Smoke leakage prevention side suction type range hood convenient to maintain

A side-suction type, range hood technology, applied in the direction of removing soot, heating, household heating, etc., can solve the problems of soot escaping, affecting the fume exhaust effect of the side-suction type range hood, easily blocking soot, etc., to prevent escape. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

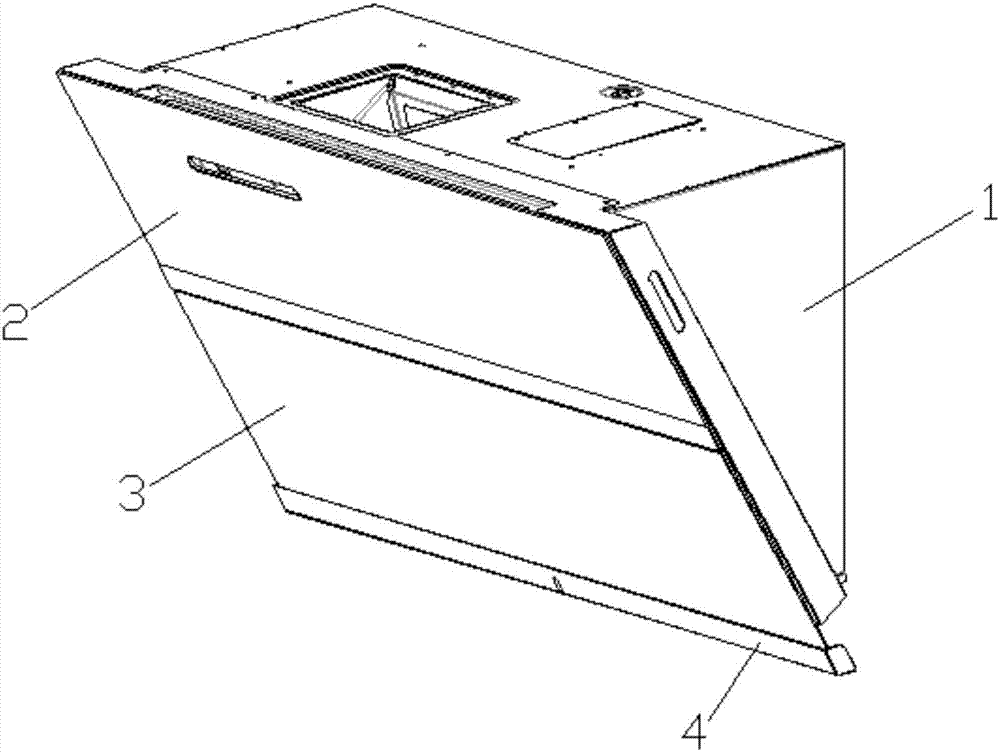

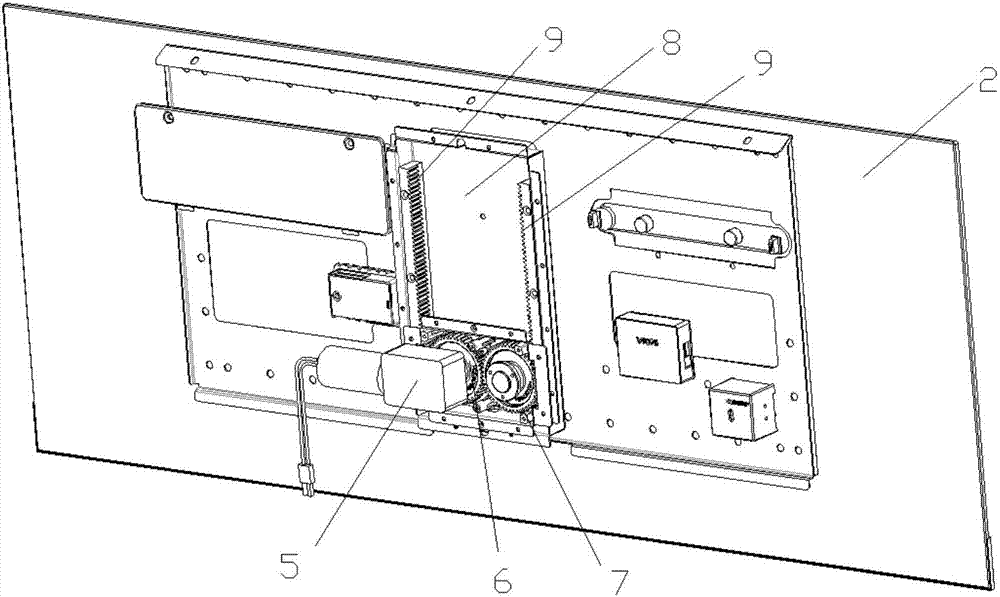

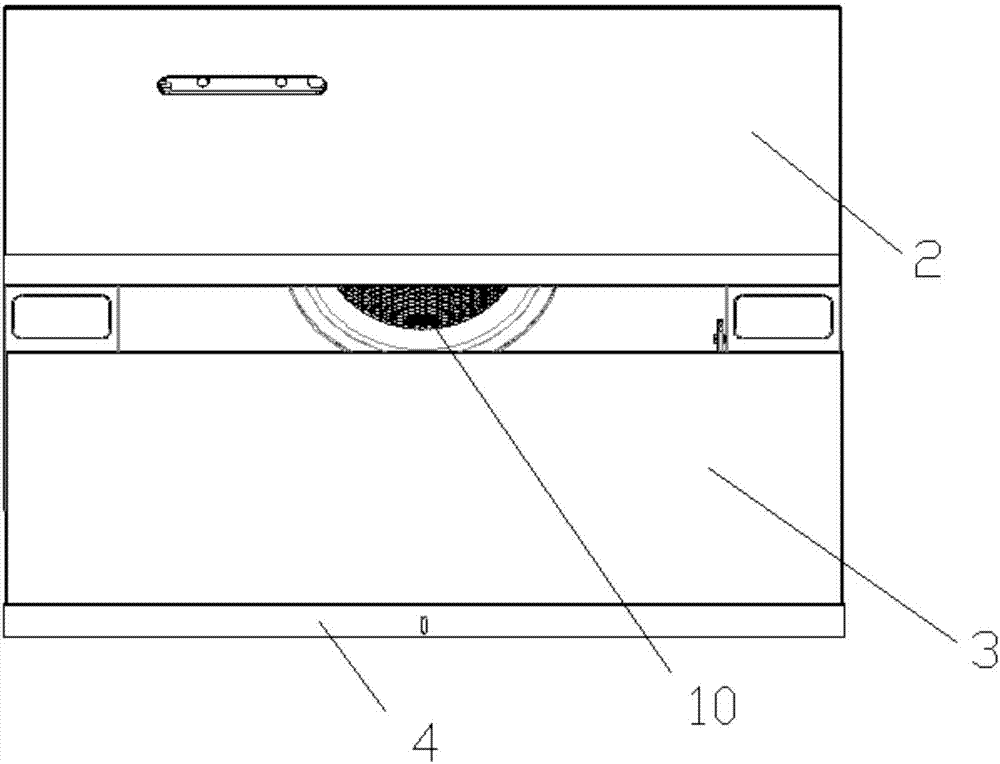

[0019] The present invention provides a side-suction range hood that prevents running smoke and is easy to maintain. The specific structure is as follows: figure 1 with figure 2 As shown, it includes a housing 1 and a front panel, wherein the top surface and the back of the housing 1 adopt a right-angle design structure, which can make the back of the housing 1 tightly contact with the wall when the range hood is installed. At the same time, the front panel is installed inclined downwards to reduce the space between the bottom of the front panel and the wall, further preventing the oil fumes from escaping along the bottom of the front panel to the back of the range hood. The front of the front panel is respectively provided with a main air suction port 10 and an auxiliary air suction port 11 , and the auxiliary air suction port 11 is a mesh structure and is located at the bottom of the main air suction port 10 . In order to prevent the smell of oil fume in the public flue wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com