Metal cleanser composition

A cleaning agent and composition technology, applied in the direction of detergent composition, surface active detergent composition, organic cleaning composition, etc., can solve the problem of detergency of detergency and defoaming, rust, and rust resistance To achieve the effect of suppressing the generation of bubbles, sufficient cleaning power, and not easy to rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

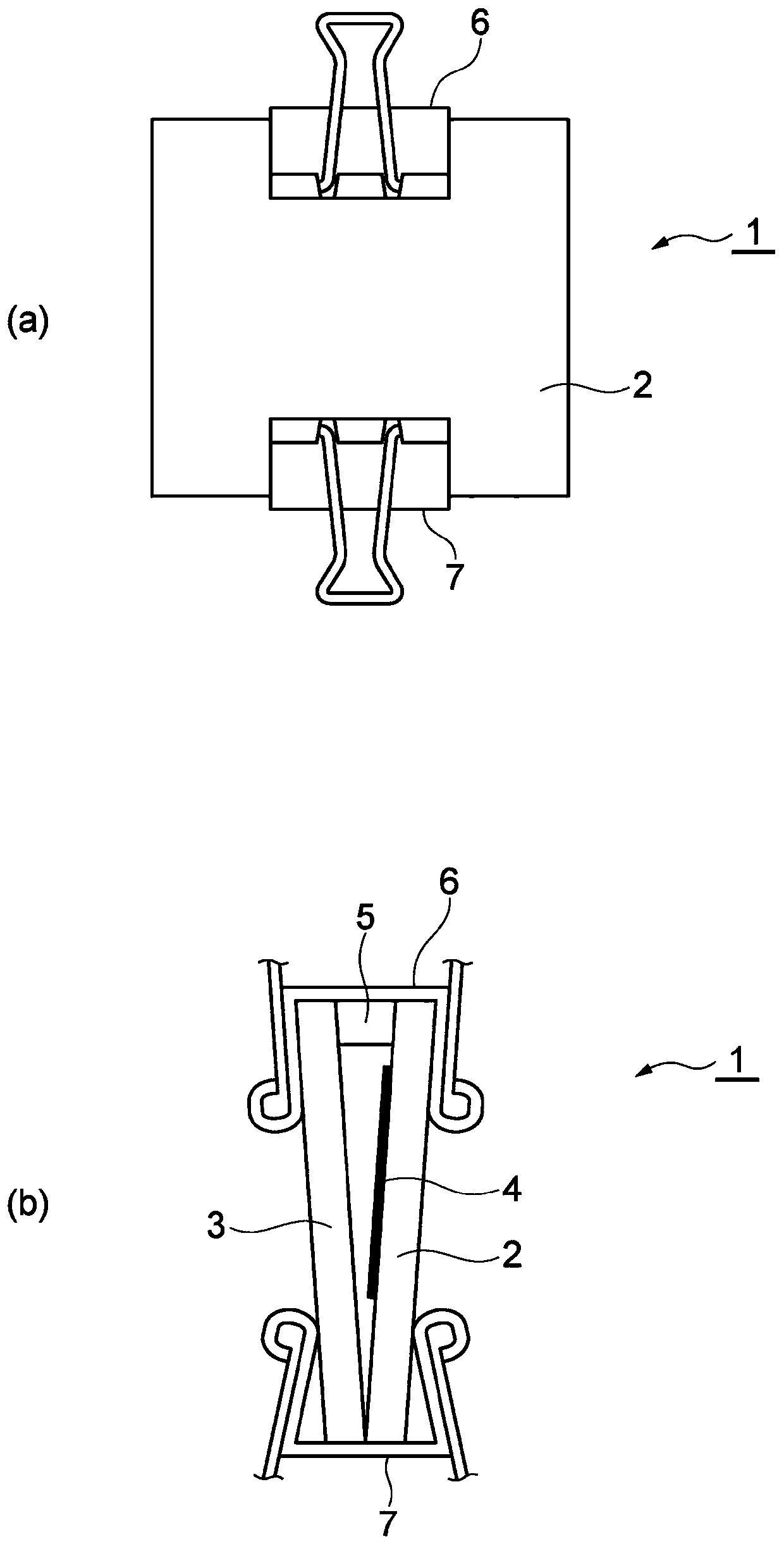

Image

Examples

Embodiment 1~12、 comparative example 1~30

[0116] According to the components and composition (mass %) shown in Tables 1-6, the cleaning composition for metals was prepared. Specifically, (G) ion-exchanged water was added and mixed with (A) component and (C) component to make it uniform, and (B) component, (D) component, and (E) component were added and mixed, and it prepared. The metal cleaning compositions obtained in Examples 1 to 12 and Comparative Examples 1 to 30 were diluted with ion-exchanged water to adjust to a 3% by mass aqueous solution, and this was used as a test solution for the following evaluation tests.

[0117] In the table, details of the components of *1 to *7 are as follows.

[0118] *1: Sodium polyacrylate (weight average molecular weight 6000)

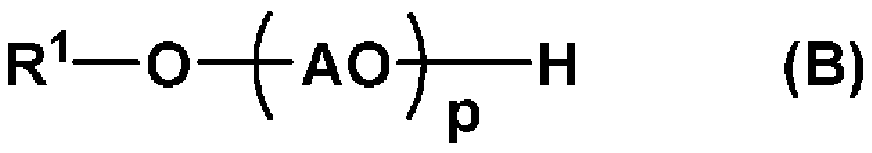

[0119] *2: Butanol EO (1) adduct is R in the above general formula (B) 1 is an alkyl group with 4 carbon atoms, (AO) p Compounds that are polyoxyethylene with an average added mole number of 1

[0120] *3: 2-Ethylhexanol EO(1)PO(1.5) adduct is R in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com