A flocculation washing machine and its control method

A technology of flocculation washing machine and control method, which is applied in other washing machines, separation methods, chemical instruments and methods, etc., can solve problems such as easy adhesion, difficulty in flocculation discharge, and increased workload, so as to reduce the detection value and be suitable for popularization and use , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

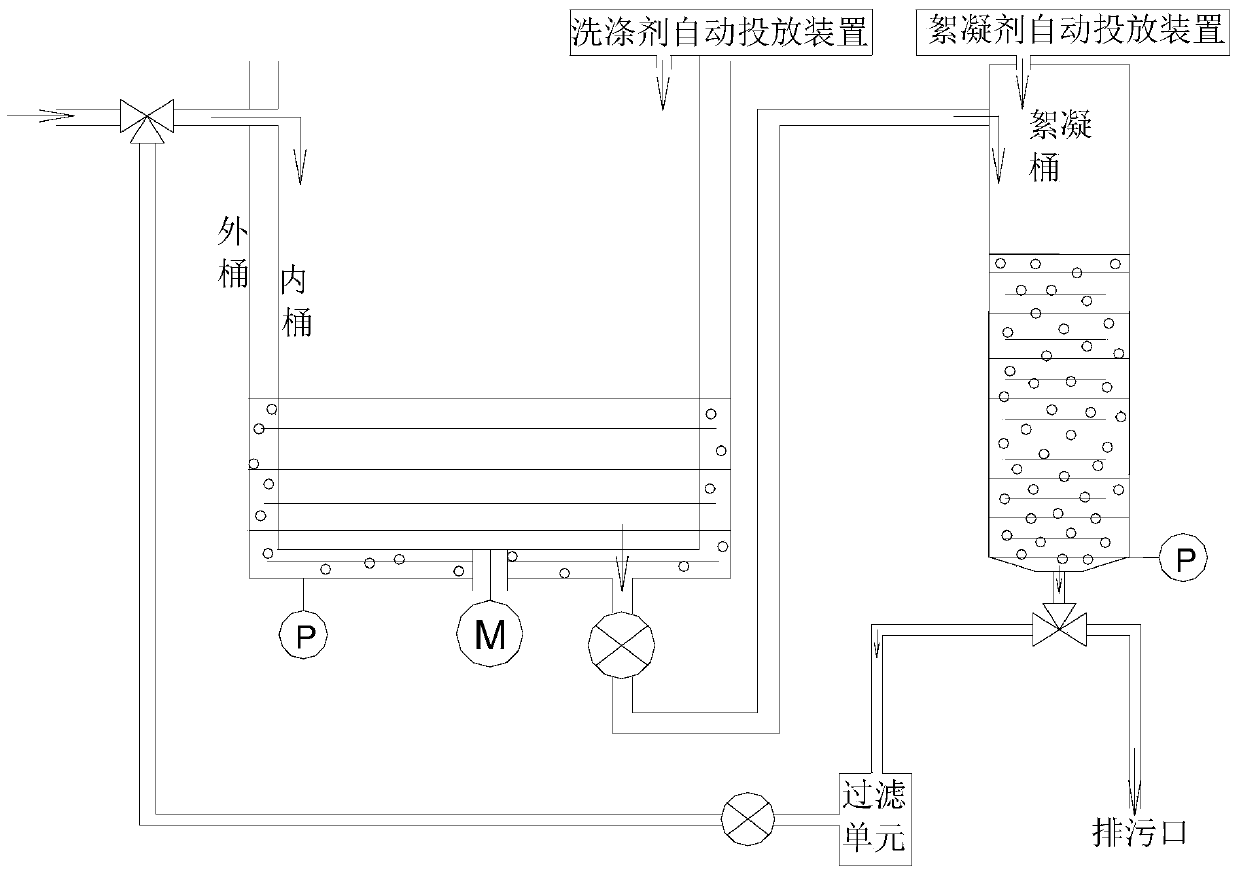

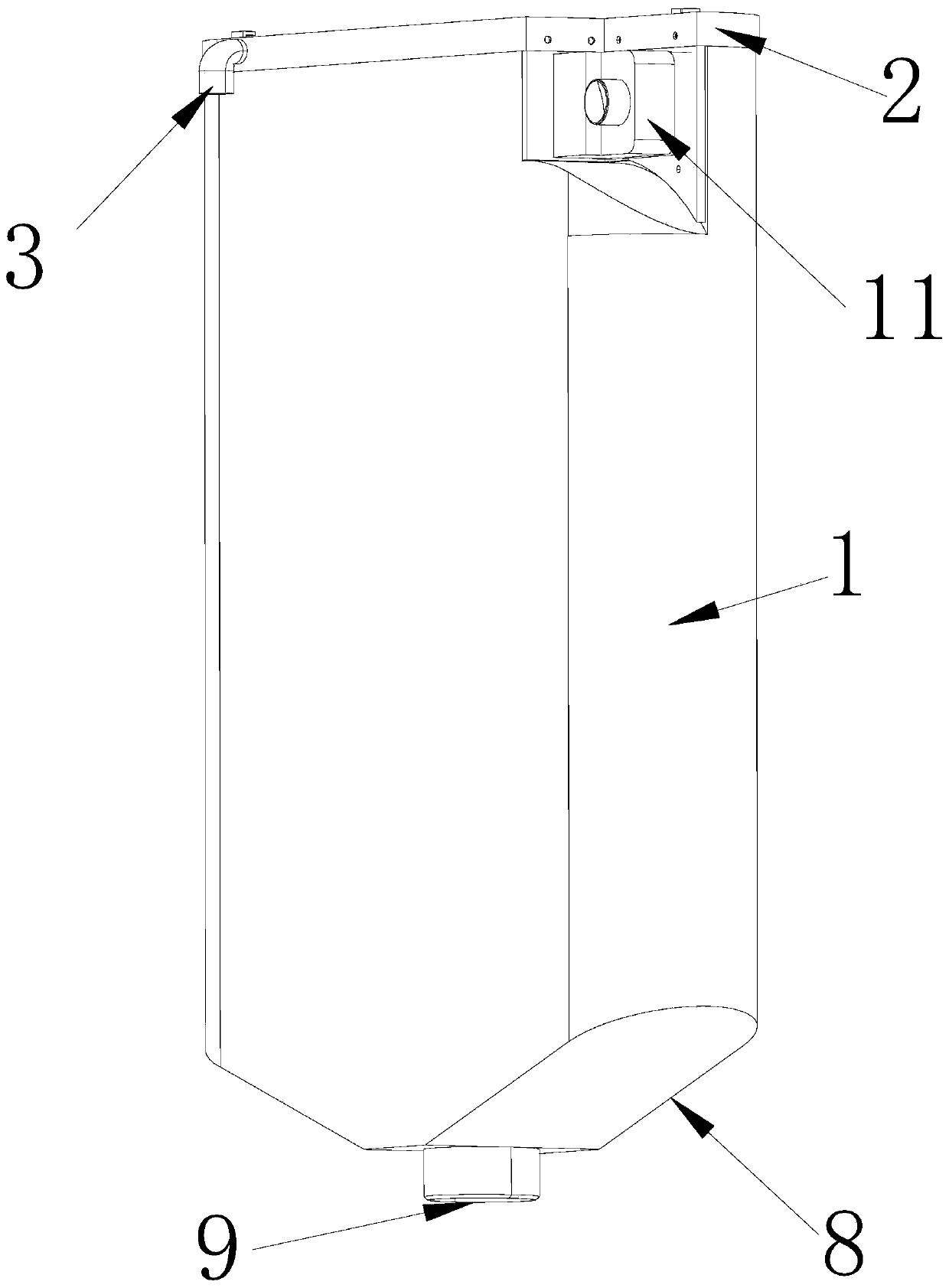

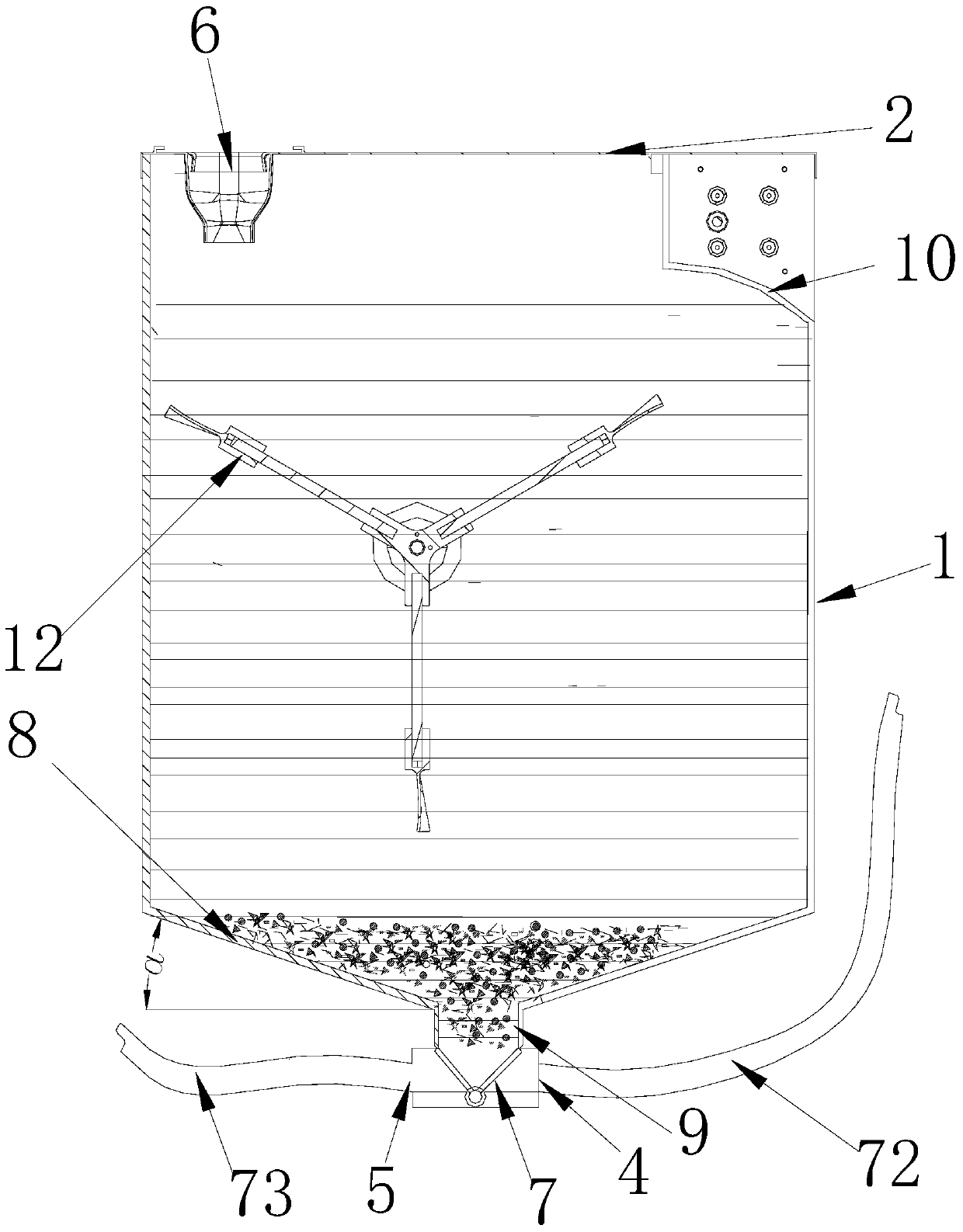

[0048] Such as Figure 2 to Figure 3 As shown, in this embodiment, the flocculation bucket 1 includes a bucket cover 2 that is closed at the upper opening of the flocculation bucket 1; the flocculation bucket 1 is provided with a water inlet 3, a feeding port 6 and a water outlet 9; The upper part of the bucket 1 is connected with the outer bucket of the washing machine through the water inlet pipe 71; the feeding port 6 is arranged on the top of the flocculation bucket 1, and is used for adding flocculants. The water outlet 9 of the flocculation bucket 1 is located at the bottom 8 of the flocculation bucket 1; the water outlet 9 is connected with the inlet of the tee 7, and the two outlets of the tee 7 are the return port 4 and the drain port 5 respectively, and the return port 4 passes through the return port The water pipe 72 is connected with the outer tub. Preferably, the water inlet pipe 71 and the water return pipe 72 are respectively provided with water pumps to contr...

Embodiment 2

[0052] This example introduces a control method of a sedimentation flocculation washing machine. Before the flocculation process ends, the water in the flocculation bucket is allowed to stand for a certain period of time, so that the flocs produced during the flocculation process sink to the bottom of the flocculation bucket; the flocculation process After the end, the flocs that sink to the bottom of the flocculation bucket are discharged to the outside of the washing machine, and then the still clean water flows back into the outer bucket of the washing machine.

[0053] In this embodiment, the flocculation bucket 1 is provided with a water level sensor for detecting the water level in the flocculation bucket 1, so as to judge the clean water return node during the flocculation process and realize the control of the whole flocculation process.

[0054] The specific steps of the control method of the above-mentioned subsidence type flocculation washing machine are as follows: ...

Embodiment 3

[0067] Such as Figure 2 to Figure 3 As shown, in this embodiment, the bottom 8 of the flocculation bucket 1 is provided with a water outlet 9 that communicates with the outside of the washing machine and discharges the settled flocs. The setting is inclined downward so that the water outlet 9 is at the lowest point of the flocculation bucket 1, so as to facilitate the collection and discharge of the settled flocs. Such as Figure 2 to Figure 4 As shown, the bottom 8 of the flocculation bucket 1 is conical with an inclination angle of α, and the water outlet 9 is set at the center of the conical bottom 8, so that the water outlet 9 is set at the lowest point of the flocculation bucket 1, so that the settled flocs Collected at the central cone angle of the bottom 8 of the flocculation bucket 1, and flow toward the water outlet 9 under the action of the conical bottom 8, so as to facilitate the outward discharge of flocs.

[0068] Such as Figure 4 As shown, in this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com