Electric water conservancy stop valve

A shut-off valve and water conservancy technology, applied in the direction of lifting valve, valve detail, valve device, etc., can solve the problems of large fluid resistance and poor sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention will be further described, but the present invention is not limited to these examples, under the premise of departing from the gist of the present invention, any improvement made falls within the protection scope of the present invention.

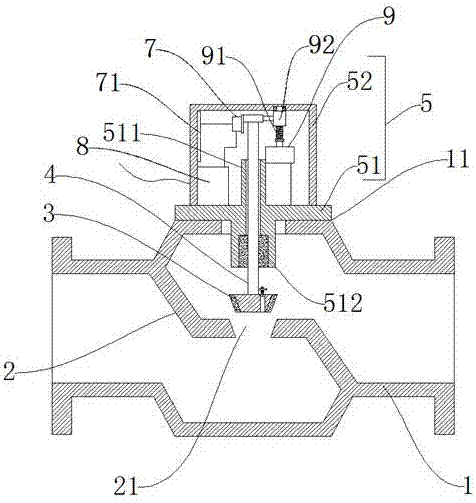

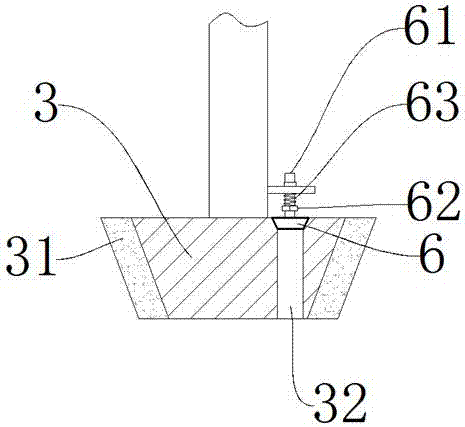

[0018] As shown in the figure, an electric hydraulic shut-off valve according to the present invention includes a valve body 1 and a valve core 3. The valve body 1 is provided with a valve seat 2, and the middle of the valve seat 2 is provided with a tapered The permeable hole 21, the valve core 3 is equipped with a control rod 4, the valve body 1 is provided with an installation platform 11, and the installation platform 11 is equipped with an electric drive mechanism 5 through a sealing ring and bolts. The electric driving mechanism 5 includes a fixed bottom plate 51 and a sealing cover 52, a vertical sliding sleeve structure 511 is arranged in the middle of the fixed bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com