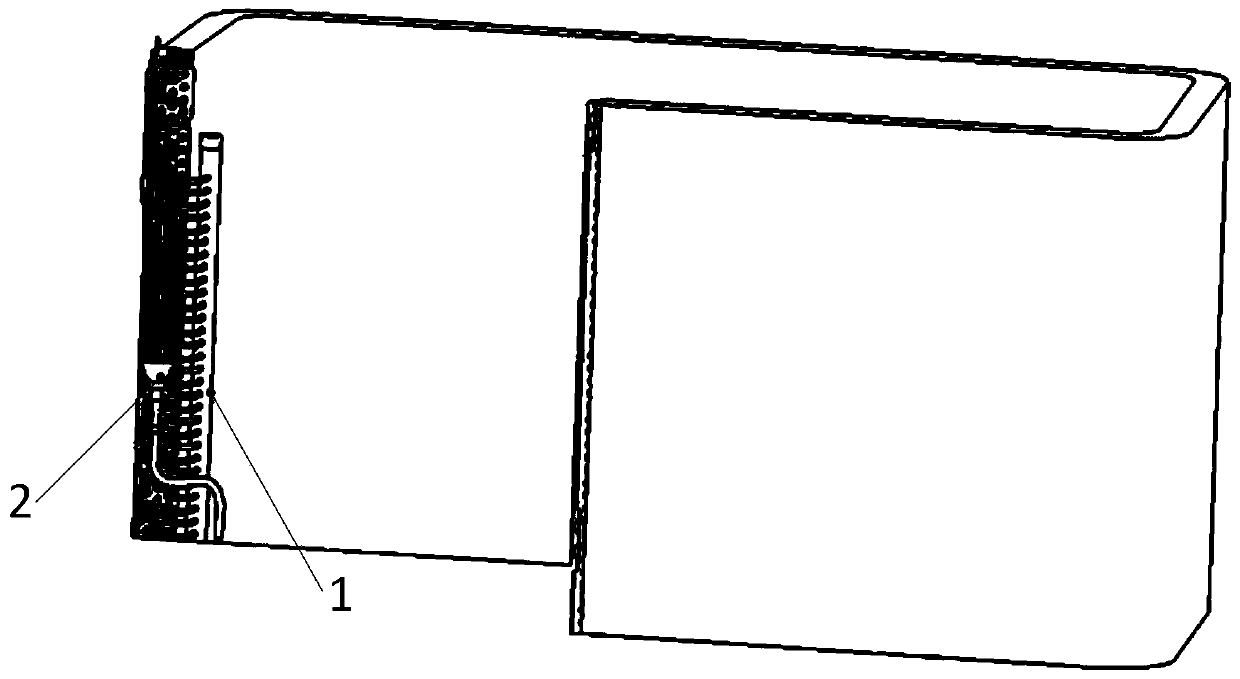

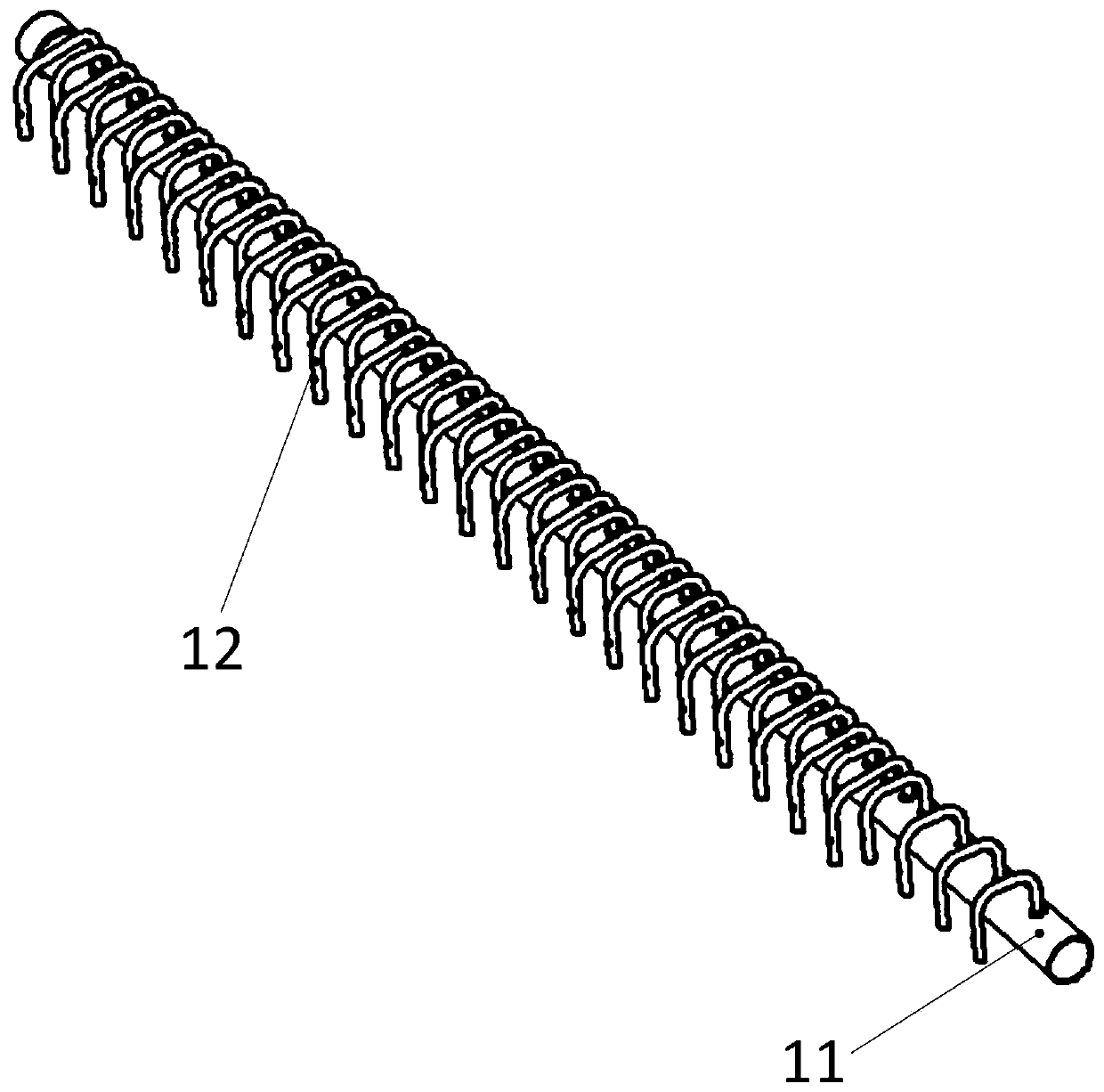

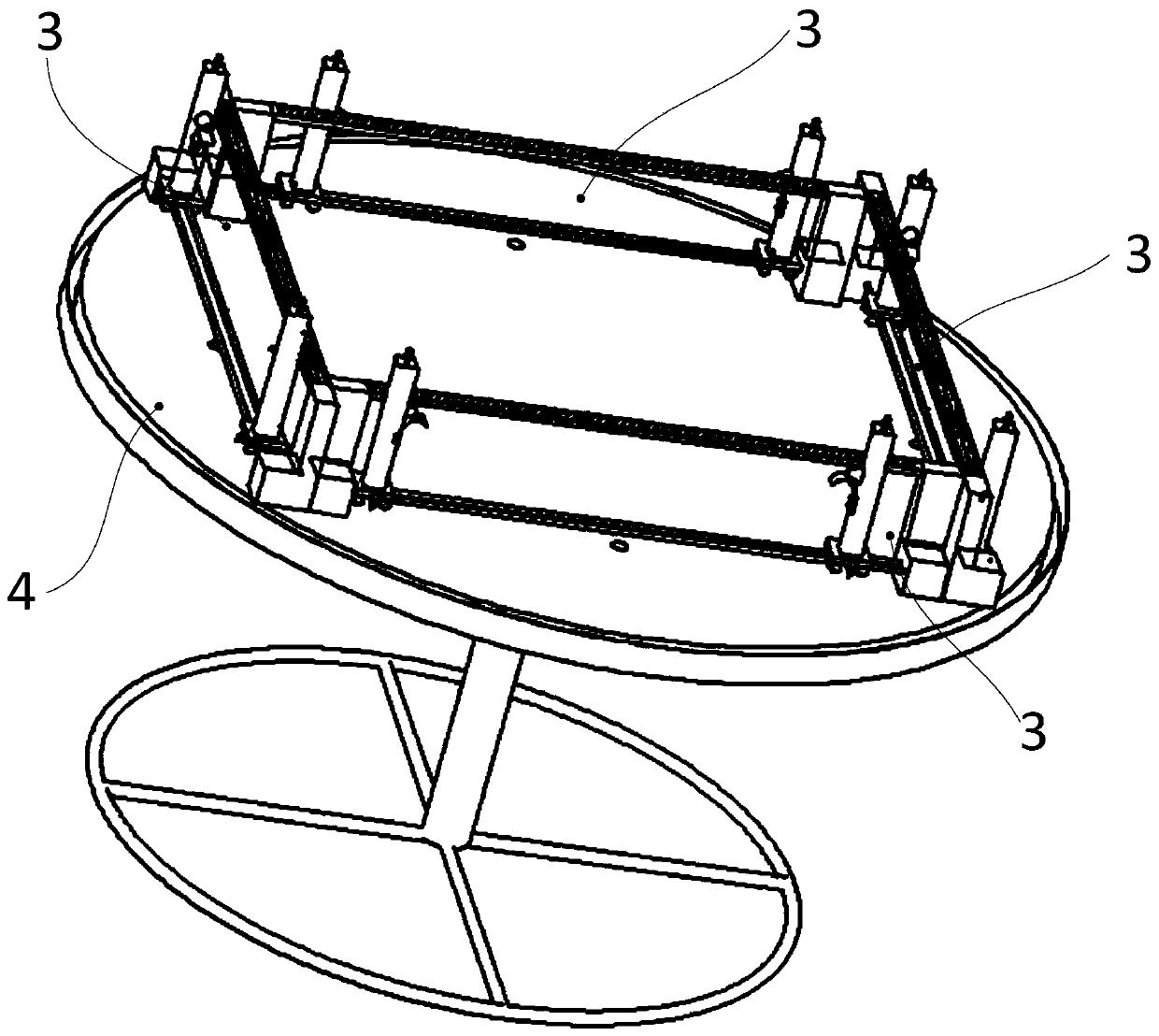

Welding tool for gas collection assembly of heat exchanger and welding tool device

A technology for welding tooling and heat exchangers, which is applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., and can solve problems such as the inability to reliably fix the gas-collecting main pipe and the gas-collecting branch pipe, and the deformation of the gas-collecting assembly as a whole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention. For example, although this embodiment is described as an example in which a stand is separately configured for the welding tool and the welding tool is fixed on the stand in a detachable manner, it can be understood that in some application scenarios, the welding tool can be integrated There is a support frame, or the welding tool can also be fixed on the table top of other existing equipment, and those skilled in the art can set the fixing position of the welding tool according to actual needs.

[0027] It should be noted that, in the description of the present invention, terms such as "upper", "lower", "inner", "outer" and other indicated dire...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap