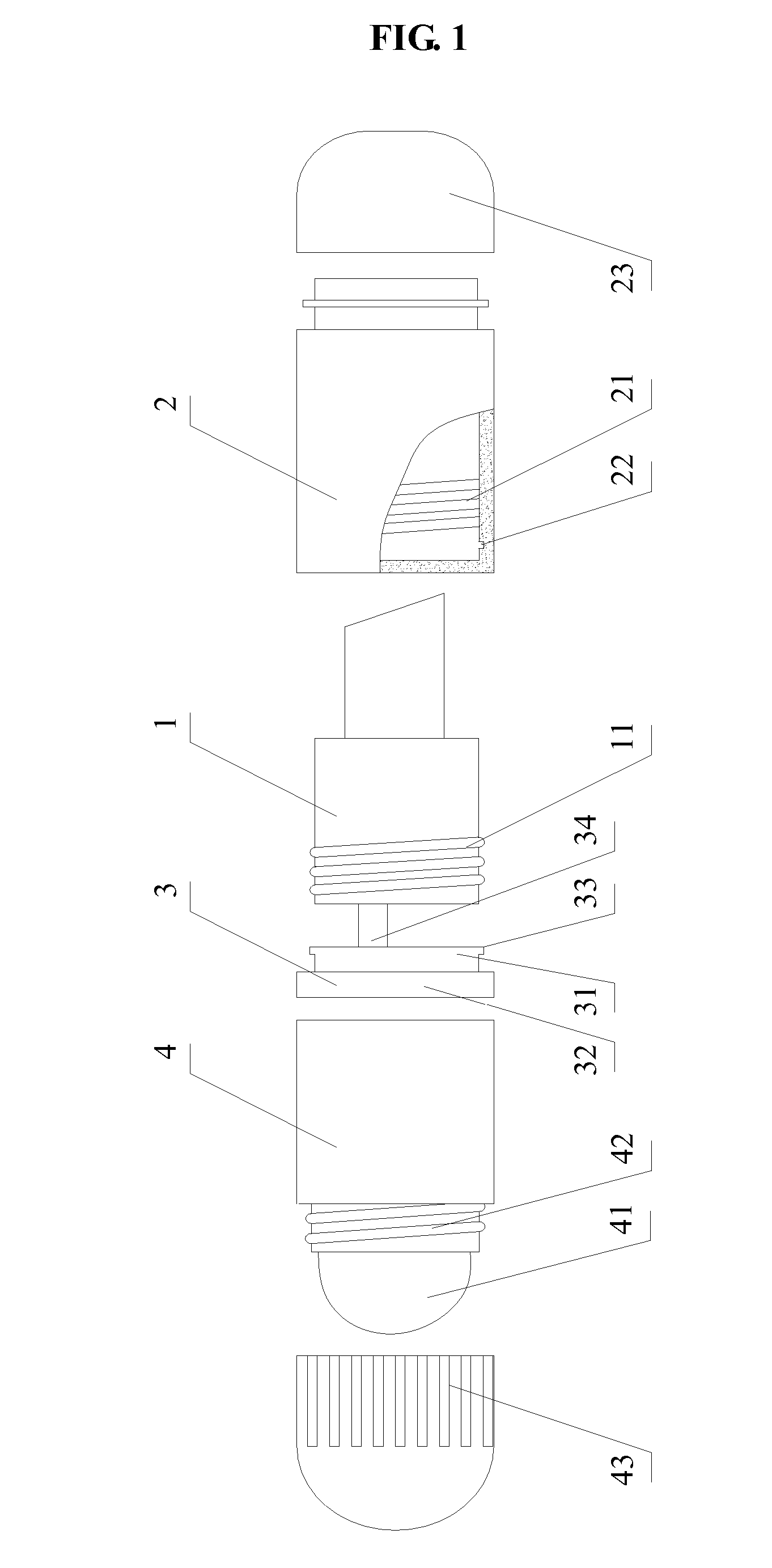

Solid-liquid twofold dauber

InactiveUS7367736B2Convenient for using and carryingTurn controlLiquid surface applicatorsCoin-freed apparatus detailsLiquid mediumEngineering

The invention relates to a double-duty applicator for solid and liquid mediums, comprising a columned bearer and an outer tube combined to contain solid medium, and extending from a double-stage columned base. At the other end of said base is fixed a soft tube containing liquid medium. Said outer tube covers the outside of the bearer, with inner threads on the inner wall therein, which matches with outer threads of the bearer. The bottom end of the outer tube is fixed outside a smaller columned flange of the base through fastening slots, and a limiting mechanism is positioned between the bottom of the bearer and the base to limit the turning of the bearer. The invention adds a liquid medium applicator to the conventional solid medium applicator structure, and combines both applicator structures together, thereby making it easy to carry and use.

Owner:MTL CORP

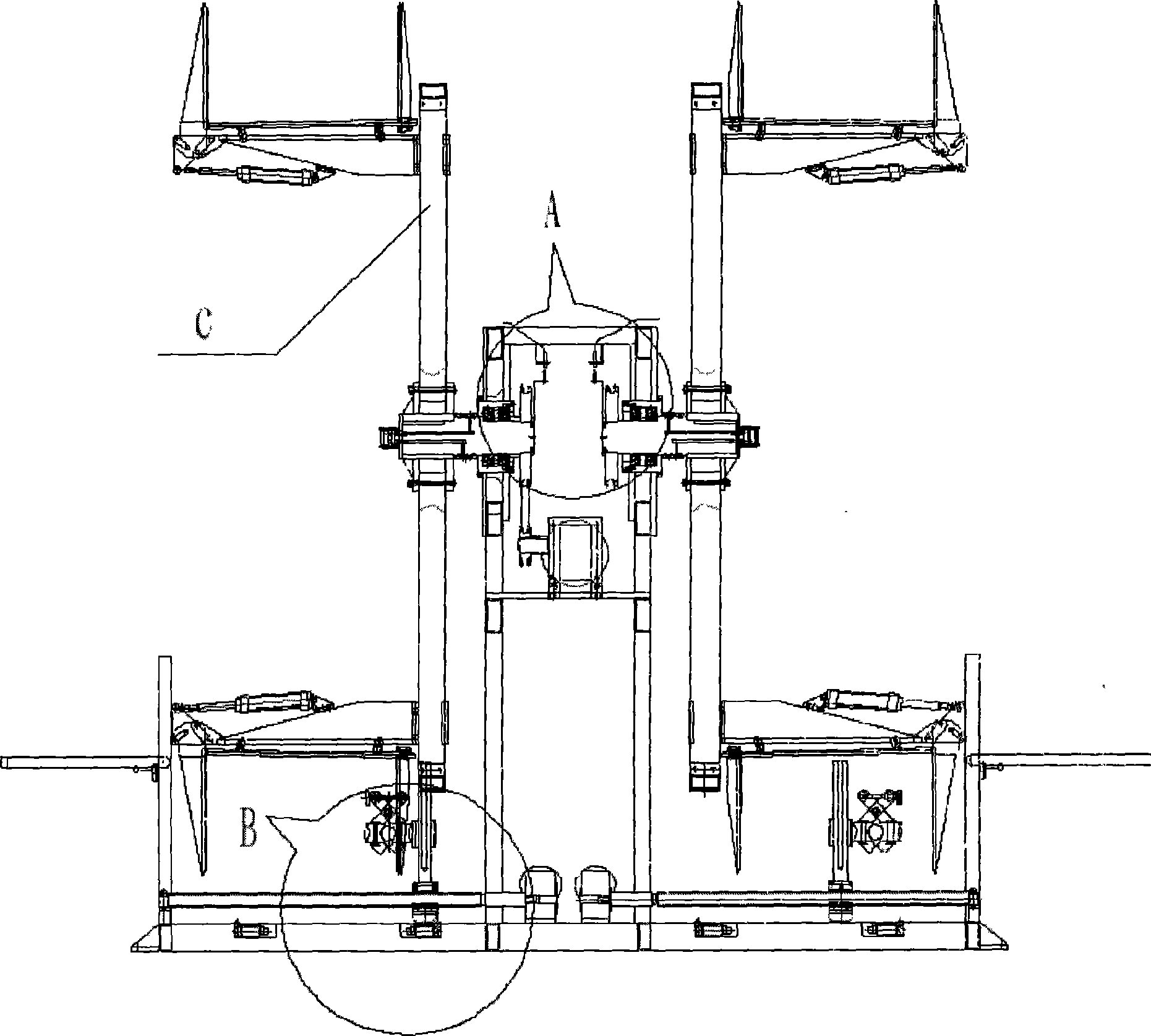

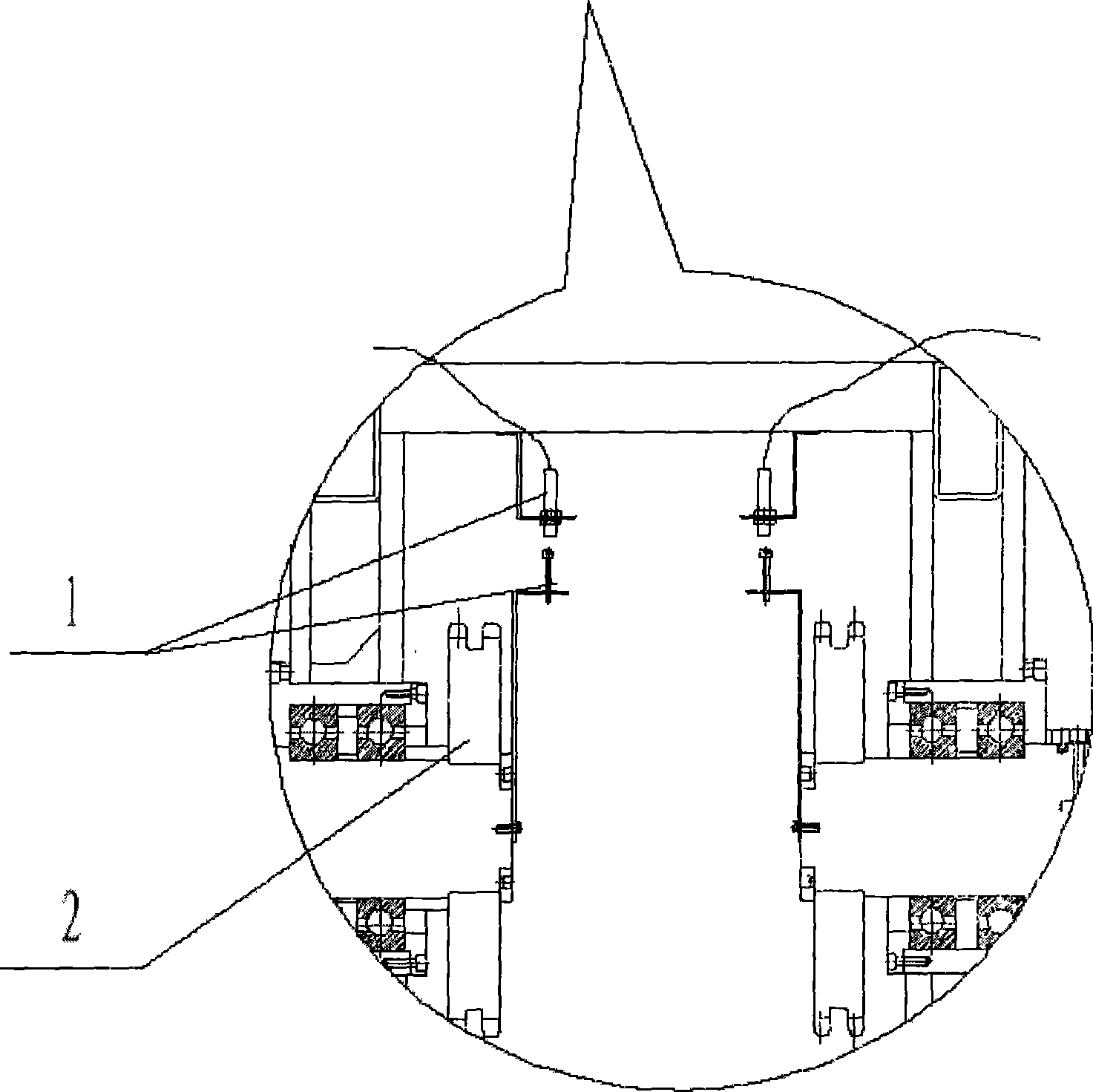

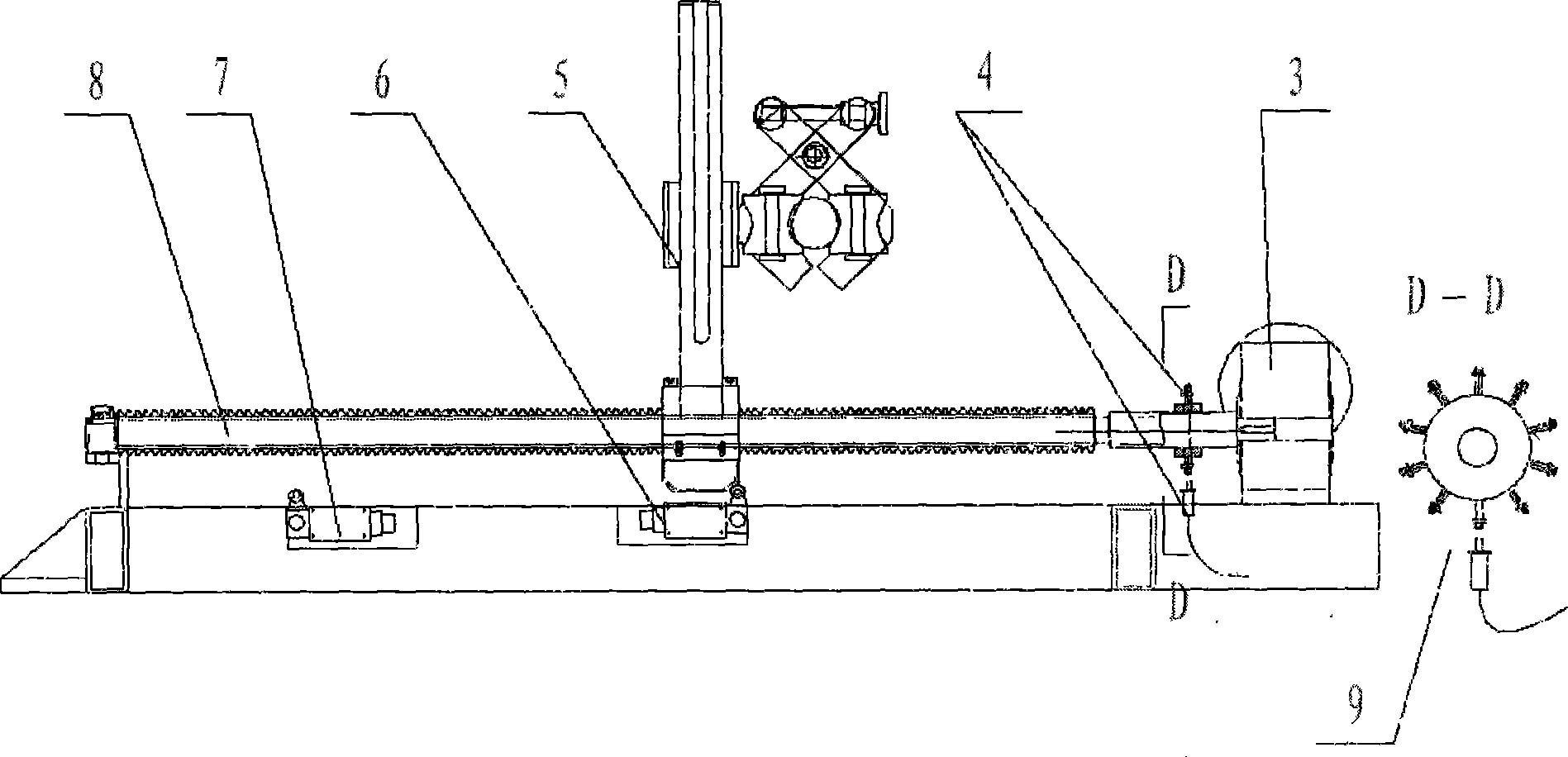

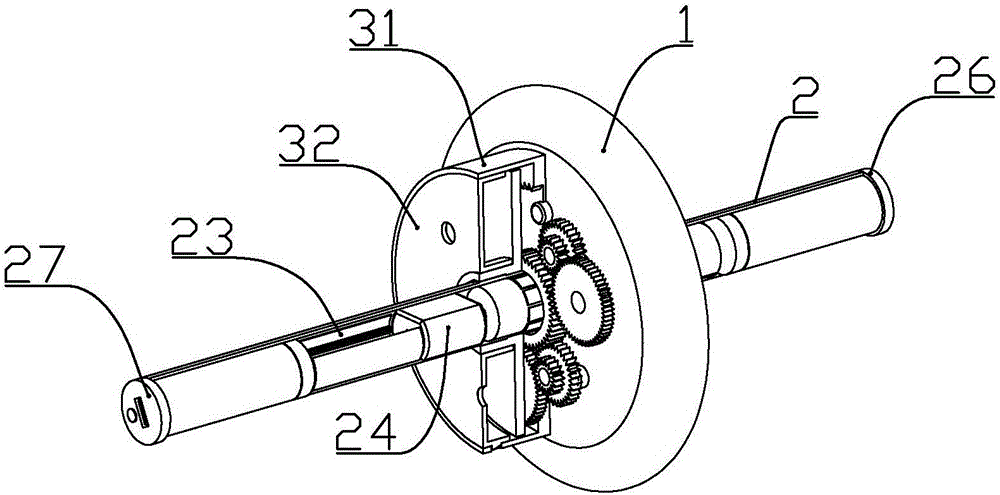

Strand winding apparatus of heavy caliber pipe winder

InactiveCN101434354AAccurate line advancementAccurately control the number of turnsFilament handlingWinding machineMotor drive

The invention provides a winding displacement device of a winding machine for pipes with large diameter, which comprises a winding disk, a winding displacement screw mandrel, a winding displacement unit and a winding displacement motor, wherein, the winding displacement unit is arranged on the winding displacement screw mandrel; the winding displacement motor is connected with the winding displacement screw mandrel; the winding displacement unit winds the pipes on the winding disk; the winding displacement motor drives the winding displacement screw mandrel to propel so as to guarantee that the winding displacement unit winds the pipes on the proper position of the winding disk; and the winding displacement screw mandrel is connected with the winding displacement unit by threads and provided with a fixed thread pitch. By adopting the threaded connection, the invention leads the winding displacement unit to actively propel forward when the winding displacement screw mandrel rotates, thus overcoming the friction loss caused by the adoption of purely mechanical structure in the prior art, and can accurately control the rotating number of the winding displacement screw mandrel through the corresponding relation of the fixed thread pitch and the pipe diameter so as to realize the propelled distance needed by the winding displacement unit and lead the propulsion to be accurate, further, a sensing device can be used for realizing automatic feedback and control, thus leading the invention to be simple in structure, convenient and durable.

Owner:GUANGDONG LIANSU MACHINERY MFG

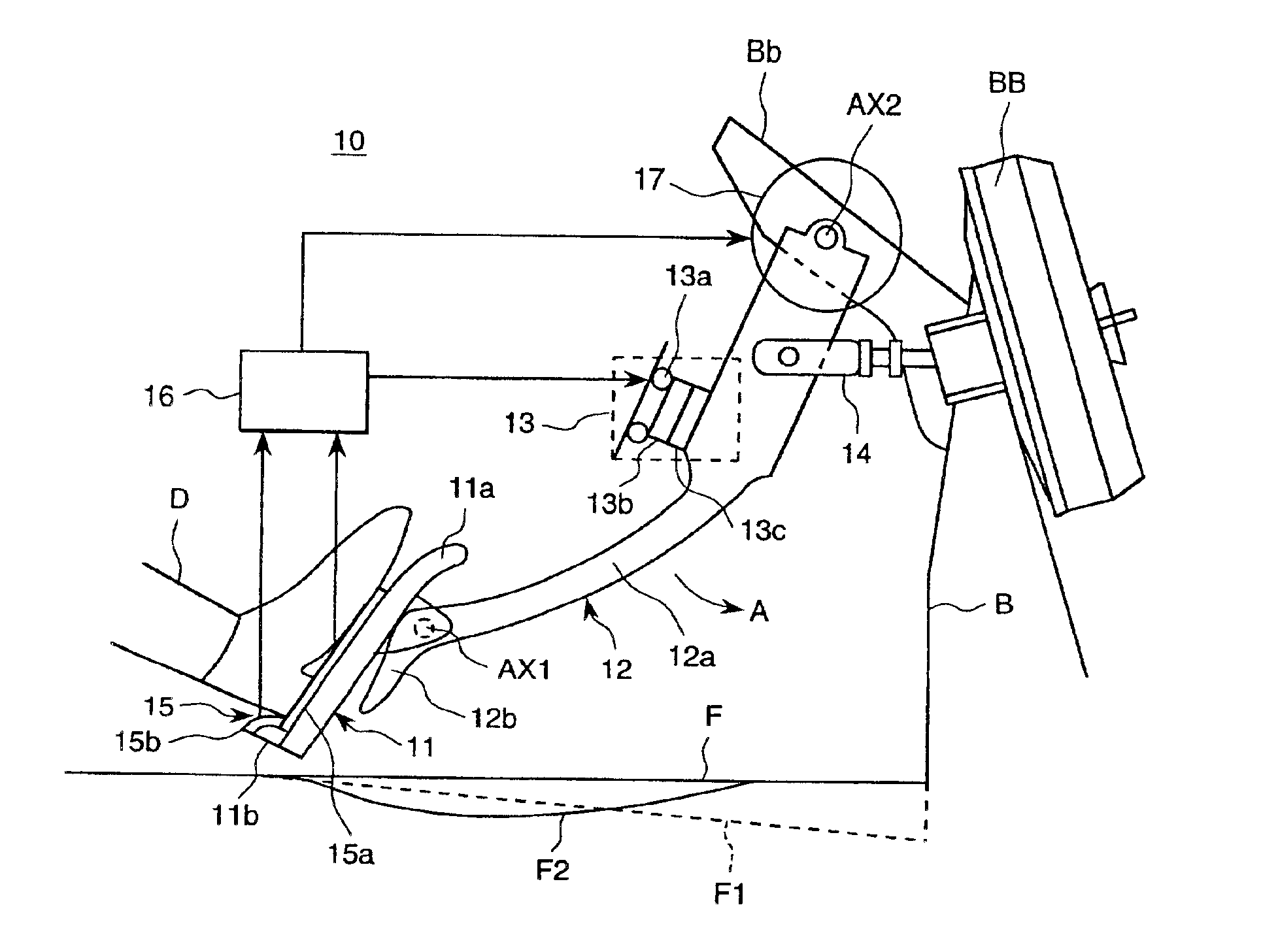

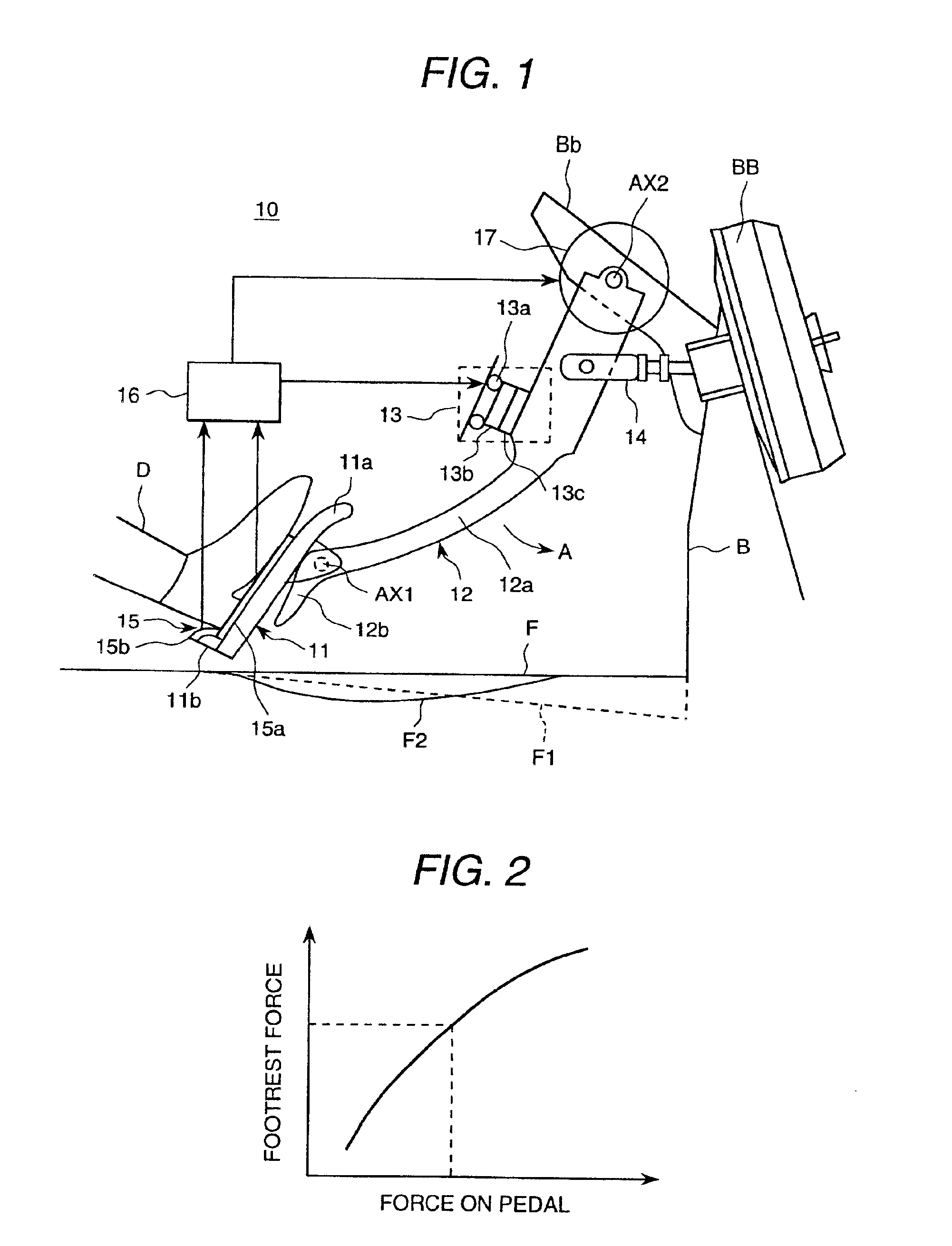

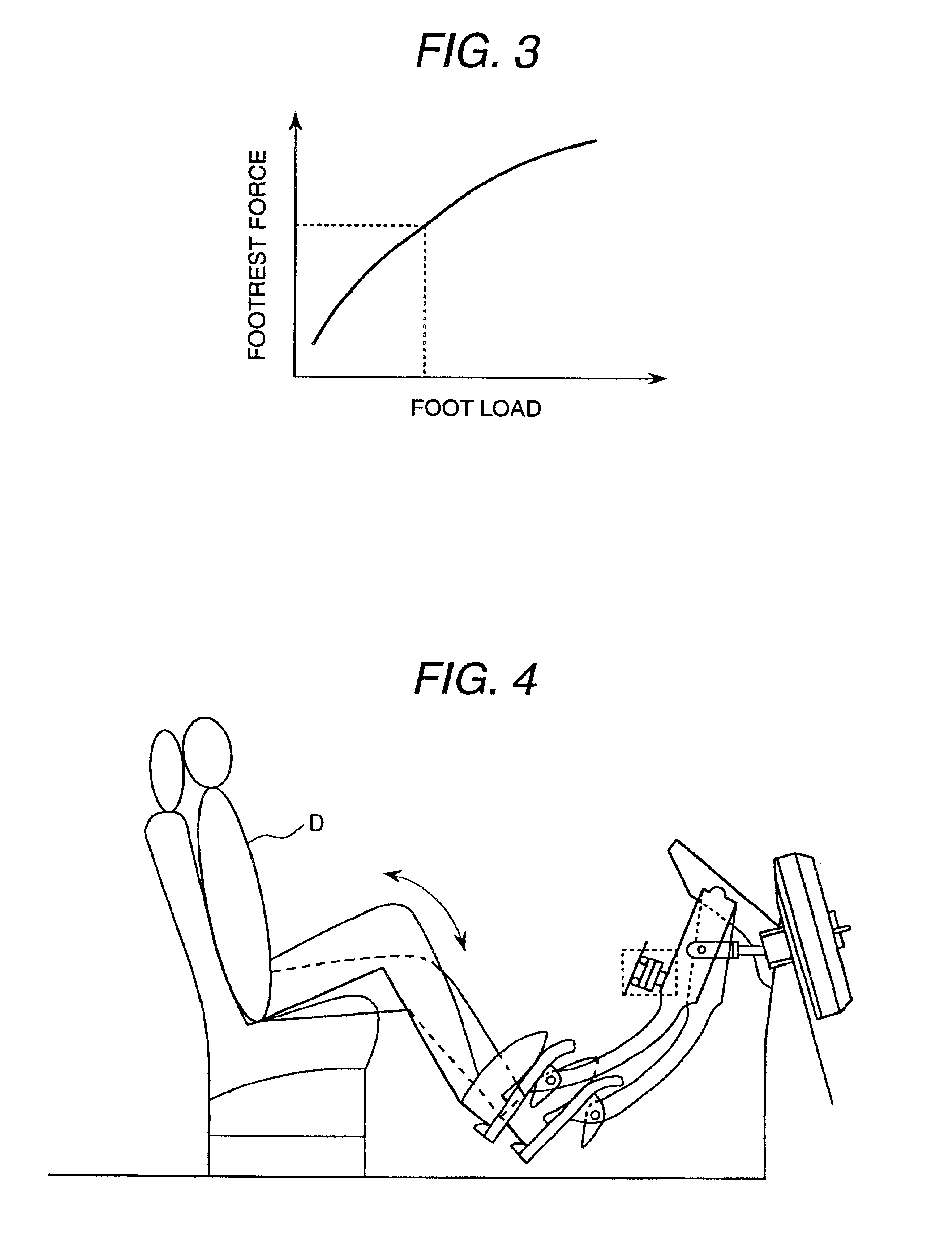

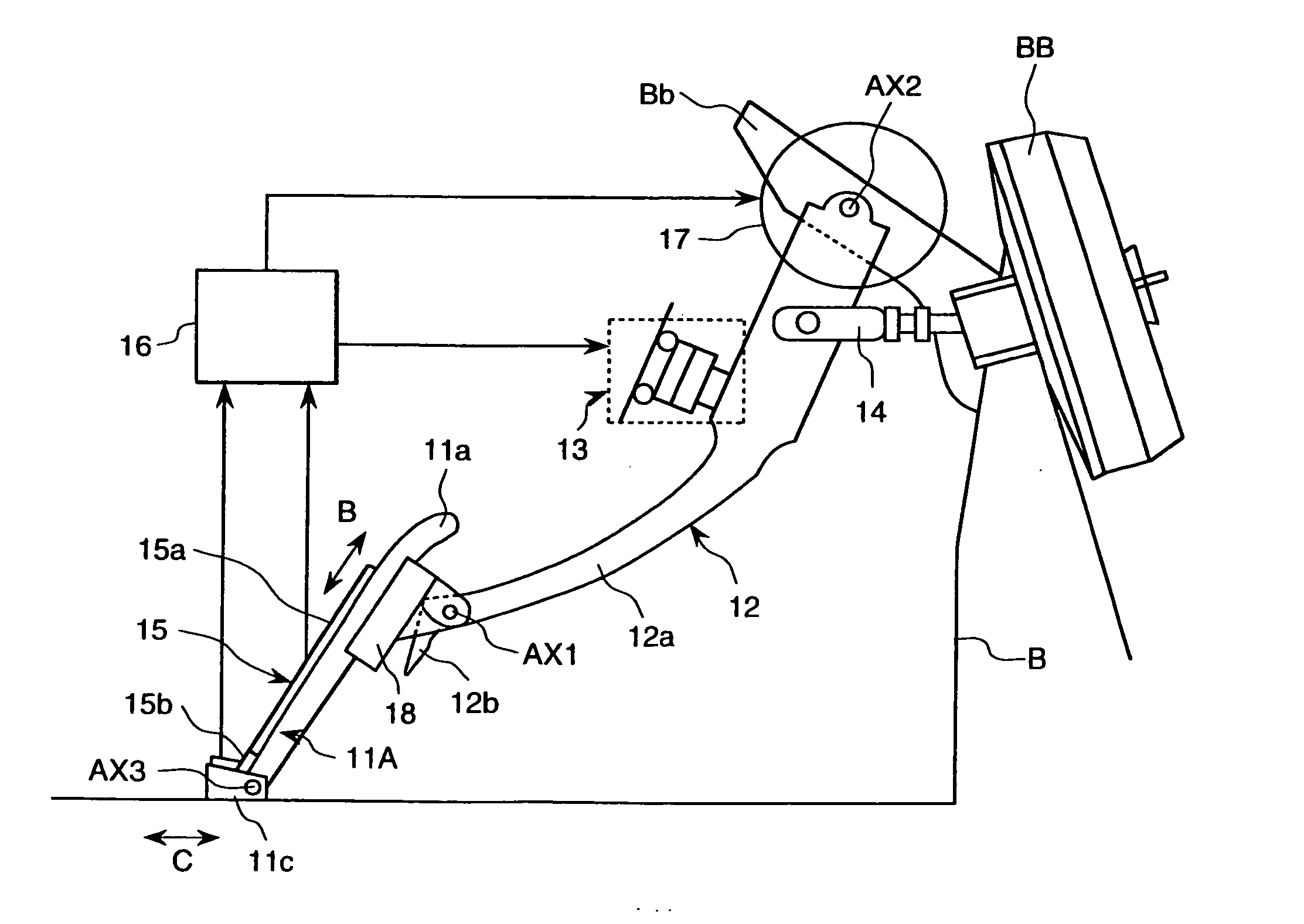

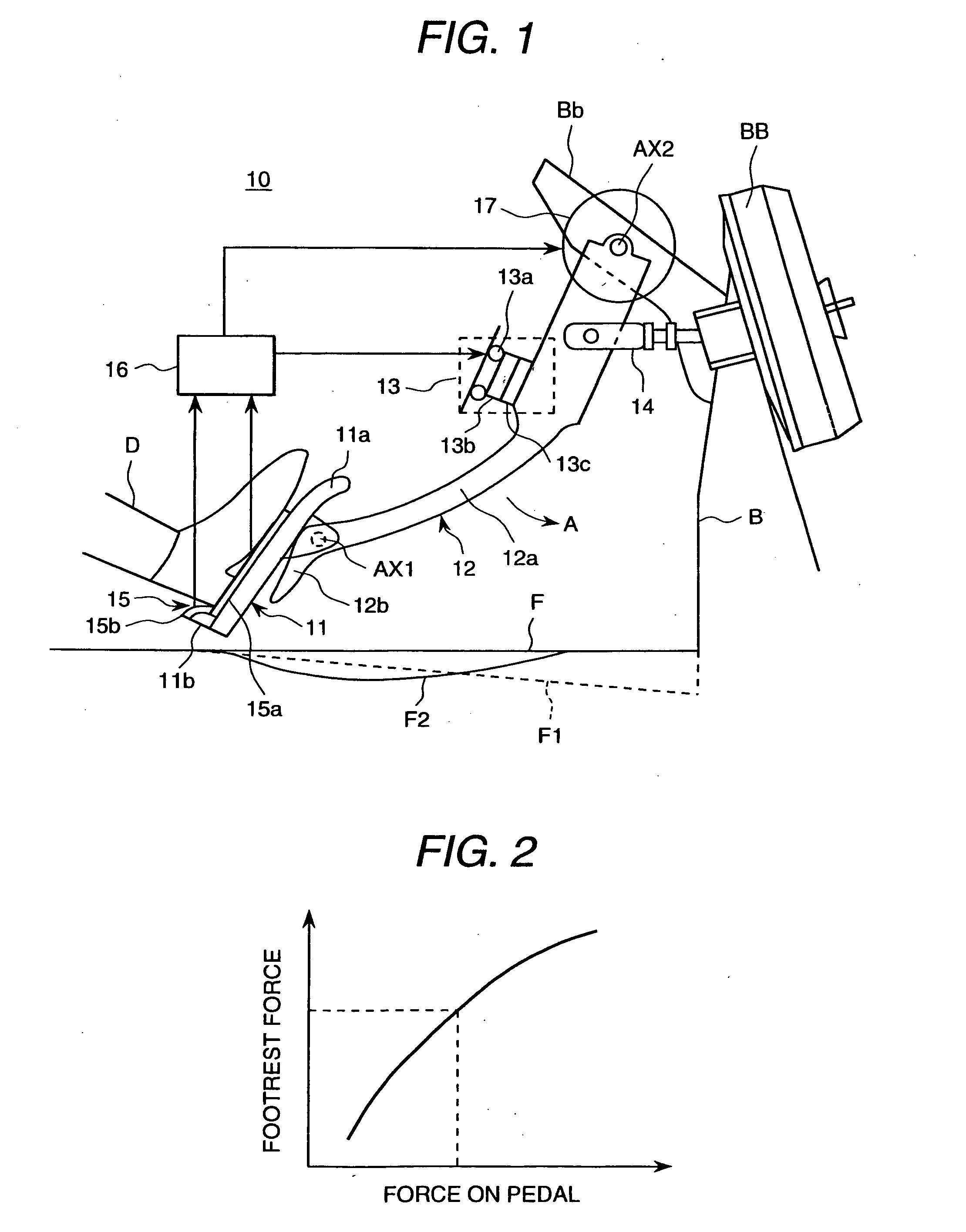

Pedal device for a vehicle and automobile using the same

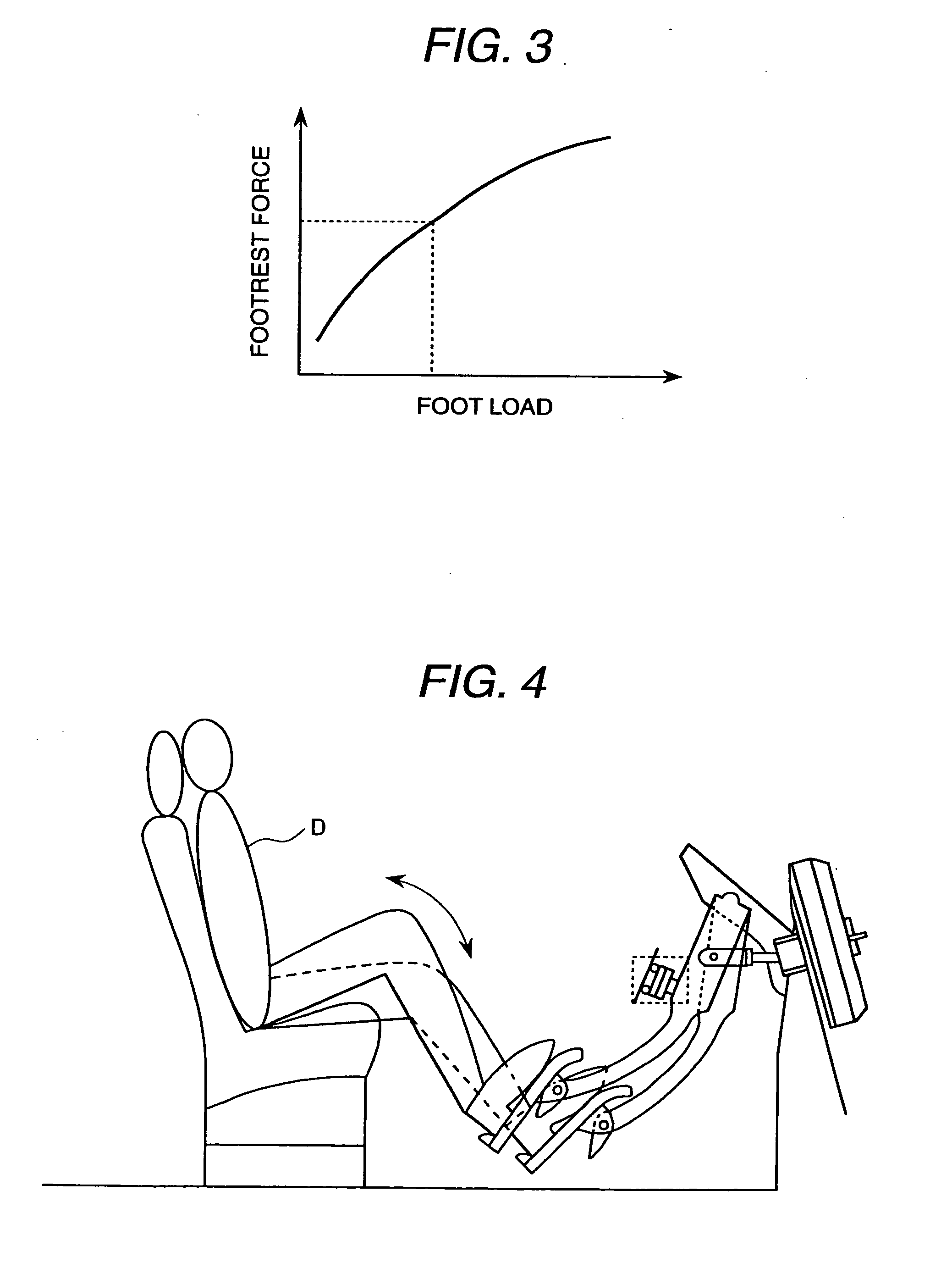

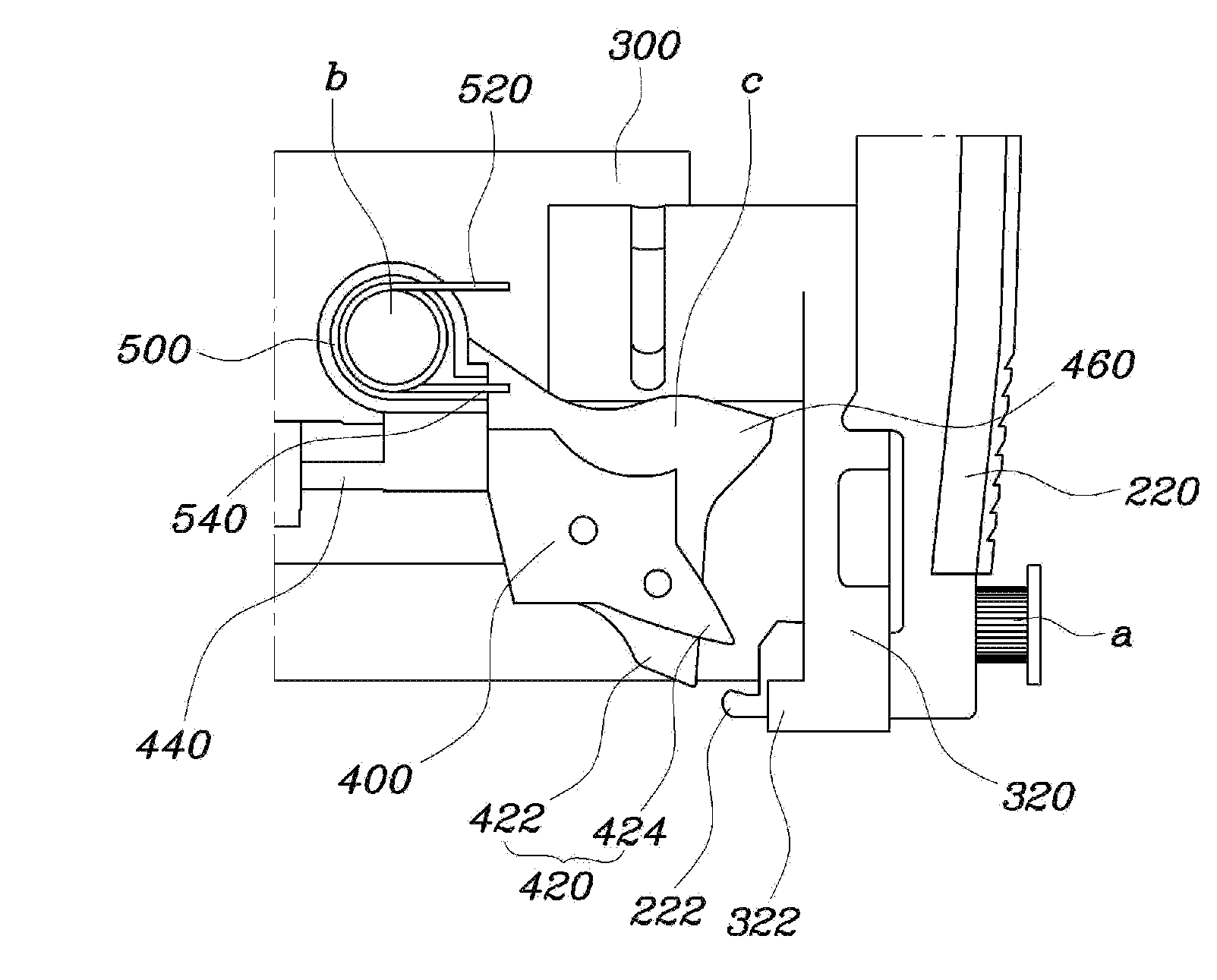

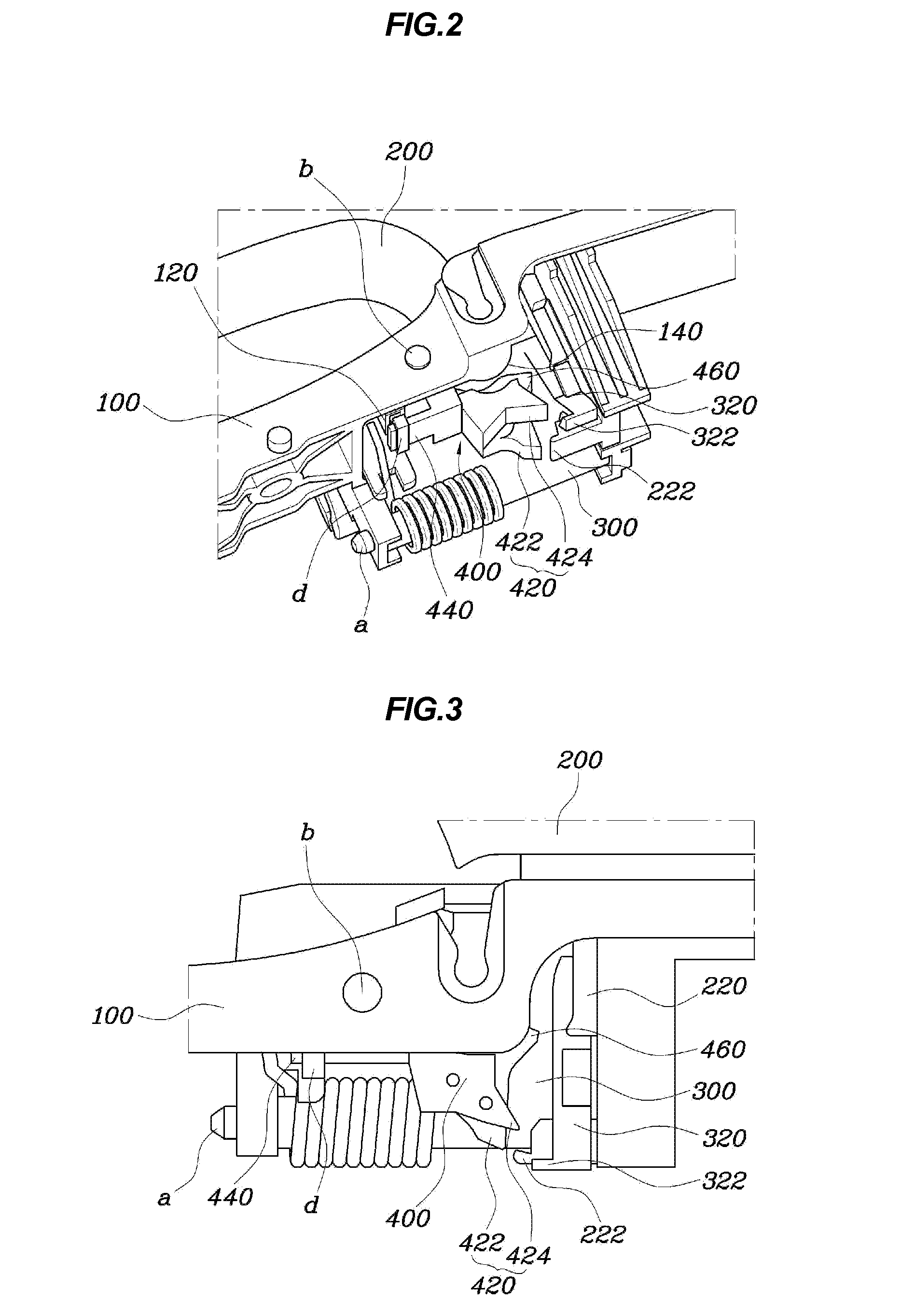

InactiveUS6883398B2Turn controlReduce impactControlling membersMechanical apparatusMaster cylinderFootplate

Pedal device 10 has a pedal member 11 depressed by the driver, and arm member 12 engaged with the pedal member, for turning when the pedal member is depressed, and transmitting driver's force-on-pedal to the brake master cylinder. When the driver's force-on-pedal which acts on pedal member 11 is less than the fixed value, footrest means 13 restricts the turning of the arm member. Pedal member 11 is composed of footplate 11a to be depressed by the driver, and protruding portion 11b engaged with the footplate, on which driver's heel can be put.

Owner:HITACHI LTD

Pedal device for vehicle and automobile using the same

InactiveUS20050005728A1Turn controlReduce fatigueControlling membersMechanical apparatusDriver/operatorMaster cylinder

Pedal device 10 has a pedal member 11 depressed by the driver, and arm member 12 engaged with the pedal member, for turning when the pedal member is depressed, and transmitting driver's force-on-pedal to the brake master cylinder. When the driver's force-on-pedal which acts on pedal member 11 is less than the fixed value, footrest means 13 restricts the turning of the arm member. Pedal member 11 is composed of footplate 11a to be depressed by the driver, and protruding portion 11b engaged with the footplate, on which driver's heel can be put.

Owner:KOJIMA TAKAO +4

Door holding device for vehicle

ActiveUS20150123410A1Turn controlPrevent openingRoad vehiclesAccident situation locksEngineeringDoor handle

A door holding device for a vehicle, may include a door handle having a first side disposed on a door base turnably and a second side in which a holder extending inwardly of the door base may be formed, a door lever hinged to the door base and having a guide that may be locked to the holder of the door handle so as to turn with the door handle, and a blocking lever disposed on the door base turnably by a hinge shaft and having a stopper formed to correspond to turning tracks of the holder of the door handle and the guide of the door lever.

Owner:HYUNDAI MOTOR CO LTD

Vehicle door mirror device

A vehicle door mirror device has a detent plate which is provided in the bottom of a housing having a motor actuator therein and a detent piece which is arranged at a stand or a stay. Depressions are formed in the detent plate, protrusions are formed on the detent piece, and a stopper is provided on the stand. A restricting wall is provided at the bottom portion of the housing. The range of the turning angle of the housing is set from the state where the stopper is in contact with the restricting wall to where the protrusion on the detent piece comes into contact with the depression on the detent plate. The same detent piece can be used while changing the rotation angle of the housing by changing the position of the detent piece relative to the stand, whereby the types of parts used can be reduced.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

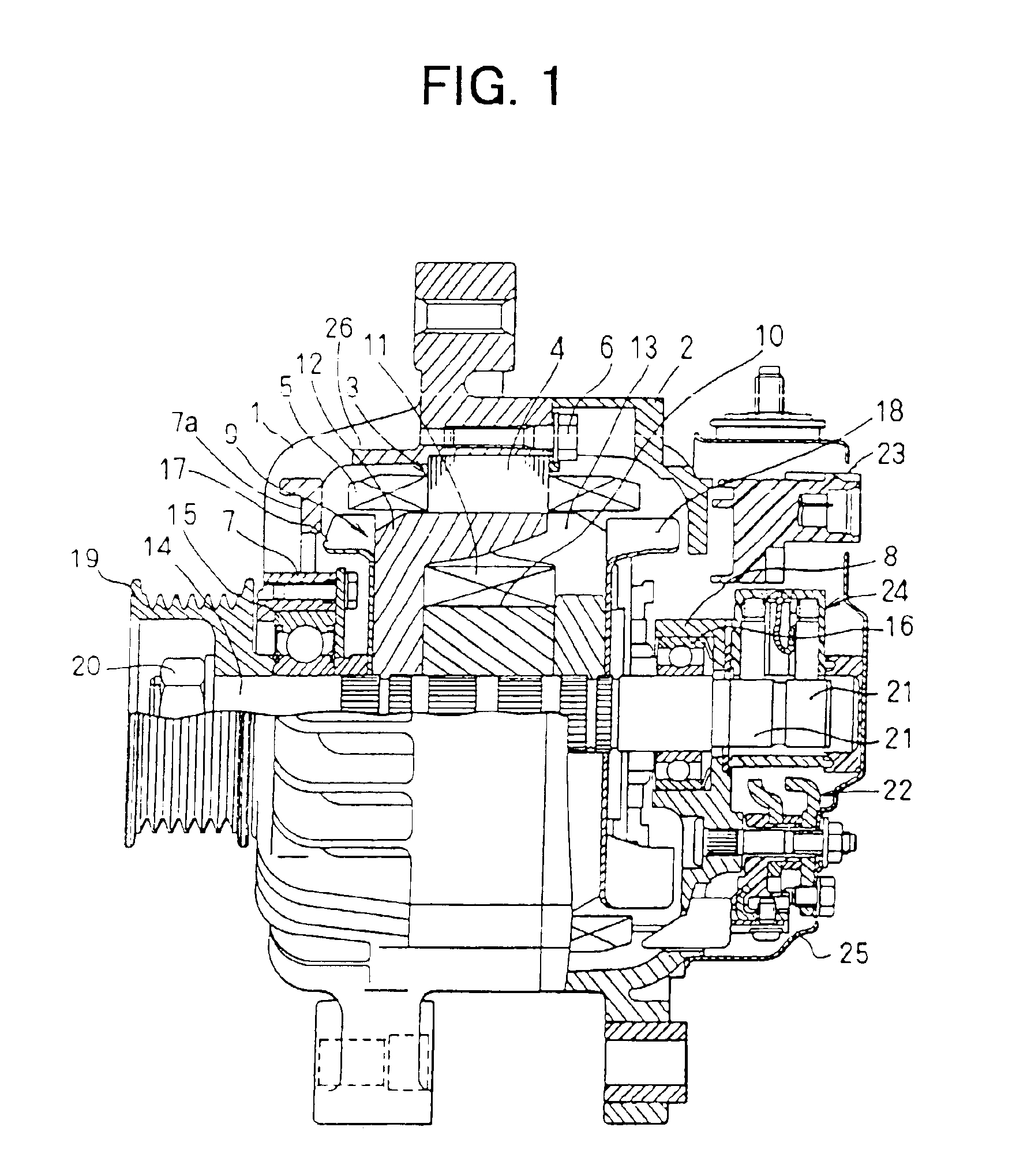

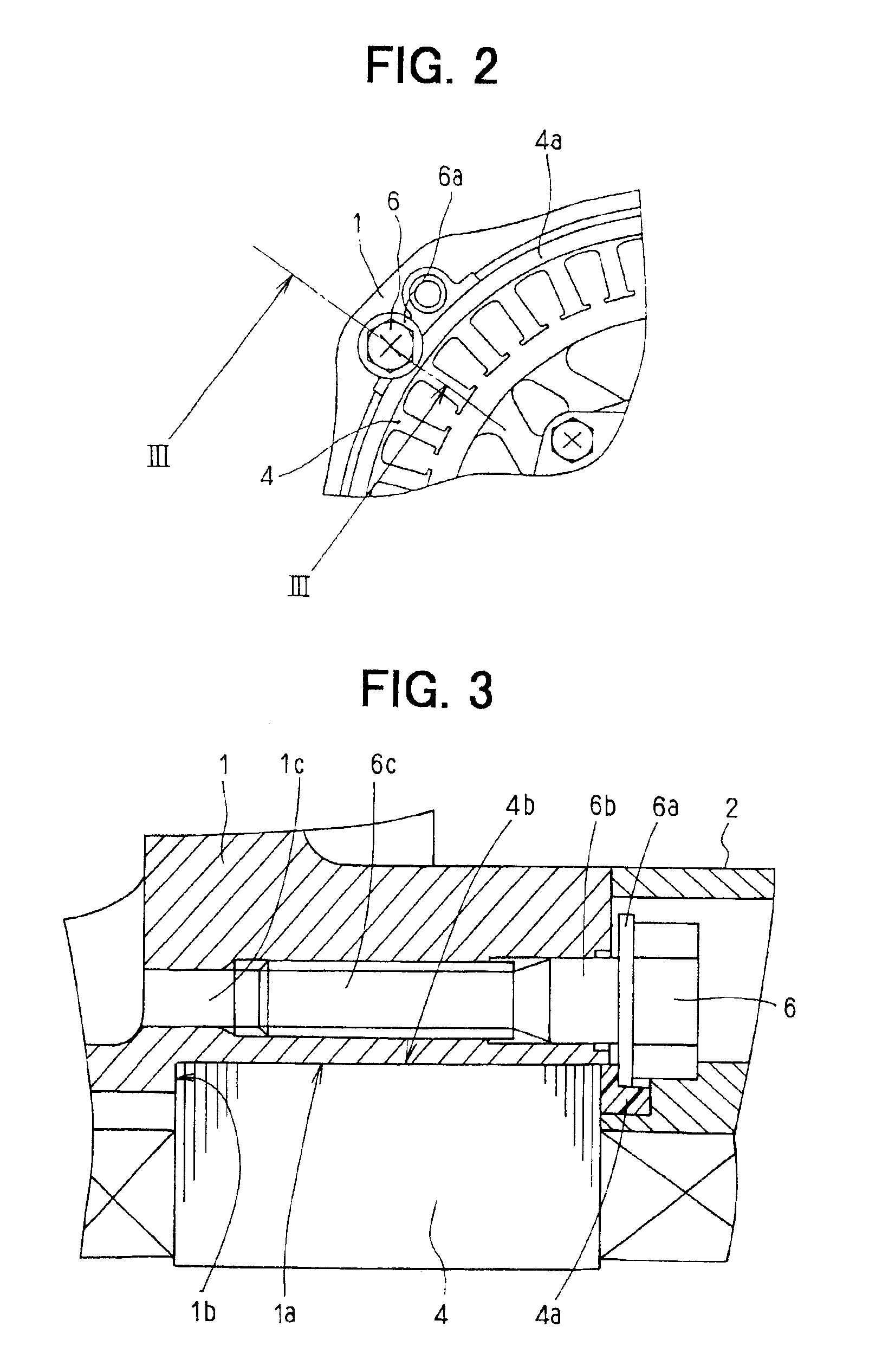

Rotary electric machine having stator rotation-restricting bolt

InactiveUS6927520B2Turn controlElectric power loss can be suppressedSynchronous generatorsMagnetic circuit stationary partsElectric machineEngineering

A stator core is fixed to a housing by pressing an axial end portion thereof in an axial direction by a flange or a washer of a bolt. An intermediate member, which is softer than the flange or the washer of the bolt, is provided at a contact portion between the flange or the washer and the axial end portion of the stator core. The stator core may have a cavity to directly receive the flange or washer of the bolt in place of the intermediate member.

Owner:DENSO CORP

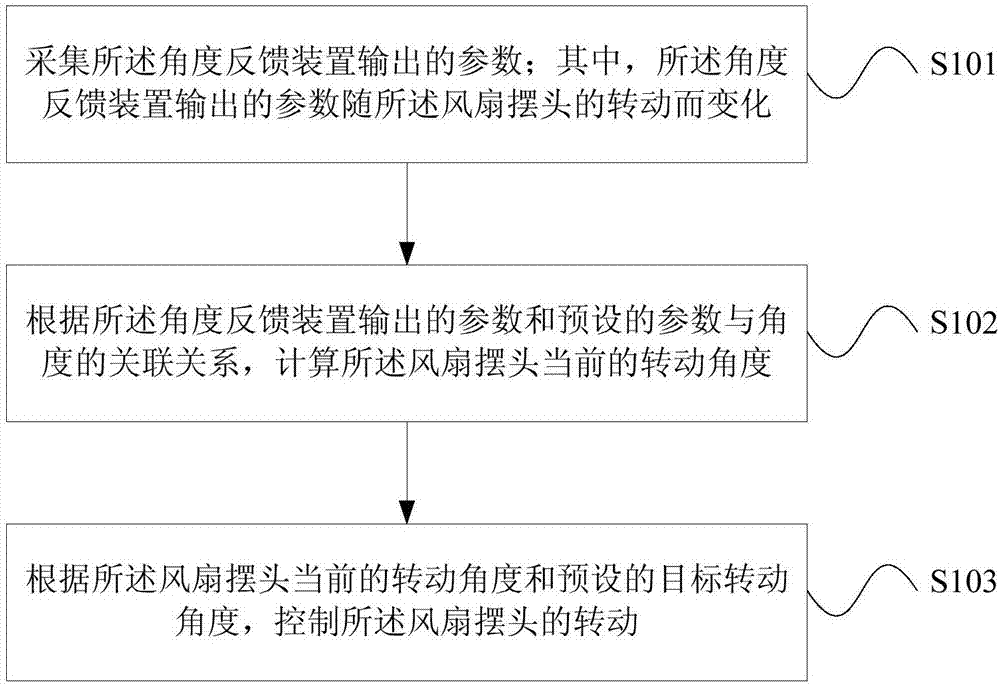

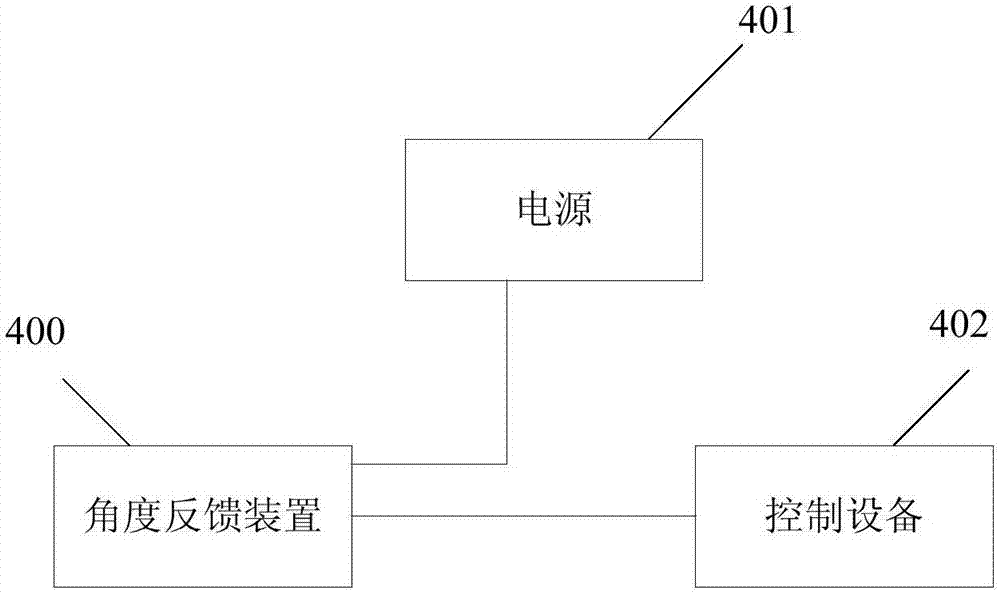

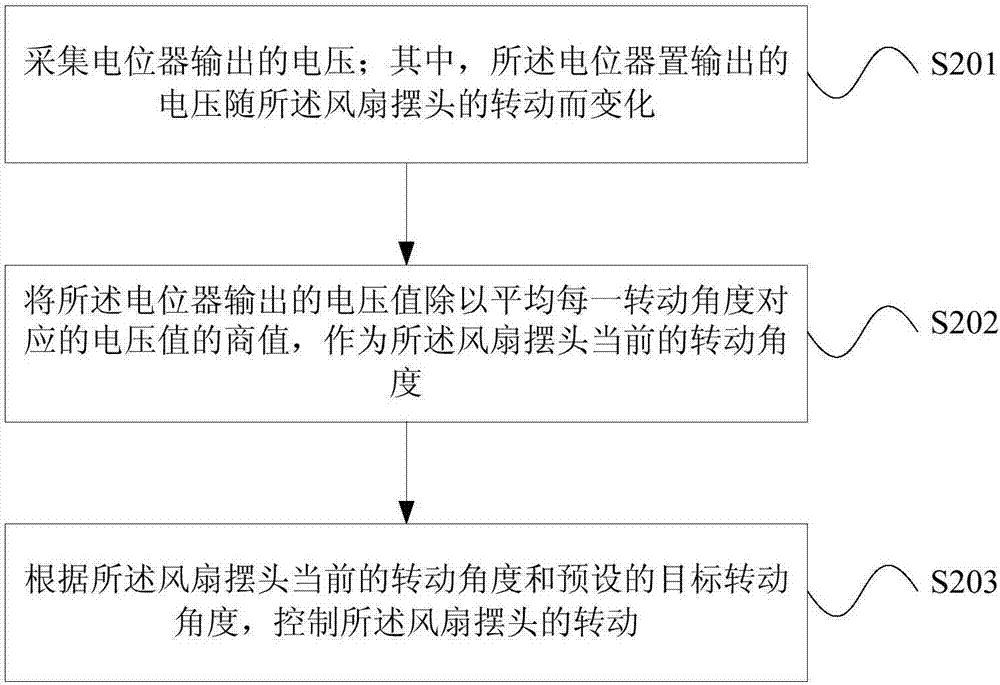

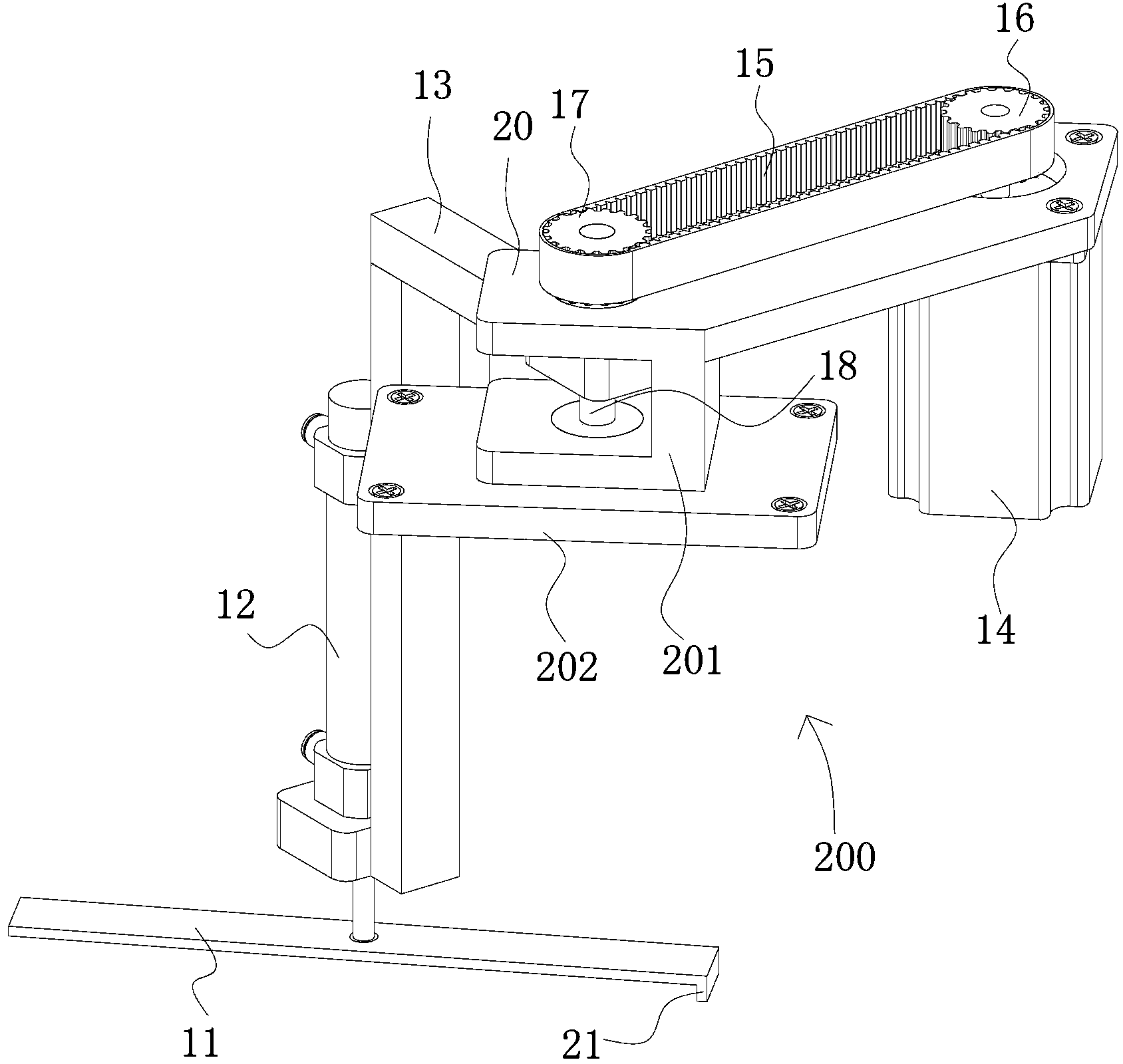

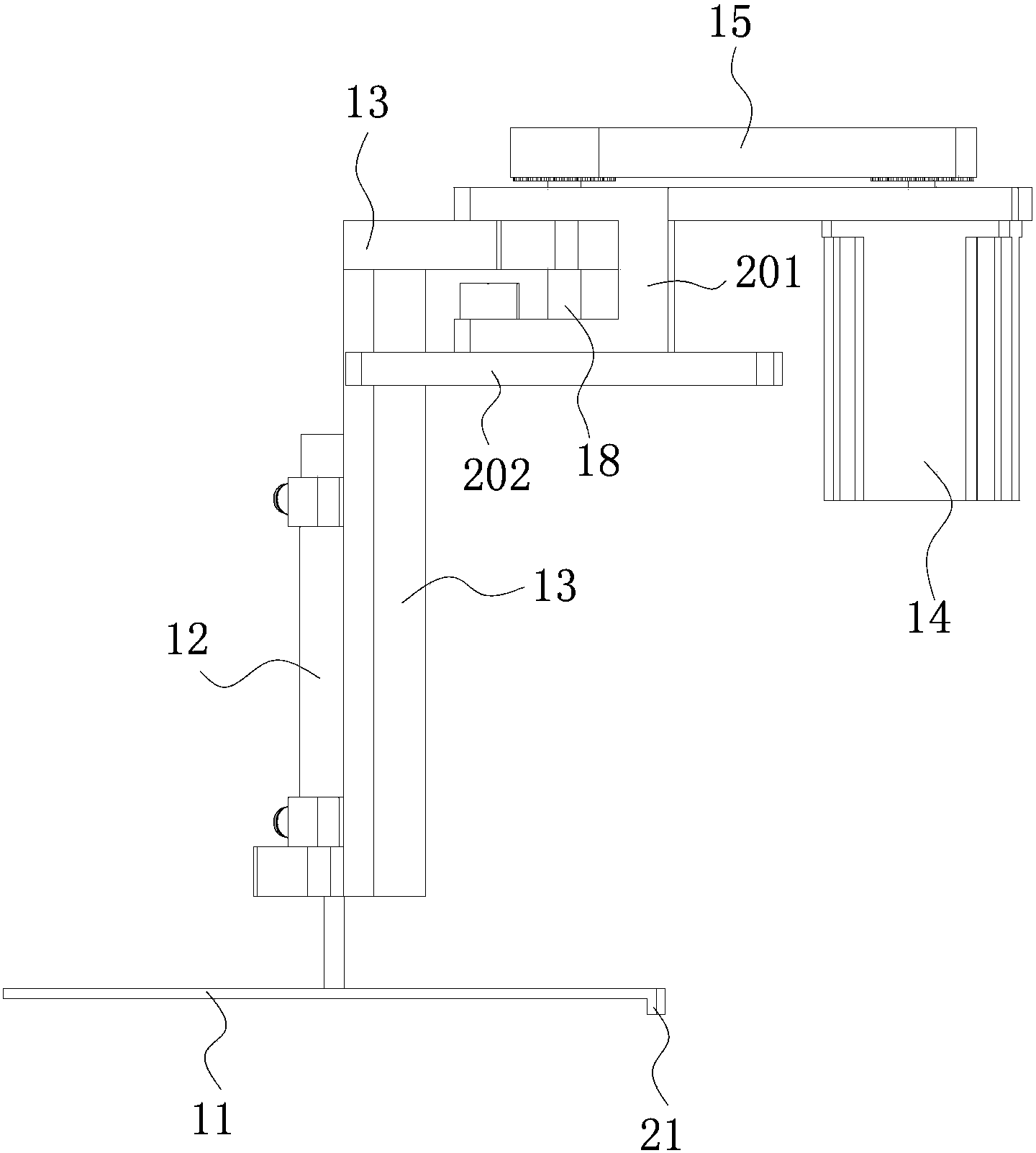

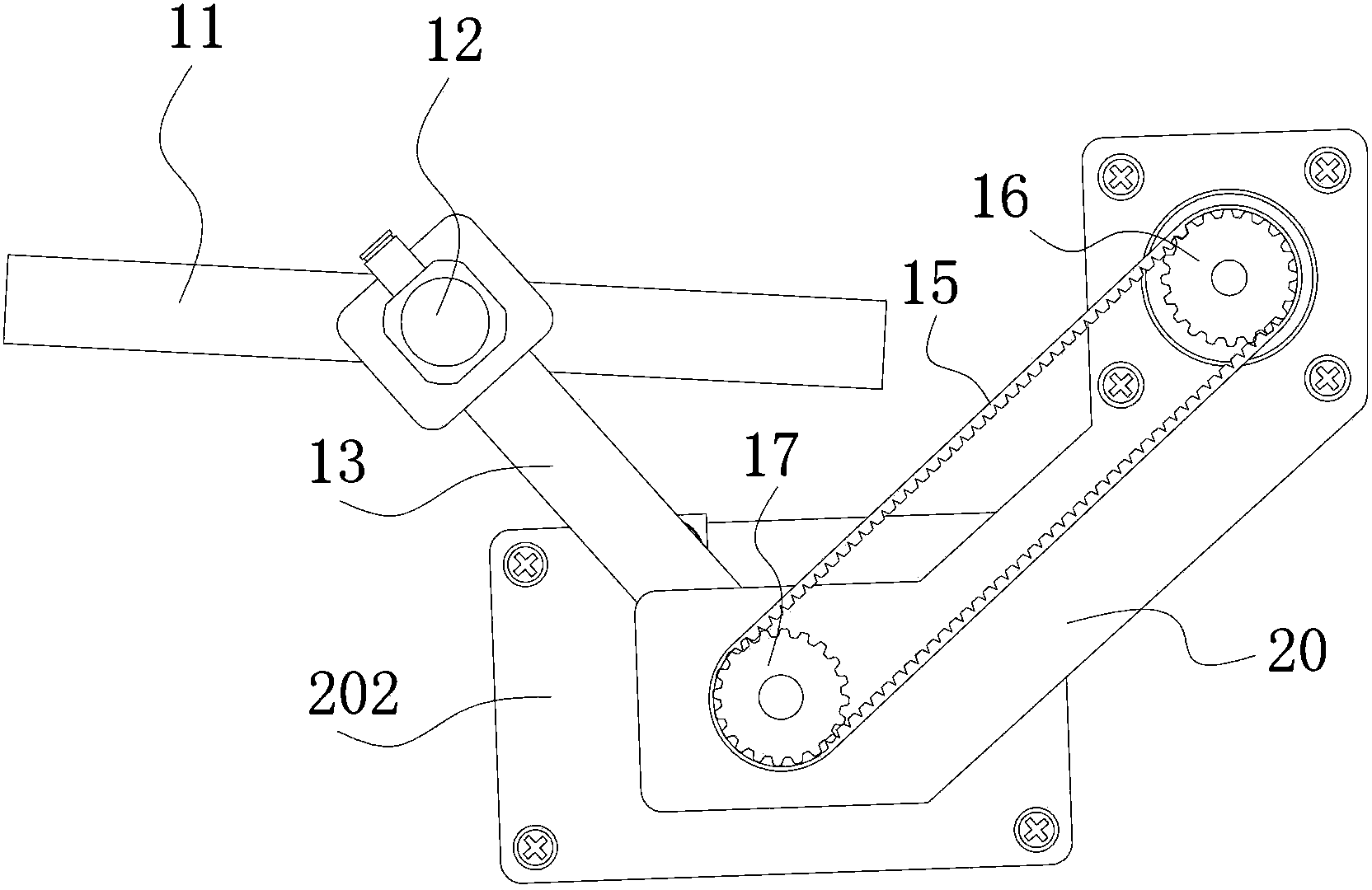

Control method for rotation angle of fan swing head, device and fan

ActiveCN107191403AExtended service lifePrecisely control the rotation angleAC motor controlPump controlBrushless motorsControl theory

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD +1

Sewing machine, sewing auxiliary device and sewing method

ActiveCN103352329AEasy sewing actionSewing does not affectProgramme-controlled sewing machinesSewing-machine control devicesAutomatic testingLine segment

The invention discloses a sewing machine, a sewing auxiliary device and a sewing method. The sewing auxiliary device is installed on an existing sewing machine, and the sewing machine is controlled through a controller to carry out automatic sewing so as to finish sewing a plurality of sewing line segments which are continuous, different in direction, and same or different in length. The sewing auxiliary device comprises the controller, a rotary mechanism, a stirring sheet and a pressing driving device for driving the stirring sheet to perpendicularly move. The rotary mechanism and the pressing driving device are electrically connected with the controller. The rotation, in the horizontal direction, of the stirring sheet is fixedly controlled by the rotary mechanism and the stirring sheet.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

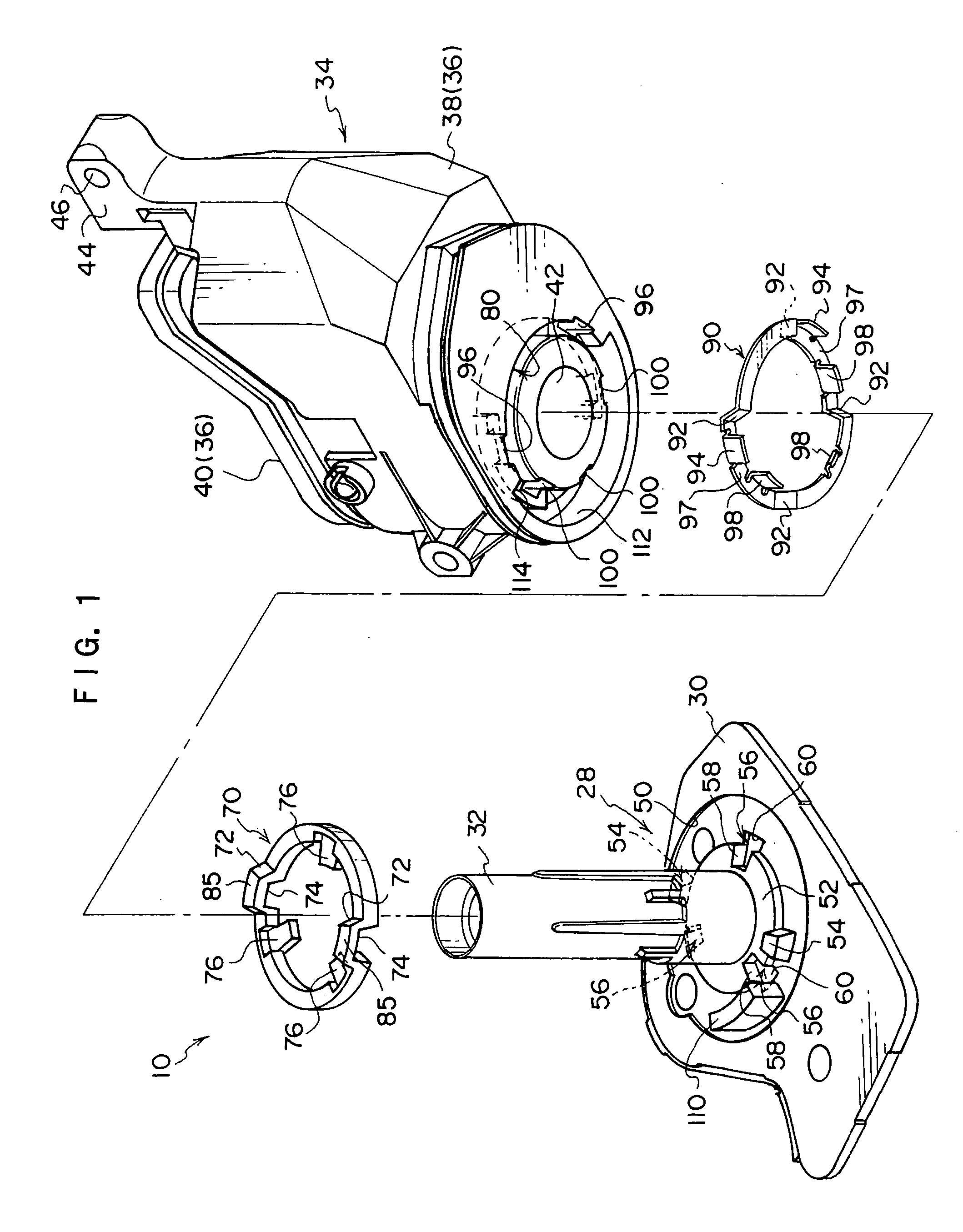

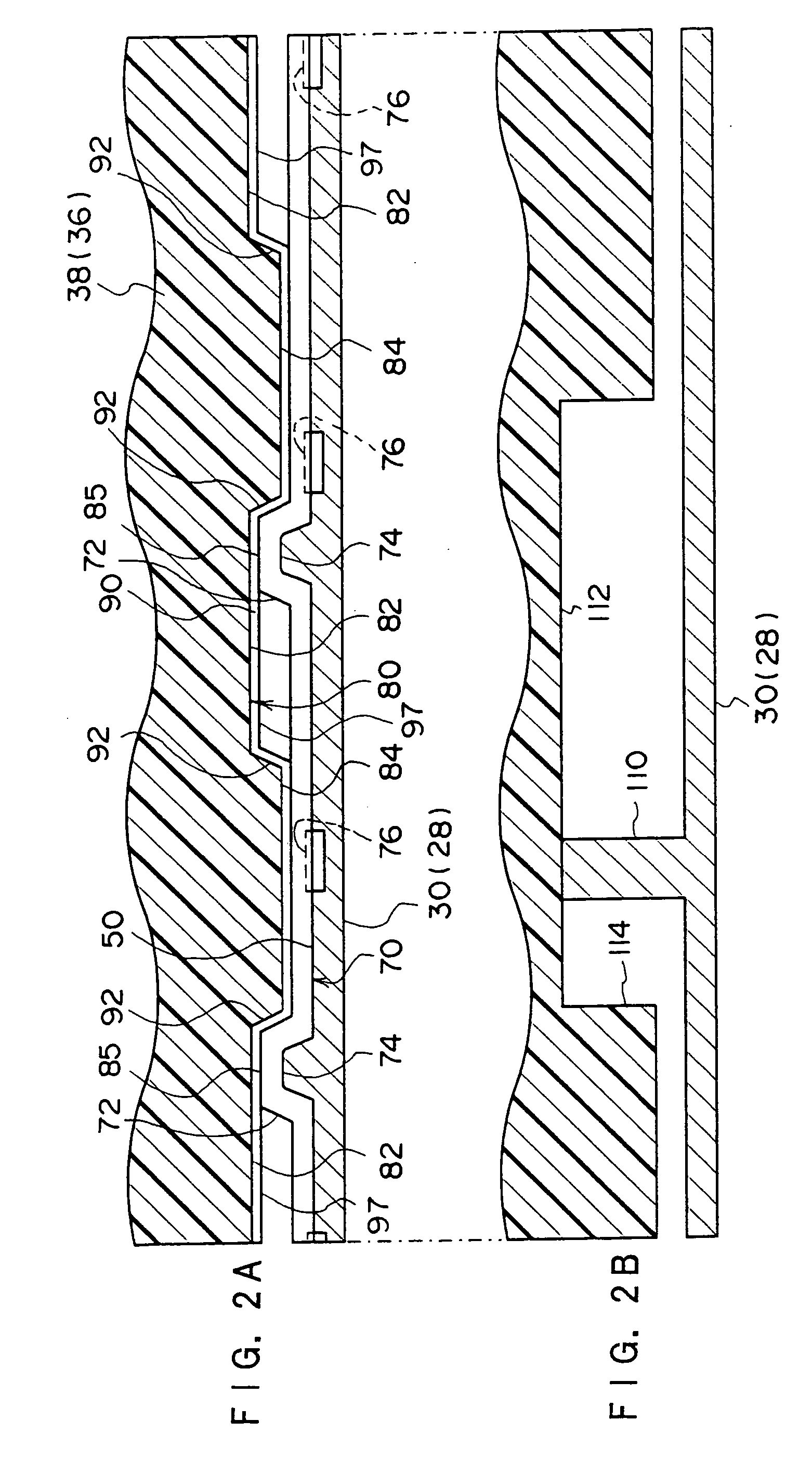

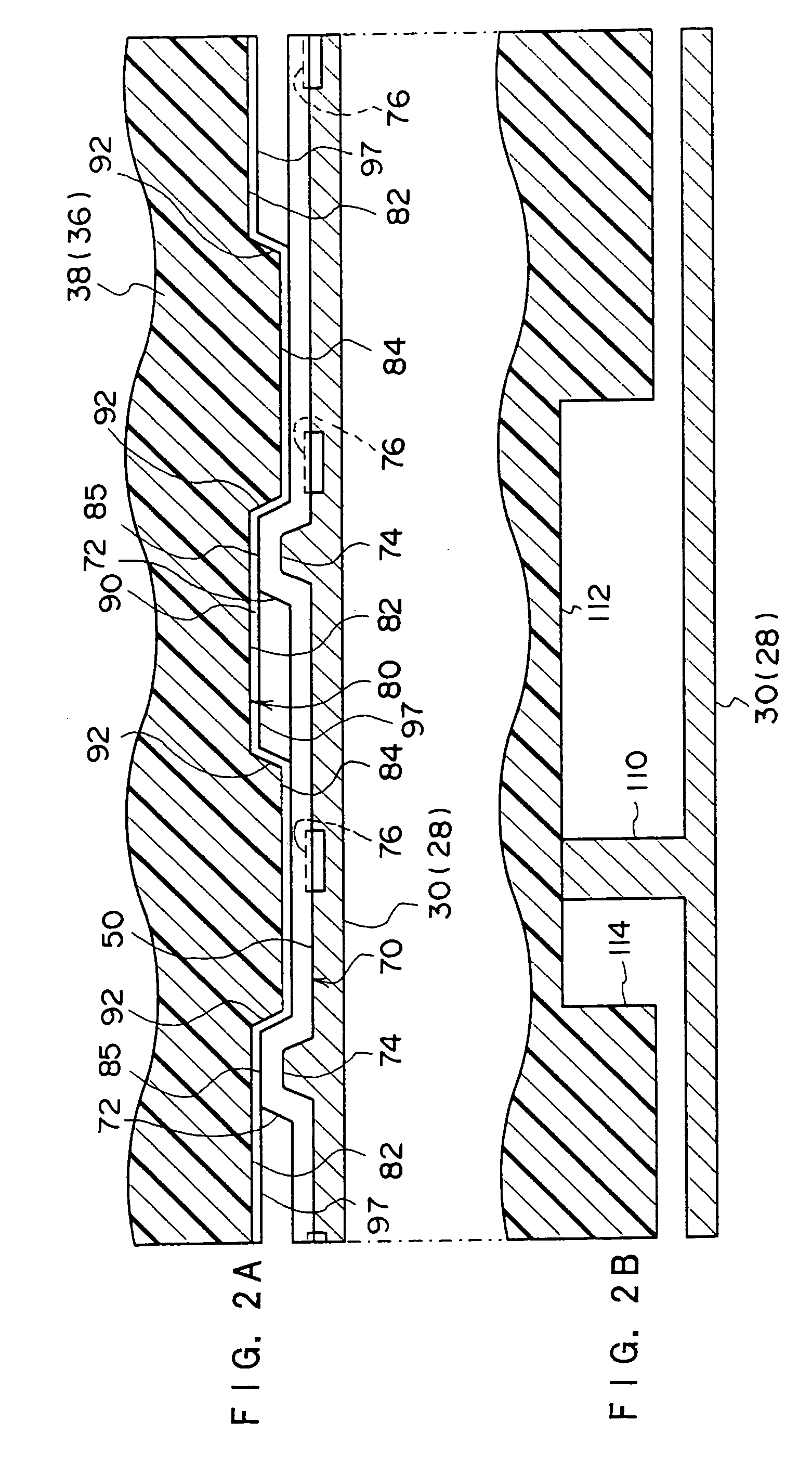

Lamp holder for lamp with a single base and lighting apparatus using the same

InactiveUS7232242B2Improve reliabilityImprove securityCoupling device connectionsLighting support devicesLight equipmentEffect light

A lamp with a single base is mounted on a lamp holder by processes of contacting a second mounting face of the base with a first mounting face of the lamp holder and turning the base in a first turning direction with respect to the lamp holder. A plurality of engaging projections is formed on the lamp holder with which a plurality of engaging protrusions of the base is engaged, when the base is turned in a first turning direction. A pair of hooking receivers is formed on a mounting face of the lamp holder so as to be hooked with a hooking protrusion of the base. A pair of lamp holding springs is provided on the lamp holder for applying forces for restricting turning of the base in a second turning direction opposite to the first turning direction under a condition that the second hooking portion of the base is hooked with the first hooking portion. Thus, safety and reliability of mounting of the lamp on the lamp holder can be increased.

Owner:MATSUSHITA ELECTRIC WORKS LTD

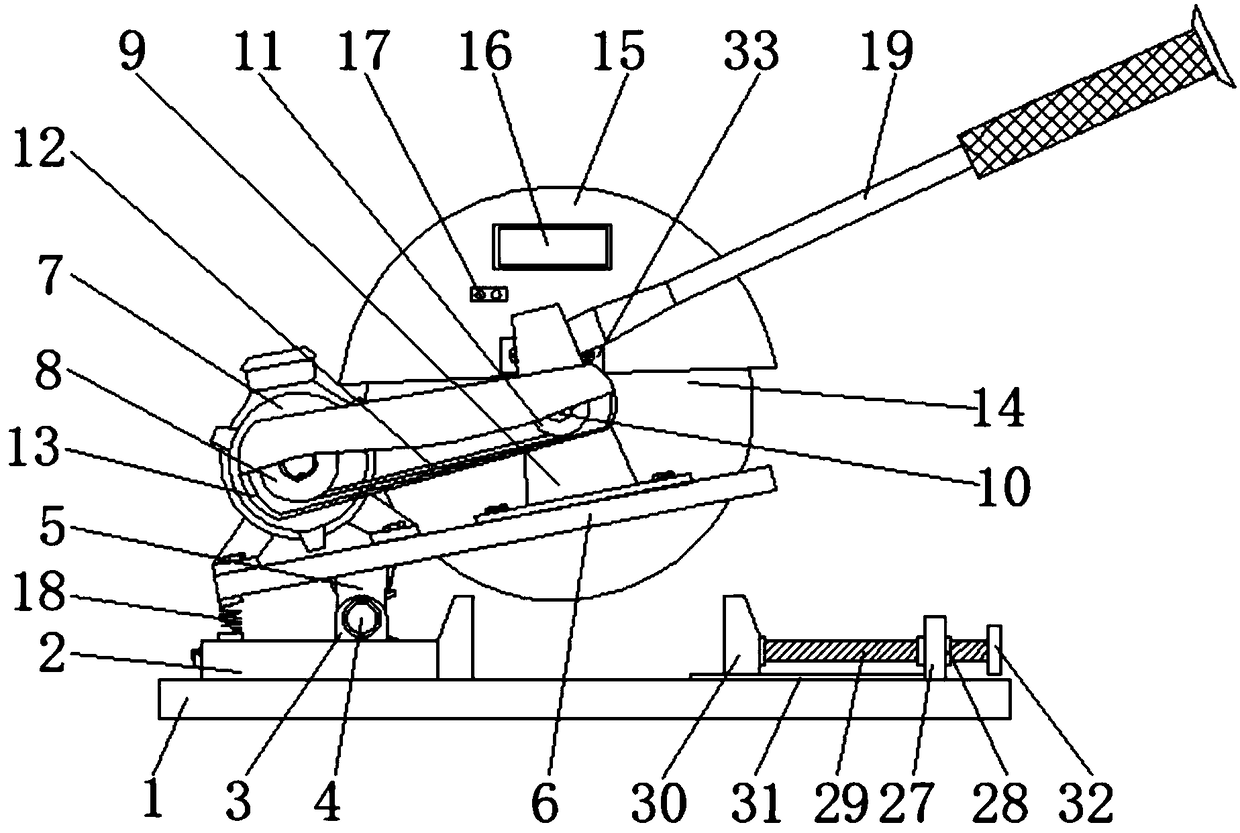

Steel pipe angle cutting machine for processing of stainless steel pipes

InactiveCN109176277ASolve the problem of inaccurate angleMeet the technical requirements of processingGrinding machinesGrinding work supportsEngineeringResistor

The invention discloses a steel pipe angle cutting machine for processing of stainless steel pipes, and relates to the technical field of cutting machines. The steel pipe angle cutting machine comprises a fixed bottom plate; the top of the fixed bottom plate is fixedly connected with an angle adjusting box, a supporting hinge column is arranged in the angle adjusting box in a penetrating mode, thetop end of the supporting hinge column is rotatably connected with a U-shaped fixing block through a rotating pin, and the top of the U-shaped fixing block is fixedly connected with a motor fixing plate; and the position, over the U-shaped fixing block, of the top of the motor fixing plate is fixedly connected with a rotating motor. According to the steel pipe angle cutting machine for processingof the stainless steel pipes, the problem that the cutting angle is inaccurate during cutting of the steel pipe angle cutting machine is solved; the supporting hinge column is rotated to drive a conductive rod to rotate, thus a sliding electric pole moves on a conductive resistor plate, and an angle measuring circuit communicates with different resistors; and the angle is judged through a currentvalue in the circuit, the deflection direction is judged through an indicator lamp, and the angle value is displayed on a cutting angle display screen more accurately and more conveniently.

Owner:襄阳福康达机械有限公司

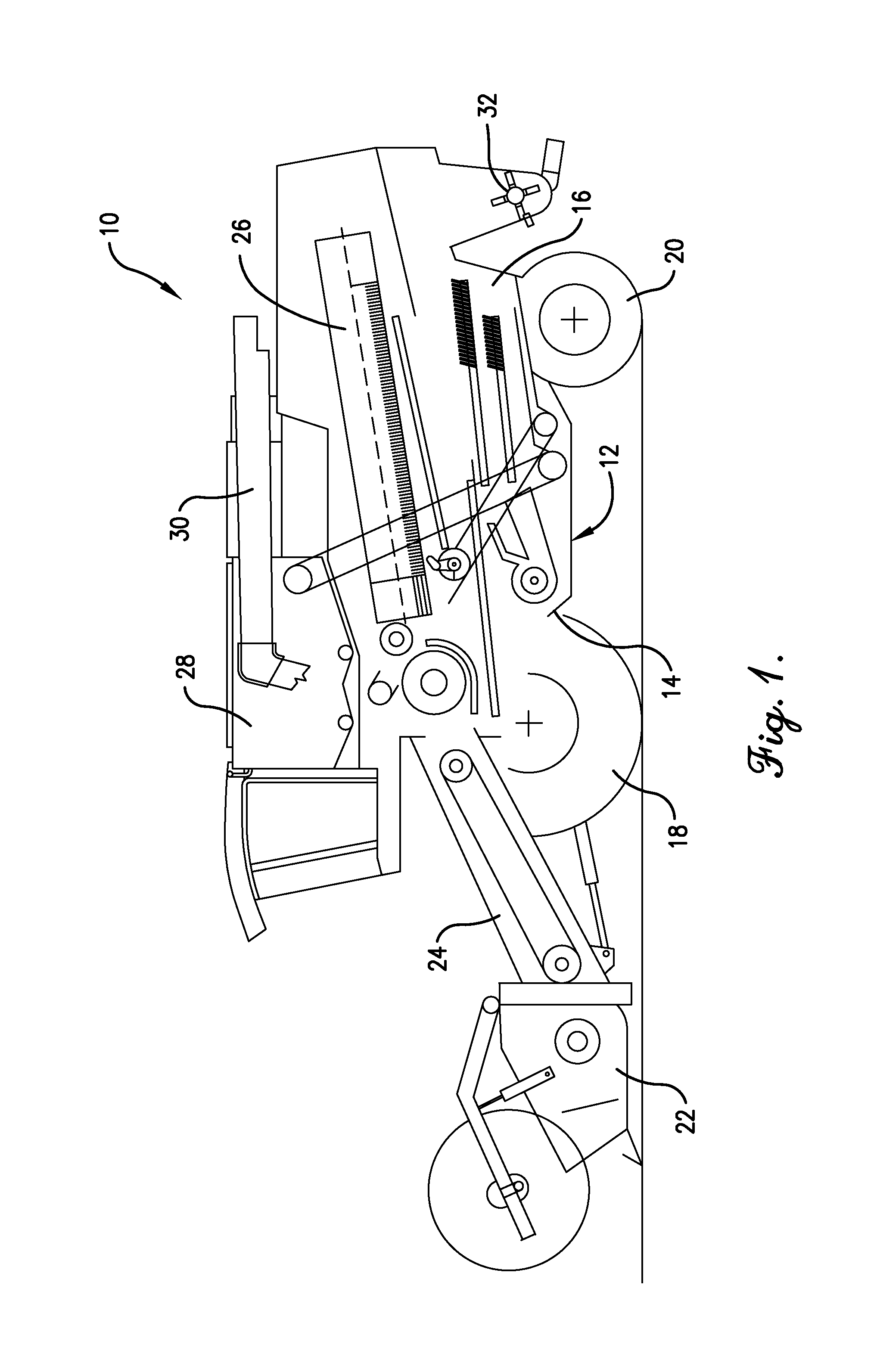

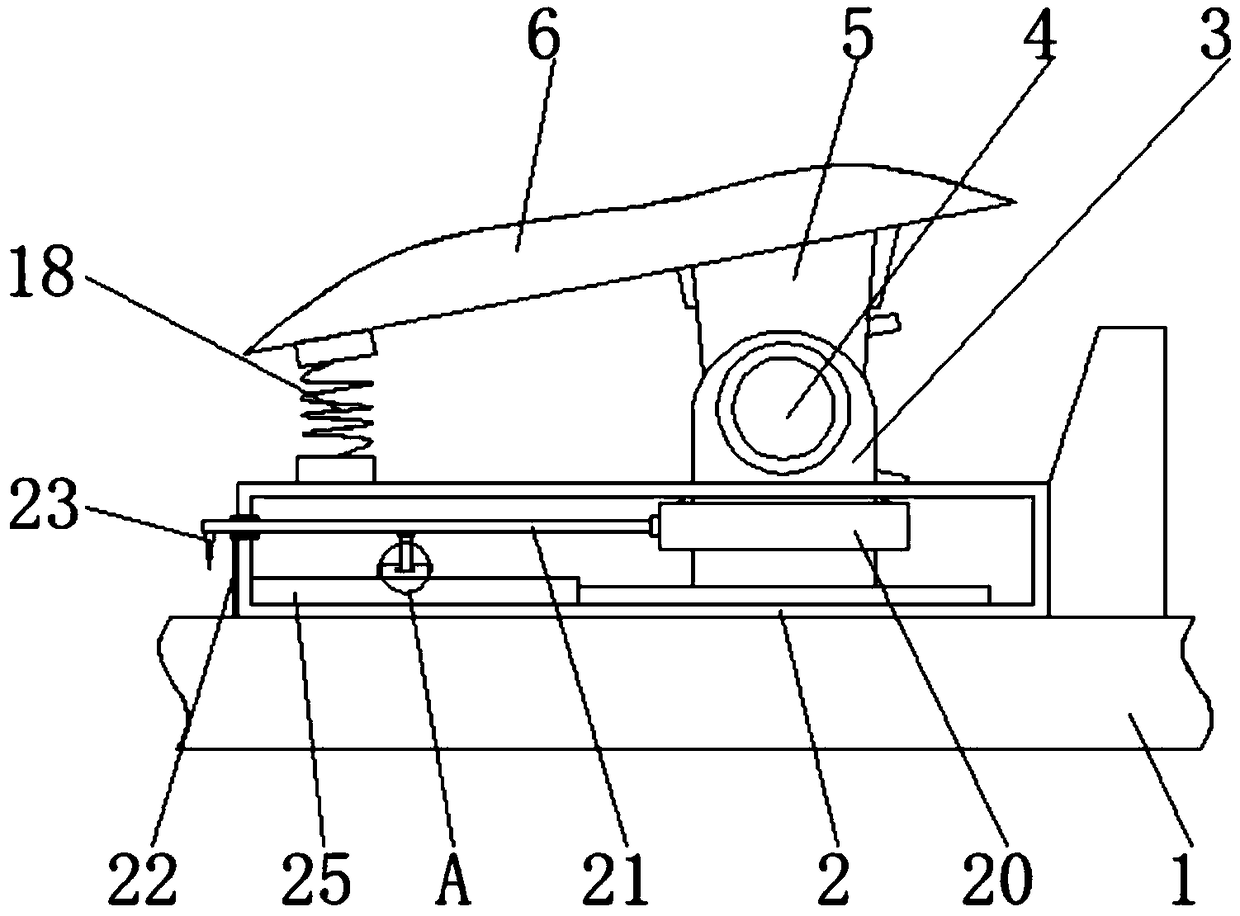

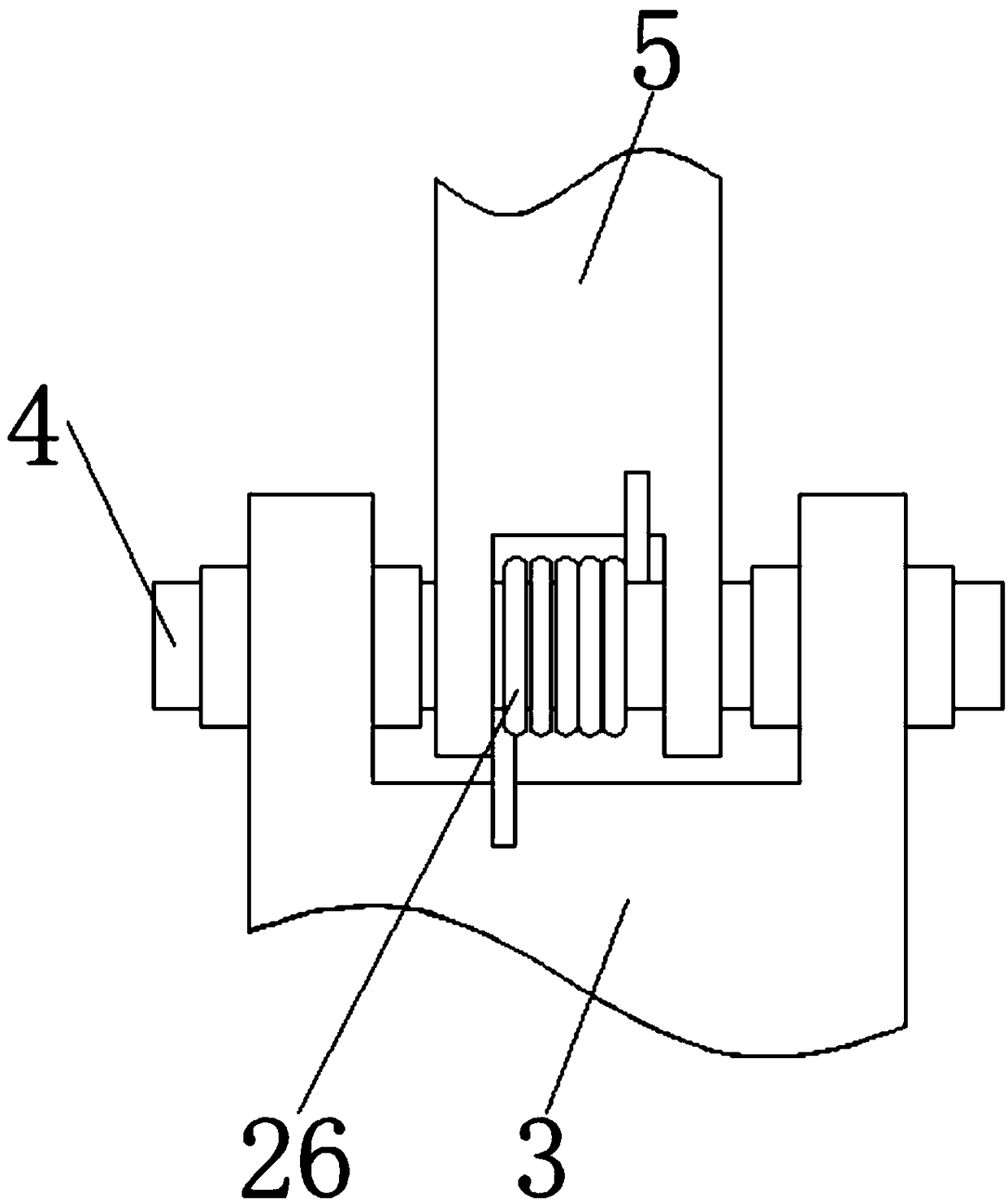

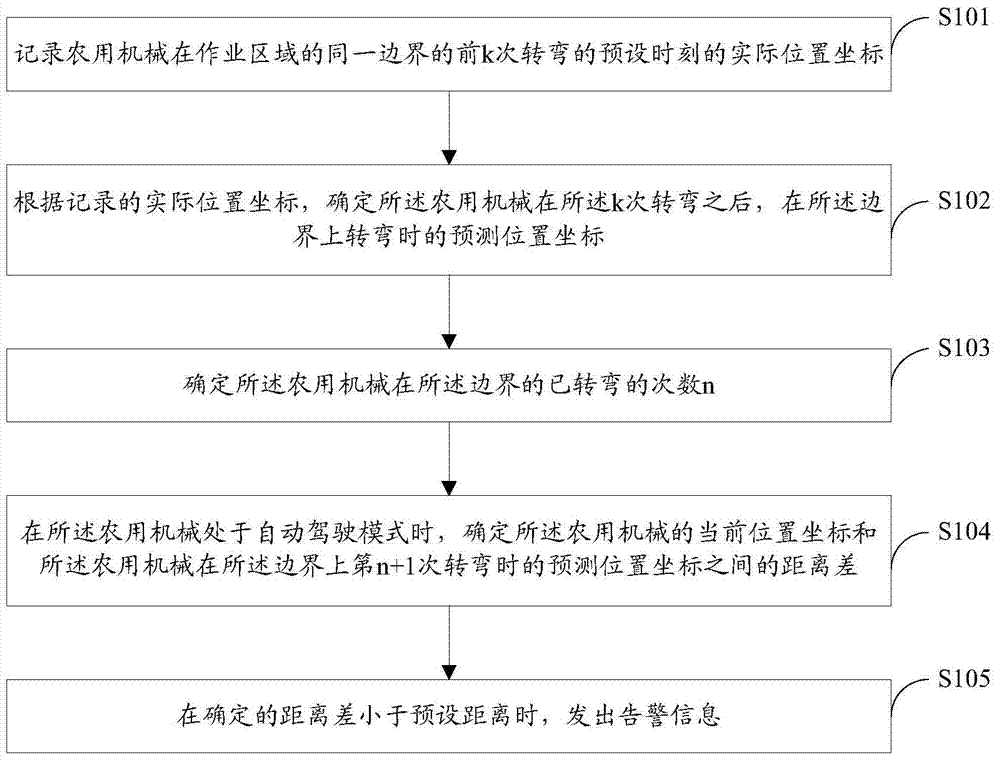

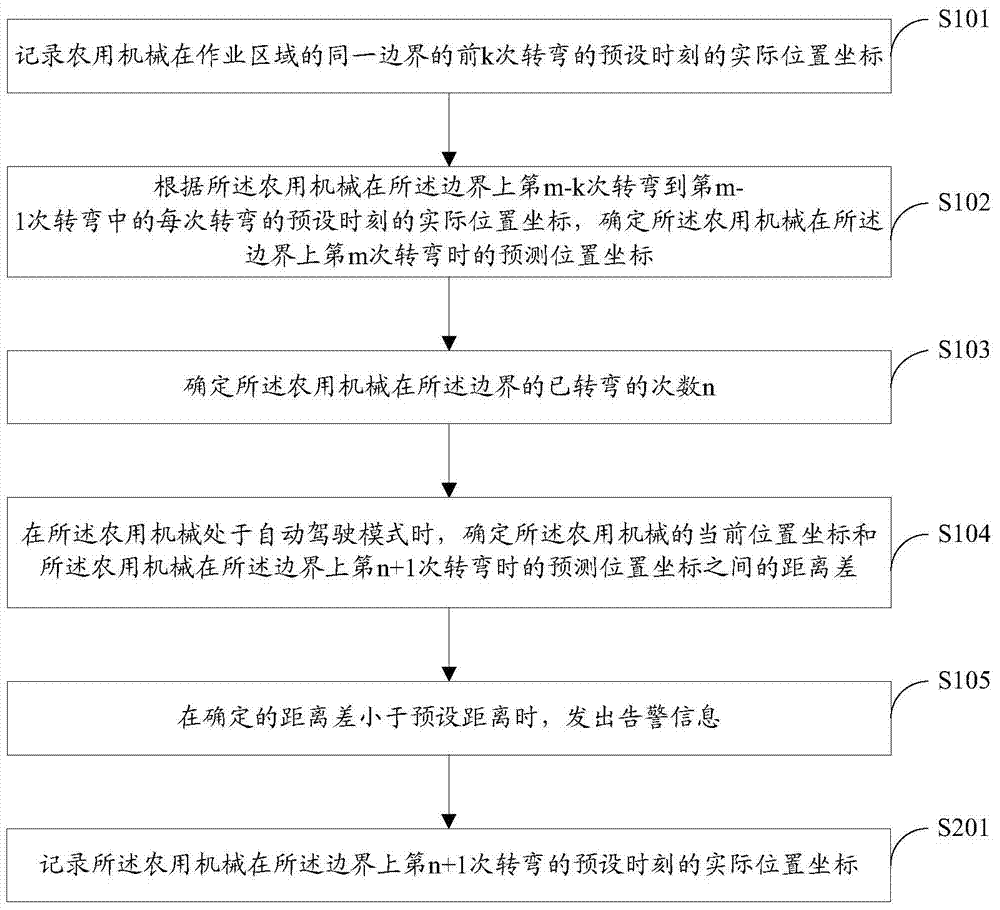

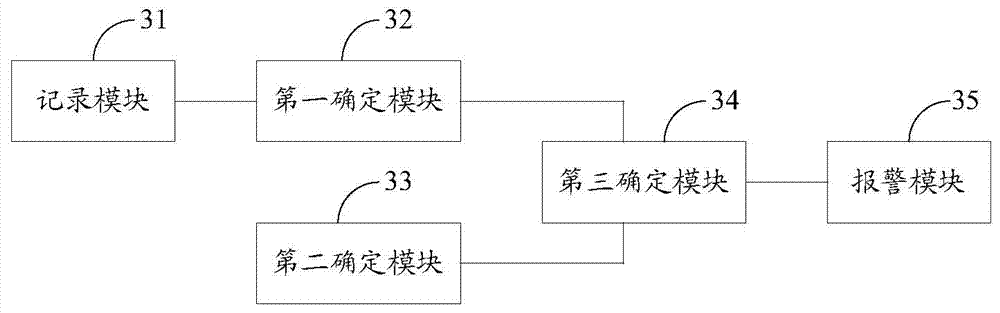

Turning pre-warning method and device for agricultural machine and agricultural machine

The embodiment of the invention provides a turning pre-warning method and device for an agricultural machine and the agricultural machine, which are used for solving the problem that existing headland prediction warning is not applicable for non-rectangular farmland. The method comprises the following steps: actual position coordinates of the agricultural machine at preset moments of the first k times of turning on the same boundary of a working area are recorded, wherein k is a natural number; prediction position coordinates of the agricultural machine on the boundary are determined according to the recorded actual position coordinates when the agricultural machine turns after turning k times; the turning times n of the agricultural machine on the boundary is determined, wherein n is a natural number larger than or equal to k; the distance difference between the current position coordinates of the agricultural machine and the prediction position coordinates of the agricultural machine during the (n+1)th turning on the boundary is determined; when the distance difference is smaller than a preset distance, a warning message is sent out.

Owner:ZOOMLION HEAVY IND CO LTD

Solid-liquid twofold dauber

InactiveUS20070102443A1Easy to useConvenient carryingLiquid surface applicatorsCoin-freed apparatus detailsLiquid mediumEngineering

The invention relates to a double-duty applicator for solid and liquid mediums, comprising a columned bearer and an outer tube combined to contain solid medium, and extending from a double-stage columned base. At the other end of said base is fixed a soft tube containing liquid medium. Said outer tube covers the outside of the bearer, with inner threads on the inner wall therein, which matches with outer threads of the bearer. The bottom end of the outer tube is fixed outside a smaller columned flange of the base through fastening slots, and a limiting mechanism is positioned between the bottom of the bearer and the base to limit the turning of the bearer. The invention adds a liquid medium applicator to the conventional solid medium applicator structure, and combines both applicator structures together, thereby making it easy to carry and use.

Owner:MTL CORP

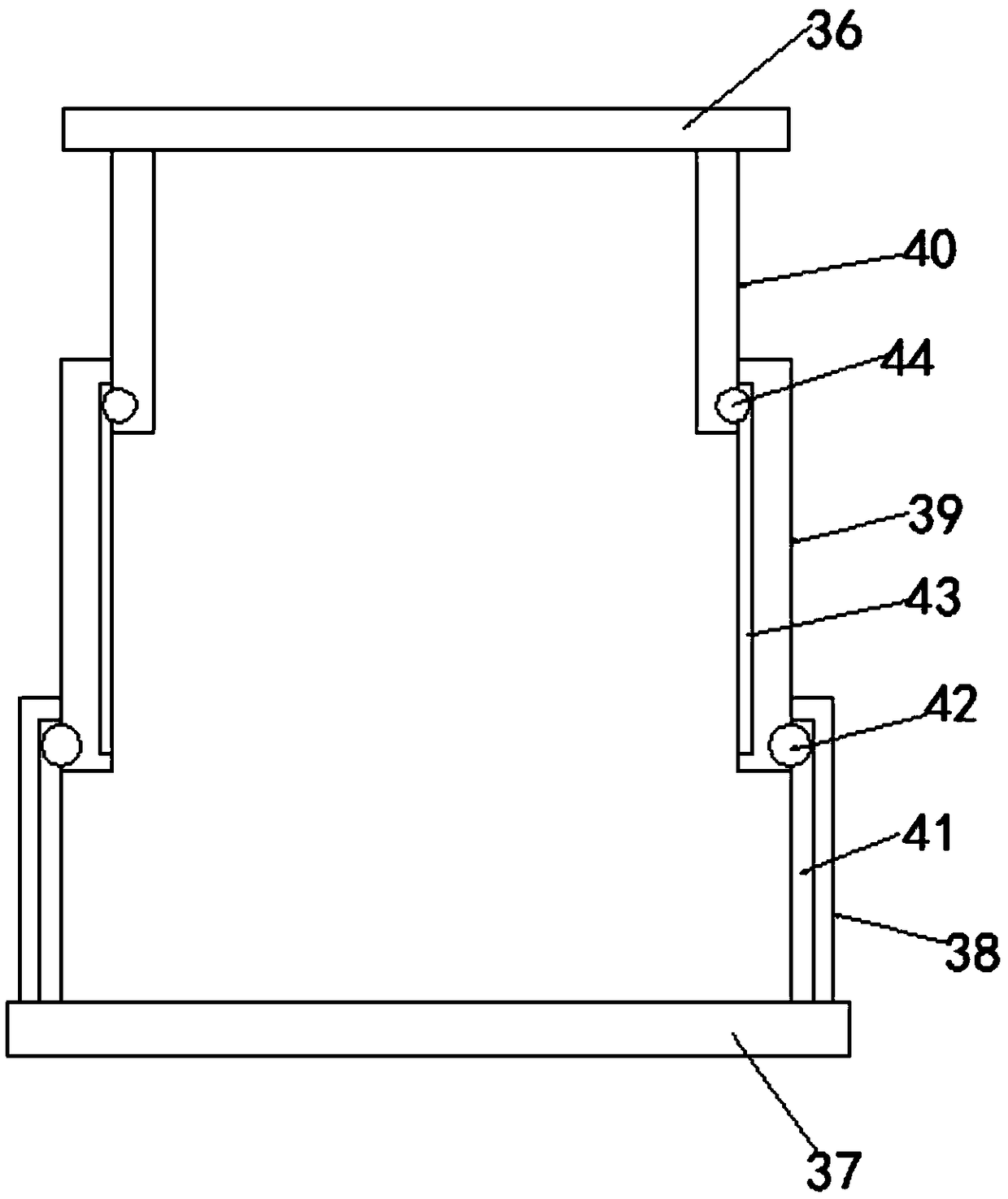

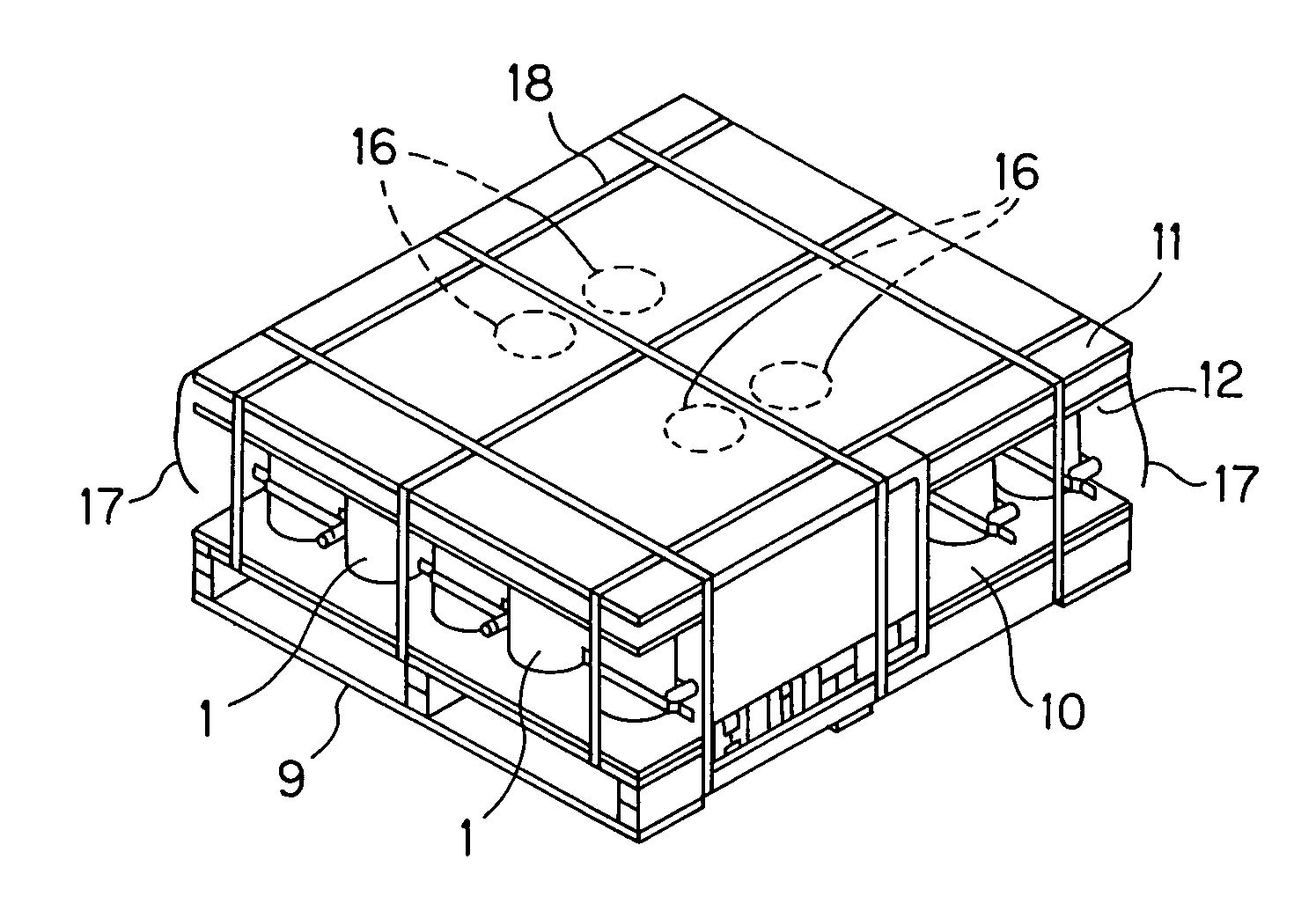

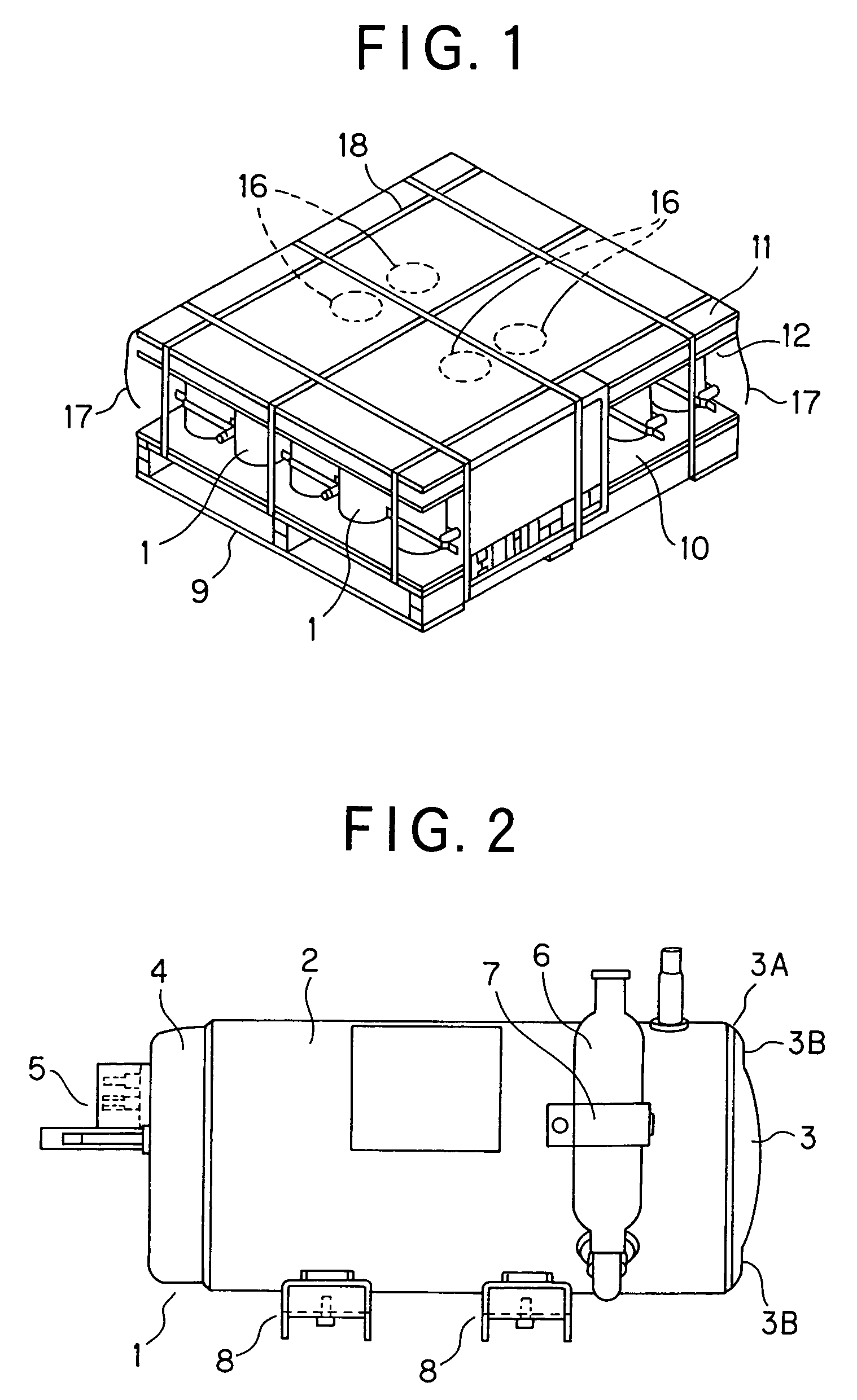

Packaging apparatus and method for compressor

ActiveUS7458461B2Avoid damageTurn controlPackaging vehiclesContainers for machinesEngineeringMechanical engineering

A compressor packaging apparatus for fixing plural compressors each of which has dish-shaped end caps at both the upper and lower end portions of a cylindrical compressor body, including an upper plate and a lower plate between which the compressors are sandwiched and fixed, the lower plate being equipped with a plurality of stepped fitting portions in which the lower end caps of the compressors are fitted, and first paper pipes fitted to the stepped fitting portions. Furthermore, an intermediate plate having plural insertion holes in which the compressor bodies are inserted is provided, and second paper pipes fitted to the end caps at the upper portions of the compressors and third paper pipes may be provided between the upper plate and the intermediate plate.

Owner:SANYO ELECTRIC CO LTD +1

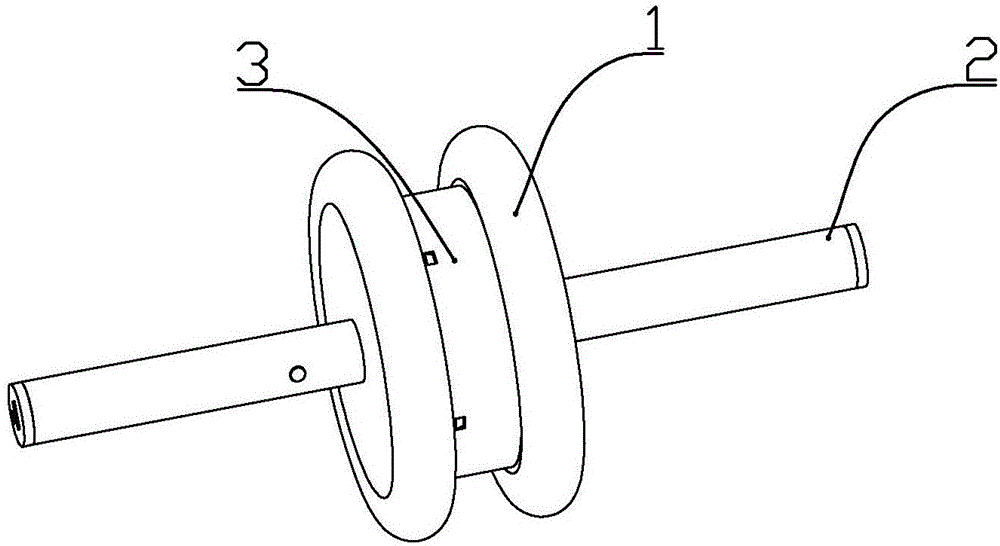

Abdominal muscle exercise equipment

ActiveCN106267711AEven by forceTurn for easy controlMovement coordination devicesCardiovascular exercising devicesPortable powerEngineering

The invention discloses abdominal muscle exercise equipment. The abdominal muscle exercise equipment comprises a supporting pipe, two rollers arranged on the supporting pipe and a speed change mechanism installed between the two rollers. Motors are fixedly installed at the two ends in the supporting pipe respectively, a circuit board and a storage battery are fixedly installed at the positions, at the outer ends of the two motors, in the supporting pipe respectively, portable power sources are installed at the two ends in the supporting pipe, and a reverse rotation button is fixedly connected to the position, close to one roller, of the outer wall of the supporting pipe. The speed change mechanism comprises a transmission base, a positioning frame and an annular gear. According to the abdominal muscle exercise equipment, rotation of the rollers can be conveniently controlled, and the situation that as the rollers roll out of control, strain of a user is caused can be prevented; the abdominal muscle exercise equipment can serve as a common abdominal exercise roller by taking out the speed change mechanism; the portable power sources in the supporting pipe can be taken out as needed to serve as a portable charger.

Owner:NANTONG TENGTAI SPORTING FITNESS CO LTD

Door holding device for vehicle

ActiveUS9617759B2Turn controlPrevent openingAccident situation locksRoad vehiclesEngineeringCar door

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com