Detergent composition for hard surfaces

A technology of hard surface and cleaning agent, applied in the direction of surface active detergent composition, non-surface active detergent composition, detergent composition, etc., can solve the problems of not achieving cost reduction, rising chemical cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

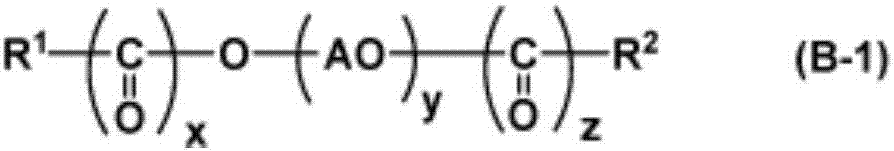

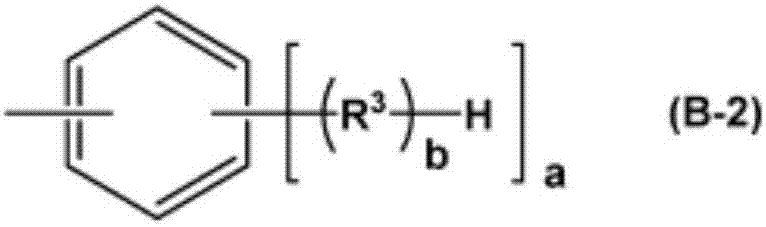

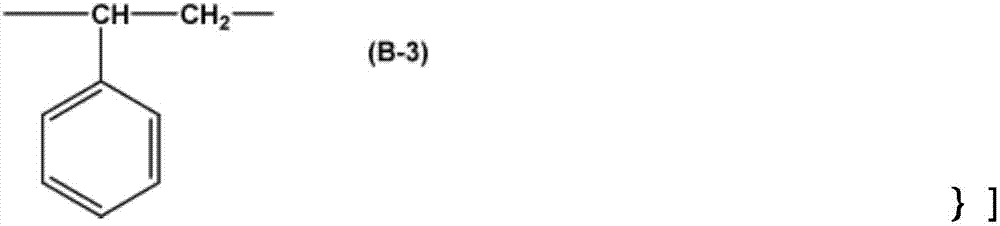

Method used

Image

Examples

Embodiment 1~15、 comparative example 1~7

[0097] The cleaning compositions for hard surfaces of Examples 1-15 and Comparative Examples 1-7 were prepared like the components and compositions (mass %) shown in Tables 1-4. Specifically, (A) component and (E) component were added to (F) ion-exchange water, and it mixed and made uniform, and (B) component, (C) component, (D) component were added and mixed, and it prepared. The hard surface cleaning compositions obtained in Examples 1 to 15 and Comparative Examples 1 to 7 were diluted to 3% by mass with ion-exchanged water, and the hard surface cleaning compositions were adjusted for the following evaluations. test.

[0098] [Detergency evaluation test]

[0099] A commercially available cold-rolled steel sheet cut into 50 mm×50 mm×1 mm was used as a test piece. The surface of the test piece was washed with n-hexane, and 0.2 g of antirust oil (ANTIRUST P2800 manufactured by Jikun Nippon Oil & Energy Co., Ltd.) was applied as a pollutant to prepare a contaminated sample.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight-average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com