Printed circuit board and method of manufacturing thereof

A technology for printed circuit substrates and manufacturing methods, which is applied in the fields of printed circuit manufacturing, printed circuits, printed circuits, etc., can solve problems such as not being able to adapt to the trend of miniaturization, achieve the effect of improving product quality and performance, and reducing board bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

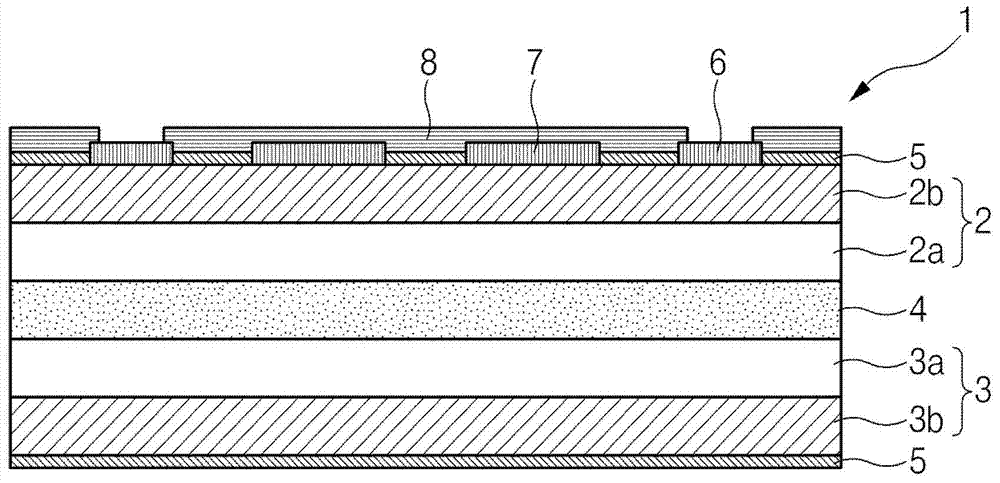

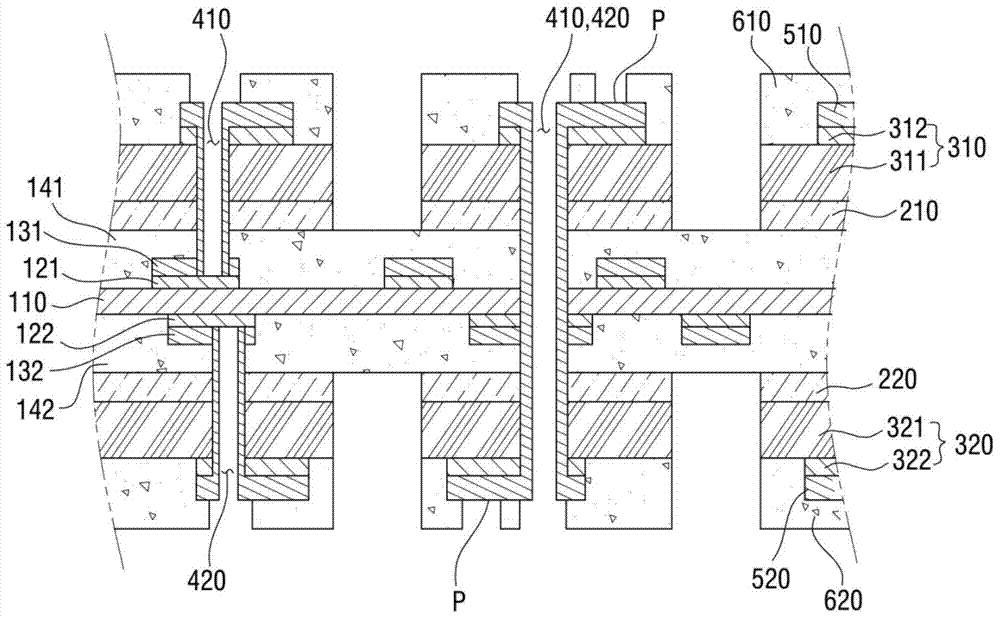

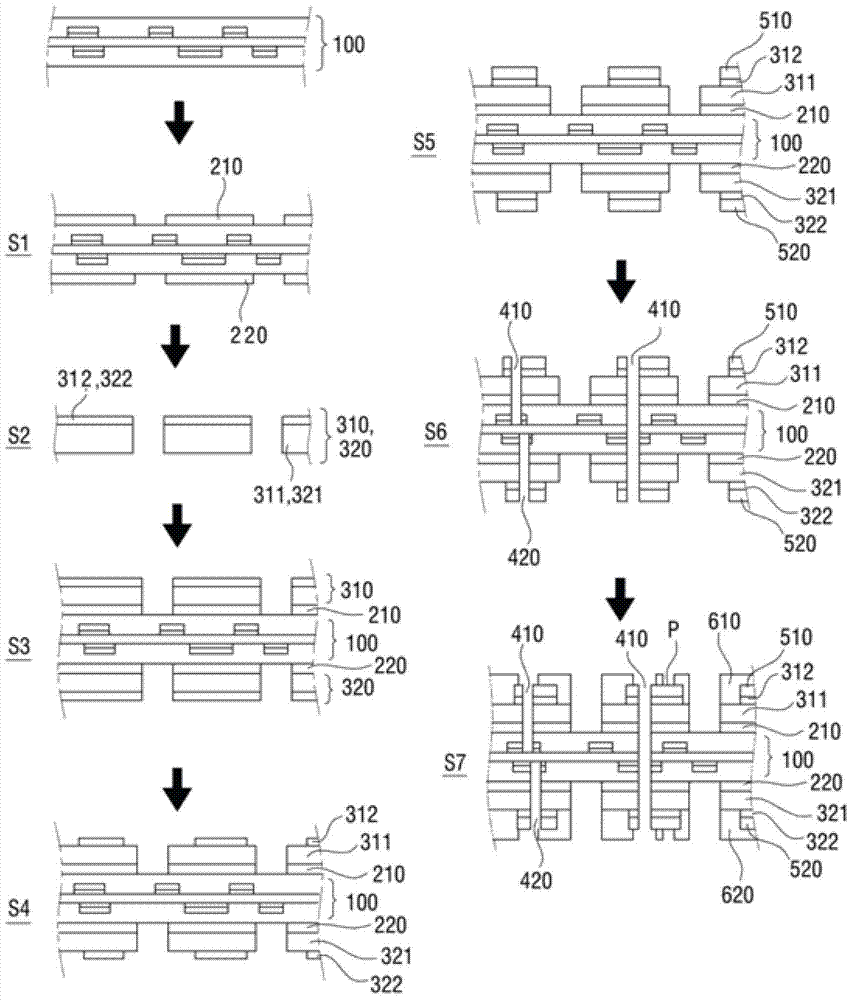

[0056] figure 1 is a cross-sectional structure diagram illustrating a conventional printed circuit board; figure 2 is a cross-sectional structure diagram illustrating a printed circuit board according to an embodiment of the present invention; image 3 is a manufacturing process diagram illustrating a printed circuit board according to an embodiment of the present invention; Figure 4a It is a comparison chart illustrating the amount of SMD front and rear inclination of the printed circuit board according to the embodiment of the present invention; Figure 4b It is a comparison chart illustrating the amount of SMD front and rear inclination of a conventional printed circuit board; Figure 5 It is a comparison graph showing the flexural strength of a printed circuit board according to an embodiment of the present invention and a printed circuit board of the prior art.

[0057] Such as Figure 2 to Figure 3 As shown, the printed circuit board according to the embodiment of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com