Autorotation Drive Mechanism And Film Label Sticking Device Using The Same

A driving mechanism and label sticking technology, applied in the direction of transmission, electromechanical device, electromechanical transmission, etc., can solve the problems of inconsistent diameter, folded film label, surface damage of film label, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

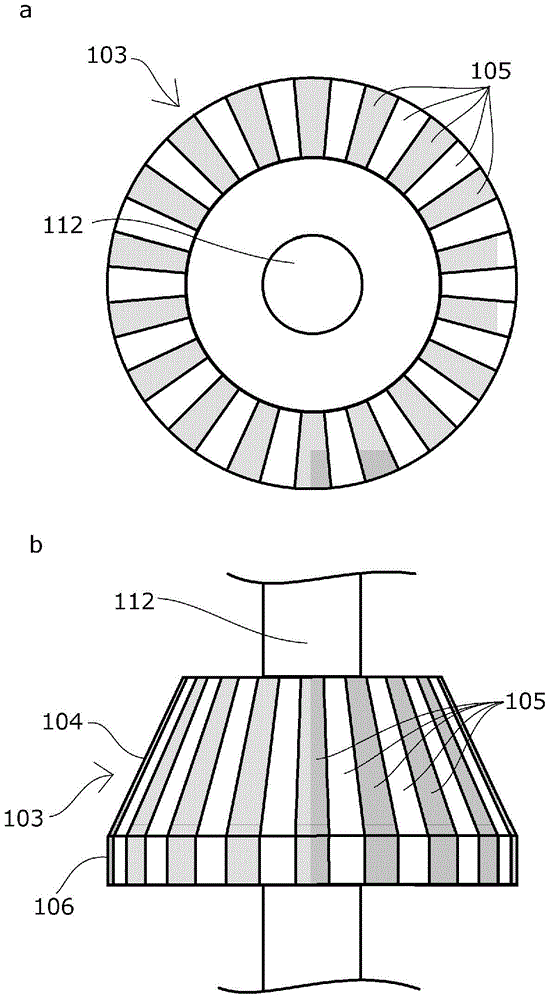

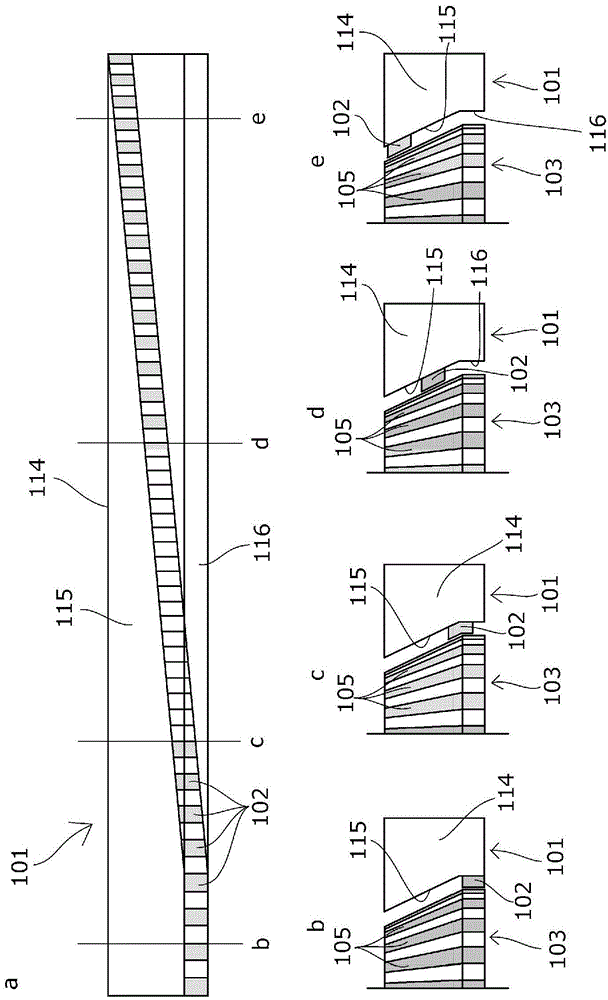

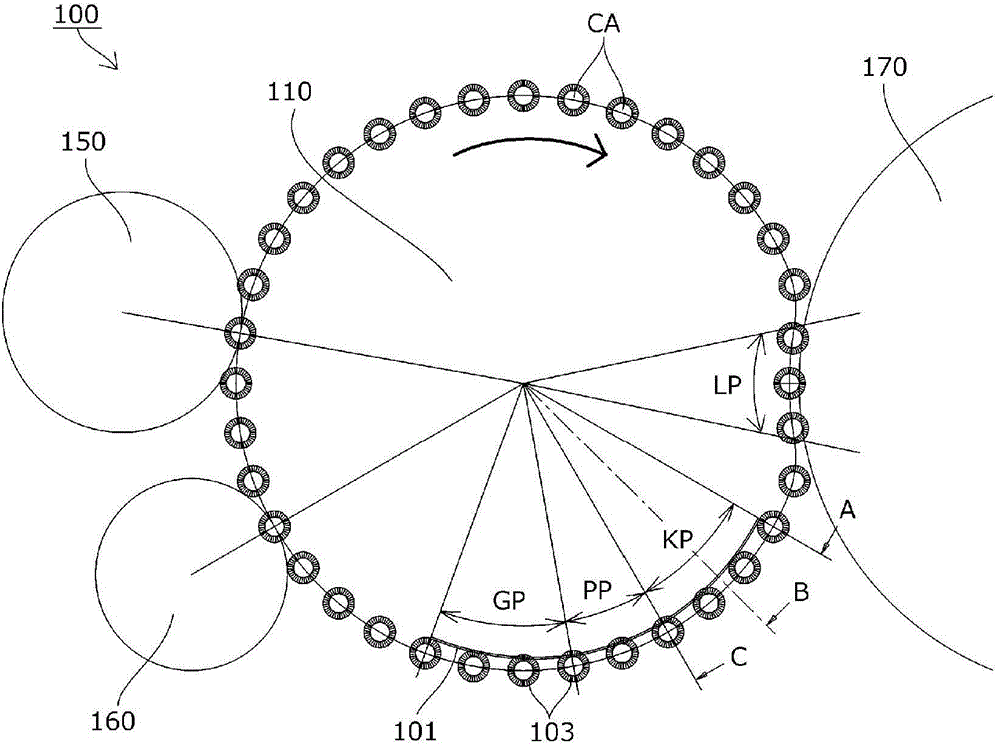

[0036] The autorotation driving mechanism of the present invention includes: a movable driven member having a driven mechanism on a tapered portion and connected to an autorotation shaft; a driving member arranged along the moving direction of the driven member, A transmission mechanism is provided, and the above-mentioned transmission mechanism is arranged to be opposed to any position in the direction of the rotation axis of the above-mentioned driven mechanism.

[0037] Therefore, as long as it is a mechanism that can rotate a plurality of rotation axes while continuously moving without a special driving device or a control device, and can change the rotation speed arbitrarily with a simple structure, its specific structure may be as follows: arbitrary structure.

[0038]In addition, the film label sticking device of the present invention is a film label sticking device that continuously moves a plurality of can bodies while rotating on their own, and sticks film labels on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com