Rotary conveying type metal piece spot check station

A metal piece, left-rotating technology, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of putting on and putting down, placing trouble, directly falling to the ground, etc., to ensure the work rhythm and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

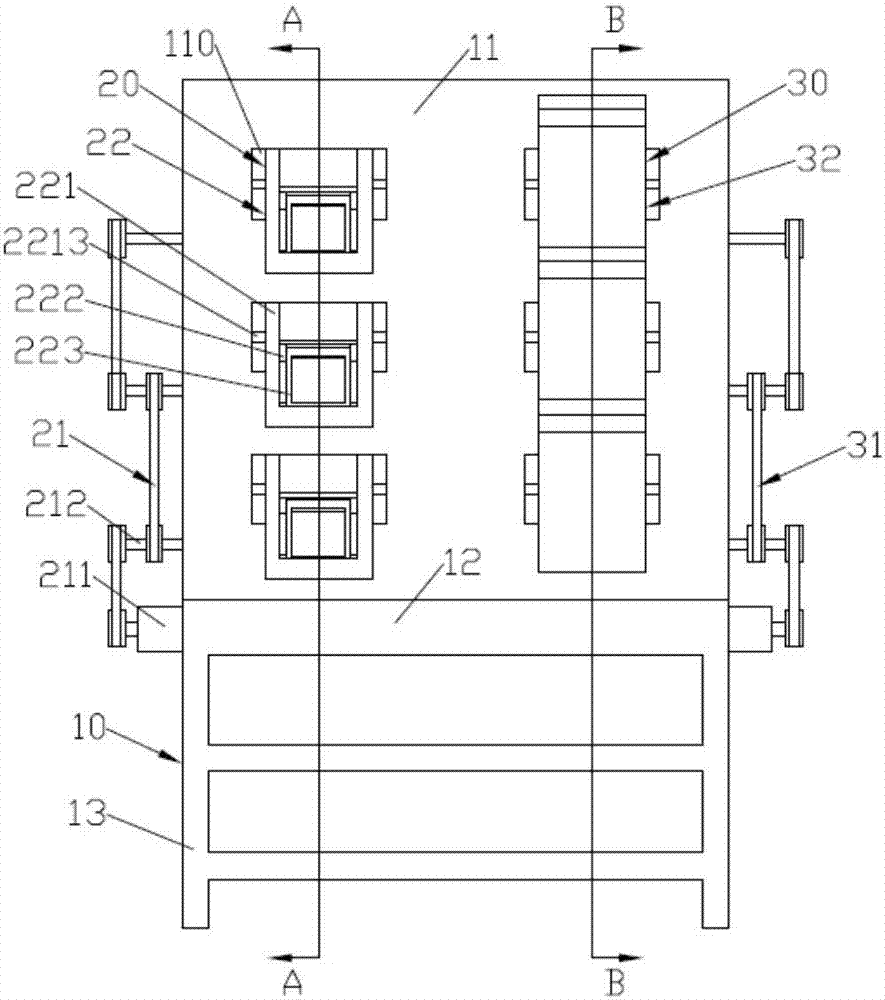

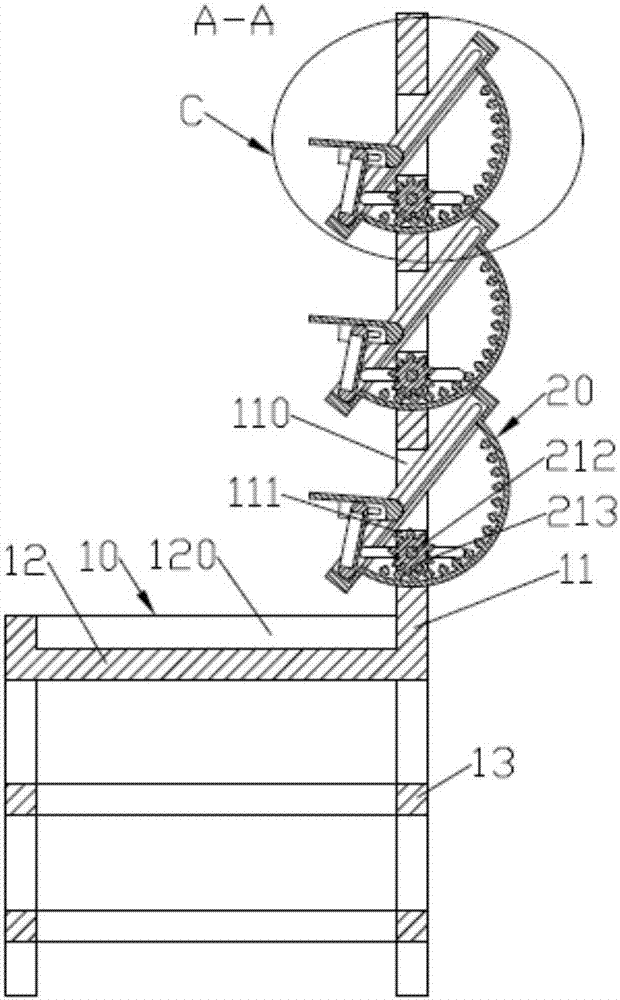

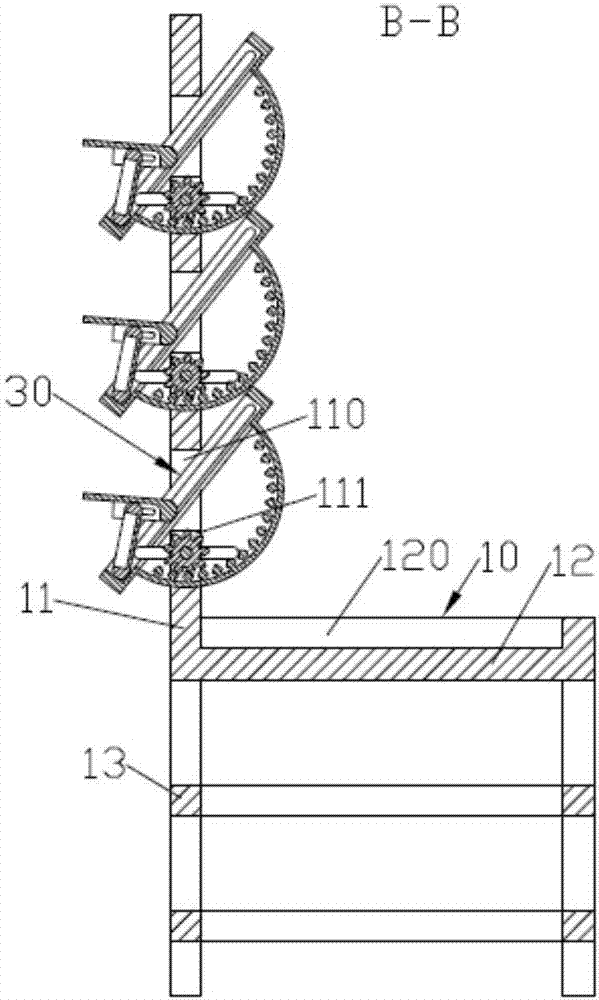

[0020] like Figure 1 ~ Figure 4 As shown, a metal parts sampling table for rotary transmission includes a support frame 10, a left rotation carrier 20 and a right rotation carrier 30; the support frame 10 includes a square main support plate 11 in a vertical state, a detection desktop 12 and a desktop Support foot unit 13; detection desktop 12 is horizontally arranged and main support plate 11 is fixed on the front end surface of detection desktop 12; desktop support foot unit 13 is fixed on the bottom surface of detection desktop 12; left rotation carrying device 20 and right rotation carrying device 30 They are respectively located on the left and right parts of the main support plate 11; the structure of the left rotation bearing device 20 and the structure of the right rotation bearing device 30 are symmetrical to each other; Transfer bearing frame 22; right rotation bearing device 30 includes right rotation drive device 31 and some right rotation bearing frames 32 evenly...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap