Grating film and three-dimensional display device

A technology of a three-dimensional display device and a grating film, which is applied in the direction of diffraction gratings, optics, optical elements, etc., can solve the problems of inconvenient relative movement, etc., and achieve the effect of improving the display effect and improving the flickering of the screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0047] Example 1

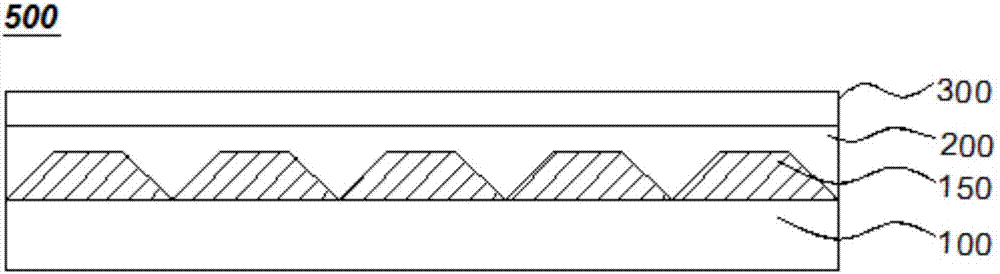

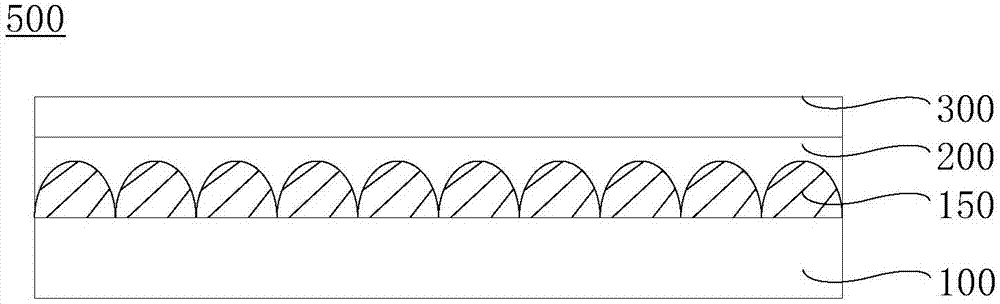

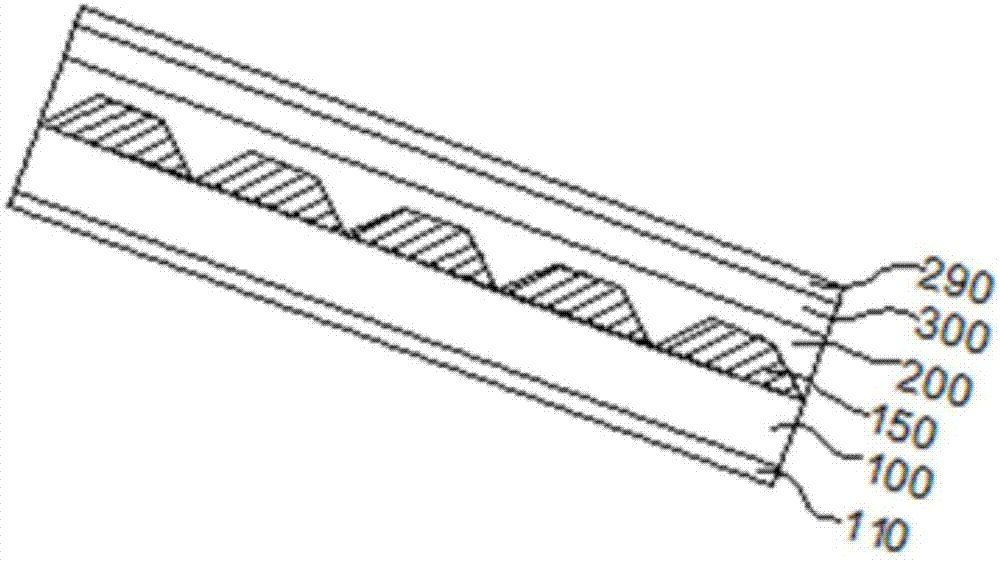

[0048] The embodiment of the present invention provides a grating film, such as figure 1 As shown, the grating film 500 includes a first substrate 100, a first microstructure 150, a second microstructure 200, and a second substrate 300 arranged in sequence;

[0049] The first microstructure 150 is disposed on the surface of the first substrate 100, and the second microstructure 200 is disposed on the surface of the second substrate 300; the shape of the first microstructure 150 is complementary to the shape of the second microstructure 200, and the first microstructure 150 It is anastomosedly connected with the second microstructure 200.

[0050] In the embodiment of the present invention, the grating film 500 includes a first substrate 100 and a second substrate 300 disposed opposite to each other. The materials of the first substrate 100 and the second substrate 300 are both flexible and high-transmittance materials, such as PET (polyethylene glycolterephthalate...

Example Embodiment

[0060] Example 2

[0061] The embodiment of the present invention provides a stereoscopic display device, such as Figure 5 As shown, the stereoscopic display device 1000 includes a 2D liquid crystal display module 450 and the grating film 500 provided in the first embodiment;

[0062] The first substrate 100 of the grating film 500 and the side of the 2D liquid crystal display module 450 close to the user are bonded together by the adhesive 400; the extension direction of the first microstructure 150 and the second microstructure 200 of the grating film 500 is consistent with The extension direction of the sub-pixels of the same color in the 2D liquid crystal display module 450 is vertical.

[0063] Figure 5 A cross-sectional view of the stereoscopic display device 1000 is shown. Among them, in the 2D liquid crystal display module 450, in the direction perpendicular to the cross-sectional view, each column of sub-pixels has three sub-pixels: R (Red), G (Green), and B (Blue, blue) ...

Example Embodiment

[0074] Example 3

[0075] The embodiment of the present invention provides a stereoscopic display device, such as Picture 10 As shown, the stereoscopic display device 1000 includes a 2D liquid crystal display module 450 and the grating film 500 provided in the first embodiment;

[0076] The second substrate 300 of the grating film 500 and the side of the 2D liquid crystal display module 450 close to the user are bonded together by the adhesive 400; the extension direction of the first microstructure 150 and the second microstructure 200 of the grating film 500 is consistent with The extension direction of the sub-pixels of the same color in the 2D liquid crystal display module 450 is vertical.

[0077] Picture 10 A cross-sectional view of the stereoscopic display device 1000 is shown. Since the thickness of the second substrate 300 of the lenticular film 500 is less than the thickness of the first substrate 100, when the second substrate 300 of the lenticular film 500 is arrange...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap