Automatic rotating nozzle and adjustment method of nozzle rotating speed

A technology of automatic rotation and rotation speed, which is applied in the direction of spraying device and spraying device with movable outlet, which can solve the problems of difficult adjustment, easy wind dispersion, and the blowing distance cannot meet the requirements, and has strong adaptability to high and low wind speeds. , The high and low torque is obvious, and the effect of blowing and showering is efficient and stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better illustrate the present invention, further description will now be made in conjunction with the embodiments and accompanying drawings.

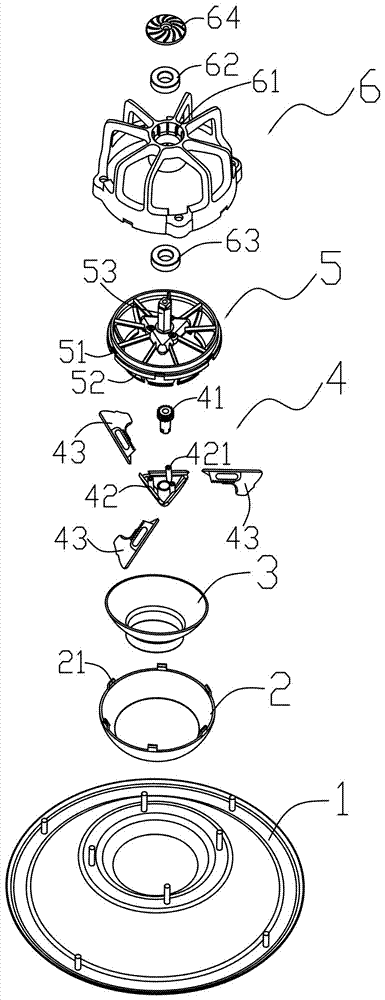

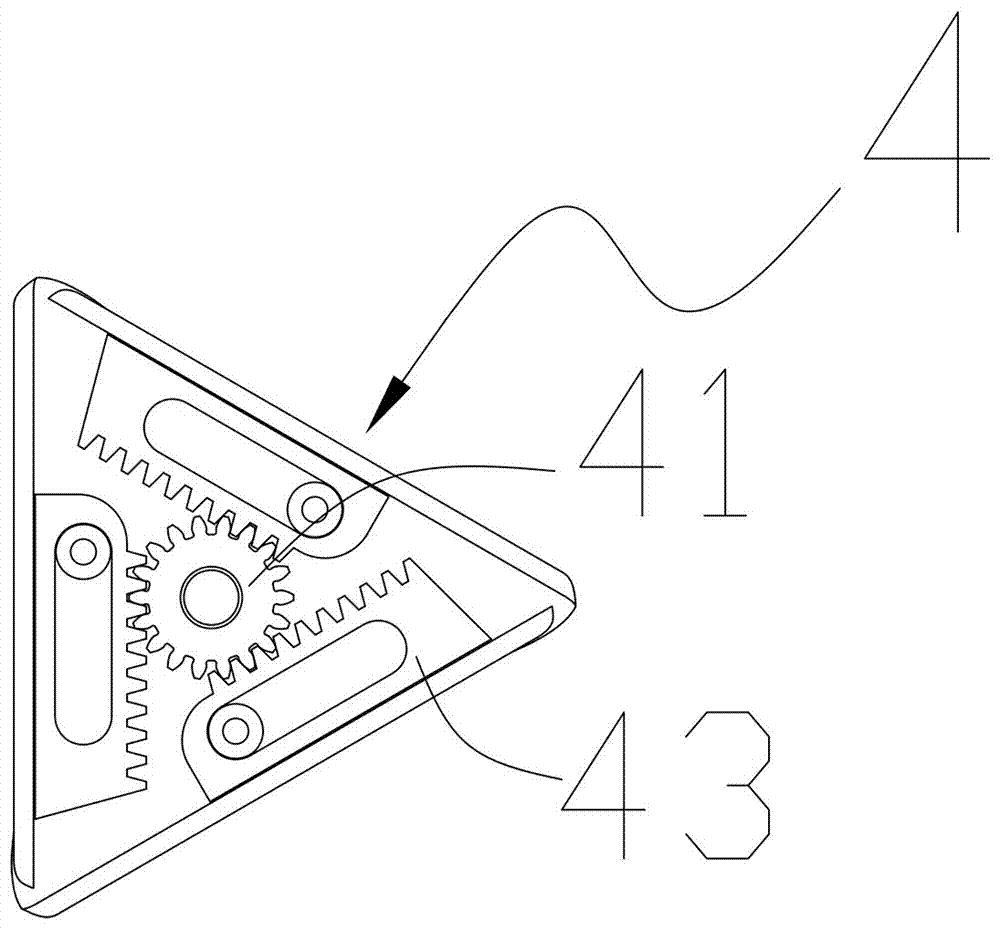

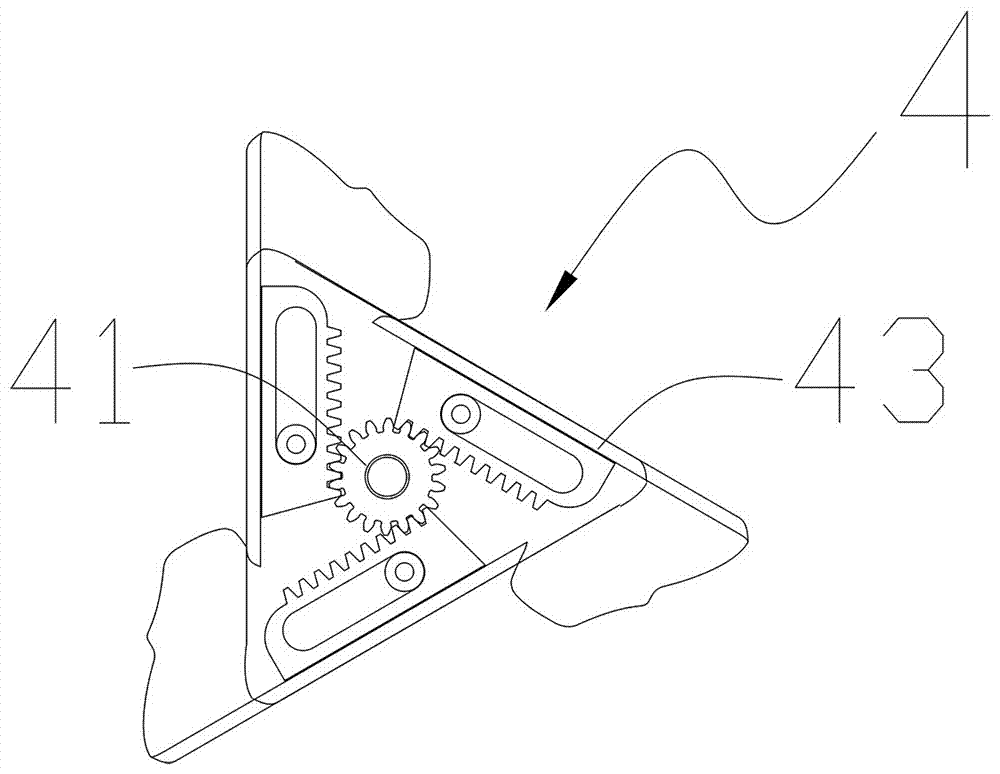

[0028] Such as figure 1 As shown, the automatic rotating nozzle includes an outer cover 1 and a blowing nozzle 3, the blowing nozzle 3 is a bowl-shaped structure with an open bottom, the top of the outer cover 1 is open, and the blowing nozzle 3 is placed at the top opening of the outer cover, and the automatic rotating nozzle also includes The main rotor 5, the slave rotor 2, the blade adjustment device 4 and the rear seat 6, the slave rotor 2 is placed between the opening at the top of the outer cover 1 and the blowing nozzle 3, the slave rotor 2 top opening and the main rotor 5 The outer side is fixed by fasteners. In this embodiment, the fasteners are provided with a plurality of upward buckles 21 at the top opening of the slave swivel 2 and the outer side of the main swivel 5 is provided with buckles with the sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com