Display substrate and manufacturing method thereof and display device

A technology for display substrates and substrates, which is applied in the direction of image reproducers, static indicators, and picture replicators of solid-state color display devices, and can solve the problems of sub-pixel display brightness and chromaticity deviation, display screen flicker, time inconsistency, etc. , to achieve the effect of improving display quality, improving screen flicker, and improving user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0064] In order to further illustrate a display substrate, a manufacturing method thereof, and a display device provided by the embodiments of the present invention, the following detailed description is given with reference to the accompanying drawings.

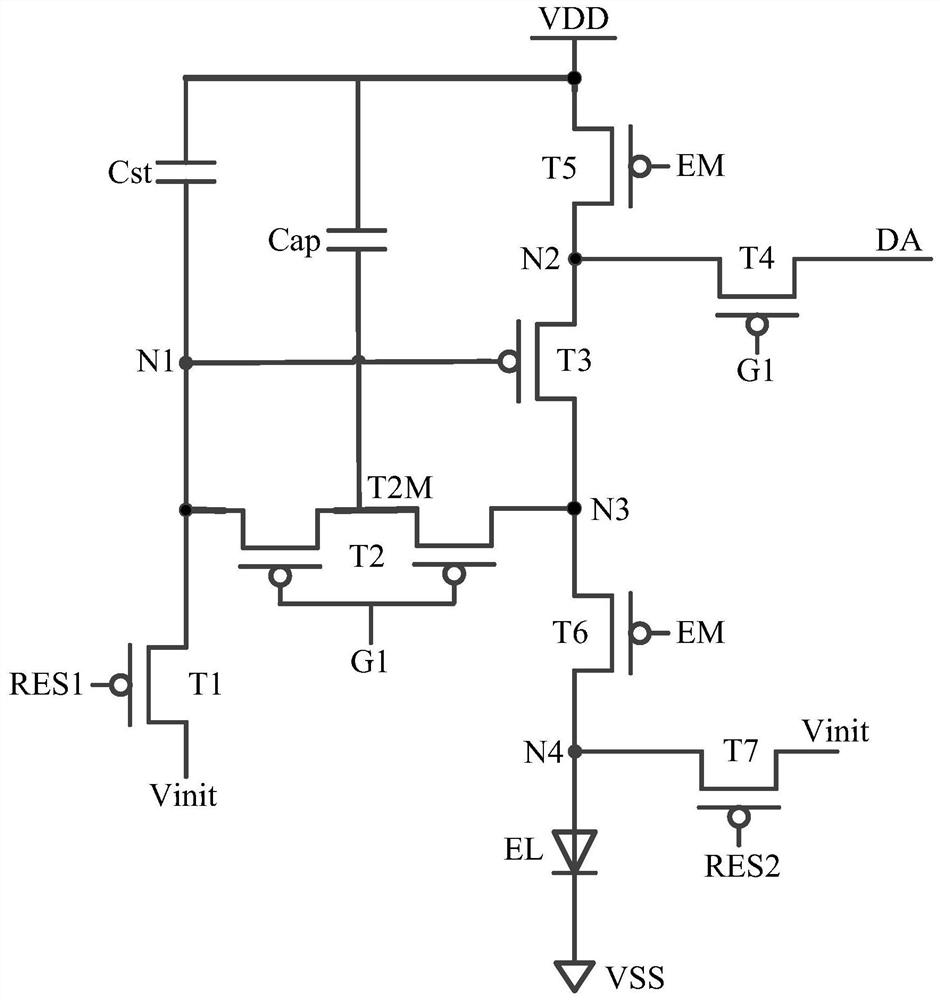

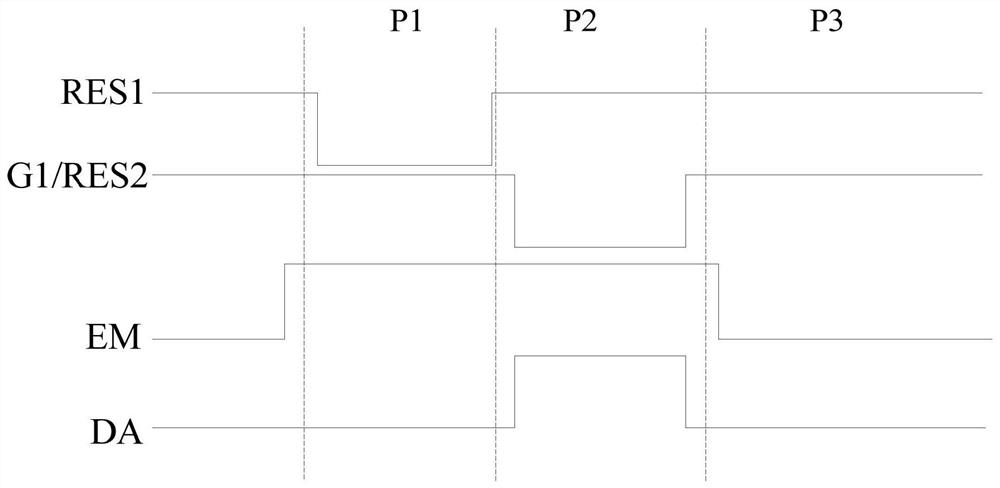

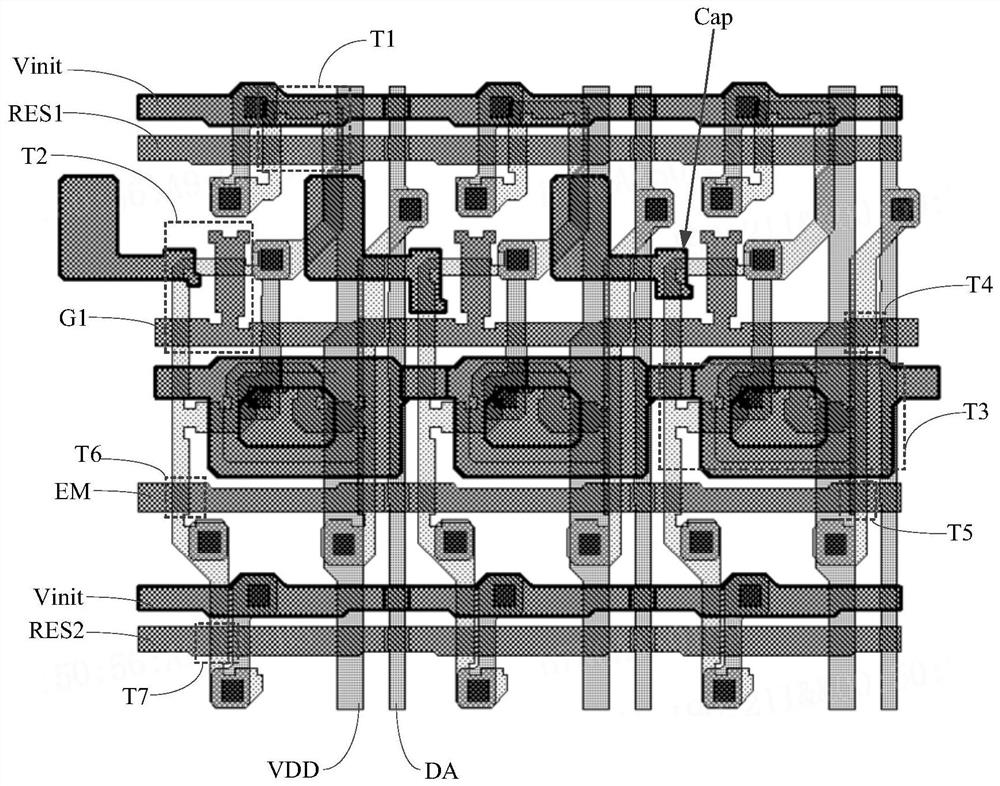

[0065] like figure 1 and image 3 As shown, the display substrate provided by the embodiment of the present invention includes a plurality of sub-pixels, each sub-pixel includes a sub-pixel driving circuit, and the sub-pixel driving circuits included in the plurality of sub-pixels are distributed on the base of the display substrate in an array. Each sub-pixel driving circuit includes first to seventh transistors T1 to T7, and a storage capacitor Cst. The second transistor T2 serves as a compensation transistor in the sub-pixel driving circuit, and the third transistor T3 serves as a driving transistor in the sub-pixel driving circuit. The compensation transistor has a double gate structure, the first electrode of the comp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap