Solid state relay

A solid-state relay and resistor technology, applied in the field of auto parts, can solve the problems of high cost and large heat generation of MOSFET tubes, and achieve the effect of low internal resistance, low price and low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

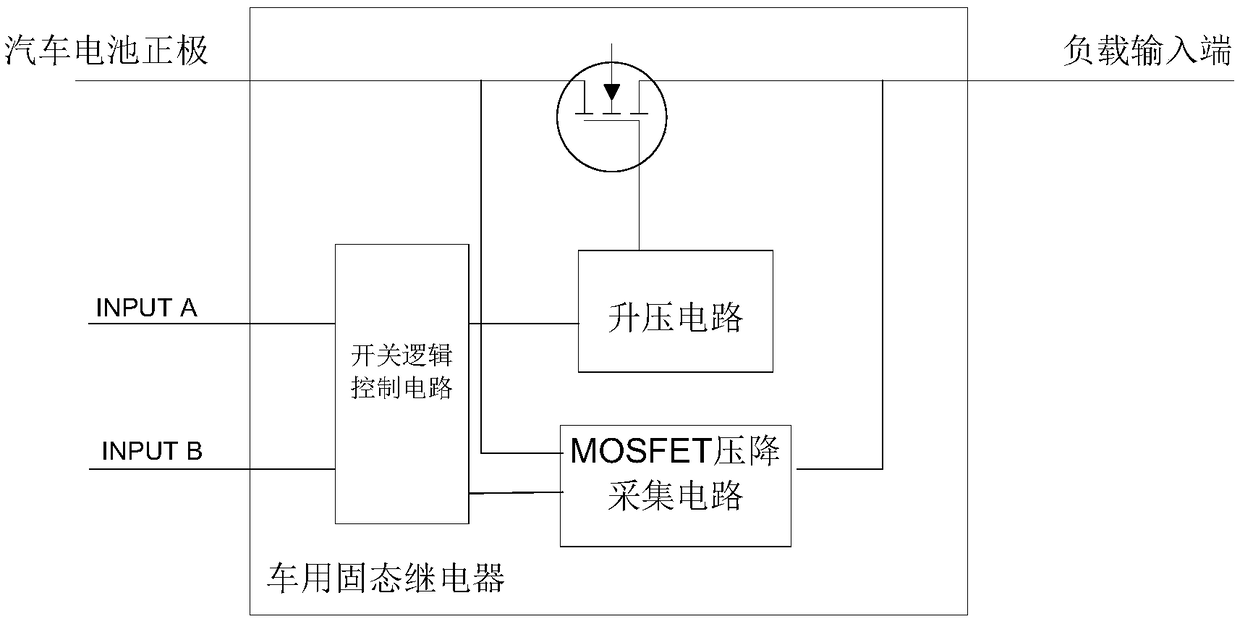

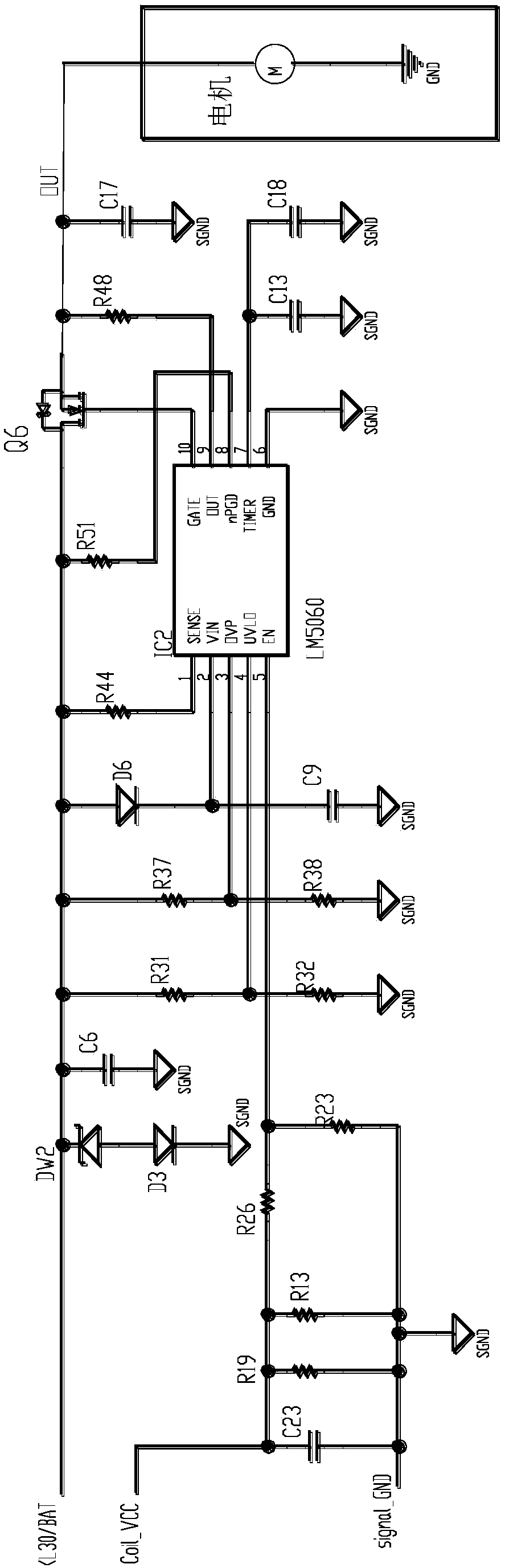

[0020] According to one or more embodiments, such as figure 1 As shown, a solid state relay is used in electric vehicles to replace electromagnetic relays used in vehicles. The solid state relay includes an N-type MOSFET transistor, the drain of the N-type MOSFET transistor is connected to the positive pole of the car battery, the source of the N-type MOSFET transistor is connected to the load input terminal, and the gate of the N-type MOSFET transistor is connected to the charge pump booster circuit.

[0021] The drain of the N-type MOSFET transistor is also connected to the N-type MOSFET transistor voltage drop acquisition circuit.

[0022] The solid state relay also includes a switch logic control circuit, and the input terminal A and the input terminal B of the solid state relay are connected to the switch logic control circuit. The function of the switching logic control circuit is to convert the positive or negative control level of the external input connected to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com